In complex machinery, knowing how each element is connected plays a critical role in ensuring smooth operation and maintenance. Properly identifying connections and configurations helps to maintain peak performance, reducing the likelihood of errors during repairs or replacements. The layout of internal mechanisms provides invaluable insight for those responsible for equipment upkeep.

By exploring the detailed arrangement of key elements, users can develop a deeper understanding of how these components work together. This knowledge allows for quicker diagnostics and improved efficiency when addressing any potential issues. A clear view of the internal framework ensures that servicing can be carried out with precision and confidence.

In this section, we will dive into the configuration of vital elements, providing a closer look at the design and structure that drive optimal functionality. This approach is essential for both professionals and enthusiasts seeking to extend the lifespan and reliability of their equipment.

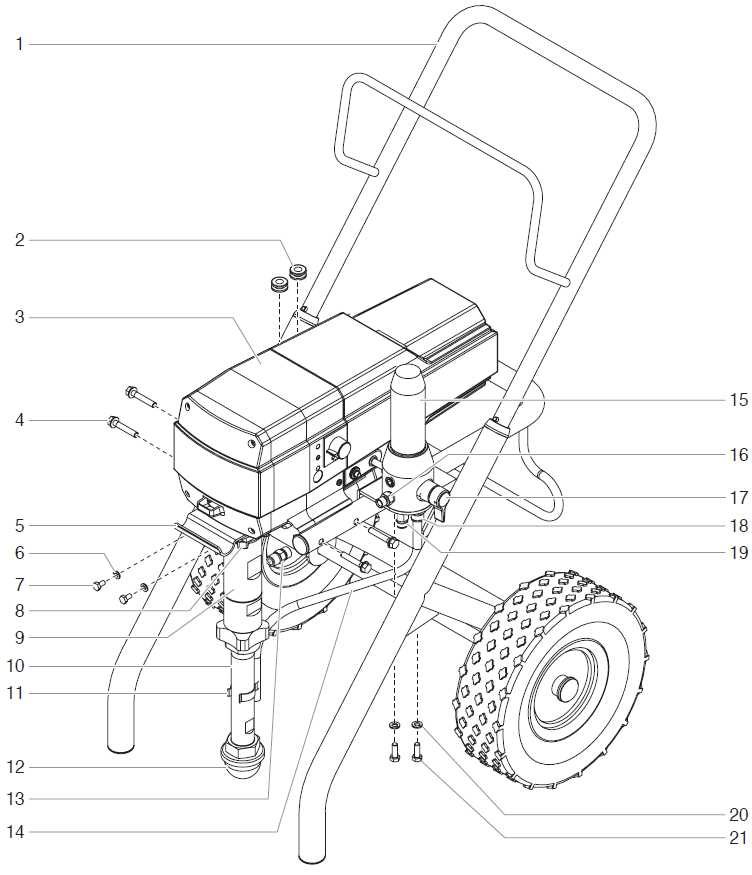

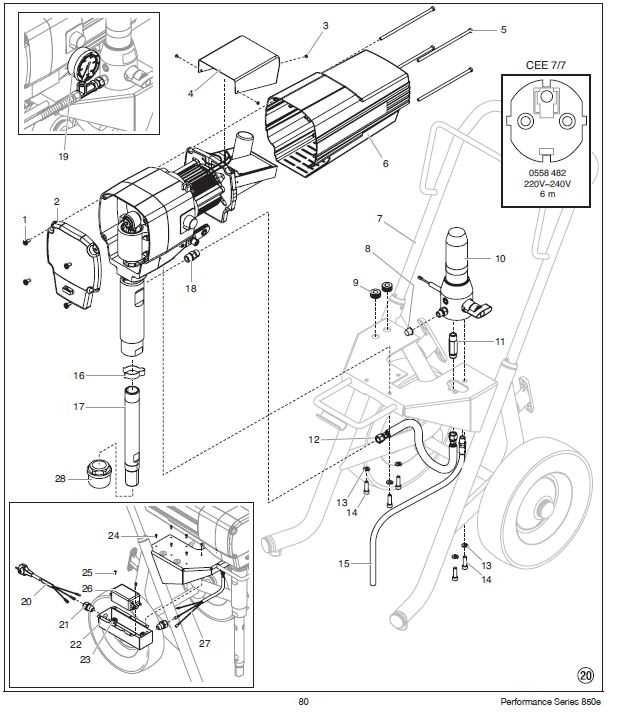

Titan 840 Parts Breakdown

The comprehensive disassembly of this equipment provides a detailed understanding of its key components. Identifying the arrangement and purpose of various elements within the system can assist in maintenance and repairs, offering a clear overview of its inner workings.

Main Structural Components

The framework and key mechanisms form the backbone of the machine, ensuring its stability and functionality. Each structural element is precisely designed to support the operation and bear the stress of intensive use.

Critical Mechanical Elements

The driving forces behind

Key Components of Titan 840

Understanding the essential elements of this high-performance system is crucial for efficient operation and maintenance. This section highlights the core structures that make up the system, emphasizing the importance of each in ensuring optimal functionality.

- Main framework: The foundation that supports all other units, designed for durability and stability during use.

- Fluid distribution mechanism: This component ensures even and precise flow, critical for smooth performance.

- Control interface: Provides the user with full access to various settings and adjustments for a customized experience.

- Power supply module: A reliable source that delivers consistent energy to the entire system, ensuring uninterrupted operation.

- Protective casing: Designed to shield sensitive internal parts from external factors, enhancing longevity.

- Main Control Unit: Located centrally, it governs all essential operations, coordinating the entire system.

- Cooling System: Positioned near heat-generating elements, it ensures stable temperatures for prolonged operation.

- Power Distribution Module: Responsible for regulating and distributing electrical flow to various sections.

- Power System: Supplies energy for all operations, ensuring reliability and stability.

- Control Interface: Allows users to interact with the system, enabling adjustments and monitoring.

- Cooling Mechanism: Prevents overheating, thereby prolonging the lifespan of the unit.

- Communication Ports: Facilitate data transfer and connectivity with other devices.

- Structural Framework: Provides support and houses all internal components securely.

- Robust Construction: The framework is designed for durability, ensuring longevity under various operational conditions.

- Efficient Layout: Components are arranged to maximize accessibility and minimize maintenance time.

- Innovative Technology: Integration of advanced technology enhances performance and reliability.

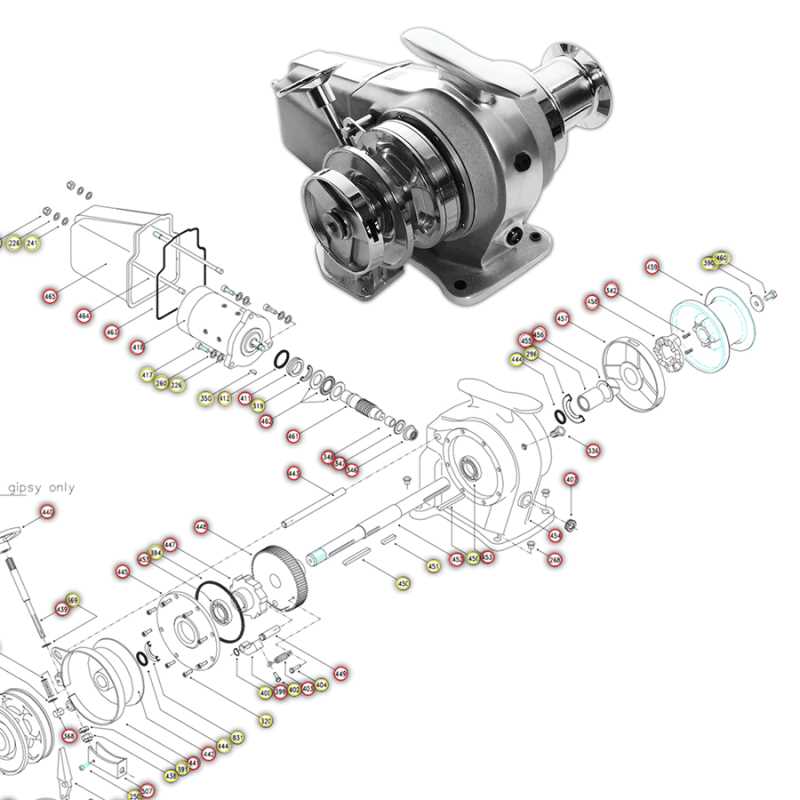

Understanding the Titan 840 Mechanism

The operation of complex industrial systems relies heavily on precise mechanical configurations. These systems often involve intricate networks of interconnected components, each serving a specific role in ensuring smooth performance. Grasping the internal functionality of these machines is crucial for effective use and maintenance, especially when aiming to improve efficiency or troubleshoot potential issues.

Core Functions and Movements

At the heart of such equipment are essential moving parts that control the flow and distribution of power. These elements work together to provide the necessary motion and action required for optimal function. Understanding how energy transfers through the system helps in predicting wear and recognizing the need for adjustments.

Interaction Between Components

The interaction between various elements within the system is vital to its overall functionality. Every piece, from the smallest gear to the primary power source

Internal Structure of the Titan 840

The intricate layout of this equipment is carefully designed to maximize functionality while maintaining ease of access for maintenance. Each element within the unit plays a critical role in the overall operation, ensuring reliable performance in demanding conditions. Understanding the key components and their placements helps in troubleshooting and optimizing its usage.

Key Components Overview

Component Arrangement

The internal layout is organized to promote efficient airflow and quick access to frequently serviced parts. Core sections are strategically placed to balance weight and maintain stability

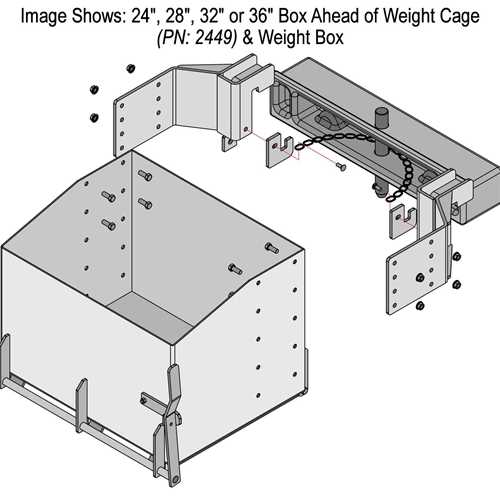

Assembly Overview of the Titan 840

The construction process of this machinery involves various components working together in a precise arrangement. Understanding the way these elements connect and function as a whole is key to ensuring proper maintenance and operation. Each segment contributes to the system’s performance, offering durability and efficiency.

Key Structural Components

The main framework is built to support heavy-duty tasks, with essential structural elements designed to withstand pressure and wear. The positioning of these elements ensures balance and stability during use, enhancing the overall reliability of the equipment.

Connection and Integration

Each element is interconnected through secure fastening points, creating a unified mechanism. The synchronization between mechanical and electrical systems is crucial for optimal performance. Proper alignment and integration of these connections allow for smooth operation and reduce the risk of

Functional Elements of Titan 840

The components of this device work together to ensure optimal performance and efficiency. Understanding these elements is crucial for effective operation and maintenance.

Key functional aspects include:

By examining these features, users can enhance their understanding of functionality and improve their overall experience.

Detailed View of Titan 840 Sections

This section offers an in-depth examination of the various components that make up the specific model in question. By breaking down the elements, readers can gain a clearer understanding of the structure and function of each segment. Such a detailed analysis assists in comprehending how these components interact and contribute to the overall performance of the equipment.

The layout is organized into distinct categories, each highlighting critical features and specifications. This approach facilitates easier navigation and ensures that users can quickly identify the elements relevant to their needs. Understanding the intricacies of each segment not only aids in maintenance but also enhances the efficiency of the entire system.

Maintenance Essentials

Proper upkeep of machinery is crucial for ensuring optimal performance and longevity. This involves regular inspections, timely replacements, and systematic cleaning to prevent wear and tear. Adopting a proactive maintenance strategy can significantly reduce downtime and enhance operational efficiency.

Key maintenance practices include:

| Task | Frequency | Description |

|---|---|---|

| Inspection | Monthly | Examine components for signs of damage or wear, ensuring all parts are functioning correctly. |

| Lubrication | Every 3 Months | Apply lubricant to moving parts to reduce friction and prevent overheating. |

| Filter Replacement | Every 6 Months | Replace air and fluid filters to maintain cleanliness and efficiency in operation. |

| Cleaning | As Needed | Remove debris and dust from surfaces to ensure optimal performance and prevent overheating. |

Identifying Crucial Parts in Titan 840

Understanding the essential components of a specific model is vital for effective operation and maintenance. Each element plays a significant role in ensuring the overall performance and longevity of the equipment. Recognizing these key sections can aid in troubleshooting and replacement tasks, thus enhancing efficiency and reliability.

Below is a table outlining the fundamental components commonly found in this equipment, along with their descriptions and functions:

| Component Name | Description | Function |

|---|---|---|

| Power Supply | Supplies the necessary electrical energy. | Powers all operational systems. |

| Cooling System | Maintains optimal operating temperature. | Prevents overheating and ensures efficiency. |

| Control Unit | Manages the functions and operations. | Coordinates all activities of the equipment. |

| Drive Mechanism | Facilitates movement and action. | Enables physical tasks and operations. |

| Sensor Array | Monitors various operational parameters. | Provides feedback for performance adjustments. |

Exploring the Design of Titan 840

This section delves into the intricate layout and structural elements of a specific model in the industrial sector. Understanding the organization of its components is essential for grasping how they function together to achieve optimal performance. A thorough examination reveals the thought and precision that went into its engineering, highlighting both aesthetic and functional aspects.

Key Features of the Design

Component Interaction

Each element within this model plays a critical role, and their interaction is carefully orchestrated to enhance functionality:

- Power Supply System: Provides stable energy for efficient operation.

- Control Interface: Facilitates user interaction, allowing for easy adjustments and monitoring.

- Cooling Mechanisms: Ensures optimal temperatures are maintained to prevent overheating.

The thoughtful interplay of these systems underscores the model’s design philosophy, aiming for excellence in both performance and user experience.

Titan 840 Component Analysis

This section aims to provide an in-depth examination of the various elements that constitute a specific model of machinery. By understanding the roles and interactions of each component, users can gain insights into optimizing performance and ensuring reliability in operations.

| Component Name | Function | Key Features |

|---|---|---|

| Power Supply | Provides electrical energy to the system. | High efficiency, compact design. |

| Control Module | Regulates operations and coordinates tasks. | Programmable, user-friendly interface. |

| Cooling System | Maintains optimal temperature during operation. | Silent operation, energy-efficient. |

| Drive Mechanism | Translates commands into physical movement. | High torque, responsive feedback. |

| Frame Structure | Houses and supports all internal components. | Durable materials, lightweight design. |