Exploring the intricate design of mechanical systems is essential for anyone involved in maintenance or repair. A well-organized layout of engine components not only aids in identifying specific parts but also enhances the overall efficiency of troubleshooting processes.

In this section, we will delve into a detailed representation of various elements within a specific engine model. By examining the configuration and relationships between components, one can gain a clearer understanding of how each part contributes to the machine’s functionality.

Grasping the ultimate arrangement of these elements allows for informed decisions during repairs or upgrades. Familiarity with the structure ensures that users can navigate the complexities of the engine with confidence, ultimately leading to better performance and longevity.

Overview of the Engine Model

This section provides an insightful look into a popular small engine design widely used in various outdoor equipment. Renowned for its reliability and efficiency, this model is often favored by both professionals and hobbyists alike. Its robust construction and straightforward functionality make it an excellent choice for numerous applications.

Key Features

- Compact design suitable for tight spaces

- High torque output for effective performance

- Easy maintenance procedures for user convenience

- Fuel efficiency that reduces operating costs

Applications

This versatile engine can be found in a range of equipment, including:

- Lawn mowers

- Snow blowers

- Generators

- Trimmers

Its adaptability and dependable nature have established it as a staple in the small engine market, making it a preferred option for various tasks. Whether for residential use or in commercial settings, this engine continues to deliver outstanding performance and durability.

Common Applications of TVS90 Engine

The versatile engine in question is widely utilized across various equipment, thanks to its reliable performance and adaptability. It serves as a power source in many outdoor tools and machines, meeting the demands of both professional and recreational users.

One prevalent application is in lawn care machinery, where it provides the necessary torque for mowers and trimmers, ensuring efficient grass cutting and maintenance. Another significant use is in snow removal equipment, enabling effective clearing of driveways and sidewalks during winter months.

Additionally, this engine can be found in generators, where it contributes to the generation of power for home and outdoor use. Its robustness makes it suitable for various applications, enhancing the functionality of numerous devices in different sectors.

Importance of Genuine Replacement Parts

Using authentic components for machinery repairs is crucial for maintaining performance and longevity. Substituting with inferior alternatives can lead to various issues that compromise functionality and safety.

- Quality Assurance: Genuine components are manufactured to meet specific standards, ensuring optimal performance.

- Longevity: Authentic parts typically last longer, reducing the frequency of replacements and overall maintenance costs.

- Compatibility: Original components are designed to fit seamlessly, minimizing the risk of damage during installation.

- Warranty Protection: Using genuine replacements often helps preserve the manufacturer’s warranty on equipment.

- Safety: Authentic parts are tested for safety and reliability, reducing the risk of accidents or failures.

In conclusion, opting for genuine components not only enhances performance but also ensures safety and reliability in machinery operation.

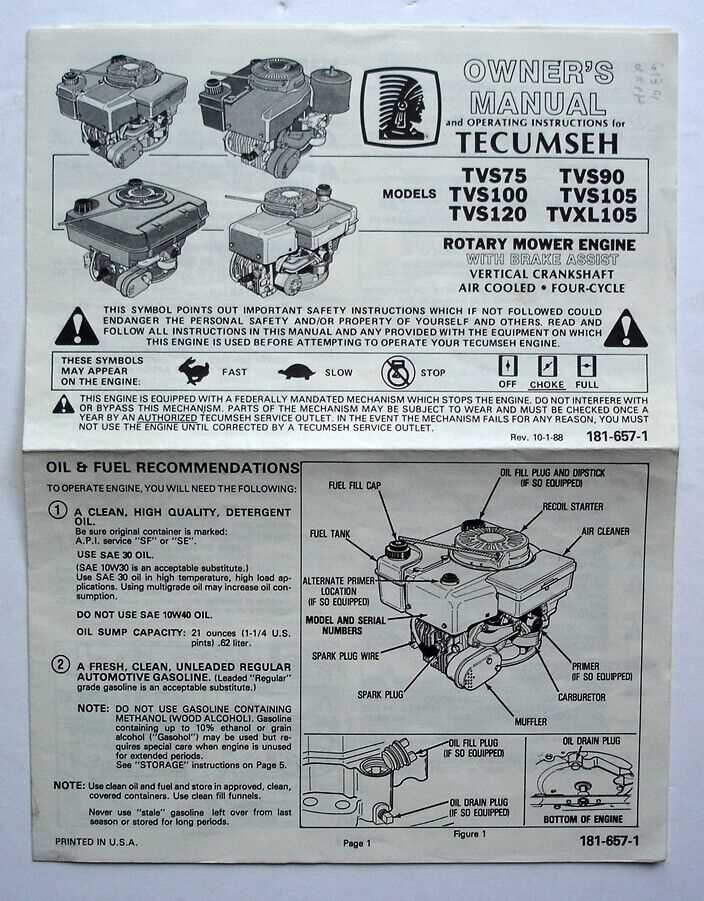

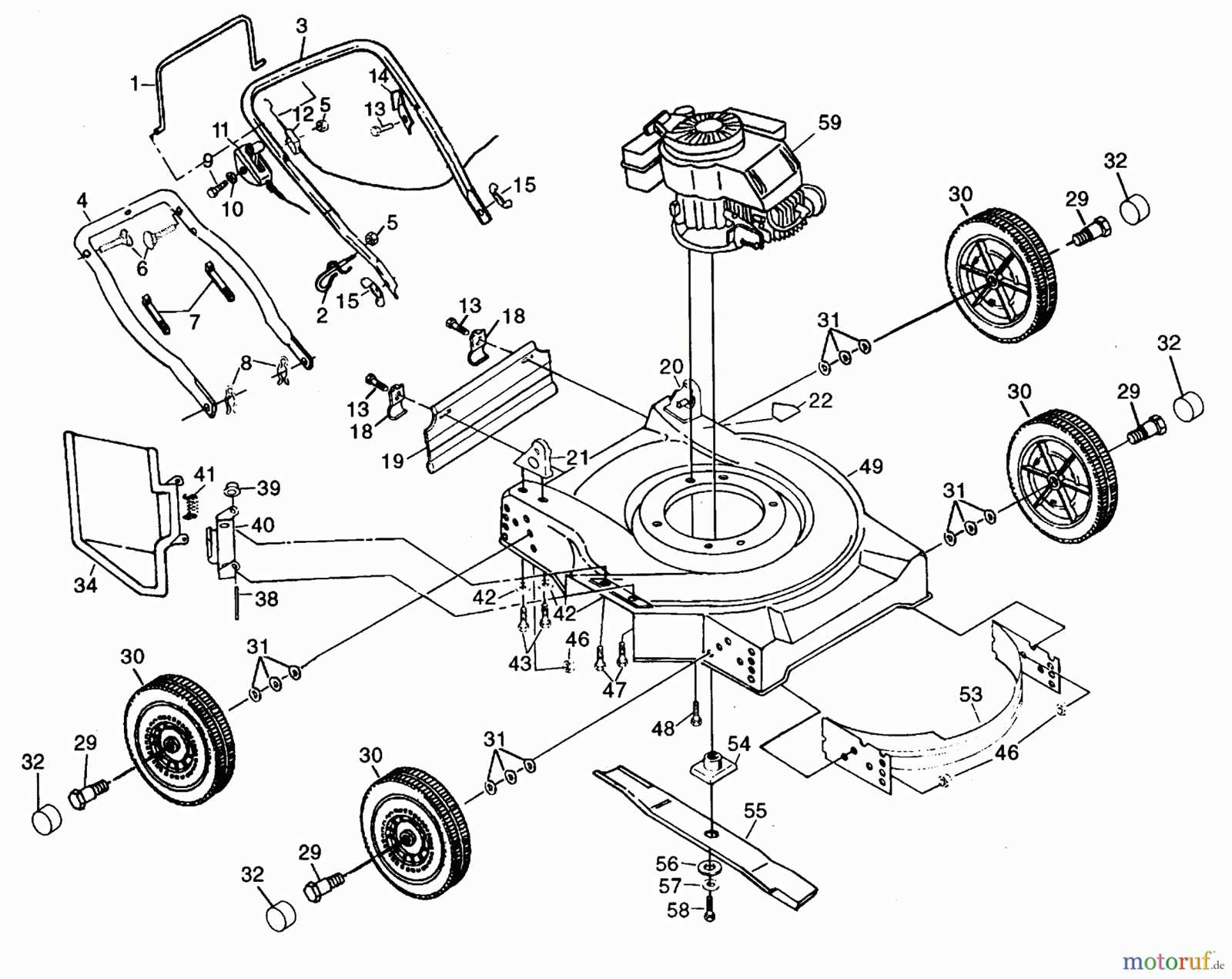

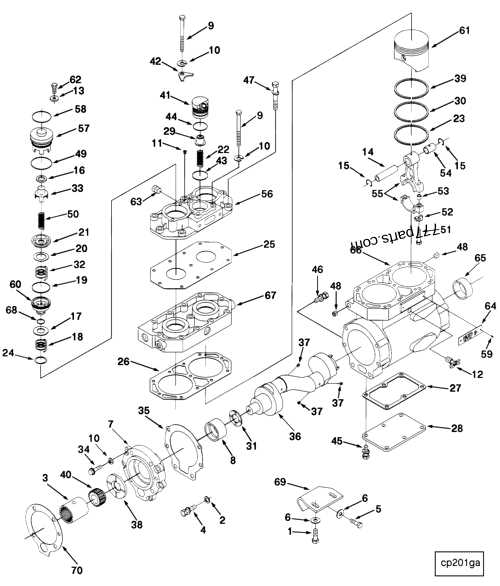

How to Read Parts Diagrams

Understanding schematics is essential for effective maintenance and repair. These illustrations provide a visual representation of components, allowing users to identify and locate each element easily. Familiarity with the symbols and layout enhances one’s ability to perform repairs efficiently.

Begin by familiarizing yourself with the key symbols used in these visuals. Each icon typically represents a specific component, and recognizing these can save time. Pay attention to any labels or numbers, as they often correlate with a list of items for ordering or reference.

Next, analyze the layout of the schematic. Components are often organized logically, showing how they connect to one another. Understanding this arrangement helps in visualizing the overall function of the assembly. Take notes on any complex sections for easier troubleshooting later.

Lastly, consult the accompanying documentation if available. This can provide additional insights and context that are invaluable when working on repairs. With practice, reading these illustrations becomes an intuitive process, leading to more successful maintenance outcomes.

Key Components of TVS90 Engine

This section explores the essential elements that constitute the functioning mechanism of the engine, highlighting their roles and interconnections. Understanding these components is crucial for maintenance and optimization of performance.

Major Parts Overview

Each part plays a significant role in ensuring efficiency and reliability. From the ignition system to the fuel delivery, every element contributes to the overall operation.

Component Functions

| Component | Function |

|---|---|

| Cylinder | Houses the piston and facilitates combustion. |

| Piston | Converts fuel energy into mechanical work. |

| Carburetor | Mixes air and fuel for optimal combustion. |

| Ignition System | Ignites the fuel-air mixture for combustion. |

| Exhaust System | Channels exhaust gases away from the engine. |

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular attention and care. By following a few essential maintenance practices, you can extend the lifespan of your machinery and enhance its performance. This guide outlines key strategies to help you achieve optimal functioning over time.

| Tip | Description |

|---|---|

| Regular Cleaning | Keep the exterior and interior components free from dirt and debris to prevent wear and ensure efficient operation. |

| Oil Changes | Replace the oil at recommended intervals to maintain proper lubrication and prevent engine damage. |

| Inspect Filters | Check and replace air and fuel filters regularly to maintain optimal airflow and fuel efficiency. |

| Check Belts and Hoses | Examine belts and hoses for signs of wear or damage, replacing them as necessary to avoid breakdowns. |

| Battery Maintenance | Ensure battery connections are clean and tight, and check the fluid levels regularly to prolong battery life. |

Implementing these practices will not only enhance the performance of your equipment but also provide peace of mind knowing that you are taking proactive steps to ensure its longevity.

Identifying Parts by Model Number

Understanding the significance of model identifiers is essential for accurately locating components for maintenance and repair. Each identifier serves as a unique key, linking you to specific elements required for optimal functionality.

To effectively identify elements, follow these steps:

- Locate the model number on the equipment.

- Refer to the manufacturer’s reference materials for accurate information.

- Cross-check the number with available catalogs or online resources.

Utilizing these methods ensures you acquire the ultimate components tailored to your equipment’s needs.

Key advantages of using model identifiers include:

- Streamlined searches for components.

- Reduced risk of ordering incorrect items.

- Increased efficiency in repairs.

Where to Buy Tecumseh Parts

Finding the right components for your outdoor equipment can enhance performance and longevity. Whether you need replacements or upgrades, it’s essential to know where to source these items effectively.

Here are some reliable options to consider:

| Source | Description |

|---|---|

| Authorized Dealers | Visit local retailers that specialize in outdoor machinery. They often carry a wide range of essential components. |

| Online Marketplaces | Websites like Amazon and eBay offer a vast selection, with customer reviews to guide your choices. |

| Manufacturer Websites | Directly purchasing from the official site ensures authenticity and compatibility. |

| Repair Shops | Local mechanics or repair shops may have access to the specific items you need or can order them for you. |

DIY Repair vs. Professional Services

When it comes to fixing equipment or machinery, individuals often face the decision between handling the repairs themselves or seeking assistance from experts. Both options have their advantages and disadvantages, which can influence the outcome and overall satisfaction with the process. Understanding these factors can help one make an informed choice based on their specific circumstances.

Advantages of DIY Repair

One of the primary benefits of tackling repairs on your own is the potential cost savings. By eliminating labor fees, you can allocate your budget toward necessary components instead. Additionally, taking on repairs yourself can provide a sense of accomplishment and deepen your understanding of the equipment. Many individuals enjoy the hands-on experience and the opportunity to learn new skills, making the process rewarding beyond just the mechanical outcome.

Benefits of Professional Services

On the other hand, enlisting the help of skilled technicians can ensure that repairs are completed efficiently and effectively. Professionals possess the expertise and tools required to diagnose issues accurately and resolve them promptly. This can be especially advantageous for complex problems that may be overwhelming for someone without extensive experience. Furthermore, relying on experts often comes with warranties or guarantees on their work, offering peace of mind regarding the longevity of the repairs.

Frequently Replaced TVS90 Components

In the realm of small engine maintenance, certain elements are prone to wear and tear due to their critical functions. Understanding which components typically require replacement can enhance the longevity and performance of the machinery. This section highlights those frequently swapped-out pieces, providing insight into their roles and importance.

Commonly Replaced Elements

Engine maintenance often involves specific parts that are essential for optimal operation. Regularly inspecting and replacing these components can prevent breakdowns and ensure efficient performance.

| Component | Function | Replacement Frequency |

|---|---|---|

| Fuel Filter | Ensures clean fuel supply to the engine | Every 100 hours of use |

| Spark Plug | Ignites the air-fuel mixture for combustion | Every 50-100 hours of use |

| Air Filter | Prevents debris from entering the engine | Every 25 hours of use |

| Oil Filter | Removes contaminants from engine oil | Every 100 hours of use |

Importance of Timely Replacements

Replacing these vital components on schedule is crucial for maintaining engine efficiency and prolonging its lifespan. Neglecting to address wear can lead to reduced performance and costly repairs, emphasizing the value of proactive maintenance.

Understanding Engine Specifications

Engine specifications play a crucial role in determining the performance and efficiency of machinery. A thorough grasp of these details enables users to make informed decisions regarding maintenance and upgrades, ensuring optimal functionality. By examining various elements, one can gain insights into the operational capabilities and requirements of the engine.

| Specification | Description |

|---|---|

| Displacement | The total volume of the engine’s cylinders, impacting power output. |

| Horsepower | A measure of the engine’s power, indicating its ability to perform work. |

| Torque | The rotational force produced, essential for acceleration and load handling. |

| Fuel Type | The type of fuel required, affecting efficiency and emissions. |

| RPM Range | The range of engine speeds at which optimal performance occurs. |

Safety Precautions During Repairs

When undertaking maintenance on machinery, ensuring safety is of utmost importance. Adopting appropriate measures can prevent accidents and injuries, promoting a secure working environment. Prior to commencing any repair task, it is crucial to be aware of potential hazards and to implement strategies that mitigate risks.

Personal Protective Equipment

Wearing suitable personal protective gear is essential. This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp edges or chemicals, and steel-toed boots to safeguard the feet. Additionally, employing ear protection can help reduce exposure to harmful noise levels during operation.

Proper Tool Usage

Using tools correctly is vital for ensuring safety during repairs. Always select the appropriate tool for the job and ensure it is in good condition. Inspect equipment for damage or wear before use, and never attempt to use damaged tools. Following manufacturer guidelines for operation and maintenance will further enhance safety and efficiency.

Resources for Tecumseh Users

Accessing reliable information is essential for users who seek to maintain and repair their outdoor power equipment effectively. A variety of platforms and materials can assist enthusiasts and professionals alike in ensuring their machinery runs smoothly and efficiently. From manuals to community forums, these resources play a pivotal role in enhancing user knowledge and skills.

Manuals and Guides

Comprehensive manuals and user guides are invaluable tools for understanding the intricacies of your equipment. They provide detailed instructions on assembly, troubleshooting, and maintenance, helping users to optimize performance and extend the lifespan of their machines.

Community Support

Engaging with online forums and local clubs offers users the opportunity to share experiences and gather insights. These communities often share tips, tricks, and personal anecdotes that can be beneficial for resolving issues and enhancing overall user experience.