Understanding the internal structure of heating systems is critical for anyone looking to maintain, repair, or optimize their performance. This section delves into the key elements that ensure efficient operation and long-term reliability. By focusing on the various connections and mechanisms involved, you’ll gain a clearer picture of how these systems function as a whole.

Key elements like thermostats, combustion chambers, and electrical circuits play a significant role in ensuring consistent heat output. Exploring each part will provide insights into their function and interdependence, helping users troubleshoot or upgrade their systems effectively.

Whether you’re looking to enhance efficiency, perform routine maintenance, or address specific issues, understanding these components can make a big difference. Each section highlights crucial details about individual elements, providing a deeper look into how they work together to deliver optimal heating performance.

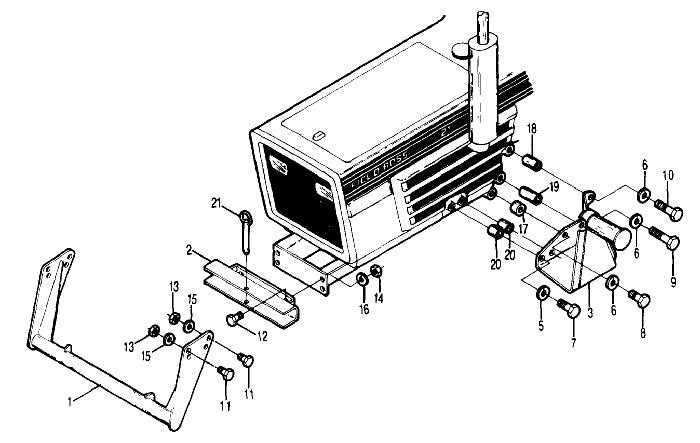

Understanding the Suburban NT-30SP Furnace Components

A comprehensive understanding of the key elements within a heating system is essential for maintaining its performance and longevity. Each piece plays a vital role in the system’s ability to generate and distribute warmth effectively. Knowing the function of these parts not only aids in troubleshooting but also ensures more efficient operation.

Heat Exchanger: The core component responsible for transferring warmth from the burner to the air being circulated. Its condition directly impacts energy efficiency and overall performance.

Burner Assembly: This part ignites the fuel, creating the necessary heat for the system. Regular maintenance ensures safe and effective combustion.

Blower Motor: Critical for moving heated air through the vents and into living spaces. A malfunctioning blower can result in poor airflow and inconsistent temperatures.

Control Board: The brain of the furnace, responsible for managing the system’s operations. It regulates ignition, airflow, and temperature to maintain optimal function.

Thermostat: The user interface for adjusting desired temperature levels. It communicates with the

Common Issues with NT-30SP Heating Systems

Heating systems, especially those installed in vehicles or mobile homes, can develop a range of operational issues over time. Understanding these common challenges can help users quickly identify problems and seek effective solutions to ensure consistent performance. Proper maintenance and timely repairs are essential to avoid larger breakdowns.

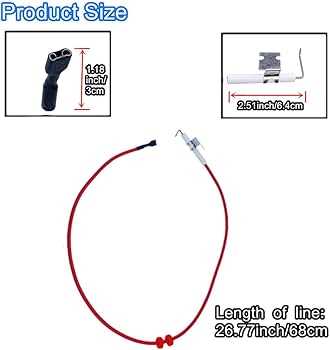

Ignition Failures: One of the most frequent problems involves failure to ignite. This can be caused by issues such as faulty wiring, malfunctioning igniters, or insufficient gas supply.

Thermostat Malfunctions: Inconsistent temperature regulation often points to problems with the thermostat. If the heating unit fails to maintain the desired heat levels, checking and possibly replacing the thermostat may resolve the issue.

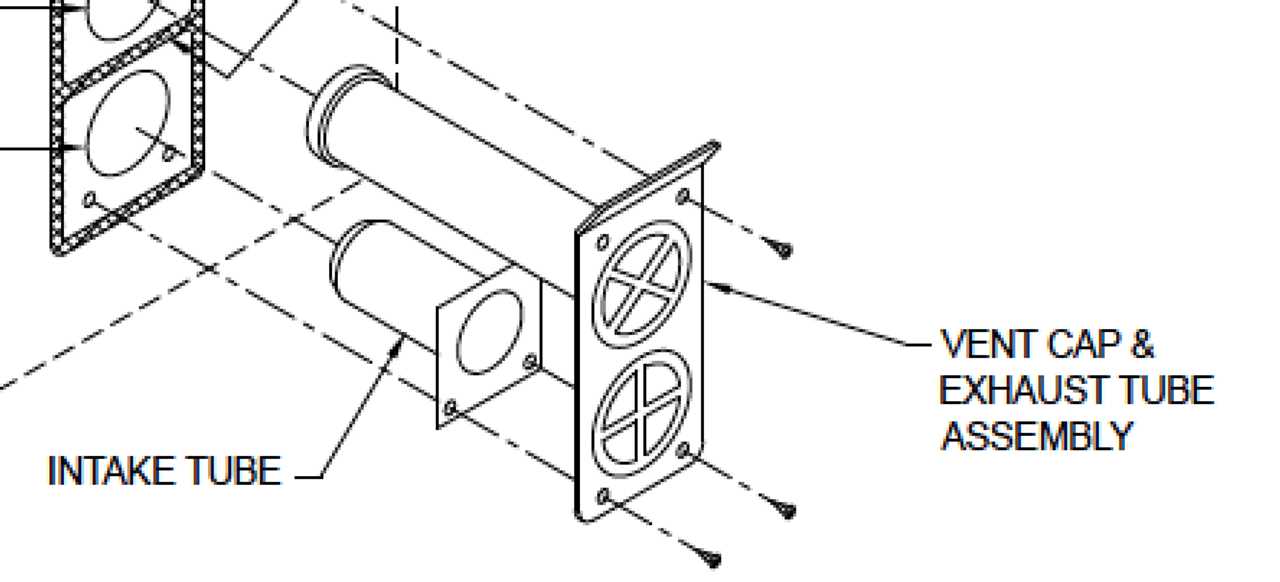

Blockages in Airflow: Debris or obstructions in the vents can restrict proper airflow, reducing efficiency and causing the heater to overheat or shut down. Regular

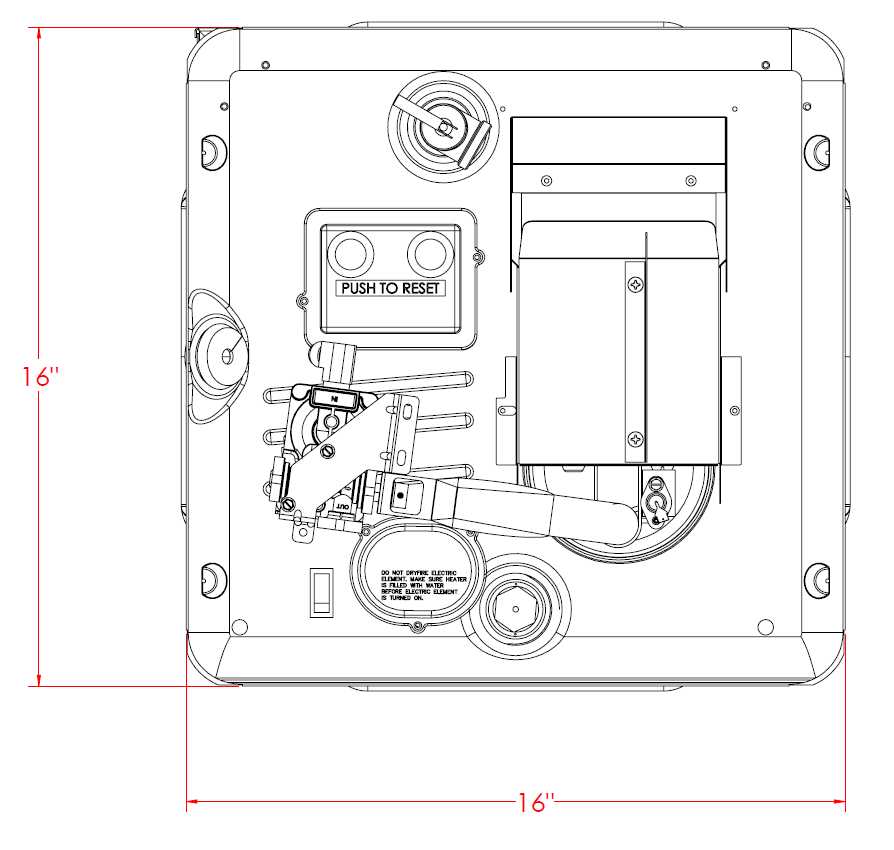

How to Identify Key Parts in the NT-30SP

Understanding the components of your heating appliance is essential for efficient operation and maintenance. Familiarity with these elements allows for quick identification when issues arise and ensures proper function over time.

Main Heating Component

The primary heating element is crucial for generating warmth. It works in tandem with several sensors and control units to regulate the temperature within the system. Inspecting this component periodically ensures it remains free from damage and debris.

Control System and Safety Features

The control module, along with built-in safety mechanisms, monitors the unit’s operation. This system prevents overheating or failure by automatically shutting down in case of irregularities. Proper functioning of these features is key to maintaining a safe and efficient setup.

Replacing the Thermostat in the Suburban NT-30SP

When the heater stops maintaining a stable temperature, it might be necessary to replace the thermostat. This component regulates the heat output, ensuring consistent performance. Following the correct steps will help you replace it safely and restore optimal functionality.

Steps for Removal

- Turn off all power sources to avoid electrical hazards.

- Access the front panel by unscrewing it carefully, exposing the internal components.

- Locate the thermostat, usually connected to wiring and sensors that control the heating system.

- Disconnect the wiring carefully, ensuring you remember the correct connections for reassembly.

- Remove the old thermostat by unscrewing its mounting screws.

Installing the New Thermostat

- Position the new unit in place and secure it with screws.

Maintaining the Fan Motor for Optimal Performance

Ensuring the longevity and efficiency of your fan motor requires regular maintenance and attention to detail. A well-maintained motor not only extends its service life but also ensures that the system operates smoothly, reducing the likelihood of breakdowns or energy inefficiencies.

Cleaning the motor and its surrounding components is one of the simplest yet most effective ways to maintain performance. Dust and debris can accumulate, leading to potential overheating or mechanical issues. Regular cleaning ensures that airflow remains unobstructed, allowing the motor to function efficiently.

Another crucial aspect is lubricating the motor’s moving parts. Over time, friction can wear down components, but proper lubrication helps to minimize this, ensuring smooth operation. Always use the appropriate type of lubricant recommended for your motor to avoid damage.

Additionally, inspecting the electrical connections is vital. Loose or corroded wires can lead to power issues, causing the motor to malfunction or stop working altogether. A thorough check of all connections should be part of you

Steps for Cleaning the NT-30SP Furnace

Regular maintenance of your heating system is essential for its optimal performance and longevity. Cleaning the unit not only enhances its efficiency but also ensures a safe environment by reducing the risk of malfunctions. The following steps outline the process to effectively clean your heating appliance, promoting its reliability and functionality.

Begin by turning off the power supply to the heating device to ensure safety during the cleaning process. Once deactivated, remove any panels or covers to access the internal components. Use a vacuum cleaner with a brush attachment to eliminate dust and debris from the interior surfaces and components. Pay special attention to the blower and combustion chamber, as these areas tend to accumulate dirt that can hinder performance.

Next, check and clean the filters, as they play a crucial role in maintaining air quality and efficient operation. If the filters are reusable, wash them with mild soap and water, and allow them to dry completely before reinserting. If they are disposable, replace them with new ones as needed.

After addressing the filters, inspect the burners for any signs of buildup or corrosion. Use a soft brush to gently clean the burner surfaces, ensuring they are free from blockages. This step is vital for proper combustion and to avoid safety hazards.

Finally, reassemble the unit by replacing the covers and panels, and restore the power supply. Perform a test run to ensure everything is functioning smoothly. Regular cleaning of your heating system will contribute to its efficiency and extend its lifespan, providing you with reliable warmth for years to come.

Safety Precautions for Handling NT-30SP Parts

When working with equipment components, it is essential to prioritize safety to prevent accidents and ensure efficient operation. Proper precautions can significantly reduce risks associated with handling machinery elements, whether during installation, maintenance, or repair tasks.

1. Wear Personal Protective Equipment (PPE): Always equip yourself with appropriate safety gear, including gloves, safety goggles, and sturdy footwear. This minimizes the chances of injury from sharp edges or heavy items.

2. Disconnect Power Sources: Before starting any work, ensure that all power sources are disconnected. This prevents accidental activation of the machinery and reduces the risk of electric shock.

3. Maintain a Clean Workspace: Keeping your work area organized and free of debris can help avoid tripping hazards and ensure that you can access tools and components easily. A tidy environment contributes to better focus and safety.

4. Follow Manufacturer Guidelines: Always consult the relevant manuals or documentation for specific instructions on handling and maintenance. Adhering to these guidelines ensures you use the equipment correctly and safely.

5. Be Aware of Potential Hazards: Familiarize yourself with any potential dangers associated with the components you are handling. Understanding these risks allows you to take appropriate measures to mitigate them.

6. Work with a Partner: If possible, collaborate with a colleague during tasks that involve heavy lifting or complex assembly. Having assistance can improve safety and efficiency, particularly when managing bulky or unwieldy items.

Implementing these safety measures will create a safer environment while working with machinery elements, allowing for more effective and secure handling practices.

Guide to the NT-30SP Electrical Connections

This section provides a comprehensive overview of the electrical connections crucial for ensuring optimal functionality in the heating system. Understanding these connections is vital for installation, troubleshooting, and maintenance, enabling users to effectively manage their equipment.

Electrical connectivity plays a significant role in the overall performance and reliability of the system. Properly wiring the components ensures efficient operation and prevents potential malfunctions. Below is a detailed table outlining the key electrical connections, including their functions and specifications.

| Connection Point | Description | Recommended Wire Gauge |

|---|---|---|

| Power Input | Connects the unit to the power supply, providing the necessary voltage. | 12 AWG |

| Thermostat | Links to the thermostat for temperature regulation. | 18 AWG |

| Fan Motor | Wires connecting to the fan motor for airflow management. | 14 AWG |

| Ignition Control | Interfaces with the ignition system to initiate heating cycles. | 16 AWG |

| Safety Switch | Connects to the safety switch, ensuring safe operation. | 18 AWG |

By adhering to these specifications and guidelines, users can achieve a reliable setup that promotes efficient heating performance and longevity of the unit.

Efficient Operation of the NT-30SP Furnace

Ensuring optimal functionality of a heating system is crucial for maintaining comfort and efficiency in any environment. Proper management and understanding of the unit can lead to significant improvements in performance, reduced energy consumption, and extended longevity. This section explores effective strategies to achieve an efficient heating operation.

Regular Maintenance Practices

Routine inspections and timely servicing play a vital role in keeping the heating system in peak condition. Regularly checking and replacing filters, cleaning burners, and inspecting electrical components can prevent potential issues. Furthermore, maintaining clear airflow and proper ventilation enhances overall efficiency, ensuring the system operates smoothly.

Temperature Settings and Controls

Utilizing programmable thermostats allows for more precise temperature control and can lead to considerable energy savings. Setting appropriate temperature levels according to the time of day or season helps to minimize unnecessary heating, thereby optimizing energy use. It’s essential to monitor and adjust settings as needed to align with changing conditions.

Troubleshooting the NT-30SP Ignition System

The ignition system is crucial for the efficient operation of any vehicle, ensuring that the engine starts and runs smoothly. Problems within this system can lead to a variety of issues, from failure to start to poor performance. This section will outline common issues, diagnostic procedures, and solutions to help identify and rectify ignition system malfunctions effectively.

Common Issues

Various factors can contribute to ignition system failures. Understanding these issues can aid in diagnosing and resolving problems efficiently. Below are some typical symptoms of ignition system troubles:

| Symptom | Possible Cause | Solution |

|---|---|---|

| Engine Won’t Start | Faulty ignition coil | Test and replace the ignition coil if necessary. |

| Inefficient Engine Performance | Worn spark plugs | Inspect and replace spark plugs to restore proper function. |

| Intermittent Stalling | Bad ignition switch | Check the ignition switch and replace if it shows signs of wear. |

| Engine Misfiring | Poor wiring connections | Inspect wiring for damage or loose connections and repair as needed. |

Diagnostic Steps

To accurately troubleshoot ignition system problems, follow these systematic steps:

- Check the battery voltage to ensure it’s sufficient for operation.

- Examine the ignition components for visible wear or damage.

- Utilize a multimeter to test the ignition coil’s resistance.

- Verify the integrity of the spark plugs and replace them if necessary.

By following these guidelines, you can effectively identify and address issues within the ignition system, ensuring optimal performance of your vehicle.