In modern machinery, precise mechanisms play a crucial role in ensuring smooth operation and efficiency. When dealing with these systems, it’s important to recognize the various elements that come together to control movements and functions with accuracy. Each piece, large or small, has a specific function that contributes to the overall performance of the equipment.

The structure is made up of interconnected elements, all working in harmony to manage the transmission of power. Understanding how these elements interact is essential for anyone looking to maintain or repair such systems. By breaking down the key components, one can gain valuable insight into their function and purpose.

This section aims to provide a clear understanding of these essential components, highlighting their roles and how they contribute to the seamless operation of complex mechanical systems.

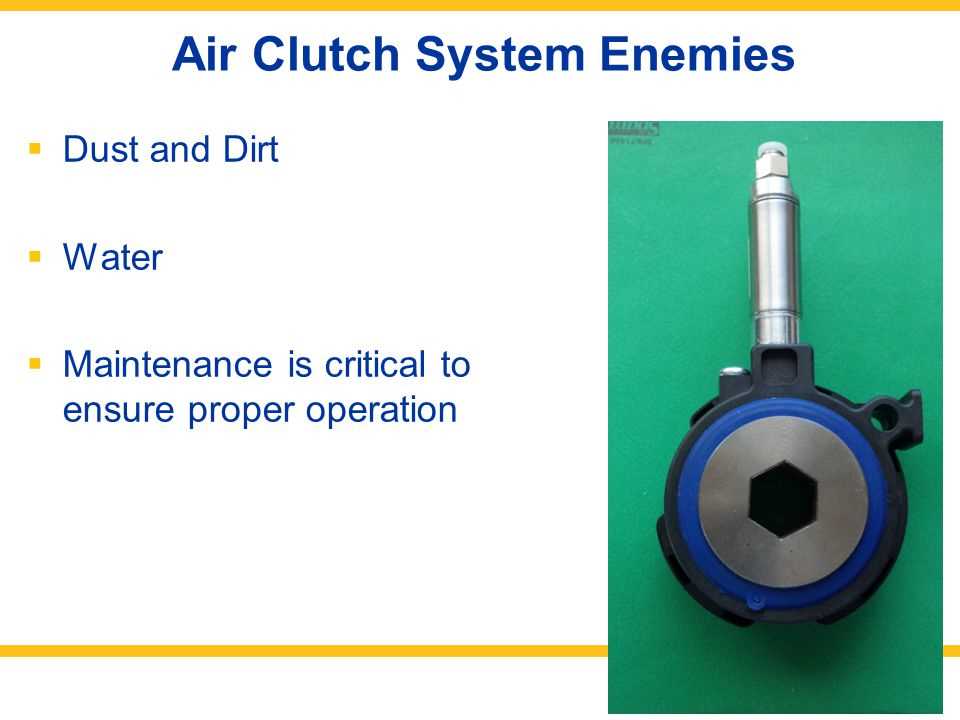

Understanding the Components of an Air Clutch System

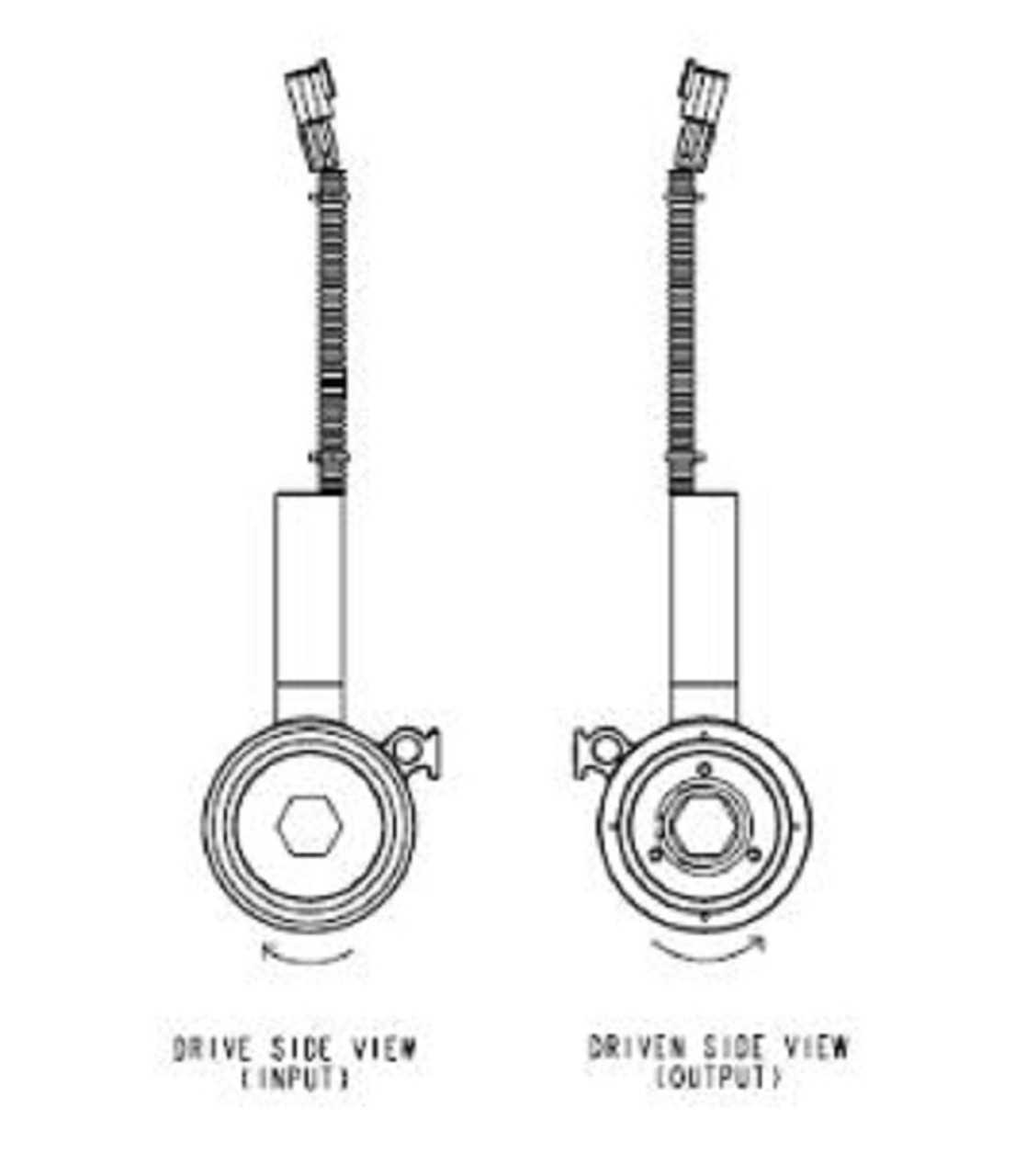

In any mechanical setup that involves transmitting power efficiently, there are several key elements working together to ensure smooth operation. This system typically functions by engaging and disengaging motion between rotating parts, controlling the transfer of energy. Recognizing these components and their roles is crucial for maintaining and optimizing performance.

Control Mechanism: This part of the system regulates when and how the energy is transferred. It ensures that the motion can be started or halted precisely, preventing unnecessary wear or slippage.

Power Source: The source of energy is the driving force behind the motion. It activates the entire system, creating the necessary conditions for engagement or release. Without this element, the system cannot function.

Exploring the Internal Mechanisms

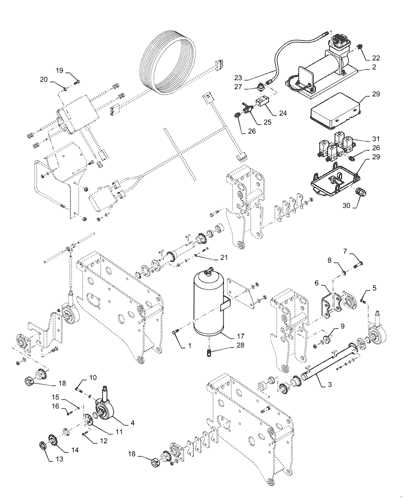

The core functionality of the system relies on a series of intricate components working together seamlessly. By understanding how each element interacts within the mechanism, we can gain deeper insights into its operational efficiency and reliability in various applications. This section provides a closer look at the key components and their roles, highlighting the importance of precision in every stage of operation.

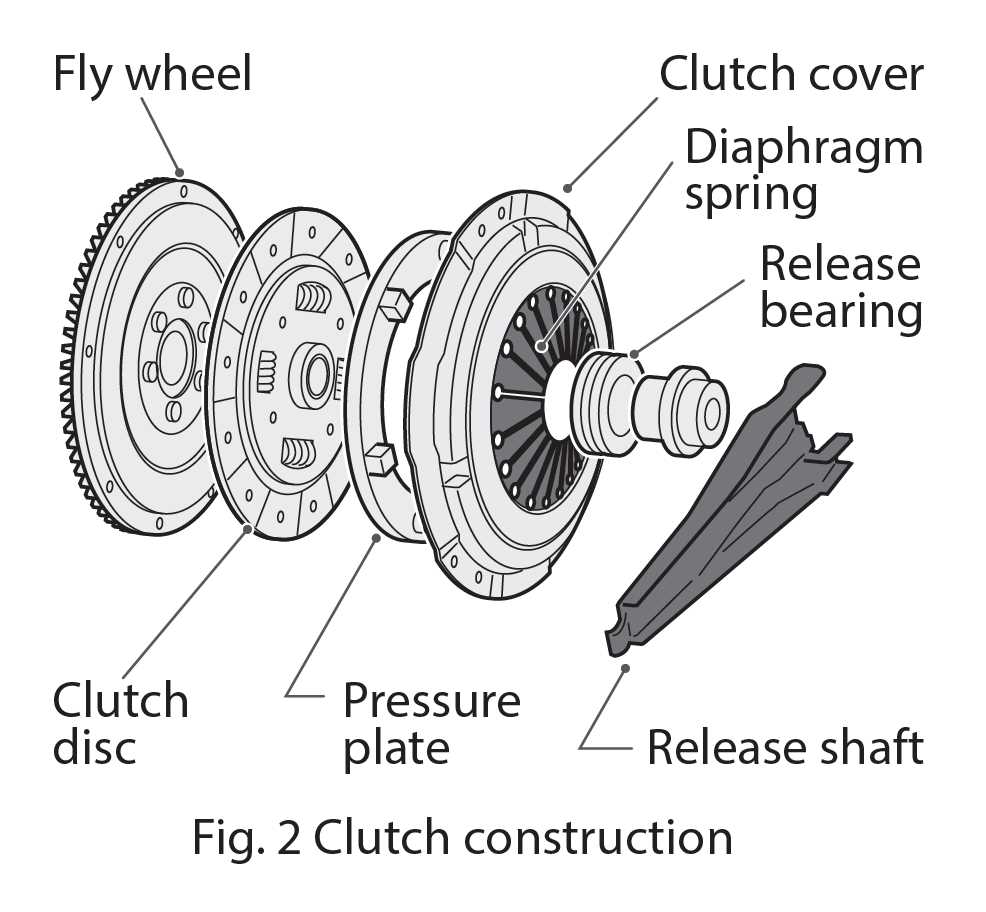

Main Components Overview

The internal structure consists of several essential elements designed for optimal performance. These include rotating assemblies, control units, and response systems. Each part plays a critical role in ensuring smooth operations, and any malfunction in one can significantly impact the entire system. Understanding the interaction between these components is key to troubleshooting and maintenance.

| Component | Function | Maintenance Tips | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rotating Assembly |

Key Elements of Clutch OperationThe mechanism responsible for regulating the connection between rotating components is a vital part of many mechanical systems. Its smooth engagement and disengagement are essential for proper functionality, allowing for control over power transmission. Understanding its core features is crucial for maintaining performance and preventing wear over time. Engagement and Disengagement ProcessWhen initiating movement, precise coordination between components ensures seamless operation. The process involves both pressure and release, which are controlled by mechanical linkages or hydraulic systems. Each step in this sequence is critical to avoid damage and ensure a responsive system. Wear and Maintenance ConsiderationsAs components are used over time, they can experience significant friction, leading to wear. Regular inspection and adjustments are necessary to maintain longevity. Key aspects to consider include material quality, lubrication, and alignment of parts.

Importance of Proper Air Pressure ManagementEffective management of pneumatic force is crucial in various mechanical systems. Maintaining optimal pressure levels ensures that equipment operates efficiently and safely, thereby prolonging its lifespan and enhancing overall performance. Neglecting this aspect can lead to significant operational issues and potentially hazardous situations. Enhancing EfficiencyProper control of pneumatic pressure directly influences the efficiency of machinery. By ensuring that the correct levels are maintained, components can function at their best, reducing energy consumption and minimizing wear and tear. This proactive approach not only supports better productivity but also lowers operational costs over time. Safety Considerations

Inadequate pressure management can pose serious safety risks. Over-pressurization may cause components to fail or even rupture, leading to injuries or equipment damage. Conversely, insufficient pressure can result in sluggish performance and unpredictable behavior. Implementing rigorous monitoring and adjustment practices helps mitigate these risks, promoting a safer working environment. Optimizing the Performance of Air Clutches

Enhancing the functionality of pneumatic engagement systems involves understanding various factors that contribute to their efficiency and reliability. By addressing key components and their interactions, users can ensure optimal operation, resulting in improved performance and reduced wear. Key Considerations for Efficiency

Techniques to Maximize Functionality

|