When it comes to maintaining outdoor equipment, one of the most crucial aspects is understanding how the individual mechanisms work together. Each element has a specific role that ensures the overall system operates efficiently and reliably. A deeper knowledge of these components can help ensure smooth operation and extend the life of your machinery.

Identifying and maintaining these essential elements can prevent potential breakdowns and reduce the need for costly repairs. Recognizing how different elements connect and interact is fundamental for anyone looking to troubleshoot or optimize performance.

Exploring these systems in detail allows for better maintenance and repair practices, ensuring that every piece is functioning as it should. This guide aims to simplify the process, offering a clear breakdown of essential mechanisms and their roles.

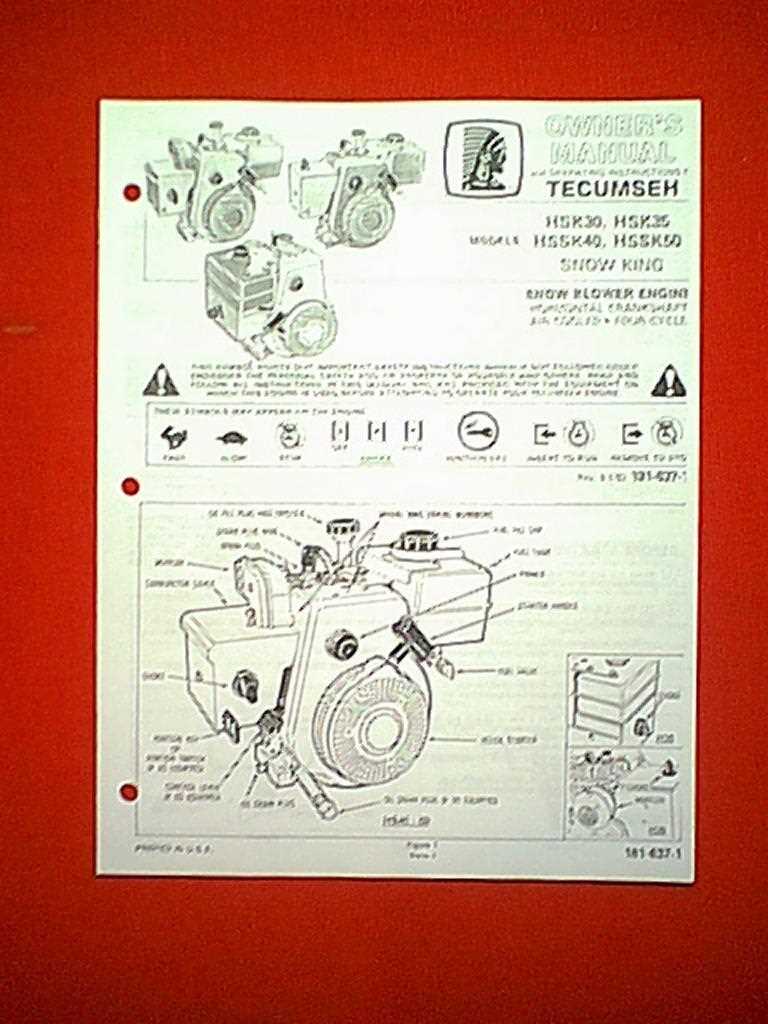

Understanding the Tecumseh HSSK50 Engine

The small engine discussed in this section is a reliable power source commonly found in various outdoor equipment. Known for its efficiency and robust performance, it plays a crucial role in powering machines that require consistent energy output. To understand this engine better, it’s important to explore its fundamental components, which ensure smooth operation and longevity.

Main Components

- Fuel delivery system – ensures a consistent flow of fuel.

- Ignition system – responsible for starting and maintaining engine function.

- Cooling system – prevents overheating during extended use.

Performance and Maintenance

Maintaining the engine is essential for optimal performance. Regular upkeep, such as cleaning and replacing worn-out elements, ensures durability and enhances its efficiency. Familiarizing yourself with its key parts helps in identifying any potential issues early, ensuring long-term reliability.

Key Components of the HSSK50 Model

The design of this engine model includes several crucial elements that work together to ensure efficient performance. These components are designed to enhance reliability, durability, and ease of maintenance, making them essential for the smooth operation of the system.

- Engine block: The central structure that houses most of the internal parts, offering both protection and support.

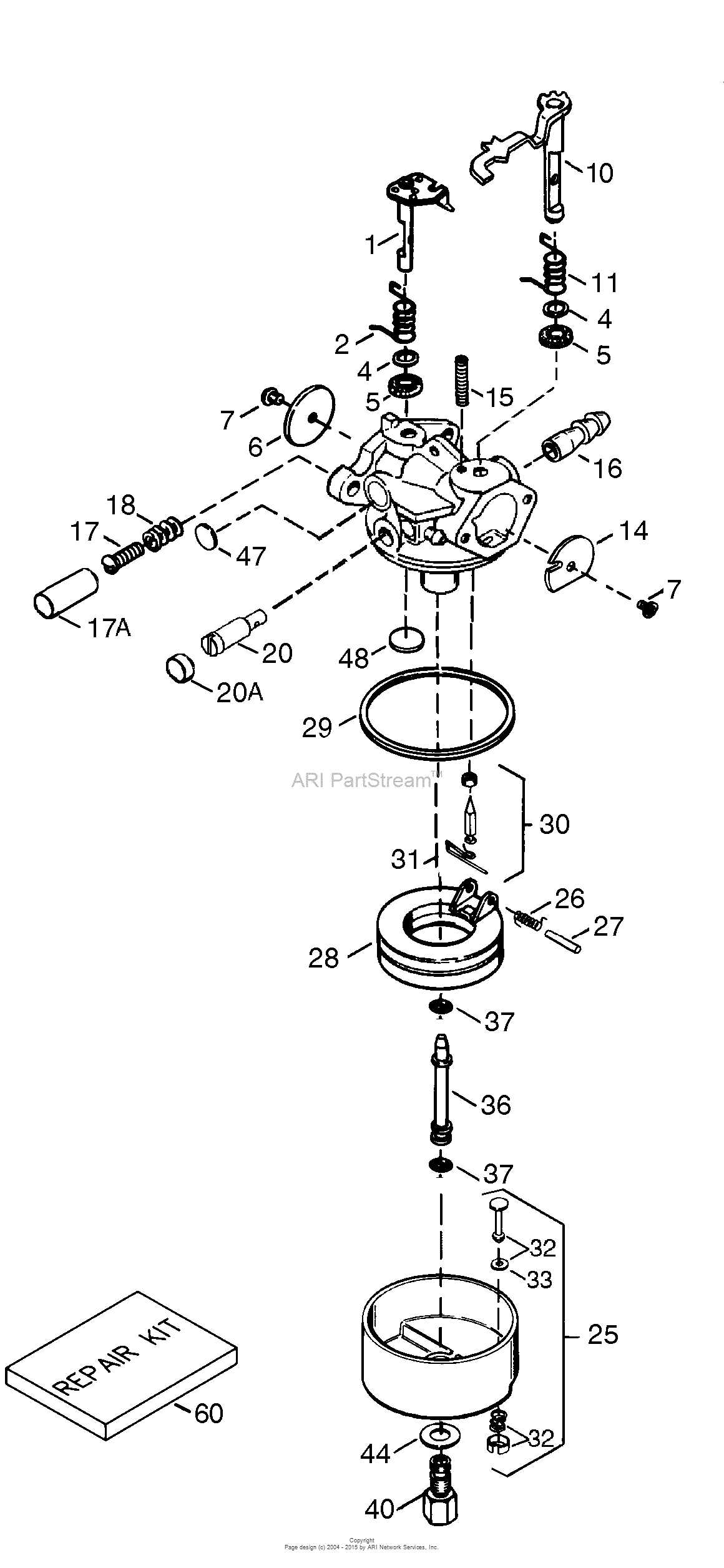

- Carburetor: A critical part that mixes air and fuel in the right proportions, ensuring optimal combustion.

- Ignition system: Responsible for generating the necessary spark to ignite the fuel-air mixture in the combustion chamber.

- Exhaust system: This component helps to expel gases produced during combustion, maintaining engine efficiency.

- Cooling system: Designed to prevent the engine from overheating, it regulates temperature and ensures consistent performance.

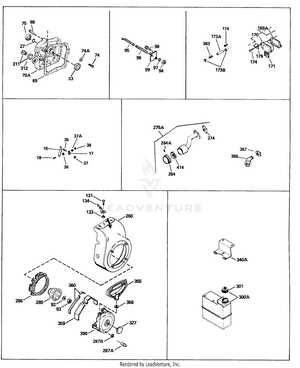

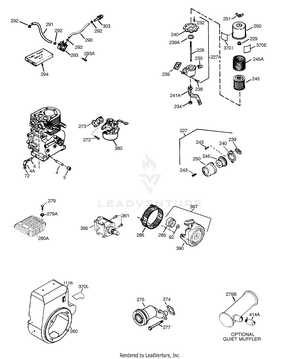

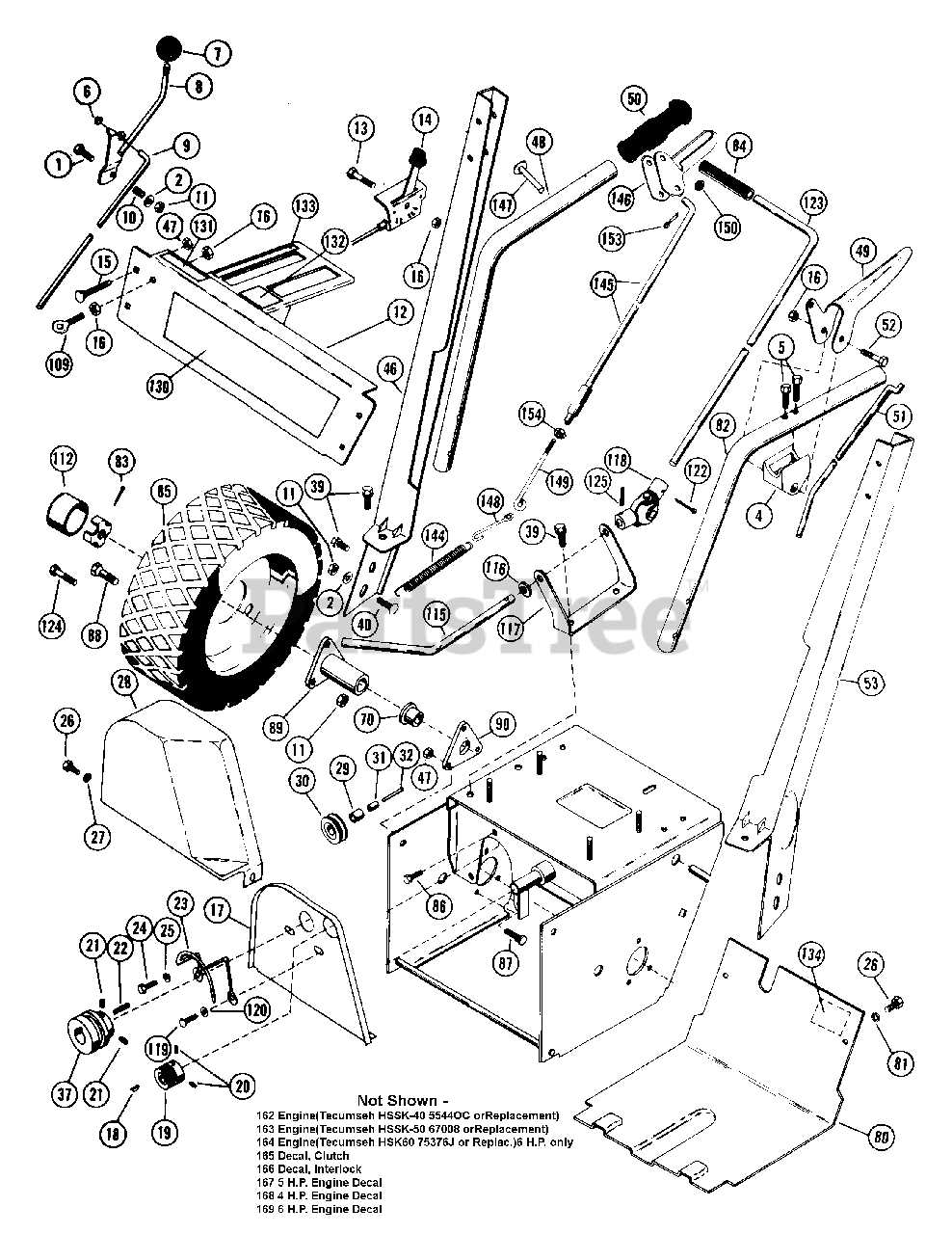

Locating Parts on a Tecumseh Diagram

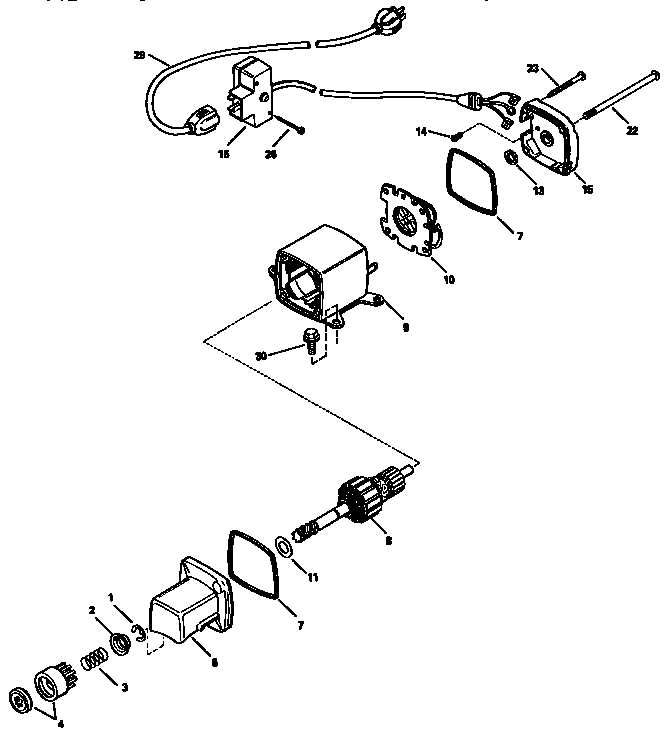

Understanding the layout of a component map is essential for identifying specific elements within a machine. These visual guides allow users to navigate through various mechanical elements, helping to pinpoint the location of needed components with ease. By carefully analyzing the structure and following the layout, you can efficiently identify the correct section where a particular element is located.

In most cases, these illustrations are organized logically, grouping elements based on their function or position within the system. This makes it simpler to trace connections and locate individual items without confusion. Using this approach, finding the right part becomes a straightforward process, ensuring smooth repairs and maintenance.

Common Replacement Parts for HSSK50

Maintaining efficient operation of this engine model often requires replacing some components due to regular wear and tear. To ensure the smooth running of the machinery, certain elements are prone to breakdowns and may need to be swapped with new ones over time. Keeping these components in good condition is essential for optimal performance.

Key Engine Components

Some of the critical engine elements that are most frequently changed include moving parts that handle fuel, air, and ignition. These components are crucial for the overall function and should be inspected regularly to avoid unexpected failures. Regular upkeep will help prevent larger mechanical issues.

Maintaining Durability

For long-term use, certain key elements need to be replaced periodically. This ensures that the engine remains reliable and functions as intended. When these parts show signs of aging, replacing them promptly is essential to avoid damage to the entire system.

How to Identify Worn-out Engine Parts

Understanding when key components in your engine have deteriorated is crucial for maintaining optimal performance and avoiding further damage. Regular inspections can help detect early signs of wear and prevent more severe issues down the line. Below are key areas to focus on during your examination.

Common Signs of Wear

- Unusual noises: If your engine starts making clunking or grinding sounds, this could indicate that certain components are no longer functioning properly.

- Decreased performance: A noticeable reduction in power output or difficulty starting may suggest internal damage or aging components.

- Excessive vibration: Unbalanced or worn elements can lead to increased vibration, which may cause further damage if left unchecked.

Visual Inspection Tips

- Check for visible wear: Look for cracks, corrosion, or deformation in metal surfaces that could affect functionality.

- Inspect fluid levels: Leaks or unusually low levels of oil

Proper Maintenance for Tecumseh HSSK50 Engines

Ensuring the longevity and efficiency of small engines requires regular upkeep and attention. Proper care not only enhances performance but also prevents premature wear and tear. By adhering to essential maintenance practices, users can maximize the lifespan of their machinery and ensure reliable operation.

Regular Oil Changes: Routine oil changes are crucial for keeping the engine lubricated and running smoothly. It is recommended to check the oil level frequently and replace it according to the manufacturer’s guidelines. Clean oil reduces friction and helps maintain optimal performance.

Air Filter Maintenance: Keeping the air filter clean is essential for optimal airflow and performance. A clogged filter can restrict airflow, leading to inefficient combustion and potential engine damage. Inspect and clean or replace the filter as necessary to ensure the engine receives adequate air supply.

Fuel System Care: Proper care of the fuel system is vital for maintaining engine efficiency. Using fresh fuel and adding a fuel stabilizer can help prevent issues related to stale gasoline. Additionally, regular inspection of fuel lines and filters will ensure a clean and unobstructed fuel flow.

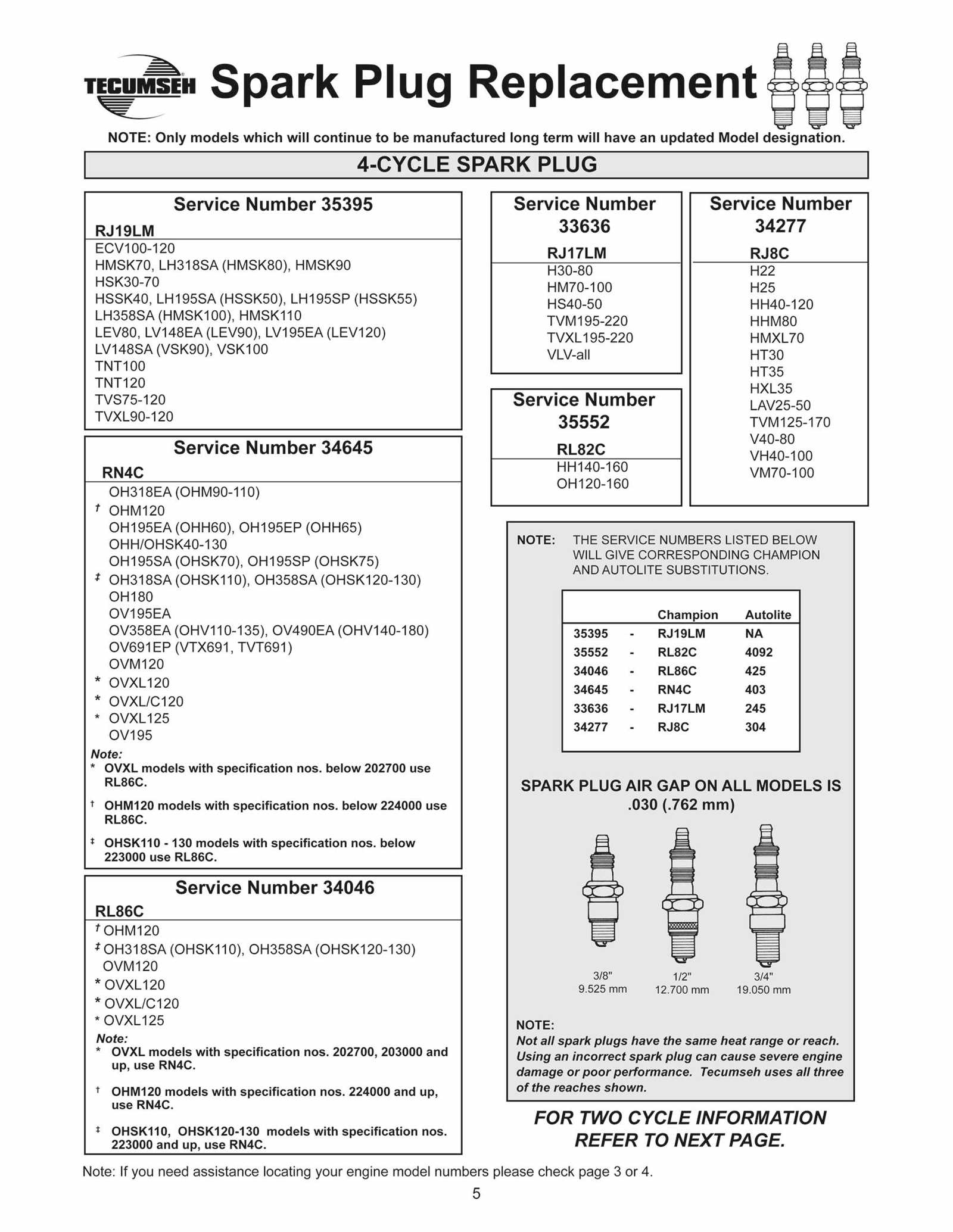

Spark Plug Inspection: The spark plug plays a critical role in ignition. Regularly inspecting and replacing worn or fouled spark plugs can lead to improved starting and overall engine performance. Ensure the correct gap is set for optimal combustion.

By following these maintenance tips, users can ensure their small engines remain in top condition, providing reliable service and performance for years to come.

Benefits of Using a Detailed Parts Diagram

Utilizing a comprehensive visual representation of components can significantly enhance the understanding of mechanical systems. Such illustrations not only aid in identifying individual elements but also facilitate the assembly and maintenance processes. By providing clarity and organization, they serve as an invaluable resource for both professionals and hobbyists alike.

One of the primary advantages of having access to an intricate layout is the reduction of errors during repair or installation. With a clear guide, users can easily locate the required components, ensuring that the correct pieces are utilized in the right context. This meticulous approach minimizes the risk of damage and increases the efficiency of the task at hand.

Moreover, these visuals promote better communication among technicians and support teams. When everyone has access to the same detailed reference, discussions about repairs or modifications become more straightforward and productive. This shared understanding fosters collaboration and enhances the overall effectiveness of maintenance activities.

Finally, having a well-organized reference can save time and resources. By quickly identifying and addressing issues, individuals can avoid unnecessary delays and expenses. Overall, the use of such comprehensive representations proves beneficial in promoting accuracy, efficiency, and effective communication in various mechanical endeavors.

Installation Tips for New Engine Components

When replacing components in an engine, ensuring proper installation is crucial for optimal performance and longevity. This section provides practical advice to guide you through the installation process of new engine elements, emphasizing accuracy and efficiency.

Preparation Steps

Before beginning the installation, it’s essential to take the following preparatory actions:

- Gather all necessary tools and components.

- Consult the specific installation guide for your engine model.

- Ensure your workspace is clean and organized to prevent any mishaps.

Installation Process

Follow these steps to successfully install new engine components:

- Begin by removing the old parts carefully, taking note of their arrangement.

- Clean the surfaces where the new components will be fitted.

- Install the new elements in the reverse order of removal, ensuring they fit snugly.

- Tighten bolts and screws to the manufacturer’s specifications to prevent leaks.

- Double-check all connections and fittings for security before testing the engine.

Where to Find Genuine Tecumseh Parts

For those seeking authentic components for their small engine equipment, finding reliable sources is crucial. Various options are available to ensure you acquire quality items that meet your machinery’s requirements.

Authorized Dealers: One of the most trustworthy places to start your search is through authorized retailers. These establishments are recognized for their commitment to providing original products, ensuring compatibility and performance.

Online Marketplaces: Numerous e-commerce platforms specialize in engine supplies. When using these websites, it is essential to verify the seller’s reputation and read reviews to confirm the authenticity of the items offered.

Local Repair Shops: Local mechanics often have access to genuine components or can order them on your behalf. Establishing a relationship with a nearby repair service can lead to valuable recommendations and assistance in sourcing the right materials.

Manufacturer’s Website: Visiting the official website of the manufacturer can also yield valuable information. They often provide a list of authorized dealers and other resources to help locate genuine components.

In conclusion, ensuring the integrity of the items you purchase is vital for the longevity and efficiency of your machinery. By exploring these avenues, you can confidently find the necessary materials to keep your equipment running smoothly.

Exploring Aftermarket Options for HSSK50

When considering alternatives for enhancing your small engine performance, exploring aftermarket components can be a beneficial approach. These options often provide enhanced durability, improved efficiency, and cost-effective solutions for maintenance or upgrades.

Aftermarket components are designed to meet or exceed the standards of original equipment, providing a reliable choice for enthusiasts and professionals alike. Here are some key points to consider:

- Quality and Performance: Many aftermarket products are engineered with advanced materials and technology, often resulting in superior performance compared to stock items.

- Availability: A wide variety of options is available through various retailers and online platforms, making it easier to find the right fit for your engine.

- Cost-Effectiveness: Aftermarket components can often be more affordable than OEM parts, allowing for cost savings in repairs and upgrades.

In summary, the exploration of alternative components can significantly enhance your engine’s operation while providing valuable options for customization and repair.

Troubleshooting with a Tecumseh Parts Diagram

Understanding the components of your machinery is essential for effective problem-solving. Utilizing a visual representation of the various elements can significantly aid in diagnosing issues, ensuring a more efficient repair process. By referring to an illustrative guide, users can identify specific parts and their functions, enabling a systematic approach to resolving malfunctions.

Identifying Common Issues

Many mechanical failures stem from common sources. By analyzing the schematic, one can pinpoint frequent trouble spots such as fuel delivery, ignition failures, or mechanical obstructions. Recognizing these areas allows for targeted inspections and repairs, reducing downtime and improving overall performance.

Step-by-Step Repair Process

Once a problem is identified, following a methodical approach is crucial. Begin by referencing the visual aid to locate the affected components. Carefully disassemble as needed, ensuring that each part is accounted for. Reassemble with attention to detail, referring back to the guide to ensure accuracy. This systematic method can greatly enhance the likelihood of successful repairs.