In the realm of vehicle recovery, the effectiveness and reliability of the operation depend on a well-organized assembly of specialized equipment. This section delves into the intricate layout and functionality of various elements that play a crucial role in facilitating safe and efficient recovery missions. By comprehensively exploring these components, we can gain a clearer insight into how they work together to ensure successful outcomes in challenging situations.

Each component is designed with a specific purpose, contributing to the overall performance of the recovery apparatus. From the primary mechanisms that initiate lifting to the accessories that enhance maneuverability, understanding their arrangement and interaction is vital for both operators and enthusiasts. By examining these elements closely, we can appreciate the engineering and design that go into creating a reliable system.

Whether you’re an industry professional or simply curious about the technology behind vehicle recovery operations, this exploration will provide valuable knowledge. Recognizing the significance of each part empowers users to make informed decisions and optimizes the overall effectiveness of recovery procedures.

Tow Truck Parts Overview

This section provides an essential understanding of the various components that contribute to the effective operation of a recovery vehicle. Each element plays a vital role in ensuring that the machinery functions efficiently and safely during the towing process.

| Component | Description |

|---|---|

| Chassis | The framework that supports the entire vehicle, providing stability and strength. |

| Lift System | A mechanism used to raise and lower the load for secure transport. |

| Winch | An apparatus that helps in pulling vehicles out of difficult situations using a cable. |

| Hook | A device that attaches to the vehicle being towed, ensuring it is held securely. |

| Lighting | Illumination systems that enhance visibility, especially during night operations. |

| Control Console | The interface used by the operator to manage the various functions of the vehicle. |

Essential Components of Tow Trucks

Understanding the vital elements of recovery vehicles is crucial for both operators and enthusiasts. These vehicles are designed with various mechanisms that facilitate the safe and efficient transport of other vehicles. Each component plays a significant role in ensuring reliability and functionality during operations.

Key Features of Recovery Vehicles

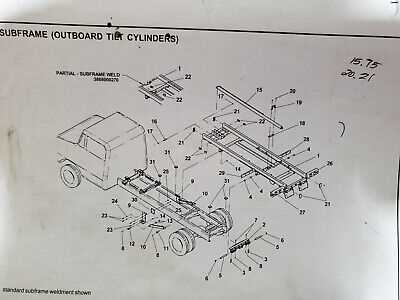

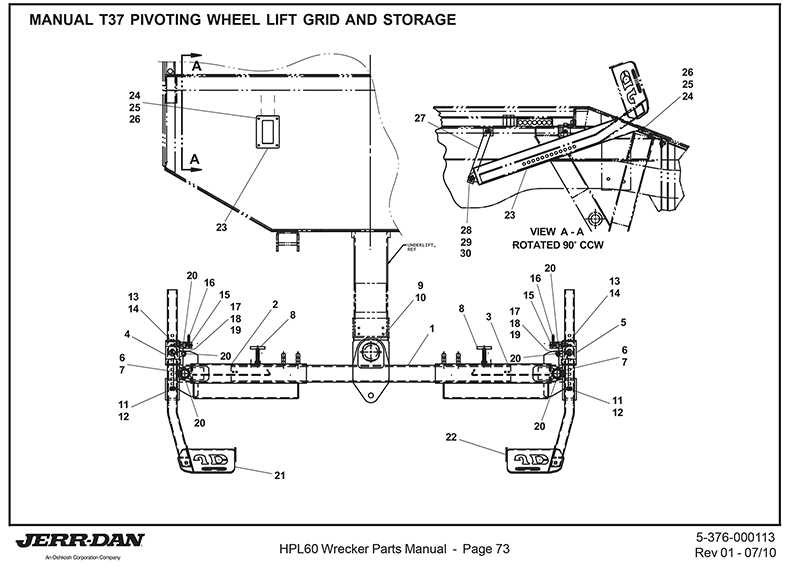

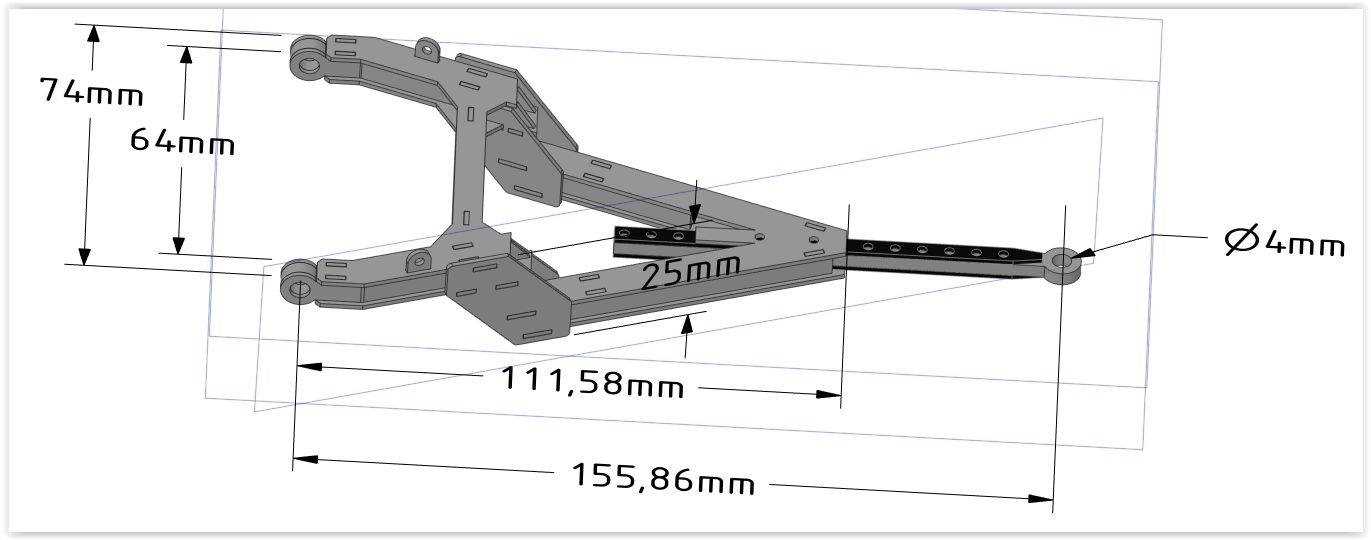

One of the most critical features includes a robust lifting mechanism, allowing for the elevation of vehicles in need. This system often consists of hydraulic components that provide the necessary force to lift heavy loads with ease. Additionally, securement tools are essential for stabilizing the load during transport, preventing any movement that could lead to damage.

Safety Mechanisms

Safety is paramount in vehicle recovery. Integrated lighting systems enhance visibility during nighttime operations, while warning signals alert surrounding traffic to potential hazards. Moreover, the use of advanced braking systems ensures that the vehicle maintains control, particularly when carrying heavy loads on inclines.

In summary, these crucial features and mechanisms work together to provide a reliable and safe recovery experience, making these vehicles indispensable in various situations.

Types of Tow Trucks Explained

Understanding the various kinds of vehicles used for moving and assisting other automobiles is essential for anyone involved in roadside assistance or vehicle recovery services. Each type is designed with specific capabilities that cater to different needs, ensuring safe and efficient transportation of disabled or improperly parked vehicles.

Flatbed Models: These vehicles feature a long, flat platform that allows for easy loading of cars. With a hydraulic system, the platform can be tilted and lowered, providing a seamless approach for vehicles to drive or be winched onto the surface. This type is particularly useful for damaged vehicles that cannot be driven.

Wheel-Lift Variants: This style utilizes a set of arms that lift the front or rear wheels of a vehicle off the ground. It is more compact and maneuverable than flatbed designs, making it ideal for urban environments where space is limited. This method is suitable for lighter loads and quicker recoveries.

Integrated Systems: Combining features from both flatbed and wheel-lift designs, these versatile vehicles can handle a range of recovery scenarios. They have a built-in mechanism to tow vehicles with varying weights, making them suitable for both personal and commercial use.

By familiarizing oneself with these different categories, operators can choose the appropriate vehicle for specific recovery tasks, enhancing service efficiency and ensuring safety on the road.

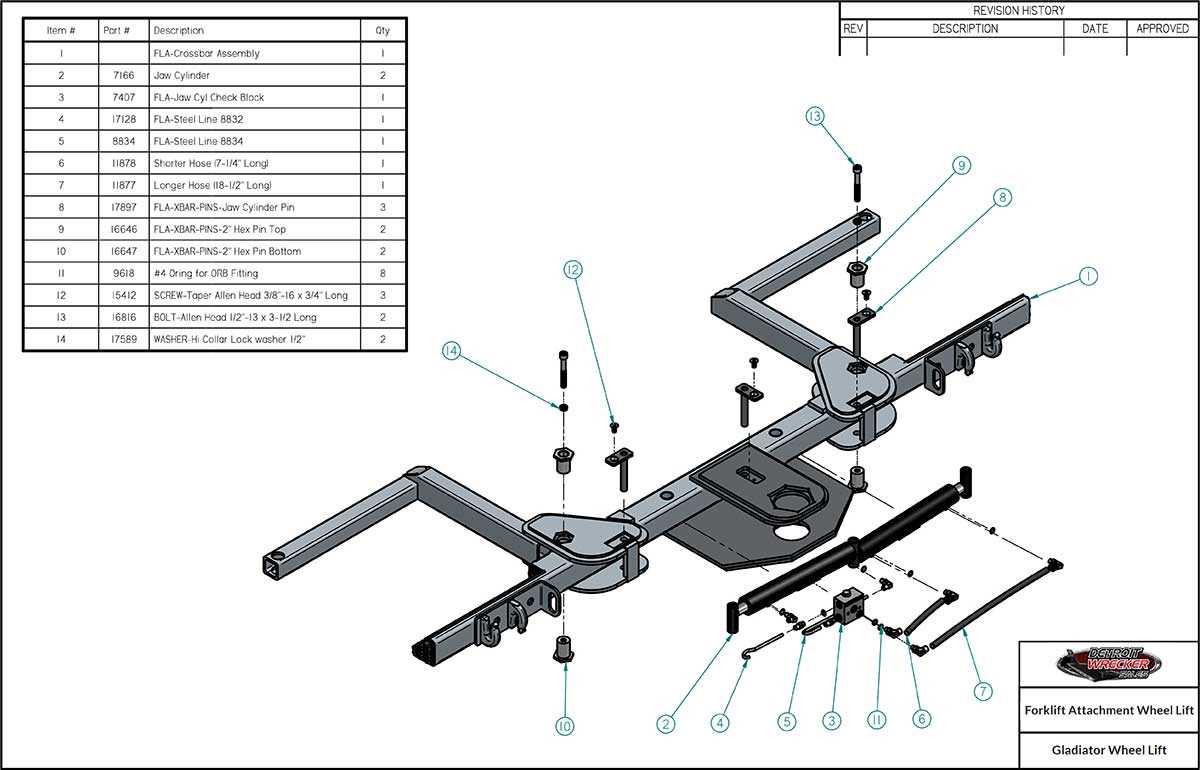

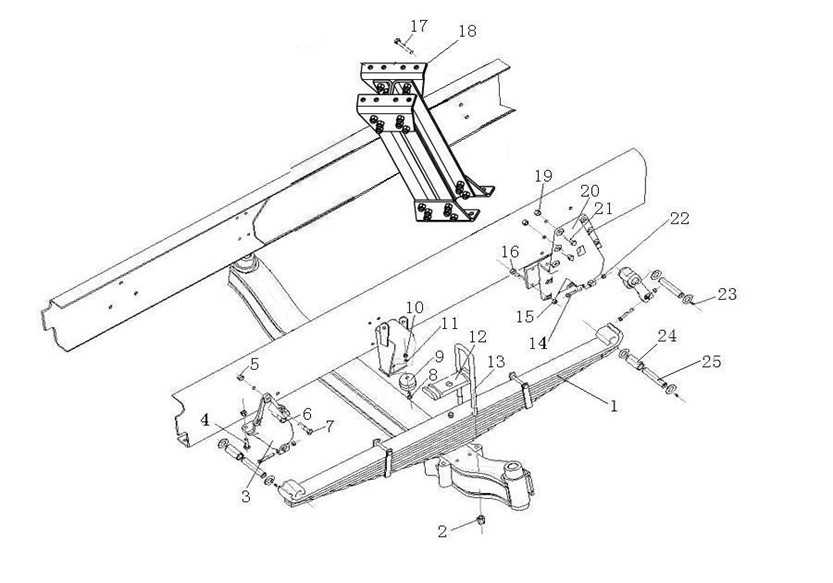

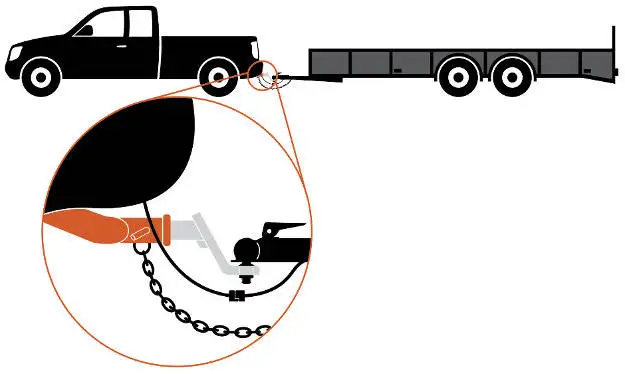

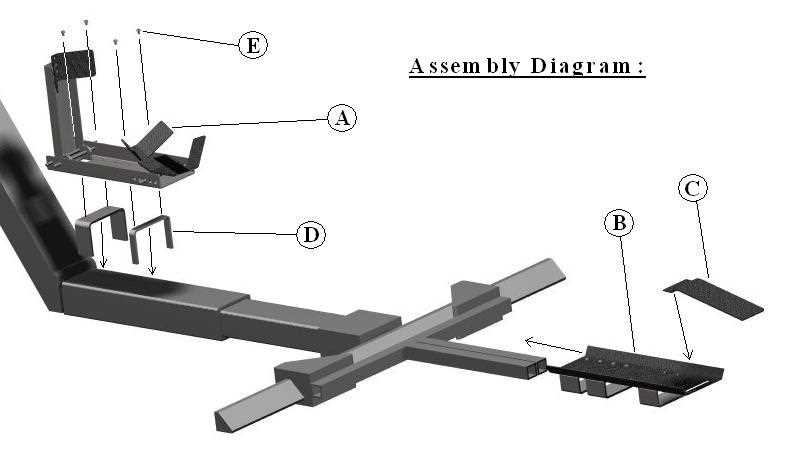

Understanding Tow Hook Mechanisms

The mechanisms designed for vehicle recovery are essential for ensuring safe and efficient lifting and hauling. These systems consist of various components that work in harmony to facilitate the connection between the recovery vehicle and the one being assisted. A thorough understanding of these mechanisms can enhance the effectiveness of vehicle recovery operations.

Key components involved in these mechanisms include:

- Hooks: These are the primary connectors that secure the recovery vehicle to the disabled one.

- Straps and Chains: Used to provide additional strength and stability, ensuring a secure attachment.

- Mounting Brackets: These components support the hooks and allow for flexible positioning during recovery.

- Safety Features: Various mechanisms, such as latches and locks, are implemented to prevent accidental disconnection.

When operating recovery equipment, it is vital to consider the following:

- Ensure the hook is rated for the weight of the vehicle being assisted.

- Inspect all components for wear and damage before use.

- Follow proper attachment techniques to maintain safety.

Understanding the intricacies of these recovery mechanisms will not only promote safe practices but also enhance the overall efficiency of recovery operations.

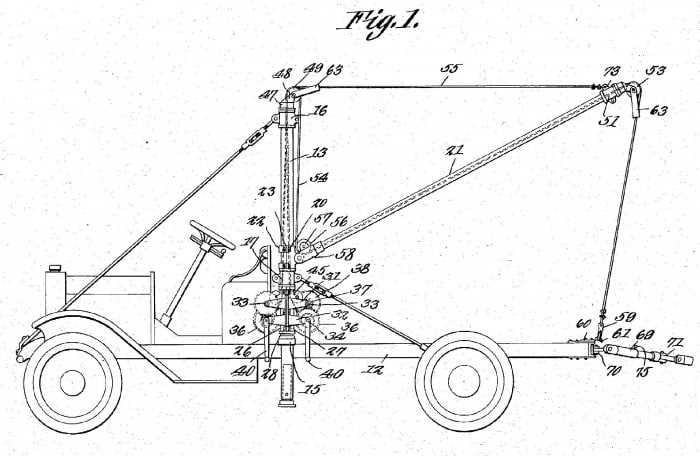

Importance of Winches in Towing

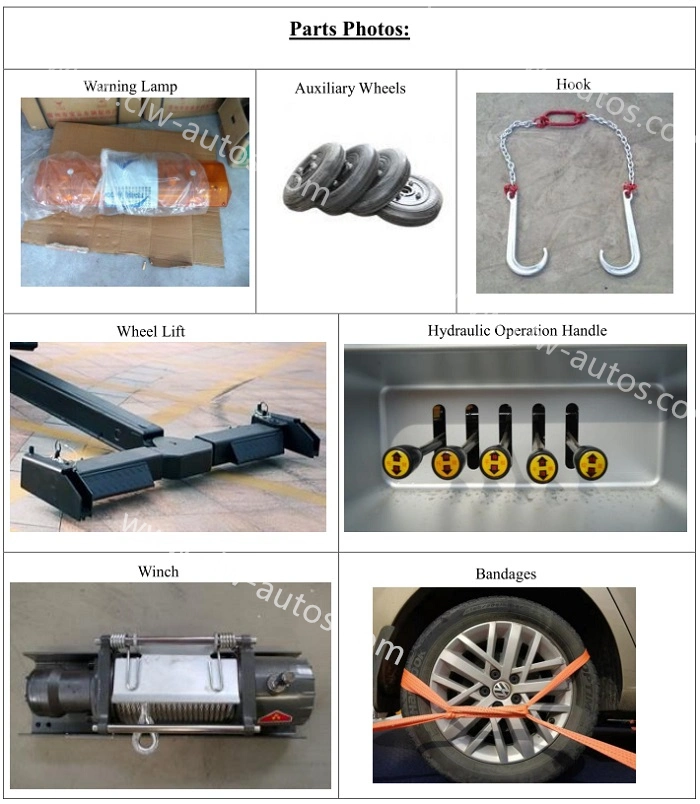

Winches play a crucial role in recovery and transportation operations, providing the necessary force to move heavy objects efficiently. Their versatility makes them indispensable for various tasks, from assisting stranded vehicles to lifting equipment in challenging environments.

Equipped with robust mechanisms, these devices facilitate smooth operations, enabling operators to exert control over the load with precision. Reliability is a key factor, as the performance of a winch directly influences the safety and effectiveness of the entire operation. When properly utilized, winches significantly reduce the risk of accidents and ensure that vehicles are handled with care.

Moreover, the presence of a high-quality winch enhances the overall capability of any recovery setup. Accessibility to difficult locations becomes feasible, and operators can tackle a wide range of scenarios with confidence. This adaptability not only increases efficiency but also expands the operational scope, making winches an essential component in any recovery fleet.

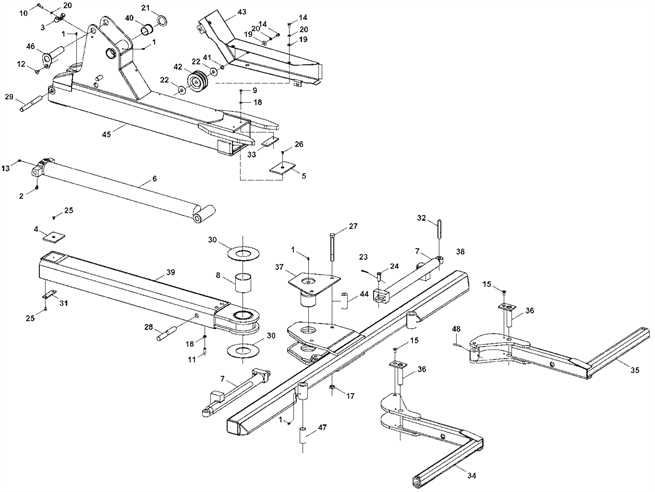

Hydraulic Systems in Tow Trucks

Hydraulic systems play a crucial role in enhancing the operational efficiency of vehicles designed for hauling and recovery tasks. These systems utilize fluid power to facilitate movement and control various functions, providing the necessary force to lift and maneuver heavy loads safely.

The primary components of hydraulic systems include:

- Hydraulic Pump: Converts mechanical energy into hydraulic energy by pressurizing the fluid.

- Hydraulic Fluid: Transmits power throughout the system, ensuring smooth operation.

- Actuators: Convert hydraulic energy back into mechanical energy, enabling movement of arms or other mechanisms.

- Valves: Control the flow and pressure of the hydraulic fluid, allowing for precise handling of loads.

These systems offer several advantages:

- Increased Lifting Capacity: The power generated allows for lifting substantial weights with minimal effort.

- Smooth Operation: Hydraulic systems provide fluid and controlled movements, reducing the risk of sudden jerks or drops.

- Versatility: Can be adapted to various recovery techniques and equipment configurations.

In summary, hydraulic mechanisms significantly enhance the functionality and safety of vehicles designed for recovery and towing operations, making them indispensable in this field.

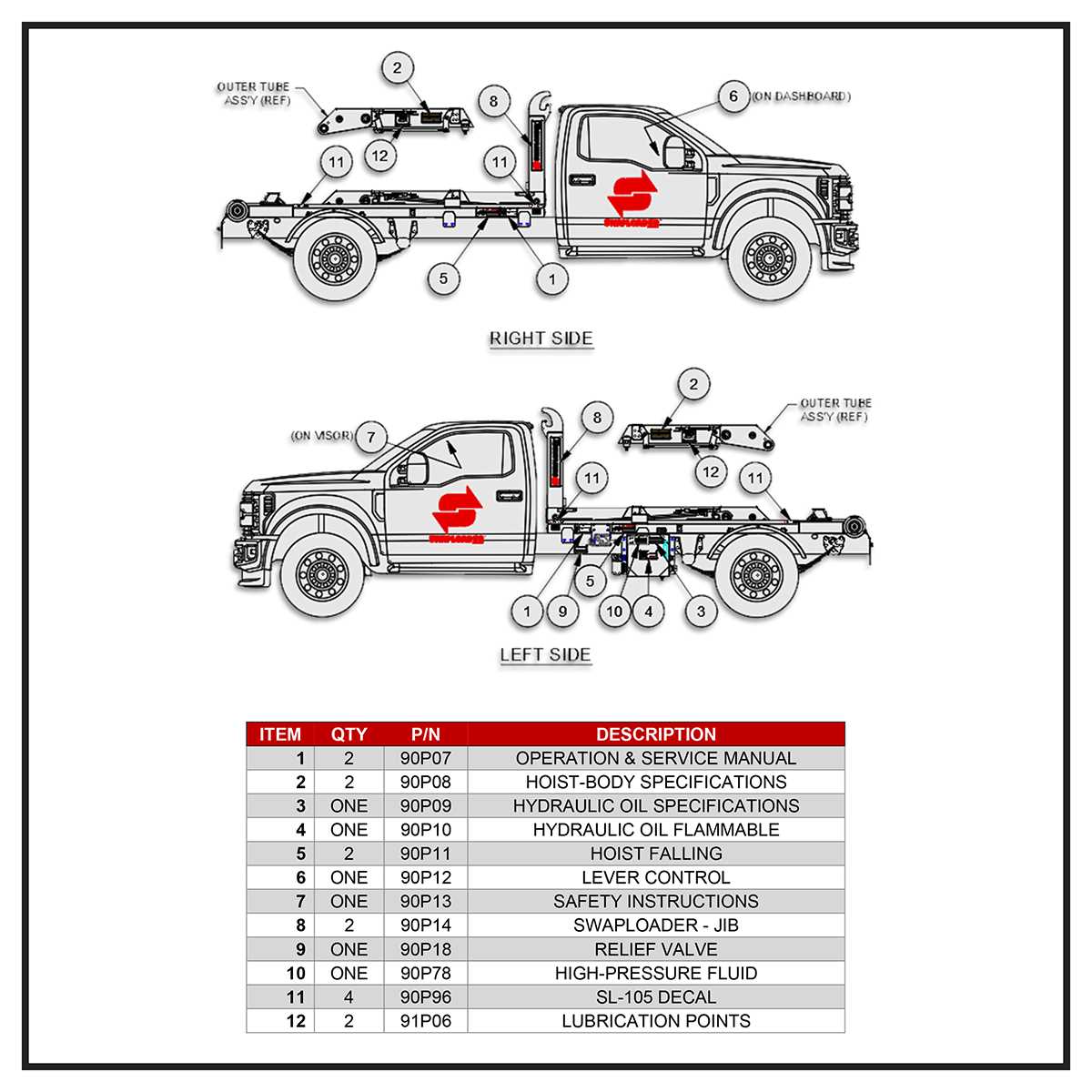

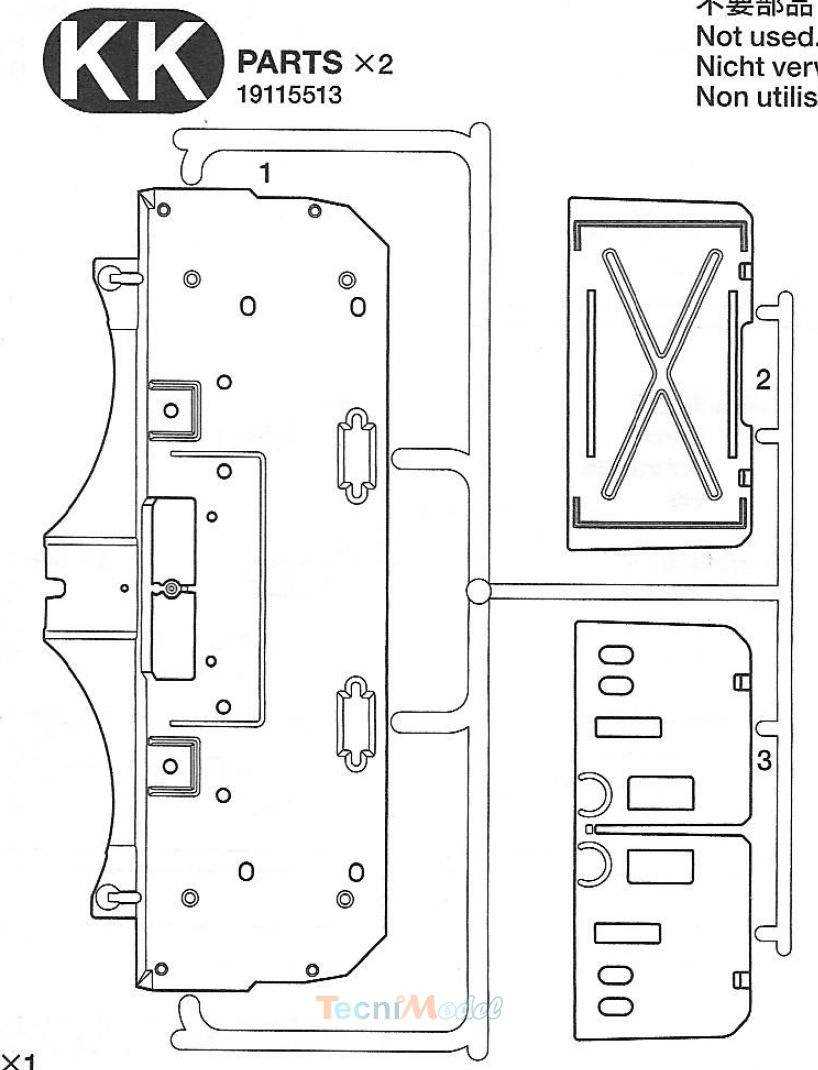

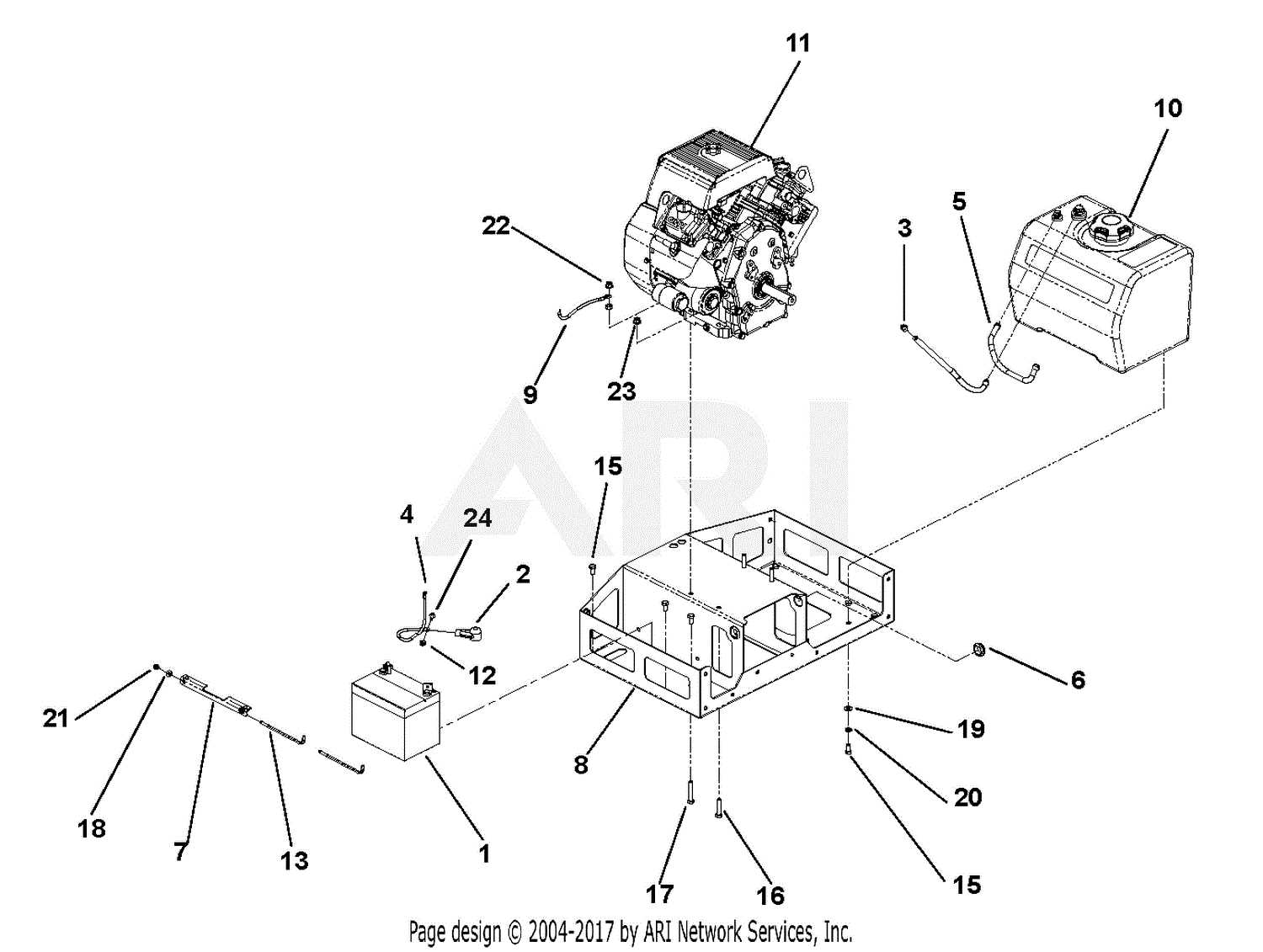

Electrical Wiring for Tow Truck Parts

The intricate web of electrical connections plays a crucial role in ensuring the efficient operation of various components within a recovery vehicle. Understanding how these systems interact is vital for maintaining functionality and enhancing safety.

At the heart of the electrical framework are the batteries and alternators, which provide the necessary power. The wiring harness distributes this energy to different elements, including lights, winches, and control systems. Proper installation and maintenance of these connections can prevent potential failures.

Additionally, fuses and relays serve as essential protective devices. They safeguard the electrical circuits by interrupting the flow of current during overload conditions. Familiarity with the placement and specifications of these components is critical for effective troubleshooting.

Overall, mastering the intricacies of electrical wiring not only enhances the performance of recovery vehicles but also ensures compliance with safety standards, thereby promoting reliable operation in various situations.

Common Accessories for Tow Trucks

When it comes to enhancing the functionality and efficiency of vehicles designed for transport and recovery, a range of essential accessories plays a pivotal role. These tools not only improve operational capabilities but also ensure safety and convenience during various tasks. Understanding these components is crucial for optimizing the performance of recovery vehicles in diverse situations.

One important accessory is a heavy-duty winch, which provides the necessary strength to pull vehicles from difficult locations. Additionally, a set of safety chains can enhance security during transportation, ensuring that the load remains stable and secure. Recovery straps are another vital element, allowing for flexible connections to a variety of vehicles, making them indispensable in recovery operations.

Moreover, lighting equipment, such as LED light bars, improves visibility during night operations, increasing safety for both the operator and other road users. Outfitting vehicles with reflective markers and cones also ensures that they are easily identifiable in low-light conditions. Lastly, specialized dollies and cradles enable smooth maneuvering of vehicles, making the entire process more efficient.

Safety Features in Towing Equipment

Ensuring the safety of operators and other road users is paramount in the operation of recovery gear. Various mechanisms and technologies are integrated into these systems to enhance safety during vehicle transport and recovery operations. These features not only protect personnel but also help prevent accidents and equipment damage.

One essential safety feature is the use of heavy-duty winches equipped with automatic braking systems. These winches provide controlled descent and help prevent uncontrolled drops, which can lead to severe injuries or property damage. Additionally, reflective surfaces and bright colors on the equipment enhance visibility, especially in low-light conditions, reducing the risk of collisions.

Another critical aspect is the incorporation of safety chains and safety hooks. These components ensure that the load remains securely attached, minimizing the risk of detachment during transit. Properly designed lighting systems, including emergency flashers and work lights, further contribute to safety by increasing the visibility of the equipment on the road.

Regular maintenance checks and inspections are also crucial to ensuring that all safety features function correctly. By adhering to these safety protocols, operators can significantly reduce the likelihood of accidents and enhance the overall safety of recovery operations.

Maintenance Tips for Tow Truck Parts

Regular upkeep is essential for ensuring the reliability and performance of your vehicle’s components. By following proper maintenance practices, you can extend the lifespan of these critical elements, reduce the likelihood of unexpected failures, and ensure optimal functionality.

- Inspect Regularly: Conduct frequent checks on all mechanical elements to identify wear and tear early.

- Keep Clean: Maintain cleanliness by removing dirt, debris, and grease from all surfaces to prevent corrosion.

- Lubricate Moving Parts: Apply appropriate lubricants to joints and hinges to minimize friction and wear.

- Check Fluid Levels: Regularly monitor and replenish fluids such as oil, coolant, and hydraulic fluids to ensure proper operation.

- Replace Worn Components: Stay vigilant for signs of damage and replace any compromised components promptly.

By adhering to these essential guidelines, you can enhance the durability and performance of your vehicle’s systems, ensuring that they operate smoothly and efficiently for years to come.

Choosing Quality Tow Truck Components

When it comes to selecting essential components for your recovery vehicle, the quality of these elements can significantly impact performance, safety, and durability. Investing in high-quality components not only enhances the functionality of your machine but also ensures reliability in various towing conditions.

Key Considerations for Selection

Prior to making a purchase, consider the following aspects to ensure you choose the best components for your needs:

- Material Quality: Look for components made from durable materials that can withstand heavy loads and harsh conditions.

- Compatibility: Ensure that the components are compatible with your specific vehicle model to avoid issues during installation and operation.

- Brand Reputation: Opt for well-known brands with positive reviews to guarantee performance and reliability.

- Warranty and Support: Check if the manufacturer offers a warranty and customer support for their products.

Benefits of Investing in Quality Components

Choosing premium components provides numerous advantages, including:

- Enhanced Safety: Quality components reduce the risk of malfunctions, ensuring the safety of both the operator and other road users.

- Improved Efficiency: High-grade parts typically function more effectively, resulting in better fuel economy and reduced wear and tear.

- Longer Lifespan: Investing in quality means fewer replacements over time, ultimately saving you money in the long run.