When exploring the assembly and design of off-road motorcycles, it’s important to have a clear understanding of how each element functions within the overall system. Every connection and mechanism plays a vital role in ensuring the smooth operation of the vehicle, from the engine to the smallest fastener.

Recognizing the layout and configuration of various systems helps not only in maintaining peak performance but also in diagnosing potential issues. For those looking to repair or upgrade their machine, knowing the intricacies of its framework is essential.

Furthermore, gaining insight into the key mechanisms and essential connections offers a practical advantage for both hobbyists and professionals alike. This knowledge can significantly enhance efficiency when working on these powerful machines, ensuring each part is optimally configured.

Overview of the Titan XT250 Model

This model represents a versatile and reliable solution for various tasks, balancing performance and efficiency. Designed with user-friendly features, it caters to a wide range of applications, ensuring durability and ease of use in different environments.

Engineered for consistent operation, this machine boasts a well-thought-out design that maximizes functionality. Its compact build and ergonomic structure allow for seamless operation, making it a preferred choice for those seeking reliability in everyday work.

Whether used for professional purposes or personal projects, this unit combines advanced technology with a sturdy frame, ensuring optimal results without compromising on quality.

Main Components of the XT250

The primary systems of this motorcycle are carefully designed to ensure balance, durability, and reliable performance. Each element plays a crucial role in maintaining the overall functionality, allowing smooth operation across different terrains. Understanding these essential parts is key to maintaining optimal performance and safety.

| Component | Description | ||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | The heart of the machine, providing power and driving the vehicle forward efficiently. | ||||||||||||||||||||||||||||||||||||||

| Frame | A strong structure that supports all other elements and ensures stability during motion. | ||||||||||||||||||||||||||||||||||||||

| Suspension | This system absorbs shocks from uneven surfaces, enhancing comfort and control. | ||||||||||||||||||||||||||||||||||||||

| Brakes | Essential for safety, these components allow for precise and effective stopping power. | ||||||||||||||||||||||||||||||||||||||

| Exhaust System | Responsible for directing fumes away and ensuring smoother engine performance. |

| Component | Function |

|---|---|

| Main Frame | Provides the foundational structure, supporting all essential parts and ensuring rigidity. |

| Front Fork | Absorbs shocks from the front, allowing for smooth steering and handling. |

| Rear Swingarm | Links the rear wheel to the frame, enabling controlled movement and suspension. |

| Shock Absorbers | Reduces impact from uneven terrain, improving overall ride comfort. |

Understanding the Electrical System

The electrical framework in a vehicle serves as the backbone for various essential operations, providing power to critical components and ensuring smooth functionality. Without a well-maintained system, everything from ignition to lighting could fail to operate effectively. Understanding how energy flows and is distributed is key to diagnosing potential issues and optimizing performance.

Power generation and distribution are central to this system. Components such as the alternator and battery play vital roles in supplying energy. Wires and fuses act as the highways, delivering power where it’s needed while protecting the system from overloads. Learning the connections and how they interact ensures proper maintenance and repair.

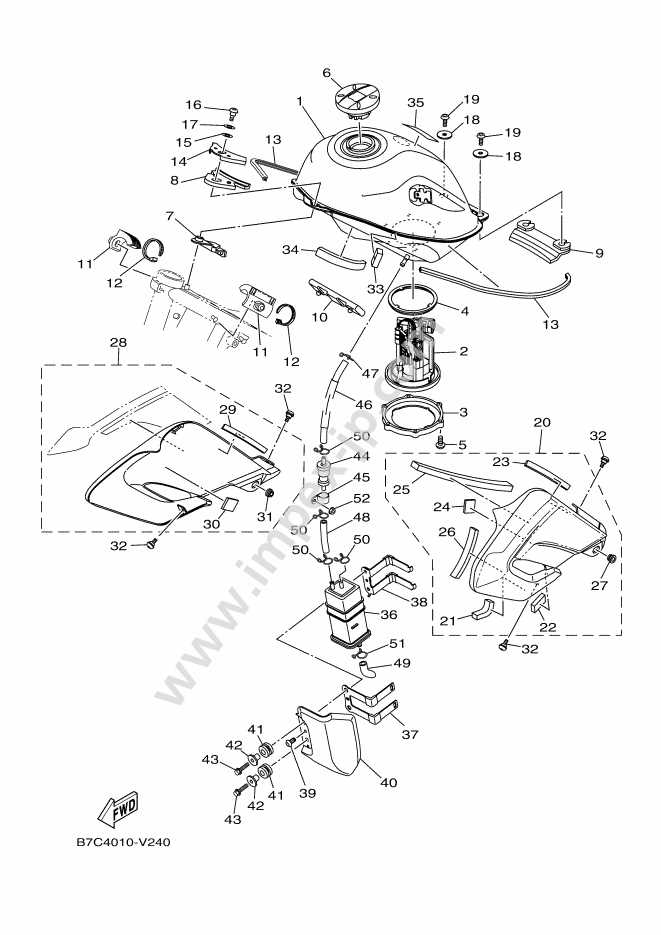

Fuel System and Related Parts

The fuel delivery mechanism plays a critical role in the efficient operation of any motorized vehicle. It is responsible for supplying the necessary fuel to the engine, ensuring optimal performance and reliability. Understanding the components involved in this system can help in troubleshooting issues and maintaining proper functionality.

Key Components

This section outlines the essential components of the fuel delivery mechanism, including their functions and importance in the overall system.

| Component | Description |

|---|---|

| Fuel Pump | Transfers fuel from the tank to the engine, maintaining the required pressure for efficient combustion. |

| Fuel Filter | Removes impurities and contaminants from the fuel before it reaches the engine, preventing damage and ensuring smooth operation. |

| Fuel Injector | Sprays fuel directly into the combustion chamber in a fine mist, allowing for better mixing with air and improving efficiency. |

| Fuel Tank | Stores the fuel until it is needed by the engine, designed to prevent leaks and ensure safety. |

Maintenance Tips

Regular maintenance of the fuel delivery mechanism is essential for longevity and performance. It is advisable to periodically check and replace the fuel filter, inspect the pump for signs of wear, and ensure the injector is functioning correctly to avoid potential issues.

Wheels and Tire Specifications

This section provides an overview of the specifications for the wheels and tires used in various vehicles, emphasizing their importance for performance and safety. Understanding the dimensions, materials, and design features is crucial for ensuring optimal handling and ride quality.

The wheels typically vary in diameter and width, impacting the overall stability and maneuverability of the vehicle. Common sizes range from smaller options suited for compact models to larger diameters designed for enhanced traction and aesthetics. Additionally, the offset and bolt pattern play vital roles in compatibility with different chassis designs.

Tires, on the other hand, are characterized by their tread patterns, sidewall height, and rubber compounds. These attributes influence grip, comfort, and durability. All-terrain tires, for instance, are designed for diverse surfaces, providing both traction and longevity. Regular maintenance, including checking tire pressure and tread depth, is essential to maximize performance and ensure safety on the road.

Brake System Components

The braking mechanism of a vehicle is a critical aspect of its overall performance and safety. Understanding the various elements involved in this system is essential for maintenance and troubleshooting. This section delves into the key components that work together to ensure effective stopping power.

Key Components

- Brake Pads: These friction materials press against the brake rotor to slow down the vehicle.

- Brake Rotors: These disc-shaped components provide a surface for the brake pads to create friction.

- Calipers: These devices house the brake pads and apply pressure to them, enabling the braking action.

- Brake Lines: These tubes transport brake fluid from the master cylinder to the calipers.

- Master Cylinder: This component generates hydraulic pressure that facilitates braking.

Additional Elements

- Brake Fluid: The hydraulic fluid that transfers force from the master cylinder to the brakes.

- Anti-lock Braking System (ABS): A safety feature that prevents wheel lock-up during hard braking.

- Brake Booster: An assistive device that amplifies the force applied to the brake pedal.

Each of these elements plays a vital role in the braking system’s functionality, contributing to the vehicle’s safety and driving experience. Regular inspection and maintenance of these components are crucial for optimal performance.

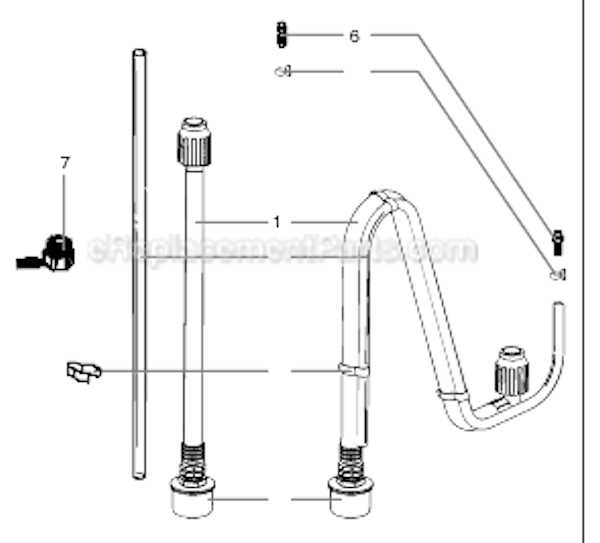

Exhaust and Muffler Setup

The arrangement of the exhaust system and silencer plays a crucial role in the overall performance and sound quality of a vehicle. A well-designed setup not only enhances efficiency but also contributes to smoother operation and reduced emissions. Understanding the components involved is essential for effective maintenance and upgrades.

Proper alignment of the exhaust pipes is vital for minimizing backpressure and ensuring optimal airflow. Regular inspections should be conducted to check for any leaks or damage, which can significantly impact performance. Replacing worn-out gaskets and seals can prevent unwanted noise and maintain a clean exhaust flow.

The choice of a muffler can influence both the sound output and the aesthetic appeal. Performance-oriented silencers often provide a more aggressive tone while still adhering to noise regulations. Additionally, investing in high-quality materials will enhance durability and reduce the likelihood of rust or corrosion over time.

Ultimately, achieving an effective exhaust and muffler configuration requires careful consideration of the specific requirements and intended use of the vehicle. Regular maintenance, paired with appropriate upgrades, will lead to improved performance and a more enjoyable driving experience.

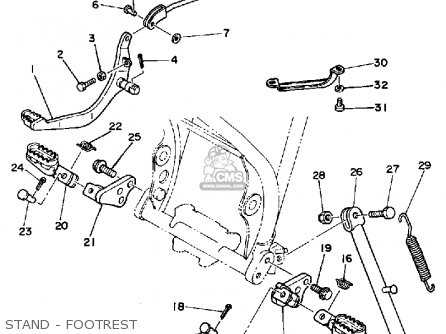

Handlebars and Control Mechanisms

The steering apparatus and associated control elements play a crucial role in the operation of any two-wheeled vehicle. These components are designed to provide stability, responsiveness, and ease of use, enhancing the overall riding experience. Understanding their layout and functionality is essential for maintaining optimal performance and ensuring rider safety.

| Component | Description | Function |

|---|---|---|

| Handlebars | A curved metal bar used for steering and controlling the front wheel. | Provides direction control and stability while riding. |

| Grip | Rubber or foam covering on the handlebars. | Ensures a firm grip and comfort during operation. |

| Throttle | Control mechanism typically located on the right grip. | Regulates engine power and speed by controlling fuel intake. |

| Brake Levers | Levers positioned on the handlebars, usually for the front and rear brakes. | Activates braking system to reduce speed or stop the vehicle. |

| Clutch Lever | Lever located on the left grip. | Disengages the engine from the transmission for gear shifting. |

Transmission and Gearbox Structure

The transmission and gearbox assembly plays a crucial role in the overall functionality of any two-wheeled vehicle. This system is responsible for transferring power from the engine to the wheels, ensuring efficient acceleration and speed control. Understanding its components and their interactions can help enthusiasts and technicians troubleshoot issues or perform maintenance effectively.

Components Overview

This system consists of several key elements, including gears, shafts, and clutches. Each component has a specific function that contributes to the smooth operation of the vehicle. Gears are responsible for changing torque and speed, while shafts connect these elements to transfer power. Clutches, on the other hand, allow for smooth engagement and disengagement, enabling the rider to shift gears seamlessly.

Functionality and Maintenance

Regular maintenance of the transmission and gearbox assembly is essential for optimal performance. Checking the fluid levels, inspecting for wear and tear, and ensuring proper alignment of components can prevent potential issues. A well-maintained system not only enhances the riding experience but also extends the lifespan of the vehicle.

Maintenance of Key XT250 Parts

Proper upkeep of essential components is crucial for ensuring the longevity and reliability of your vehicle. Regular attention to these elements can prevent unexpected breakdowns and enhance overall performance. This section outlines vital practices for maintaining these key elements effectively.

Regular Inspections

Conducting routine examinations of critical components allows for early detection of wear or damage. Focus on areas such as the engine, suspension, and electrical systems. Make it a habit to check for any signs of leaks, corrosion, or loose connections. Promptly addressing any issues will help in maintaining optimal functionality.

Cleaning and Lubrication

Keeping parts clean is essential for preventing dirt and debris buildup, which can hinder performance. Regularly clean moving components and apply appropriate lubricants to reduce friction and wear. Pay special attention to areas such as bearings and chains, as they are prone to wear over time. Additionally, ensuring that air filters are clean will improve engine efficiency.