Understanding the layout and functionality of various maintenance components is crucial for efficient upkeep. A comprehensive grasp of how each element fits into the larger system can greatly enhance the effectiveness of routine checks and troubleshooting.

In-depth knowledge about the internal configuration allows operators to identify the precise location of key elements. This can save valuable time when performing repairs or routine servicing. By having a clear visual representation of the structure, tasks like replacement or adjustment become more streamlined.

For those working with technical setups, having a reference that outlines the arrangement of internal parts is a valuable asset. It provides clarity, reduces potential mistakes, and ensures that maintenance processes are carried out with precision. Such insights can significantly extend the lifespan of equipment and optimize its functionality.

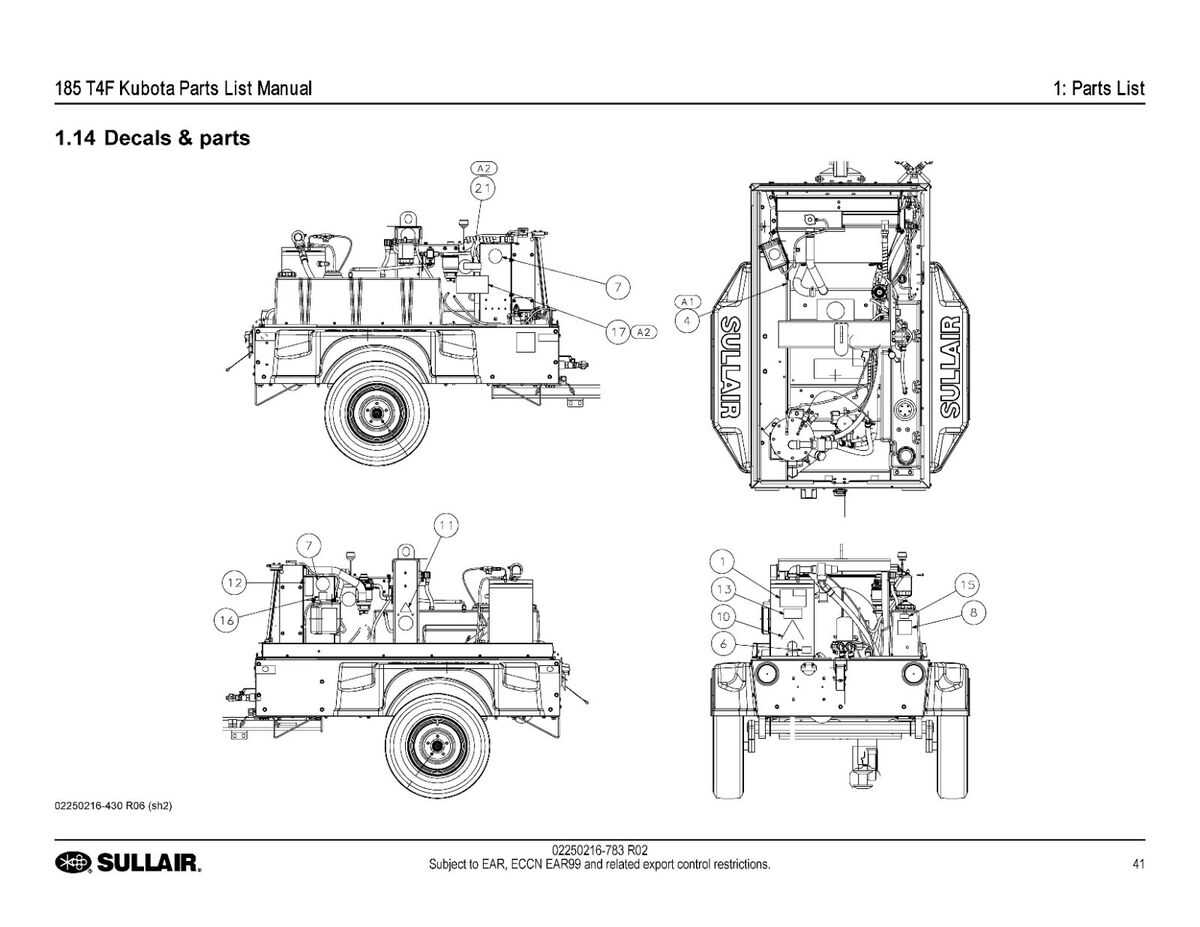

Sullair 185 Component Overview

This section provides a general look at the key elements of this air compression system. Understanding how these components work together is essential for ensuring efficient operation and maintenance.

The core of the system features a high-efficiency compression unit, designed to deliver consistent airflow and optimal pressure levels. This central component is supported by a robust cooling mechanism that helps maintain ideal operating temperatures, preventing overheating during prolonged use.

Another crucial element is the filtration setup, which ensures that the airflow remains clean, free from dust and particles that could impair functionality. Additionally, the control panel plays a vital role in monitoring and adjusting settings, offering precise management of output levels and system diagnostics.

The overall structure is built to withstand demanding conditions, with durable materials and a design that promotes easy access for regular maintenance and inspections. Each part plays a significant role in achieving reliable performance, contributing to the long-lasting operation of the equipment.

Main Functions of Sullair 185 Parts

This section outlines the essential roles of various components in a specific air compression system. Understanding these functions is crucial for effective operation and maintenance of the equipment, ensuring optimal performance and longevity.

Key functionalities include:

- Air Intake: This mechanism draws in ambient air, crucial for the compression process.

- Compression Chamber: This area compresses the air, increasing its pressure for efficient delivery.

- Cooling System: Essential for maintaining optimal operating temperatures, preventing overheating during prolonged use.

- Lubrication System: Ensures all moving parts operate smoothly, reducing wear and tear.

- Control Panel: Provides operators with vital information and allows for adjustments to operating parameters.

- Exhaust System: Safely directs the release of excess air and heat away from the unit.

Each of these elements plays a significant role in the overall functionality, contributing to the effectiveness and reliability of the system.

Key Elements in Air Compressors

Understanding the essential components of air compression systems is crucial for effective operation and maintenance. Each part plays a vital role in ensuring efficiency, reliability, and longevity of the machinery.

Compressor Mechanism

The heart of any air compression unit is its mechanism, which converts power into potential energy. This process is fundamental for creating the necessary pressure for various applications.

Cooling System

Maintaining optimal operating temperatures is essential for performance. The cooling system helps to dissipate heat generated during compression, ensuring the machine runs smoothly.

- Types of cooling: Air-cooled and water-cooled systems.

- Importance: Prevents overheating and enhances efficiency.

Filtration Components

Effective filtration is vital for protecting the internal parts of the compressor. Clean air intake reduces wear and tear, ensuring consistent performance over time.

- Types of filters: Intake, oil, and coalescing filters.

- Benefits: Extends the lifespan of the equipment and improves air quality.

Control Systems

Advanced control mechanisms are crucial for monitoring and adjusting the operation of the compressor. These systems help optimize performance and prevent potential issues.

- Functions: Pressure regulation, temperature monitoring, and automated shutdown.

- Advantages: Increases safety and efficiency.

Understanding Sullair 185 System Layout

This section delves into the overall configuration and arrangement of components within the designated machinery. A clear comprehension of the system’s structure is crucial for effective operation and maintenance. Each element plays a significant role, contributing to the efficient functionality of the entire setup.

Key Components and Their Functions

Familiarity with the essential components helps in recognizing their specific roles. Below is a table highlighting the primary elements and their respective functions:

| Component | Function |

|---|---|

| Compressor Unit | Generates compressed air for various applications. |

| Fuel Tank | Stores fuel necessary for powering the engine. |

| Cooling System | Maintains optimal operating temperatures to prevent overheating. |

| Control Panel | Provides monitoring and operational controls for the system. |

Importance of Proper Layout

Understanding the layout enhances troubleshooting and repair processes. It allows operators to swiftly identify issues and ensures that all components function harmoniously, maximizing efficiency and longevity.

Common Components in Sullair Models

In various industrial machinery, several essential elements play a crucial role in ensuring efficient operation. Understanding these components is vital for maintenance and optimization of equipment performance. This section delves into the fundamental parts commonly found across different models, highlighting their functions and significance.

Power Generation Units

Power generation units serve as the heart of machinery, converting energy into mechanical power. These units are responsible for driving various functions, making them indispensable for overall efficiency.

Air Compression Mechanisms

Air compression mechanisms are designed to increase the pressure of air within the system, providing the necessary force for operations. These components are vital for creating the power required for various tasks, ensuring optimal functionality across models.

Understanding these common elements can lead to better management and longevity of the equipment, contributing to smoother operations and reduced downtime.

Detailed Breakdown of Sullair 185 Parts

This section provides a comprehensive analysis of the components involved in a popular air compressor model. Understanding the various elements that constitute this machinery is crucial for effective maintenance and optimal performance. By examining each component, users can gain insights into the assembly and functionality, ensuring better care and longevity of the equipment.

Essential Components Overview

The main elements of this air compressor are designed to work harmoniously, contributing to its efficiency. Key features include the power unit, which drives the compressor, and the cooling mechanism that prevents overheating. Additionally, the filtration system plays a vital role in maintaining air quality, while the storage tank ensures a steady supply of compressed air for various applications.

Maintenance and Replacement Insights

Regular upkeep of these individual components is essential for reliable operation. Routine checks on the filtration and lubrication systems can prevent potential issues. Furthermore, understanding when to replace specific elements can save time and resources, allowing the equipment to operate at peak performance. Proper maintenance extends the life of the machinery and enhances its efficiency.

Maintenance Tips for Sullair 185 Components

Regular upkeep of machinery elements is essential for ensuring optimal performance and longevity. By adhering to recommended maintenance practices, users can significantly reduce the likelihood of unexpected failures and prolong the lifespan of equipment. This section provides valuable insights into effective maintenance strategies for various components.

Routine Inspection

Conducting frequent assessments of all critical elements helps identify wear and potential issues early. Consider the following steps:

- Check for signs of wear, such as cracks or corrosion.

- Inspect seals and gaskets for leaks.

- Examine connections and fittings for tightness.

Cleaning and Lubrication

Keeping components clean and adequately lubricated is vital for their efficient operation. Follow these practices:

- Remove dirt and debris regularly to prevent clogging.

- Apply suitable lubricants to moving parts as specified in the manual.

- Replace filters as needed to ensure proper airflow and fluid flow.

Essential Sullair 185 Spare Parts

Ensuring the longevity and optimal performance of your equipment relies heavily on having the right components readily available. Regular maintenance and timely replacements can prevent breakdowns and enhance efficiency. This section explores the key elements that are crucial for seamless operation, providing insights into their importance and selection.

Key Components to Consider

When it comes to maintaining machinery, specific elements should always be prioritized. These include filters that help in keeping the system clean, seals that prevent leaks, and belts that ensure proper functioning. Having high-quality alternatives for these items can significantly impact overall performance.

Importance of Quality in Components

Selecting durable and reliable replacements is essential for minimizing downtime. High-quality components not only extend the life of the equipment but also improve efficiency and reduce the risk of unexpected failures. It is advisable to consult with experts when sourcing these items to ensure compatibility and reliability.

How Sullair 185 Parts Work Together

The components of a compressed air system function in harmony to ensure optimal performance and efficiency. Understanding the interactions among these elements is crucial for maintaining a reliable operation.

Each segment plays a vital role in the overall functionality. Here are some key aspects of how these elements collaborate:

- Air Intake: This section captures atmospheric air, allowing it to enter the system for processing.

- Compression Mechanism: The heart of the system, it compresses the incoming air, increasing its pressure and temperature.

- Cooling System: Essential for dissipating heat generated during compression, preventing overheating and maintaining efficiency.

- Storage Tank: This component holds the pressurized air, ensuring a steady supply for various applications.

- Control System: Regulates the operation, monitoring pressure levels and ensuring safe functionality.

These components work in tandem, creating a seamless flow of compressed air that powers tools and machinery effectively. Proper maintenance and understanding of each element’s role can enhance longevity and performance.

Identifying Parts in Sullair Air Units

Understanding the components within air machinery is crucial for optimal performance and maintenance. Each element plays a specific role, contributing to the overall functionality of the equipment. Recognizing these parts helps users ensure their systems operate efficiently and effectively.

When examining the various elements of air units, consider the following key categories:

- Power Source: The mechanism that provides energy to the unit, typically involving engines or generators.

- Compression Mechanism: This includes cylinders and pistons responsible for air compression.

- Cooling Systems: Elements designed to regulate temperature, ensuring the machinery does not overheat during operation.

- Control Systems: Instruments and panels that allow operators to manage settings and monitor performance.

For efficient operation, it is essential to regularly inspect and maintain these components. Here are some maintenance tips:

- Regularly check fluid levels and replace any low or contaminated fluids.

- Inspect belts and hoses for wear and tear, replacing them as necessary.

- Clean filters to ensure optimal airflow and reduce strain on the machinery.

- Schedule routine check-ups with a qualified technician to catch any potential issues early.

By familiarizing yourself with the different components and their functions, you can enhance the longevity and efficiency of your air machinery.

Replacing Sullair 185 Air Compressor Parts

Maintaining the efficiency of your air compression system is crucial for optimal performance. Over time, various components may wear out or become damaged, necessitating their replacement. This section outlines the essential considerations and steps for swapping out parts in your air compressor unit, ensuring continued reliability and effectiveness.

Identifying Worn Components

Before proceeding with replacements, it is vital to identify the specific components that require attention. Commonly, issues arise from elements such as filters, valves, and belts. Regular inspection can help in early detection of wear and tear, facilitating timely replacements.

Replacement Process Overview

Once you have identified the components that need replacing, follow these general steps to ensure a successful swap:

| Step | Description |

|---|---|

| 1 | Turn off and disconnect the power supply to prevent accidents. |

| 2 | Remove any protective covers or panels to access the components. |

| 3 | Carefully detach the worn parts, taking note of their arrangement. |

| 4 | Install the new components, ensuring a secure fit and proper alignment. |

| 5 | Reattach covers or panels and restore the power supply. |

By following these guidelines, you can effectively replace damaged components in your air compression unit, ensuring long-lasting performance and reliability.

Optimizing Sullair 185 Performance

Enhancing the efficiency and reliability of a portable air compressor involves several strategic approaches. By focusing on regular maintenance, optimal operating conditions, and timely component upgrades, users can significantly improve overall functionality. This section outlines key practices to ensure peak performance of the equipment.

To achieve maximum efficiency, consider the following factors:

| Factor | Description |

|---|---|

| Routine Maintenance | Regular checks and servicing of the unit to prevent unexpected breakdowns and prolong its lifespan. |

| Air Quality | Ensuring clean and dry air intake to prevent contamination and reduce wear on internal components. |

| Optimal Operating Temperature | Maintaining suitable temperatures during operation to avoid overheating and enhance efficiency. |

| Regular Inspections | Conducting frequent evaluations of the system for signs of wear or damage to preempt larger issues. |

| Component Upgrades | Upgrading specific parts with higher quality alternatives to boost performance and reliability. |

Implementing these strategies can lead to improved operational efficiency, reduced downtime, and enhanced overall satisfaction with the performance of the machinery.