The intricacies of a railway system encompass a variety of essential elements that work together to ensure smooth and efficient operation. Each segment plays a crucial role in maintaining the functionality and safety of the entire system. A thorough comprehension of these components can enhance appreciation for the engineering behind modern transportation.

In this section, we will explore the different segments involved in rail transport, examining their structure and purpose. By delving into the specifics of each element, one can gain insights into how they interact to form a cohesive unit. This knowledge is vital for enthusiasts, engineers, and anyone interested in the mechanics of railway systems.

Understanding the configuration of these crucial elements provides a foundation for further exploration and study. Whether for educational purposes or personal interest, familiarizing oneself with these components can lead to a deeper respect for the technology that powers rail travel.

This section will explore the fundamental components that make up a rail vehicle, highlighting their roles and interactions. A comprehensive overview of these elements will provide insights into how they contribute to the overall functionality and efficiency of the system.

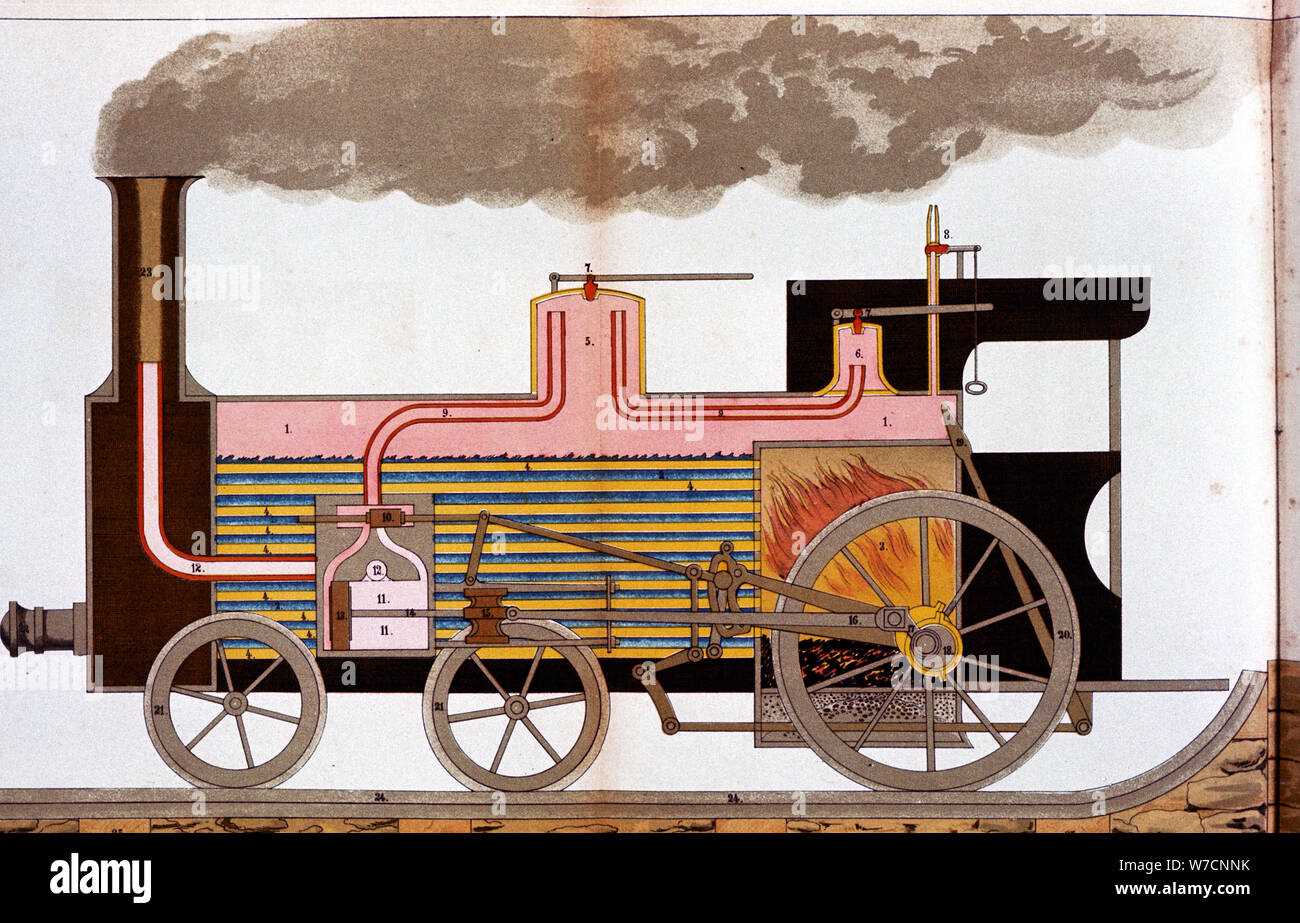

1. Overview of the Rail Vehicle

The rail vehicle is a complex machine designed for transportation along tracks. It consists of various essential components working together to ensure smooth and efficient travel.

2. Key Structural Elements

- Frame: The main structure supporting all other components.

- Body: The outer shell providing protection and aerodynamic efficiency.

- Underframe: The base structure housing vital systems and equipment.

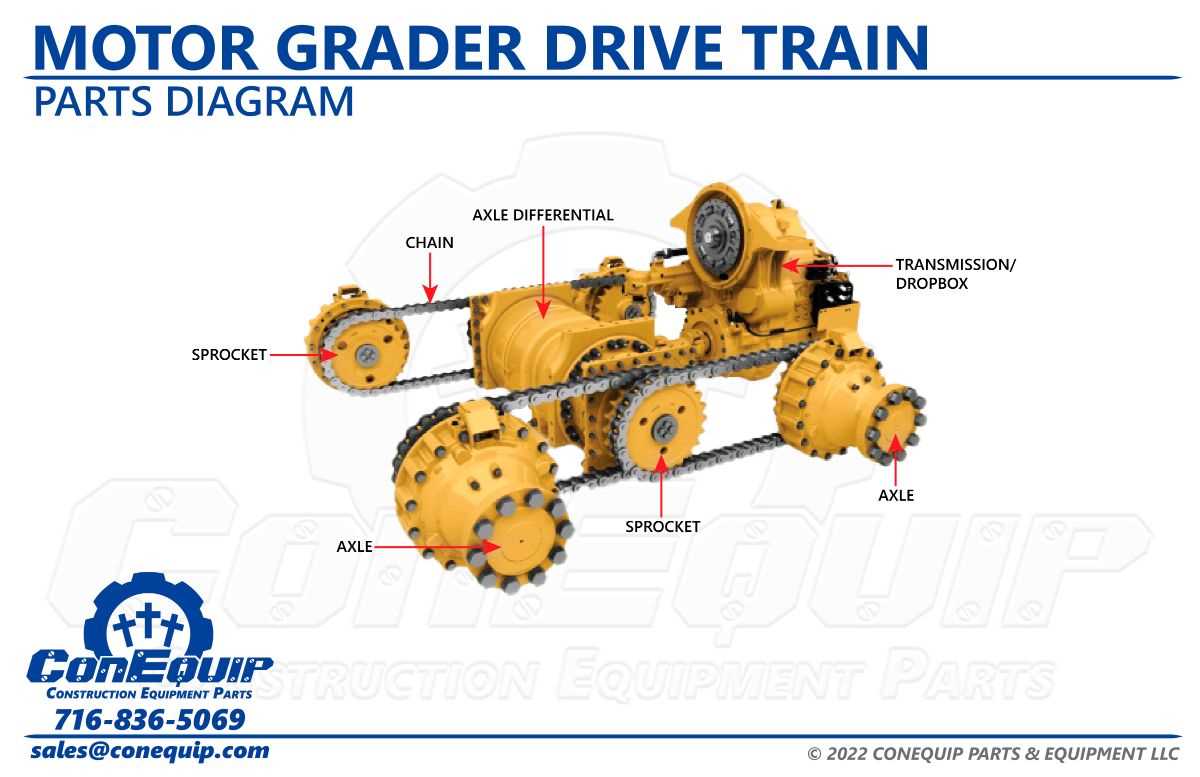

3. Propulsion Mechanisms

- Engines: Power units responsible for driving the vehicle.

- Transmission Systems: Mechanisms that transfer power to the wheels.

4. Wheel and Axle Systems

- Wheels: Circular components enabling movement along the tracks.

- Axles: Rods connecting the wheels, allowing them to rotate together.

5. Suspension Systems

Suspension systems are crucial for maintaining stability and comfort during travel. They absorb shocks and vibrations from the track, ensuring a smoother ride.

6. Braking Mechanisms

- Disc Brakes: Devices that apply friction to reduce speed.

- Air Brakes: Pneumatic systems used for controlled stopping.

7. Safety Features

- Signal Systems: Indicators ensuring safe operation on the tracks.

- Emergency Stops: Mechanisms that enable quick halting of the vehicle.

8. Interior Components

- Seating Arrangements: Designs providing passenger comfort.

- Control Panels: Interfaces for operators to manage the vehicle.

9. Maintenance Access Points

Designated areas allow for easy access to critical components for routine checks and repairs, ensuring the longevity and safety of the rail vehicle.

10. Future Developments

Innovations in design and technology are continually shaping the future of rail transportation. Advances may lead to improved efficiency, safety, and environmental sustainability.

Essential Components of Locomotives

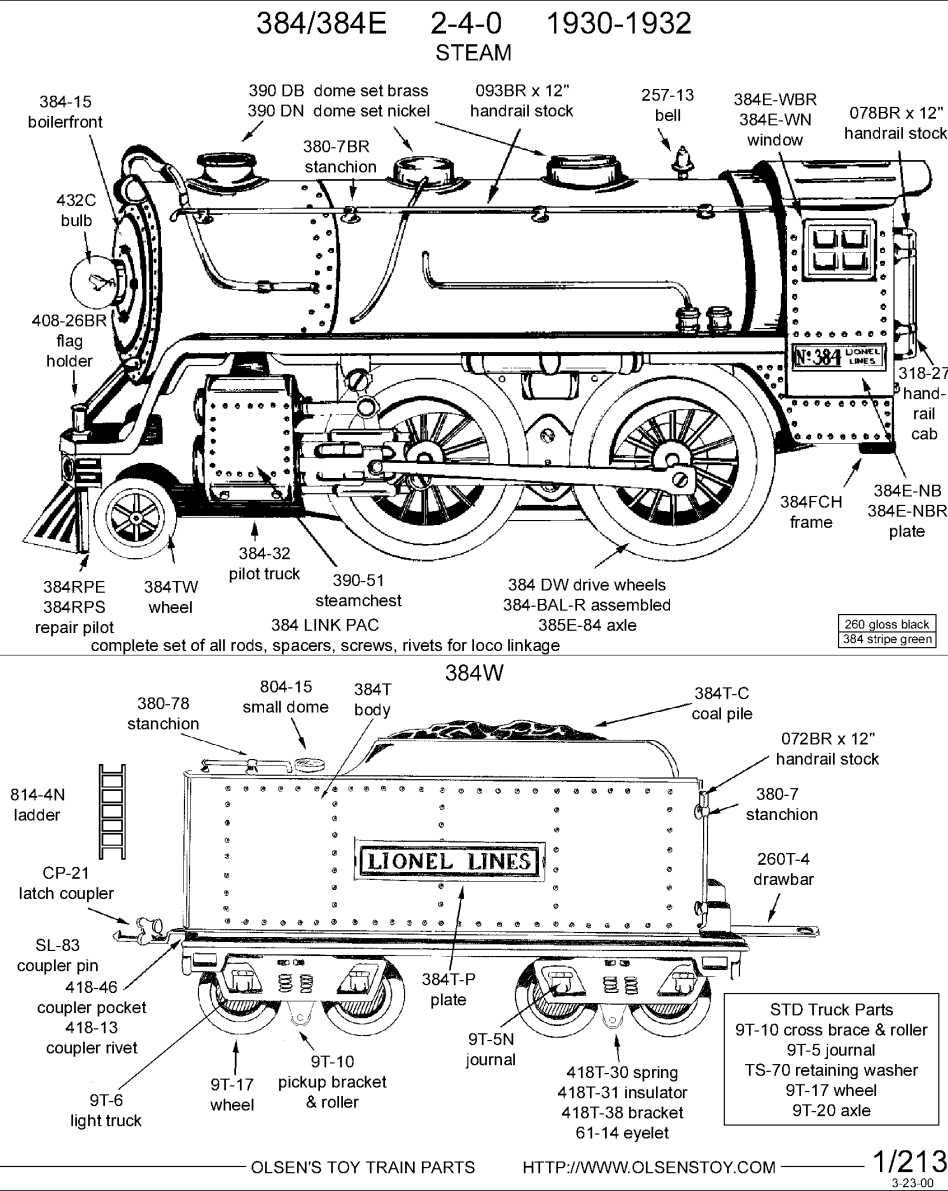

Understanding the fundamental elements that make up locomotives is crucial for appreciating their functionality and efficiency. These vital components work in unison to ensure smooth operation and optimal performance, allowing these powerful machines to transport goods and passengers across vast distances.

Main Mechanisms

- Engine: The heart of the locomotive, responsible for generating the necessary power to propel it forward.

- Transmission: Transfers the energy produced by the engine to the wheels, enabling movement.

- Brake System: Ensures safety by allowing the operator to slow down or stop the locomotive effectively.

Support Structures

- Chassis: The framework that supports all components, providing stability and strength.

- Wheels: Critical for movement, designed to handle heavy loads while maintaining traction on the tracks.

- Suspension System: Enhances comfort by absorbing shocks and vibrations, ensuring a smoother ride.

Railcar Types and Functions

Understanding the various types of rail vehicles and their distinct roles is essential for appreciating the complexity of rail transport systems. Each vehicle is designed with specific purposes in mind, contributing to the overall efficiency and effectiveness of rail operations.

- Freight Cars: These vehicles are primarily used for transporting goods and materials. They can be further categorized into:

- Boxcars: Enclosed cars for general cargo.

- Flatcars: Open vehicles suitable for heavy loads.

- Tank Cars: Designed for liquids and gases.

- Passenger Coaches: These are intended for transporting individuals and can vary widely in comfort and amenities:

- Economy Coaches: Basic seating for budget travel.

- Luxury Coaches: Enhanced comfort with additional services.

- Dining Cars: Equipped with facilities for serving meals.

- Specialty Cars: These vehicles serve unique functions within the rail network:

- Maintenance-of-Way Cars: Used for track inspection and repairs.

- Observation Cars: Provide scenic views for passengers.

- Auto Racks: Transport vehicles efficiently.

Each category of rail vehicle plays a vital role in maintaining the functionality of rail networks, ensuring that both cargo and passengers are moved safely and effectively.

Importance of Train Braking Systems

Effective stopping mechanisms are crucial for ensuring the safety and reliability of transportation systems. These mechanisms play a vital role in controlling speed and facilitating safe halts, especially in various environmental conditions. Without robust braking systems, the risk of accidents and operational failures significantly increases.

Safety is the primary function of braking systems, allowing for prompt response in emergency situations. The ability to reduce velocity quickly prevents collisions and protects passengers and cargo. Additionally, well-designed systems enhance operational efficiency by enabling smooth deceleration during regular operations, contributing to the overall performance of the service.

Furthermore, these mechanisms require regular maintenance and technological advancements to adapt to evolving safety standards and operational demands. Continuous improvements in braking technology lead to enhanced performance and reliability, ensuring the longevity of the entire transportation system.

Power Sources for Modern Trains

Contemporary rail systems rely on various energy sources to ensure efficient and sustainable operations. These power sources play a crucial role in enhancing performance, reliability, and environmental responsibility. Understanding the different types of energy systems is essential for optimizing their application in transportation networks.

Types of Energy Sources

Modern systems utilize a range of energy options, each with its advantages and applications. The most common include:

| Energy Source | Description | Advantages |

|---|---|---|

| Electricity | Utilized through overhead lines or rail tracks, providing a consistent and powerful energy supply. | High efficiency, low emissions, and capability for regenerative braking. |

| Diesel | Combustion engines that convert fuel into mechanical energy, widely used in remote areas. | Flexible operation without the need for extensive infrastructure. |

| Hydrogen | Fuel cells convert hydrogen into electricity, representing a cleaner alternative. | Zero emissions at the point of use, potential for sustainable production methods. |

| Batteries | Stored energy systems that can be recharged and utilized for propulsion. | Lower environmental impact and ability to operate in areas without electrification. |

Future Trends

As the transportation sector continues to evolve, innovations in energy technology are anticipated to enhance efficiency and reduce environmental impact. Advancements in renewable energy integration, battery technology, and alternative fuels will likely shape the future of rail systems, making them more sustainable and adaptable to global demands.

Suspension Systems in Rail Vehicles

The stability and comfort of rail vehicles heavily depend on their suspension mechanisms. These systems are designed to absorb shocks, reduce vibrations, and maintain smooth interactions between the vehicle and the track. A well-engineered suspension not only enhances passenger comfort but also prolongs the lifespan of the components involved in rail operations.

Types of Suspension Systems

Various suspension types are employed in rail vehicles, each tailored to specific operational requirements. Mechanical systems utilize springs and dampers to manage vertical movements, while air suspension offers enhanced comfort through pneumatic adjustments. The choice of system can significantly influence ride quality and overall performance.

Benefits of Efficient Suspension

Efficient suspension contributes to improved safety and operational efficiency. By minimizing the impact of irregularities in the track, these systems help prevent excessive wear on wheels and rails. Moreover, they facilitate better handling characteristics, ensuring that vehicles can navigate curves and gradients effectively.

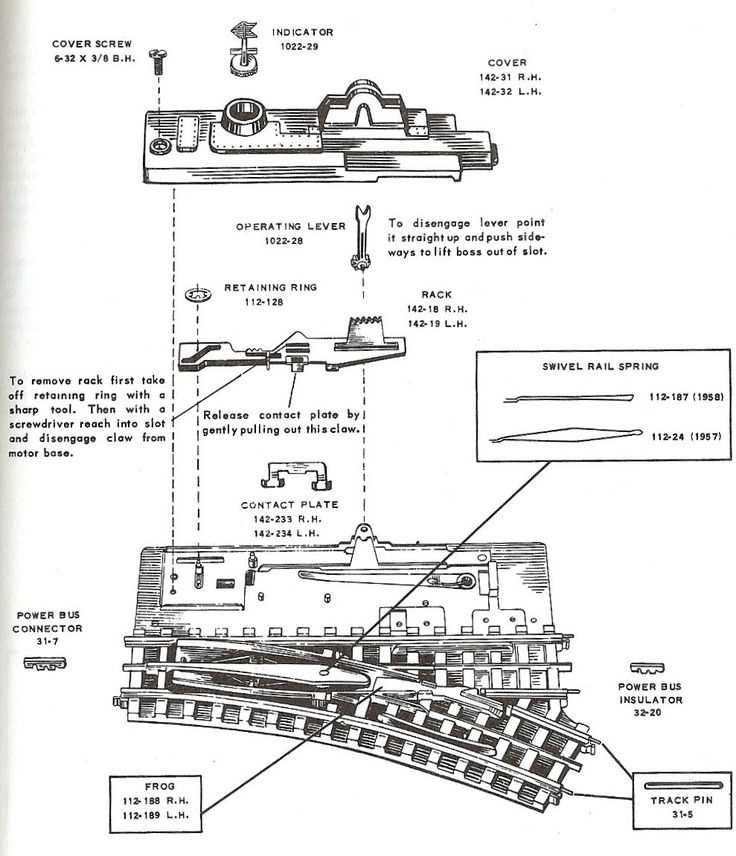

Significance of Train Coupling Mechanisms

Coupling systems play a crucial role in the operation and functionality of railway vehicles. These mechanisms ensure that multiple units can be linked together securely, allowing for efficient movement and stability during transit. Their design influences not only the performance but also the safety and reliability of the entire system.

Types of Coupling Systems

Various coupling systems exist, each with distinct features and applications. The selection of a specific mechanism often depends on the requirements of the operation and the type of rolling stock being utilized.

| Type | Description | Application |

|---|---|---|

| Automatic Couplers | Self-engaging systems that require minimal manual intervention. | Freight and passenger services for efficiency. |

| Manual Couplers | Require manual effort for engagement and disengagement. | Specialty services where flexibility is needed. |

| Transition Couplers | Facilitate the connection between different systems. | Interoperability between various rail networks. |

Impact on Efficiency and Safety

The choice of coupling mechanism directly affects operational efficiency. Well-designed systems enhance the speed and reliability of service, while also contributing to safety by minimizing the risk of disconnects during travel. Regular maintenance and inspections are essential to ensure their continued effectiveness and longevity.

Role of Train Control Systems

Control systems play a crucial role in the efficient operation of rail networks. They ensure safe and reliable movement by managing the various functions necessary for a smooth journey. By integrating technology, these systems enhance communication and coordination among different components, facilitating optimal performance.

These systems encompass various elements designed to monitor and regulate operations effectively. Their main objectives include maintaining safety standards, optimizing scheduling, and minimizing delays. Through advanced technologies, they also contribute to energy efficiency and resource management, which are essential for modern transport networks.

| Function | Description |

|---|---|

| Safety Monitoring | Ensures adherence to safety protocols to prevent accidents. |

| Signal Management | Controls the flow of traffic by managing signal operations. |

| Performance Optimization | Enhances operational efficiency by analyzing performance metrics. |

| Communication Systems | Facilitates real-time communication among operators and staff. |

Maintenance Considerations for Train Parts

Regular upkeep is essential for ensuring the longevity and efficiency of any transportation system. Attention to various components plays a vital role in minimizing the risk of failure and optimizing performance. By adopting a systematic approach to maintenance, operators can enhance safety, reduce costs, and improve reliability.

Scheduled Inspections

Routine checks are crucial in identifying wear and tear before they escalate into serious issues. These evaluations should encompass all critical components, focusing on areas susceptible to damage. Implementing a well-defined schedule can facilitate proactive maintenance, ensuring that each element functions optimally.

Lubrication and Cleaning

Proper lubrication is integral to the smooth operation of mechanical systems. Regularly applying suitable lubricants reduces friction, extending the lifespan of moving parts. Additionally, consistent cleaning prevents the accumulation of debris and grime, which can hinder performance and lead to premature wear.

Impact of Aerodynamics on Train Design

The influence of airflow dynamics plays a crucial role in the development of high-speed vehicles. By understanding how air interacts with these machines, engineers can enhance efficiency, reduce energy consumption, and improve overall performance. Optimizing the shape and structure not only minimizes drag but also contributes to stability and safety during operation.

Reduction of Drag Forces

One of the primary goals in vehicle engineering is to minimize resistance caused by air. A streamlined silhouette significantly decreases the drag coefficient, allowing for faster speeds with less energy expenditure. Effective design features such as tapered noses and smooth contours aid in guiding airflow more efficiently around the body.

Influence on Stability and Safety

Aerodynamics also affects how well a vehicle handles various weather conditions. Improved airflow management enhances stability, particularly at high velocities. Incorporating features like spoilers and fairings can mitigate turbulence, ensuring smoother rides and greater safety for passengers and cargo alike.