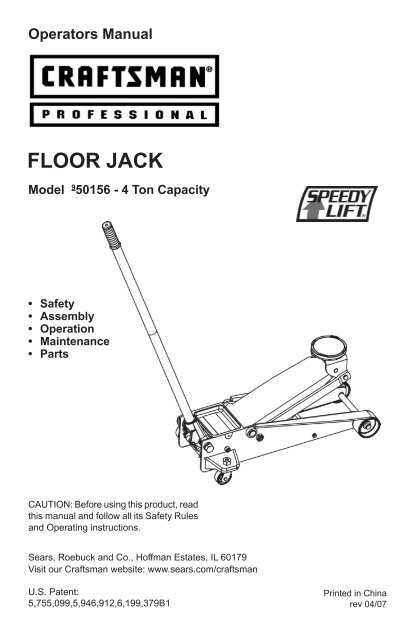

In the realm of mechanical devices designed for elevating heavy objects, a comprehensive understanding of their components is essential. These tools rely on intricate systems that work in harmony to ensure safety and efficiency during operation. By exploring the various elements involved, users can enhance their knowledge and skills when engaging with these valuable instruments.

Every lifting apparatus comprises numerous critical elements, each serving a distinct function. Familiarity with these components not only facilitates better maintenance but also empowers operators to troubleshoot effectively. Such insights ultimately lead to a more seamless and productive experience when utilizing these machines.

To delve deeper into this topic, it is beneficial to examine the layout and relationship between the various elements. A detailed overview can illuminate how each part interacts, contributing to the overall performance and reliability of the equipment. Mastering this knowledge is the ultimate goal for anyone looking to maximize their proficiency with lifting tools.

Understanding Torin Floor Jacks

Hydraulic lifting devices are essential tools in automotive and mechanical settings. They facilitate the elevation of vehicles and heavy equipment, allowing for maintenance and repair work to be conducted safely and efficiently. This section delves into the fundamental components and functionality of these devices, providing a clearer understanding of their operation.

Key features of these lifting mechanisms include:

- Hydraulic System: Utilizes fluid pressure to create lifting power, allowing for easy elevation of heavy loads.

- Sturdy Frame: Constructed to withstand significant weight, ensuring stability during use.

- Control Mechanism: Designed for user-friendly operation, enabling precise height adjustments.

When considering a lifting device, it is important to familiarize oneself with the various elements that contribute to its performance:

- Pump Assembly: The heart of the system, responsible for generating pressure.

- Lifting Arm: Transfers the hydraulic force to elevate the load.

- Safety Features: Includes mechanisms to prevent overloading and ensure user safety.

By understanding these fundamental aspects, users can make informed decisions regarding the selection, maintenance, and safe operation of these valuable tools.

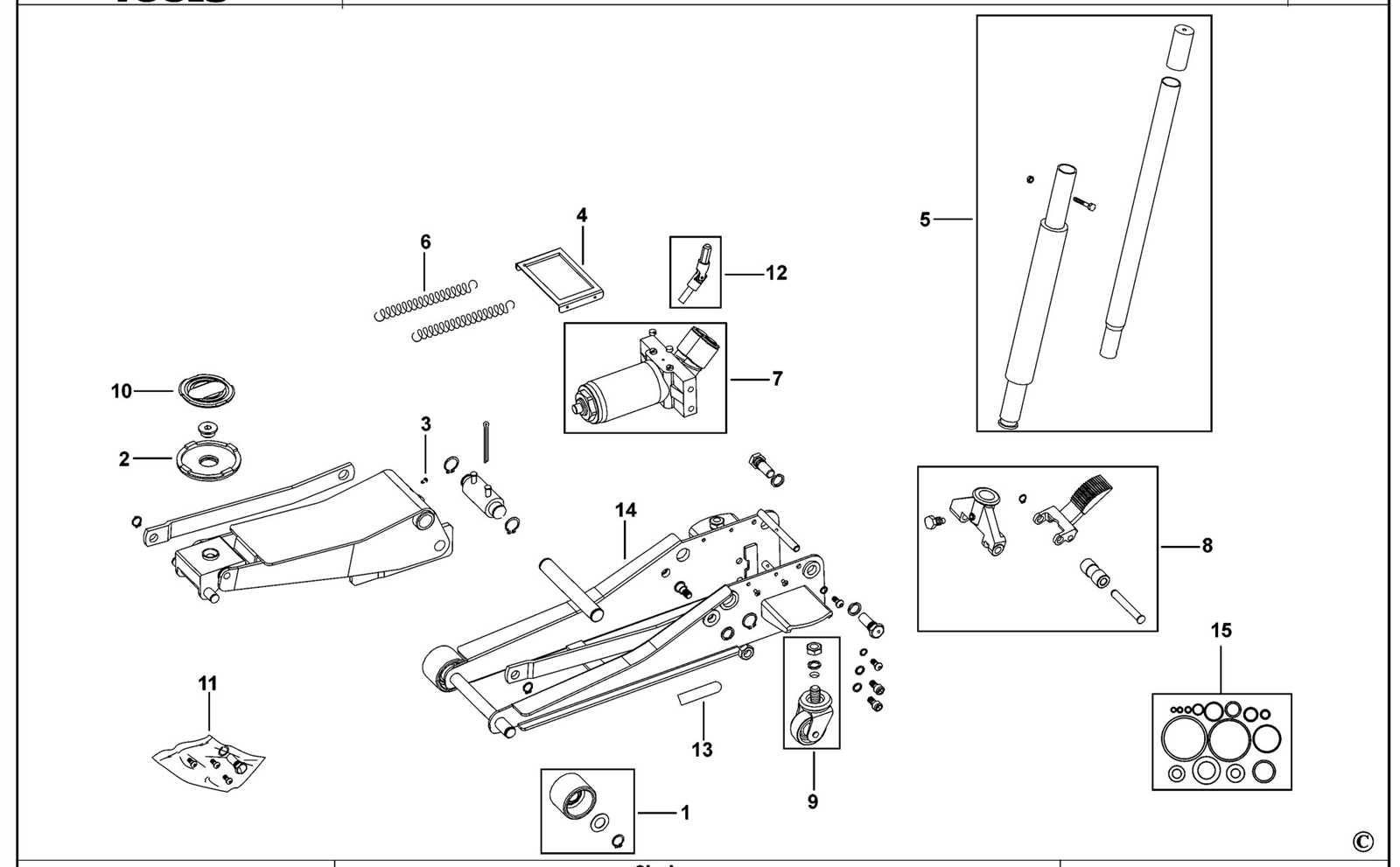

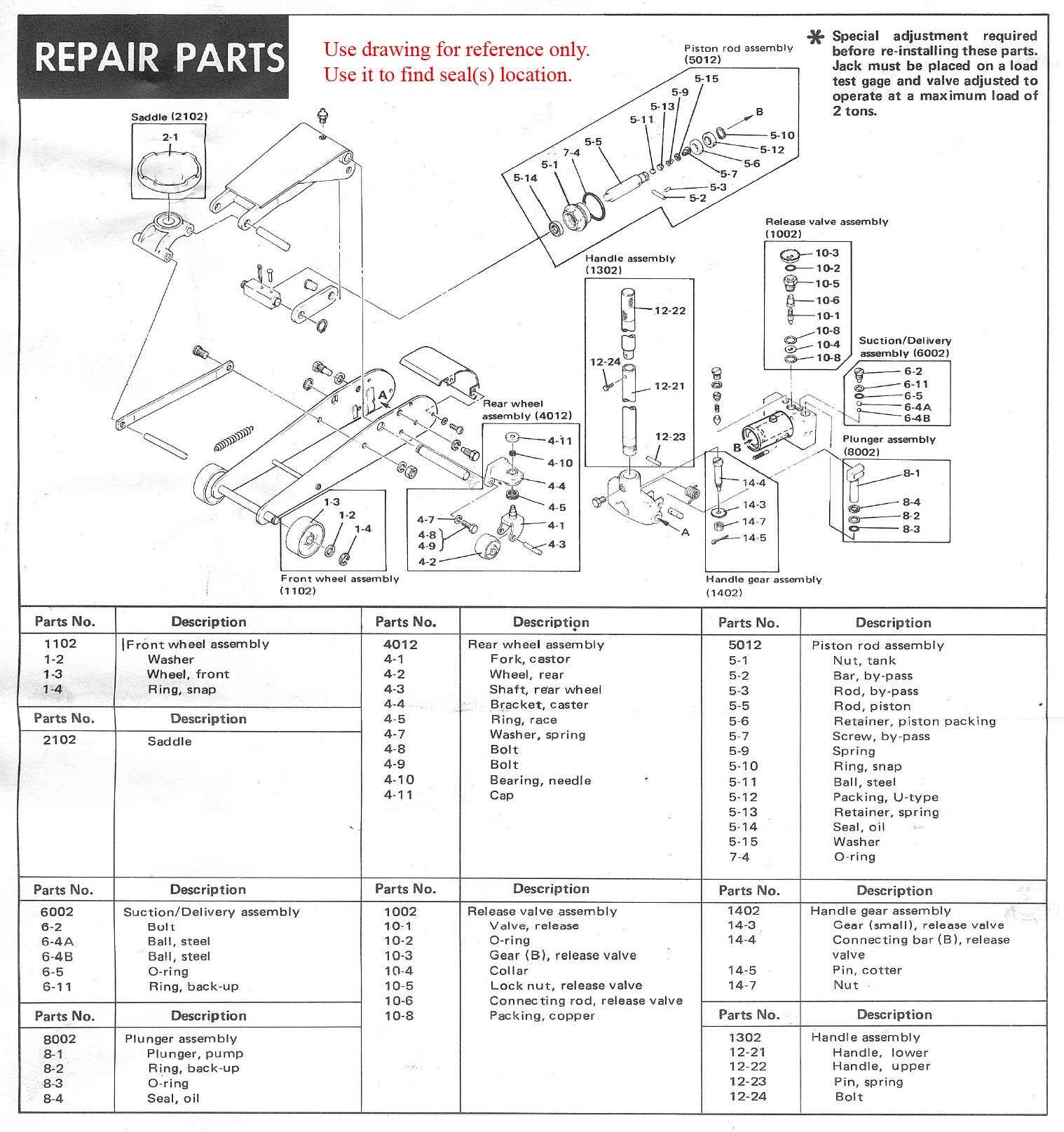

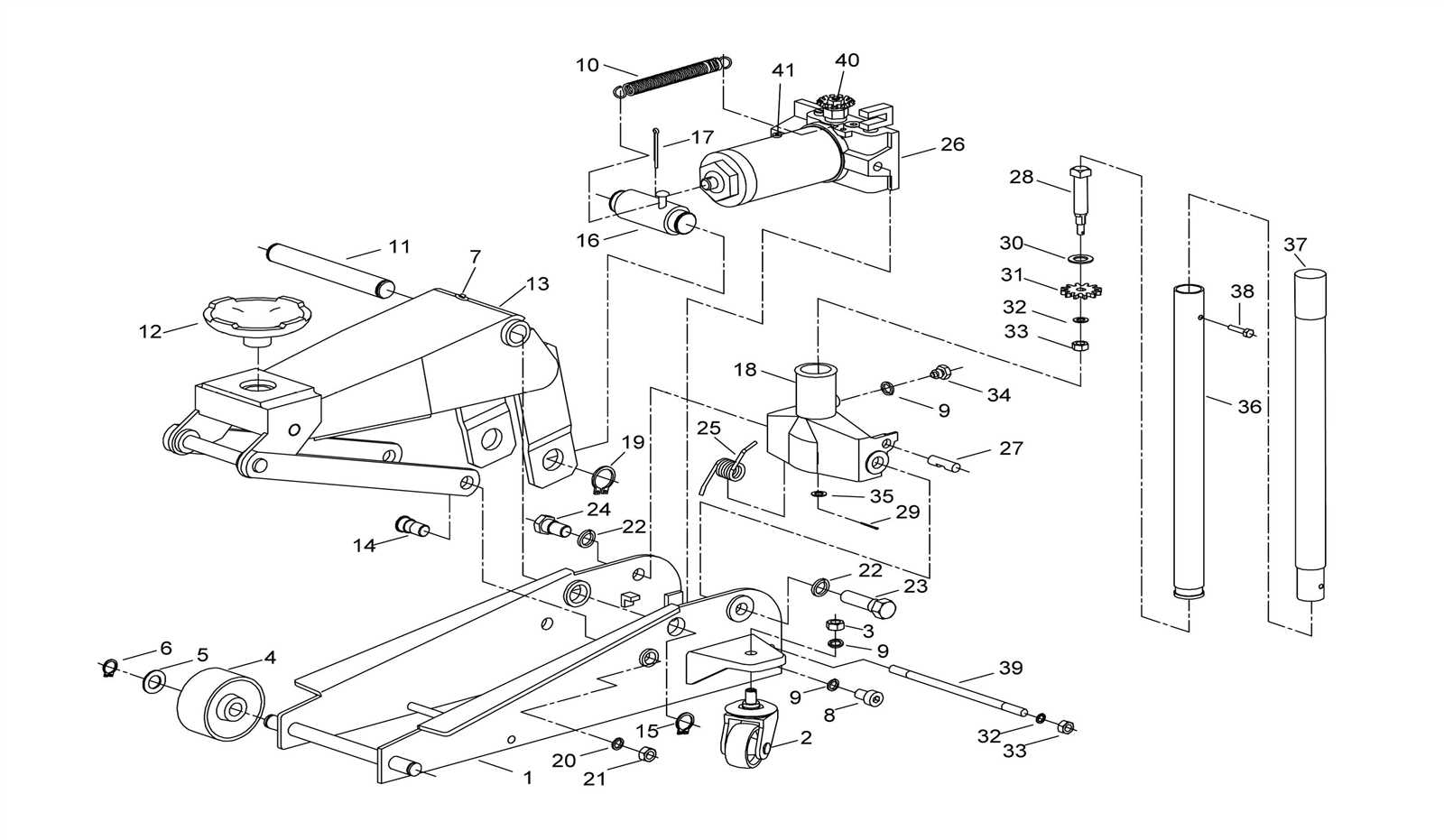

Components of a Torin Floor Jack

The efficient operation of a lifting device relies on its various elements, each playing a crucial role in functionality and safety. Understanding these components enhances the user experience and ensures proper maintenance. Here, we delve into the key constituents that make up this essential tool.

Main Elements

- Chassis: The sturdy base that supports the entire structure.

- Pump Mechanism: The system responsible for generating hydraulic pressure.

- Handle: The lever used to operate the lifting action.

- Wheels: Provide mobility, allowing easy maneuvering.

- Lift Arm: The component that raises and lowers the load.

Additional Features

- Release Valve: Controls the descent of the lifted object.

- Stability Plates: Enhance stability and prevent tipping during use.

- Hydraulic Fluid Reservoir: Stores the fluid needed for the hydraulic system to function.

Familiarity with these components not only aids in effective usage but also contributes to the longevity of the equipment.

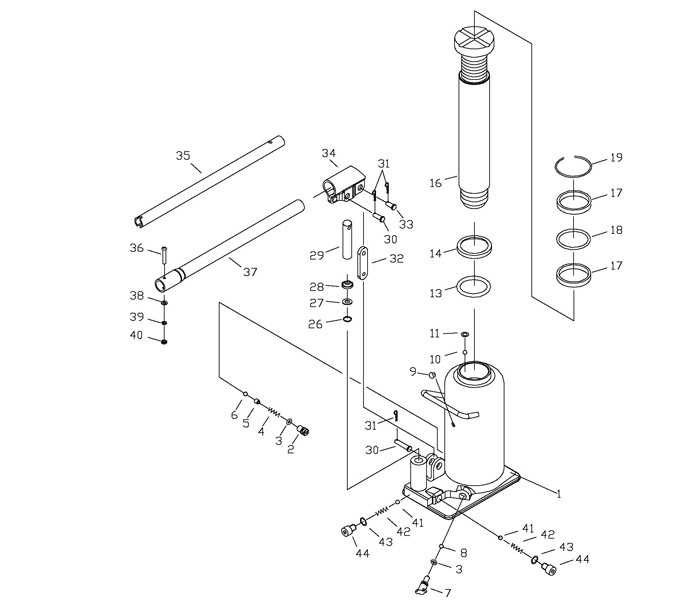

How to Read the Parts Diagram

Understanding the schematic representation of components is essential for effective maintenance and repairs. This guide will help you navigate the various sections, symbols, and notations that are typically present in these visual aids.

Identifying Components

Begin by familiarizing yourself with the different elements illustrated. Each component is usually labeled with a specific identifier that corresponds to a list, enabling easy reference during assembly or replacement.

Interpreting Symbols

Pay attention to the symbols used to denote various functionalities or connections. These symbols provide crucial information about how each piece interacts with others, ensuring you can troubleshoot effectively.

Common Issues with Floor Jacks

Understanding typical problems associated with lifting equipment is essential for effective maintenance and safe operation. These challenges can affect performance and reliability, leading to potential hazards if not addressed promptly.

- Fluid Leaks

- Stability Issues

- Failure to Lift

- Noisy Operation

- Corrosion on Components

Addressing these concerns can enhance safety and prolong the lifespan of the equipment. Regular inspection and proper care are vital in mitigating these issues.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your lifting equipment. Regular attention can prevent common issues and extend the lifespan of your tools, allowing for reliable performance over time.

Regular Inspections: Routinely examine your equipment for any signs of wear or damage. Check for leaks, rust, and ensure all components are securely fastened.

Lubrication: Keep moving parts well-lubricated to minimize friction and wear. Use appropriate lubricants as specified in the manufacturer’s guidelines.

Cleanliness: Maintain a clean working environment by removing dirt and debris from the equipment. This helps prevent corrosion and ensures smooth operation.

Storage: Store your tools in a dry, protected area when not in use. This will shield them from moisture and temperature fluctuations that can cause deterioration.

Follow Guidelines: Always adhere to the manufacturer’s recommendations for maintenance and usage. This ensures that you are utilizing the equipment correctly, enhancing its longevity.

Choosing the Right Floor Jack

Selecting the appropriate lifting device is crucial for ensuring safety and efficiency during maintenance tasks. A suitable model will depend on various factors that align with your specific needs and vehicle requirements.

- Weight Capacity: Determine the maximum weight you’ll lift. Always choose a model with a higher capacity than needed.

- Height Range: Ensure the device can reach the necessary height for your vehicles or projects.

- Portability: Consider if you need a lightweight option for easy transport or a heavier model for stability.

- Material Quality: Look for durable materials that ensure longevity and safety during use.

- Pump Mechanism: Evaluate whether a hydraulic or pneumatic system best suits your lifting needs.

By carefully considering these factors, you can delve into the options available and make an ultimate choice that meets your requirements effectively.

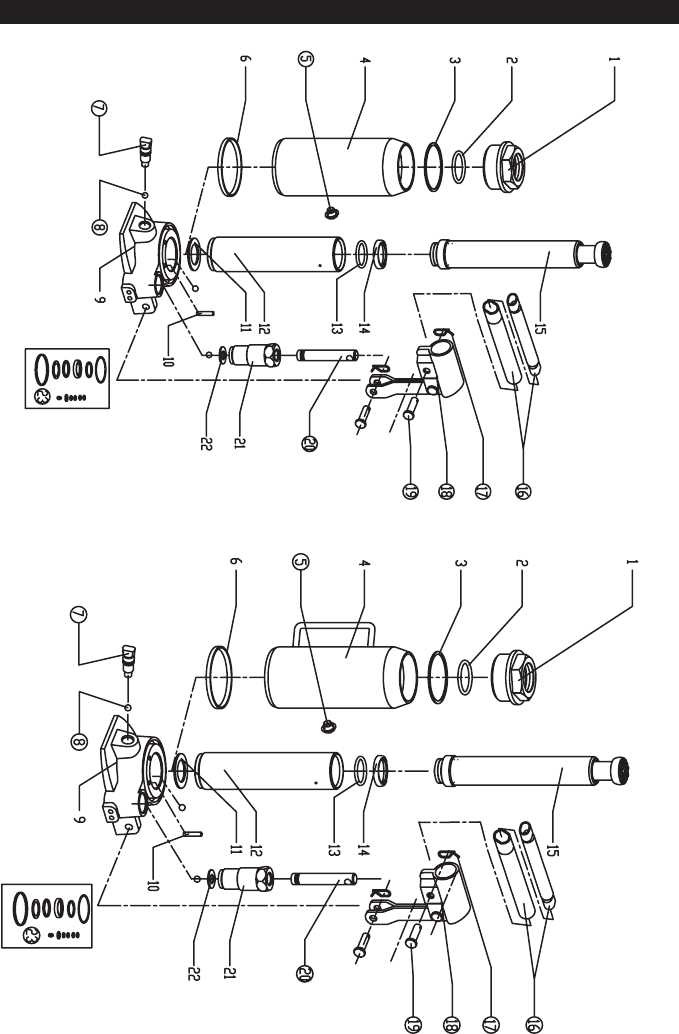

Repairing Torin Jack Components

Maintaining and fixing lifting equipment is essential for ensuring safety and efficiency during use. Understanding the components involved allows for a smoother repair process and prolongs the lifespan of the device. This section will guide you through the essential steps and considerations for addressing common issues related to your equipment.

Here are some key areas to focus on when tackling repairs:

- Identifying Common Issues:

- Leakage in hydraulic systems

- Difficulty in raising or lowering

- Unusual noises during operation

- Essential Tools:

- Wrenches and sockets

- Screwdrivers

- Replacement seals and O-rings

- Step-by-Step Repair Process:

- Start by draining any hydraulic fluid to prevent spills.

- Disassemble the necessary components carefully.

- Inspect each part for wear and damage.

- Replace faulty components with compatible replacements.

- Reassemble the unit and refill hydraulic fluid as needed.

Regular maintenance checks and prompt repairs not only enhance performance but also ensure the safety of the user. By being proactive, you can prevent minor issues from escalating into major problems.

Safety Features to Consider

When working with heavy equipment, ensuring safety should be a top priority. Various mechanisms and components are designed to enhance user protection and equipment stability. Understanding these features is essential for anyone looking to operate machinery effectively and safely.

Key Safety Mechanisms

- Automatic Safety Lock: This feature prevents unintended descent by locking the equipment in place once raised.

- Overload Protection: Sensors that detect excessive weight help avoid equipment failure and ensure safe operation.

- Stability Arms: These provide extra support and minimize the risk of tipping during use.

- Non-Slip Pads: Equipped at the base, these pads enhance grip and stability on various surfaces.

Operational Guidelines

- Always check the equipment for any wear or damage before use.

- Follow the manufacturer’s instructions regarding weight limits and operating procedures.

- Use the equipment on level ground to maintain stability.

- Keep the work area clear of obstacles to prevent accidents.

Comparing Torin Models Available

This section explores the various models available, highlighting their unique features and specifications. By examining the differences and similarities, users can make informed decisions based on their specific needs and preferences.

Model Features Overview

| Model Name | Weight Capacity | Lift Range | Material |

|---|---|---|---|

| Model A | 2 tons | 3.5″ – 14″ | Steel |

| Model B | 3 tons | 4″ – 16″ | Aluminum |

| Model C | 1.5 tons | 5″ – 12″ | Composite |

Choosing the Right Option

Selecting the appropriate model depends on various factors, including the intended use, weight requirements, and mobility needs. Assessing these aspects will guide users toward the ultimate choice that aligns with their demands.

Importance of Using Genuine Parts

Utilizing authentic components in any mechanical system is crucial for ensuring optimal performance and longevity. These original elements are designed to fit seamlessly and work harmoniously with the entire assembly, providing a level of reliability that alternatives often lack.

Quality Assurance: Genuine items undergo rigorous testing to meet industry standards, which guarantees that they will perform as expected. Counterfeit or aftermarket products may not adhere to the same specifications, leading to potential failures.

Safety: The integrity of equipment heavily relies on using the correct components. Inferior substitutes can compromise safety, increasing the risk of accidents or malfunctions.

Longevity: Authentic components typically offer greater durability, extending the lifespan of the entire system. Investing in these original pieces can save money in the long run by reducing the need for frequent replacements.

In summary, prioritizing original components is essential for maintaining performance, safety, and longevity in any mechanical application.

Where to Purchase Replacement Parts

Finding suitable components for your equipment can be crucial for maintaining its functionality and ensuring safety. Various sources provide access to quality replacements, each with its own advantages. It’s essential to explore these options to identify the best fit for your needs.

Online Retailers

The internet offers a plethora of platforms where you can find the necessary components. Here are some reliable online stores:

- Amazon

- eBay

- Specialty automotive websites

Many of these retailers provide user reviews and ratings, helping you make informed choices about the quality of items.

Local Suppliers

If you prefer a more hands-on approach, visiting local suppliers can be beneficial. Consider the following types of stores:

- Automotive parts stores

- Hardware stores

- Specialized mechanical shops

These establishments often have knowledgeable staff who can assist you in finding the right components and offer advice on installation and maintenance.

Understanding Load Capacity Ratings

When it comes to selecting lifting equipment, comprehending load capacity ratings is essential for safety and efficiency. These ratings indicate the maximum weight that the apparatus can handle, ensuring that users do not exceed the limits, which could lead to dangerous situations or equipment failure.

Capacity ratings are typically influenced by various factors, including the design, materials, and intended use of the equipment. It’s crucial to consider these aspects, as different models may have varying capabilities even if they appear similar. Always refer to the manufacturer’s specifications to understand the precise limitations of your equipment.

Moreover, load capacity is not merely about the maximum weight; it also encompasses the distribution of that weight. Unevenly distributed loads can compromise stability, increasing the risk of tipping or collapse. Therefore, users should ensure that loads are evenly balanced and properly secured during operation.

In addition, environmental conditions can impact performance. Factors such as surface type, incline, and surrounding obstacles must be taken into account when assessing load capacity. Users should be vigilant and conduct regular inspections to confirm that their equipment is in optimal condition to handle the specified loads.

Ultimately, understanding load capacity ratings is vital for making informed decisions and ensuring the safety of both the operator and the equipment being utilized. Proper knowledge and adherence to these ratings can prevent accidents and enhance operational efficiency.