The intricate world of automotive suspension systems plays a vital role in ensuring a smooth and controlled ride. Each component within this complex assembly works harmoniously to enhance vehicle stability and comfort. A thorough understanding of these elements is essential for anyone interested in automotive engineering or maintenance.

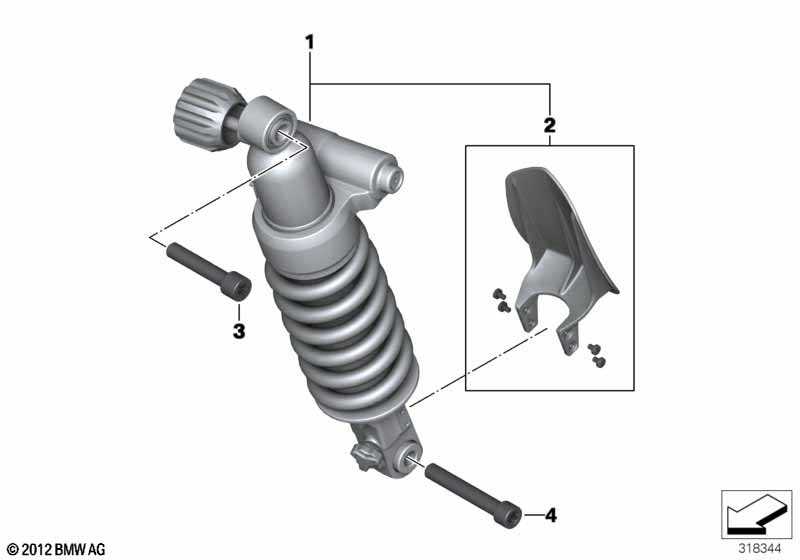

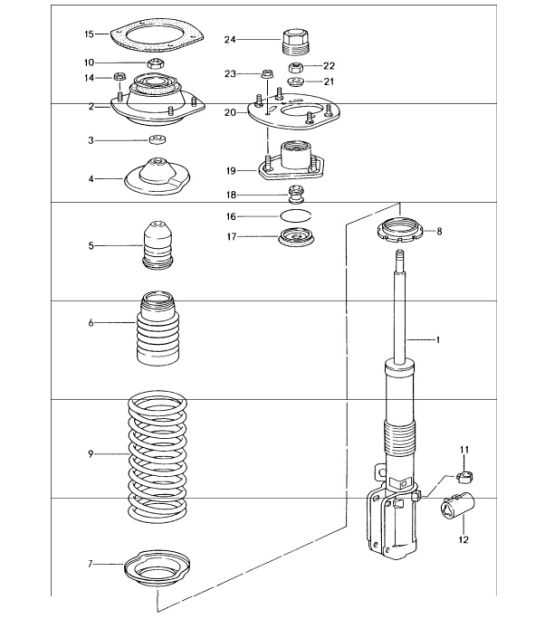

Visual representations of these components can provide invaluable insights into their function and interconnections. By examining these illustrations, one can appreciate the engineering behind the design and how each element contributes to overall performance. Recognizing the relationships among these various elements is crucial for effective troubleshooting and repair.

Whether you are a seasoned mechanic or a passionate car enthusiast, familiarizing yourself with these essential components will deepen your knowledge and improve your ability to diagnose issues. A well-informed perspective on the mechanics involved will undoubtedly aid in maintaining optimal vehicle performance.

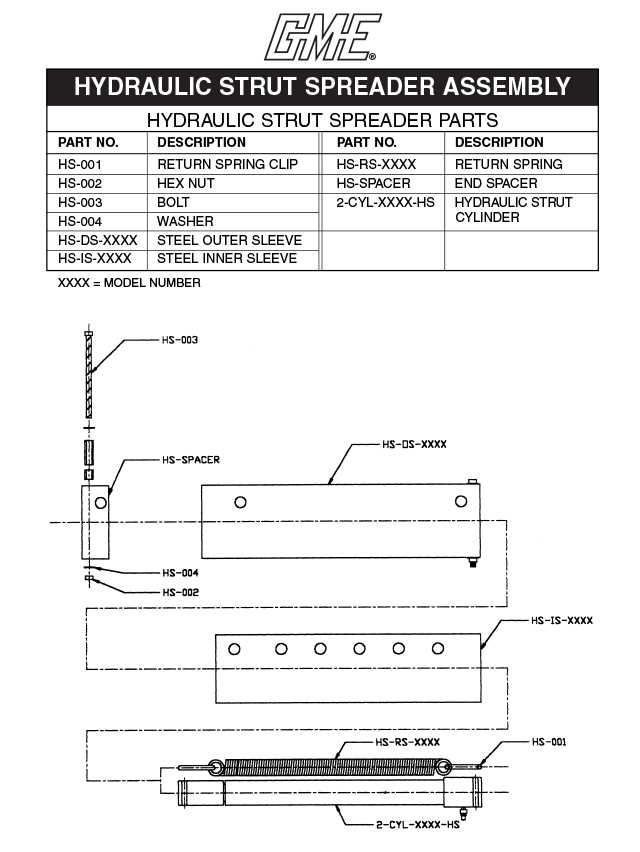

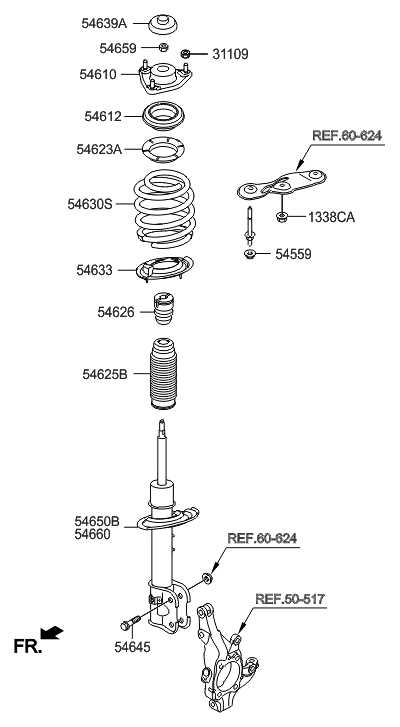

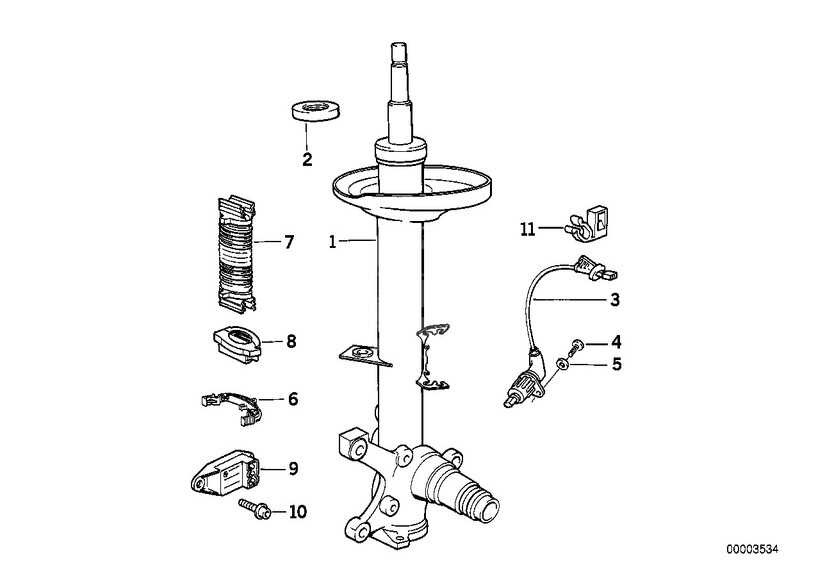

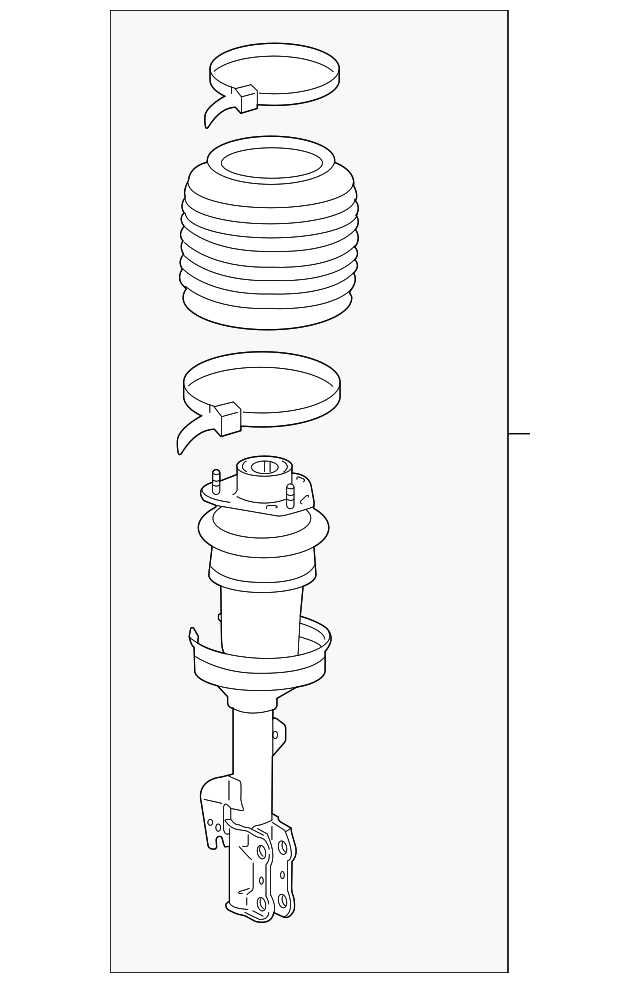

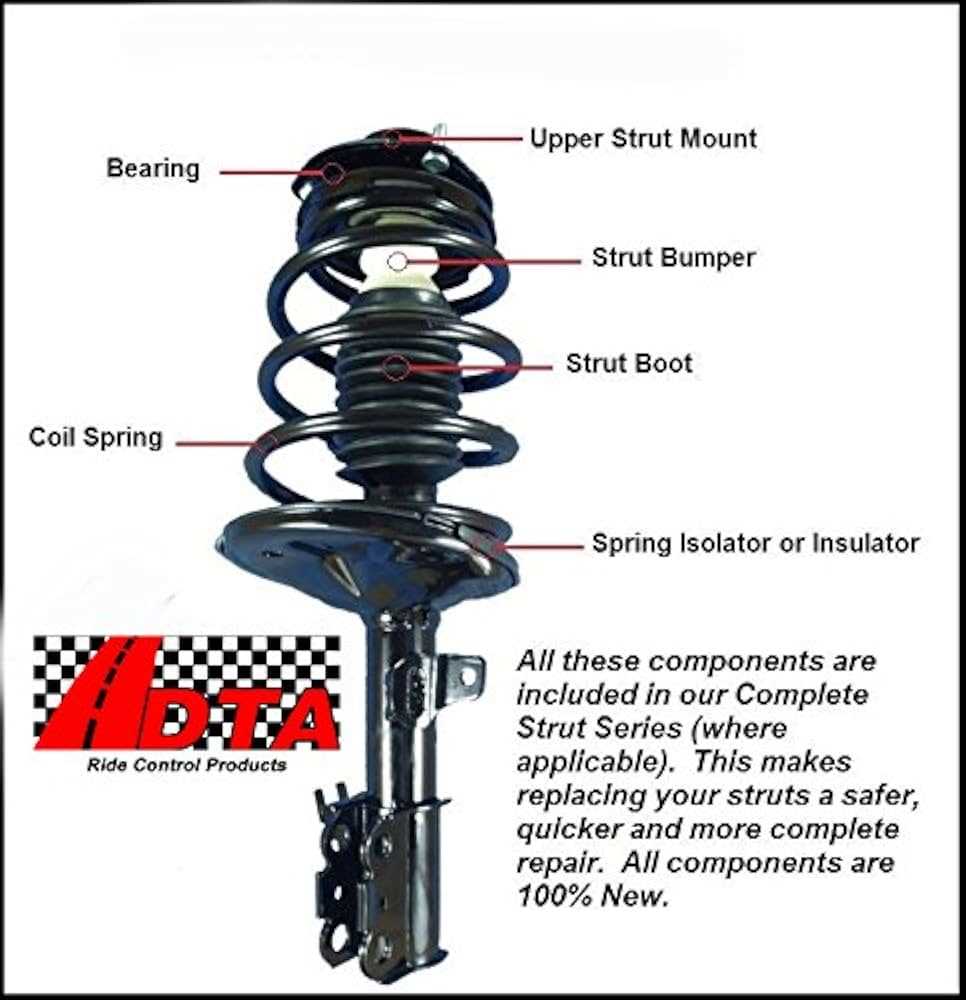

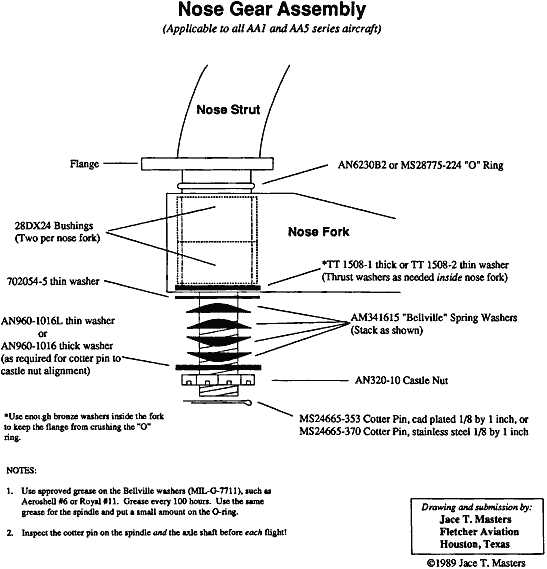

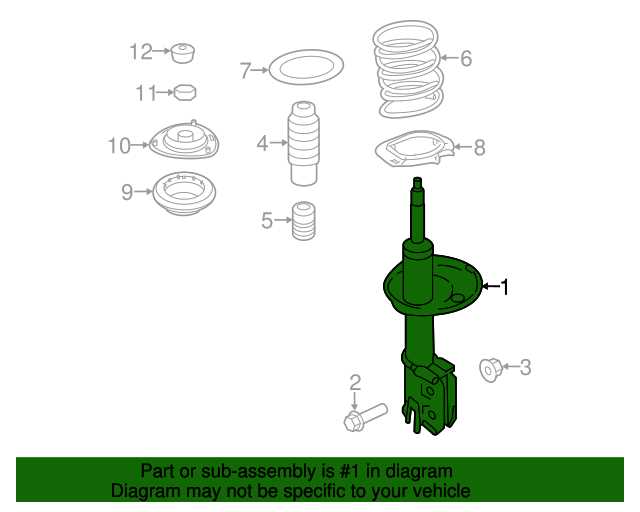

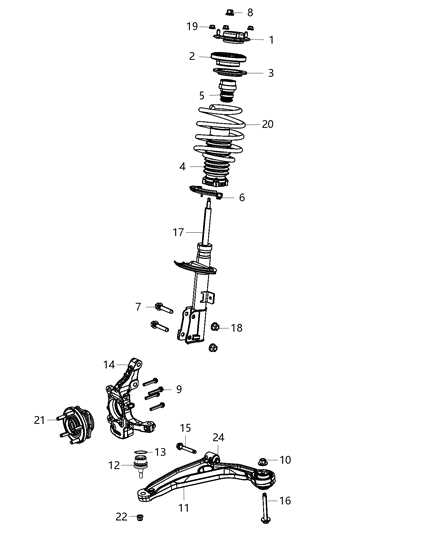

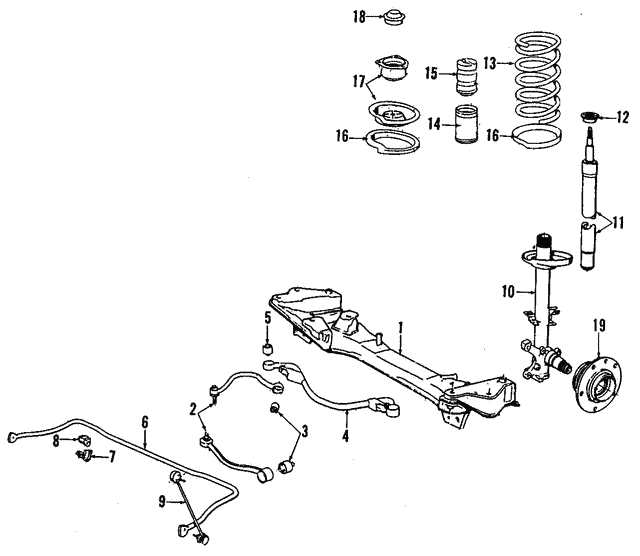

Understanding the components that make up a suspension framework is essential for maintenance and repair tasks. Each element plays a crucial role in ensuring the overall stability and functionality of the vehicle’s suspension system. This section will explore the various components involved, providing insights into their identification and purpose.

Key Components Overview

- Upper Mounting Bracket: This component connects the assembly to the vehicle’s body and supports the top of the framework.

- Lower Control Arm: A critical element that allows for the up and down movement of the wheel assembly.

- Coil Spring: Provides the necessary support and absorbs shocks during driving.

- Shock Absorber: Works to dampen the impact and vibrations, contributing to a smoother ride.

- Bushing: These rubber components reduce friction and noise while allowing for flexibility in movement.

Identifying Each Element

When examining the assembly, it is important to recognize the function of each element:

- Begin with the upper mounting bracket, ensuring it is secure and free from wear.

- Inspect the lower control arm for any signs of damage or rust that could affect performance.

- Check the coil spring for any deformities, as this can impact the vehicle’s handling.

- Examine the shock absorber for leaks, which may indicate a need for replacement.

- Finally, assess the condition of the bushings to ensure proper cushioning and alignment.

By familiarizing yourself with these components, you can effectively troubleshoot and maintain your vehicle’s suspension system.

Benefits of Quality Strut Parts

Utilizing high-grade components for suspension systems can significantly enhance the overall performance and longevity of vehicles. Quality materials contribute to improved handling, safety, and ride comfort, making them essential for both everyday driving and more demanding conditions.

Enhanced Performance

Choosing superior components can lead to remarkable improvements in how a vehicle responds to various driving conditions. Key advantages include:

- Better road grip and stability

- Increased responsiveness during turns

- Reduced body roll and improved cornering

Increased Durability

Investing in reliable components means fewer repairs and replacements over time. Benefits of durability include:

- Longer lifespan, reducing the need for frequent maintenance

- Enhanced resistance to wear and tear

- Improved performance under extreme conditions

Maintenance Tips for Strut Systems

Regular upkeep of suspension mechanisms is essential for ensuring optimal vehicle performance and safety. Proper care can extend the lifespan of these components and enhance ride quality. Here are some effective maintenance strategies to keep in mind.

Routine Inspections

- Conduct periodic checks for signs of wear or damage.

- Examine mounting points and connections for looseness or corrosion.

- Look for any leaks or fluid loss that may indicate a problem.

Driving Habits

- Avoid potholes and rough terrains whenever possible to reduce stress on the system.

- Drive at moderate speeds over bumps to lessen impact.

- Regularly assess tire pressure to ensure even distribution of weight.

Implementing these maintenance tips will help preserve the integrity of your suspension system, contributing to a smoother and safer driving experience.

Common Issues with Strut Assemblies

Components responsible for vehicle stability often encounter various challenges that can impact performance and safety. Identifying these problems is crucial for ensuring optimal handling and comfort while driving. Common issues may arise from wear, misalignment, or inadequate maintenance, which can lead to noticeable changes in the vehicle’s behavior.

One frequent concern is abnormal noise, often a result of worn bushings or other supporting elements. Drivers may experience clunking or rattling sounds during maneuvers, indicating that components need inspection or replacement. Additionally, uneven tire wear can signal that the assembly is not functioning correctly, affecting traction and overall safety.

Another issue involves compromised ride quality, where a vehicle may feel excessively bouncy or unstable. This could indicate that shock-absorbing mechanisms are failing, leading to poor road contact and an uncomfortable driving experience. Regular checks and timely replacements are essential to maintain the performance of these critical components.

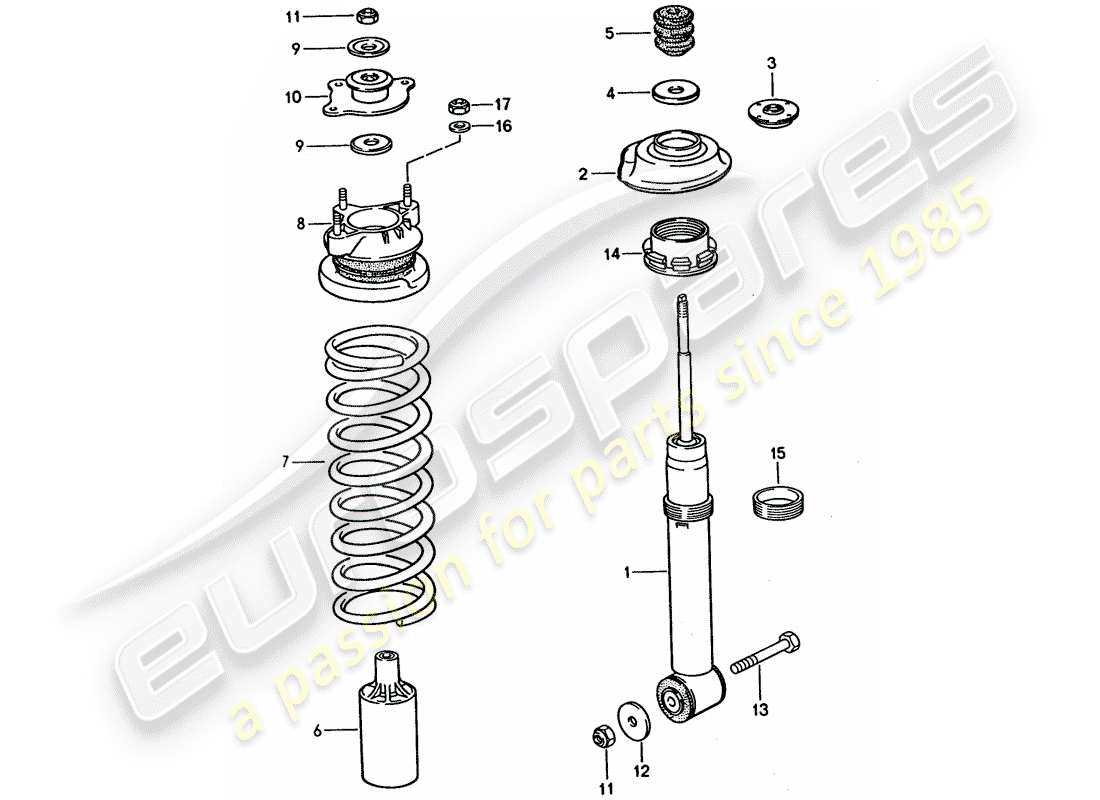

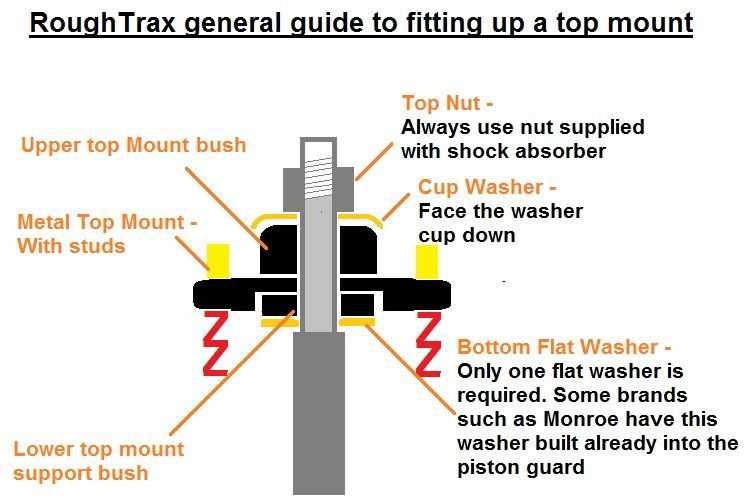

How to Read a Strut Diagram

Understanding a visual representation of suspension components is crucial for effective maintenance and repair. This guide will help you navigate through the essential elements typically found in such illustrations, enabling you to identify and interpret various sections and their functions.

Identifying Key Elements

Begin by familiarizing yourself with the main features presented in the image. Look for labels that indicate different sections and components. These annotations often highlight the names, functions, and connections of each piece, making it easier to grasp the overall structure. Pay attention to any symbols or color codes used, as these can provide additional context.

Utilizing Reference Tables

| Component | Description |

|---|---|

| Upper Mount | Connects the assembly to the vehicle frame, providing stability. |

| Lower Mount | Attaches to the wheel assembly, allowing movement and support. |

| Coil Spring | Absorbs shocks and maintains ride height for comfort. |

| Shock Absorber | Reduces bounce and controls the damping of the suspension system. |

Tools Needed for Strut Repairs

To effectively carry out maintenance and restoration of suspension components, having the right equipment is essential. A well-equipped workspace allows for efficient handling of various tasks, ensuring that each procedure is performed with precision and safety in mind.

Essential Equipment

When approaching the task, several key tools will facilitate the process:

| Tool | Purpose |

|---|---|

| Jack | To lift the vehicle for better access. |

| Socket Set | For loosening and tightening bolts. |

| Torque Wrench | To apply the correct amount of force to fasteners. |

| Spring Compressor | To safely handle coil springs during the replacement process. |

| Pry Bar | For leverage when removing components. |

Safety Gear

In addition to tools, appropriate safety gear is crucial. Always wear gloves and goggles to protect against debris and sharp objects. This ensures a safer working environment during the repair process.

Signs of Strut Wear and Tear

Over time, suspension components may exhibit signs of deterioration that can affect the overall performance and safety of a vehicle. Recognizing these indicators early can help prevent more serious issues and ensure a smoother driving experience.

Unusual Noises While Driving

One of the first signs of deterioration is the presence of strange noises while navigating over bumps or uneven surfaces. You may hear clunking or rattling sounds, which often indicate that the cushioning elements are failing to absorb shocks effectively.

Uneven Tire Wear

Another crucial indicator is the condition of your tires. If you notice irregular patterns of wear, it could suggest that the suspension system is not properly maintaining contact with the road. This misalignment can lead to premature tire replacement and compromise handling.

Upgrading Your Strut Components

Improving the components of your vehicle’s suspension system can significantly enhance its performance and ride quality. By selecting higher-quality or more advanced alternatives, you can experience better handling, increased comfort, and extended durability. This section will guide you through the essential considerations and benefits of upgrading these vital elements.

Choosing Quality Materials is crucial when replacing suspension components. Opting for parts made from superior materials can lead to increased strength and resilience, ensuring they withstand various driving conditions while providing optimal support.

Compatibility with your vehicle’s make and model is another critical factor. Ensuring that the new components are designed to work seamlessly with your existing system can prevent issues and enhance overall functionality.

Furthermore, upgrading suspension components can also contribute to improved aesthetics. Enhanced designs and finishes can elevate the look of your vehicle, making it not only perform better but also stand out on the road.

Lastly, regular maintenance of upgraded components is vital for sustained performance. By keeping them in good condition, you can maximize the benefits of your investment and enjoy a smoother, more responsive driving experience.

Safety Considerations During Repairs

When engaging in maintenance tasks, ensuring a secure environment is paramount. Proper precautions not only safeguard the individual performing the work but also protect surrounding equipment and components. Understanding the potential hazards and adhering to safety protocols can significantly mitigate risks associated with repair activities.

Essential Safety Practices

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and helmets to shield against debris and chemical exposure.

- Ensure that the workspace is well-ventilated to prevent inhalation of harmful fumes or dust.

- Keep the area tidy and free from clutter to minimize the risk of accidents.

Tools and Equipment Safety

- Inspect all tools and equipment for damage before use; faulty tools can lead to injuries.

- Follow manufacturer guidelines for using specialized machinery to ensure correct operation.

- Store tools in designated areas after use to prevent tripping hazards.