| Height Adjustment |

Allows for easy control of cutting height, offering

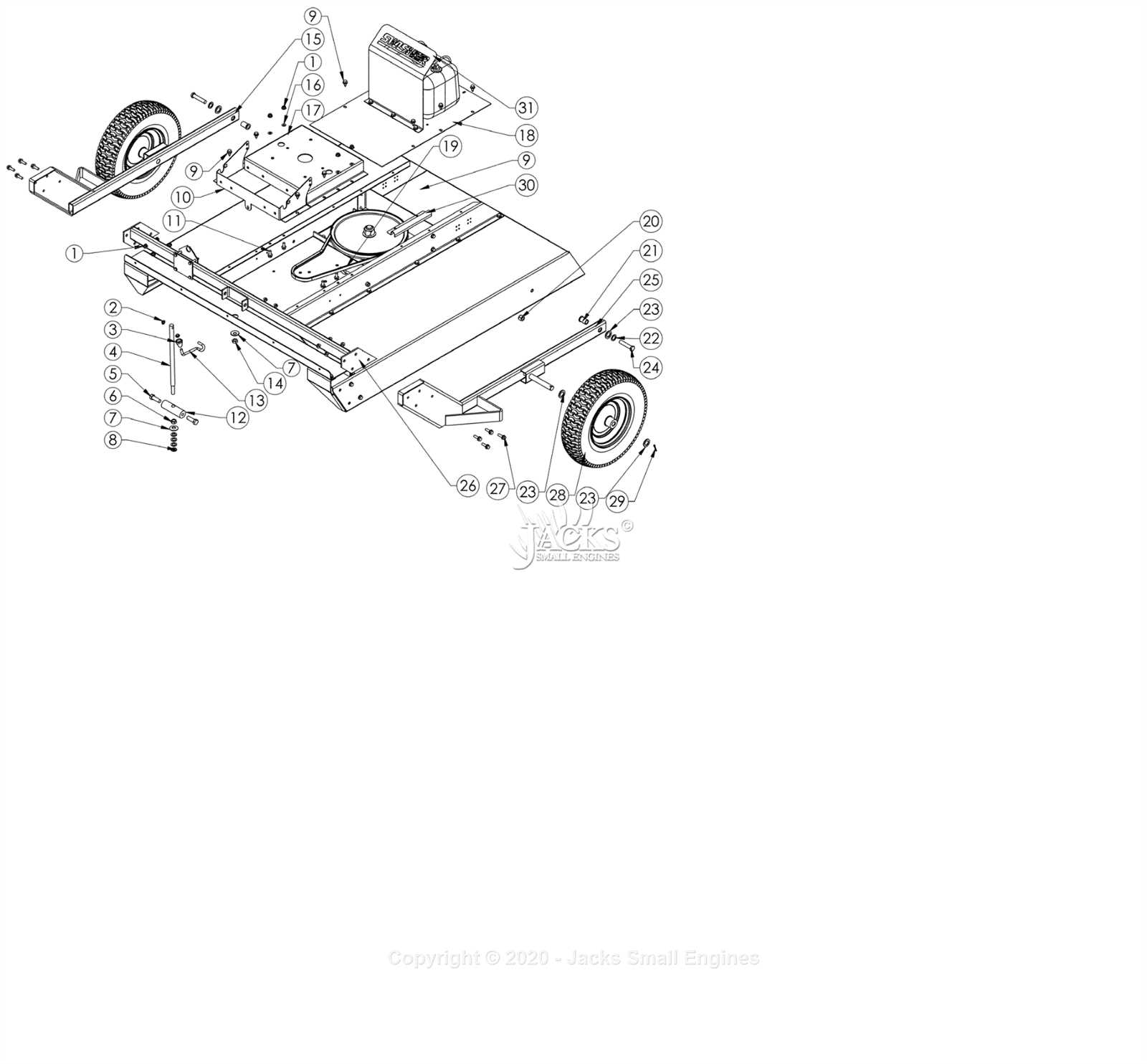

Importance of Parts Diagrams

Clear visual representations of machinery components are essential for understanding how different elements of a device function together. These illustrations provide a detailed view of each component, helping users grasp the full scope of a system’s structure.

Efficient Troubleshooting

When facing mechanical issues, a detailed breakdown of all components helps identify potential malfunctions quickly. By referencing these technical visuals, one can easily pinpoint where a failure might have occurred, reducing the time spent on repairs.

- Helps in locating malfunctioning components

- Provides a clear understanding of mechanical relationships

- Speeds up the diagnostic process

Simplified Maintenance

For those performing regular upkeep, these schematics serve as invaluable guides. They enable users to follow step-by-step procedures with confidence, ensuring each element is addressed correctly during routine inspections or

Identifying Essential Components

Understanding the core elements of a complex machine is key to ensuring its proper maintenance and operation. Each component has a specific role, and recognizing their significance allows for more effective troubleshooting and part replacement when necessary.

Main Structural Elements

The primary framework supports the entire system, providing stability and durability. This structure often houses key elements such as the drive mechanism, ensuring that the system functions smoothly and efficiently. The main body serves as a foundation, connecting various other essential parts and allowing them to work together.

Functional Mechanisms

Central to the operation are the moving parts that interact with each other to perform tasks. These include rotating components, adjustable arms, and control systems, all designed to work in harmony for optimized performance. Ensuring these mechanisms are well-maintained is critical for smooth functionality and extended lifespan.

Maintenance Tips for Longevity

To ensure that your equipment remains in optimal condition for years, regular maintenance is essential. Following a consistent schedule of inspections and servicing can prevent unexpected issues and extend the lifespan of your machinery.

Inspecting Key Components

Regularly checking all essential components is crucial for preventing wear and tear. Look for any signs of damage, such as cracks or rust, and address them immediately. Keeping all parts clean and lubricated will also reduce friction and increase efficiency.

Routine Cleaning and Lubrication

Proper cleaning, especially after each use, will prevent the buildup of dirt and debris that can hinder performance. Additionally, applying lubrication to moving parts ensures smooth operation and prevents unnecessary strain on the machine.

| Maintenance Task |

Frequency |

| Check bolts and fasteners |

Monthly |

| Inspect cutting blades |

Before each use |

| Apply lubrication |

Every 3 months |

Common Repairs and Solutions

Maintenance and troubleshooting are essential aspects of keeping equipment in optimal working condition. Regular wear and tear can lead to various issues, but most common problems can be resolved with straightforward adjustments or part replacements. Below are some typical issues that may arise during operation and practical solutions to address them effectively.

Engine Won’t Start: Ensure that the fuel system is working correctly. Check for blockages in the fuel line or issues with the ignition system. Cleaning or replacing the spark plug often resolves this issue.

Uneven Operation: If the equipment operates inconsistently, it could be due to a dull or damaged blade. Sharpening or replacing the cutting components can restore smooth performance. Inspect the engine for possible clogging that might affect power distribution.

Vibration Issues: Excessive vibrations during operation might result from loose bolts or misaligned parts. Tighten any loose components and inspect for worn-out bearings, replacing them if necessary to reduce vibrations.

Overheating: Overheating can be caused by a lack of proper airflow or clogged cooling fins. Clean the air intake and cooling areas regularly to prevent the engine from overheating.

How to Use the Diagram Effectively

Understanding how to read and interpret a schematic can significantly simplify maintenance and assembly tasks. It allows you to visualize the arrangement of components, making it easier to identify key connections and potential issues. Whether you’re dealing with simple or complex systems, mastering the use of visual aids can save you time and effort.

Identify Key Components

Begin by familiarizing yourself with the most important elements in the schematic. These are often labeled or positioned prominently, helping you quickly grasp their role in the system. Knowing these parts will allow you to approach troubleshooting or assembly with a clearer plan in mind.

Follow the Flow of Connections

Next, trace the lines or paths that connect different components. This step is crucial for understanding how each element interacts within the system. By following these paths logically, you can detect where potential malfunctions may occur or how to assemble everything correctly.

Parts Replacement Process Explained

Replacing components in mechanical systems can be a straightforward process when approached with the right tools and knowledge. Understanding the steps involved in removing worn or damaged elements and installing new ones ensures that the equipment continues to function effectively.

Step-by-Step Breakdown

- First, ensure that the machine is powered off and safely disconnected from any energy sources to prevent accidents during the replacement.

- Carefully identify the faulty or worn-out component by examining the overall condition of the system.

- Using the correct tools, begin loosening any fasteners, such as bolts or screws, that secure the old component in place.

- Remove the worn part gently, taking care not to damage surrounding areas or connected elements.

- Before installing the new piece, clean the mounting surface and ensure all connections are in good condition.

- Place the new component in position and secure it using the appropriate fasteners, ensuring everything is tightened to the manufacturer’s recommended settings.

Final Check and Testing

- Double-check all connections and fasteners to ensure nothing is loose or

Where to Find Replacement Parts

Maintaining the longevity of your equipment often requires finding suitable replacement components. Whether dealing with wear and tear or unexpected damage, sourcing the correct items is crucial for continued use. There are multiple avenues to explore when in need of specific items for repairs or upgrades.

Online Marketplaces

One of the most accessible options for finding components is online marketplaces. These platforms offer a wide variety of options from both official suppliers and third-party sellers. Search filters allow you to narrow down your choices based on compatibility, price, and shipping options.

- Check user reviews to ensure reliability

- Look for vendors offering warranties

- Compare prices from multiple sellers

Authorized Dealers

Another dependable method is purchasing from authorized dealers. These sellers provide genuine components, ensuring a perfect fit and long-term durability. Authorized sellers also offer customer support and installation guidance, which can be essential for certain components.

- Locate the nearest certified dealer

Comparing with Other Models

When assessing different machines designed for outdoor maintenance, it’s essential to examine how various models stack up against each other. Each design offers unique features and functionalities that cater to specific needs and preferences, making comparisons vital for potential buyers.

Performance and Efficiency

One significant aspect to consider is the overall performance and efficiency of the equipment. While some models excel in handling tough terrain with advanced cutting mechanisms, others may prioritize speed and ease of use. Evaluating how these characteristics align with individual requirements can lead to a more informed decision.

Durability and Build Quality

Another crucial factor in the comparison is durability and build quality. Various designs utilize different materials and construction techniques, impacting their longevity and resilience in challenging conditions. Understanding the differences can help users choose a machine that will withstand rigorous use over time.

User Testimonials and Experiences

This section delves into the insights and feedback shared by individuals who have utilized the robust mowing equipment in their various tasks. Users often highlight their experiences, providing valuable perspectives on performance, reliability, and ease of use.

Positive Feedback

Many users express satisfaction with the equipment’s efficiency in handling challenging terrains. One user noted that the machine’s durability allowed them to tackle tough vegetation with confidence, stating, “I’ve used this for years, and it never fails to impress with its power.”

Constructive Criticism

While the feedback is largely positive, some individuals offer constructive critiques. A user mentioned that while the device performs excellently, maintenance could be more straightforward. They suggested clearer instructions for upkeep, stating, “It would be great to have a simplified guide to make servicing easier.”

Final Thoughts on Performance

When considering the overall efficiency of any machinery, various factors come into play that can significantly impact its functionality. Understanding these elements can help users optimize their experience and ensure smooth operation. The performance of such equipment is often determined by design quality, ease of maintenance, and adaptability to different environments.

Key Performance Indicators

- Durability: The longevity of components plays a crucial role in maintaining optimal performance over time.

- Efficiency: A well-designed machine will operate with minimal energy consumption while delivering maximum output.

- Maintenance: Regular upkeep is essential to prevent wear and tear, ensuring the equipment remains in peak condition.

Conclusion

In summary, the effectiveness of machinery is contingent upon several interrelated factors. By focusing on durability, efficiency, and regular maintenance, users can enhance their operational experience and maximize the potential of their equipment. This holistic approach to performance will lead to increased satisfaction and better results in the long run.

|