When delving into the mechanics of large transportation vehicles, it’s essential to comprehend the intricate systems that enable their functionality. These robust machines are designed to handle immense loads and traverse various terrains, making their structural elements vital for performance and safety.

One of the critical assemblies in these vehicles consists of essential elements that support weight distribution and ensure smooth operation. Each component plays a unique role, contributing to the overall efficiency and durability of the vehicle.

In this exploration, we will break down the essential features of this assembly, highlighting their interactions and significance. By gaining a clearer understanding of these integral structures, one can appreciate the engineering that keeps heavy-duty vehicles operational and reliable.

Understanding Truck Axle Components

The fundamental elements of a vehicle’s undercarriage play a crucial role in its overall performance and stability. These components work together to support weight, facilitate movement, and ensure safety on the road. A clear comprehension of these elements is essential for anyone involved in maintenance or repair, as it enhances the ability to identify issues and implement effective solutions.

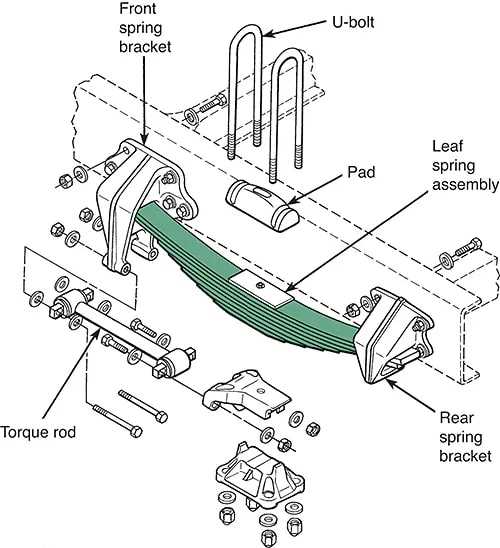

Primary Elements: At the core of this system are several key elements, each with its unique function. The central structure provides a connection point for the wheels, allowing for rotation and smooth motion. Supporting mechanisms are responsible for absorbing shocks and providing stability during operation, thereby enhancing comfort and control.

Critical Features: Among the various components, there are those designed to manage torque and improve traction. These features are vital for ensuring optimal performance, especially in challenging conditions. Additionally, the housing structure serves to protect internal mechanisms from debris and damage, ensuring longevity and reliability.

Understanding these integral components allows for better decision-making when it comes to maintenance schedules and troubleshooting. By familiarizing oneself with the various functions and interactions of these elements, one can significantly contribute to the vehicle’s efficiency and safety.

Essential Functions of Axle Parts

The components that facilitate the movement and stability of heavy vehicles play a critical role in ensuring safety and efficiency. Each element contributes to the overall functionality, allowing for smooth transportation and load management. Understanding these functions is key to recognizing how they enhance performance and durability.

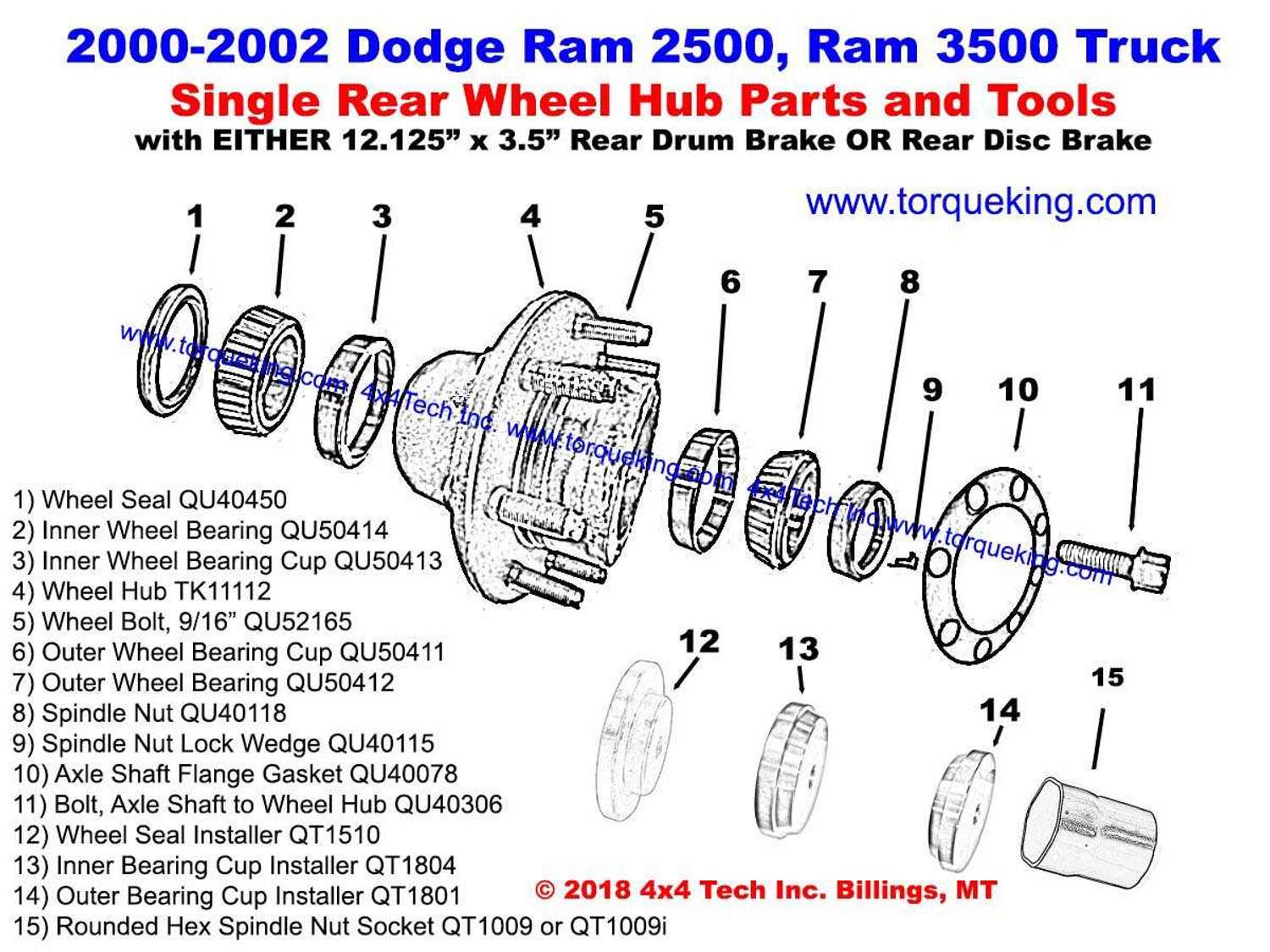

| Component | Function |

|---|---|

| Hub | Supports the wheel assembly and allows for rotation while bearing the weight of the vehicle. |

| Spindle | Connects the wheel to the main structure, providing stability and control during movement. |

| Shaft | Transmits power from the engine to the wheels, facilitating propulsion. |

| Bearing | Reduces friction between moving parts, allowing for smoother rotation and extending component life. |

| Brake Assembly | Enables controlled stopping and ensures safety during operation. |

| Spring | Absorbs shocks and maintains vehicle stability by managing load distribution. |

Types of Truck Axles Explained

Understanding the various forms of support structures in heavy vehicles is essential for effective operation and maintenance. Each configuration serves specific purposes, catering to different loads and performance requirements. This section explores the primary classifications of these structures, highlighting their unique characteristics and applications.

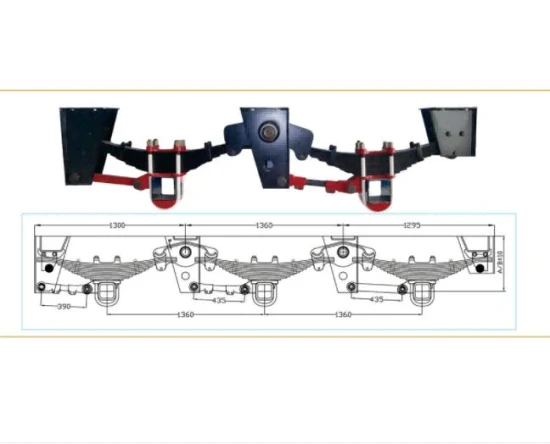

Single and Tandem Configurations

In the realm of heavy-duty machinery, the arrangement of support structures can greatly influence performance. The single setup typically consists of one main support point, offering simplicity and reduced weight. In contrast, the tandem setup features two or more points, enhancing load distribution and stability during transit.

Common Types and Their Uses

| Type | Description | Applications |

|---|---|---|

| Live | Provides power transfer while supporting the vehicle. | Freight transport, off-road vehicles |

| Dead | Only supports weight without power transfer. | Lightweight vehicles, trailers |

| Steering | Allows for maneuverability by enabling steering actions. | City vehicles, delivery vans |

| Floating | Utilizes a flexible design to adapt to uneven surfaces. | Construction vehicles, off-road applications |

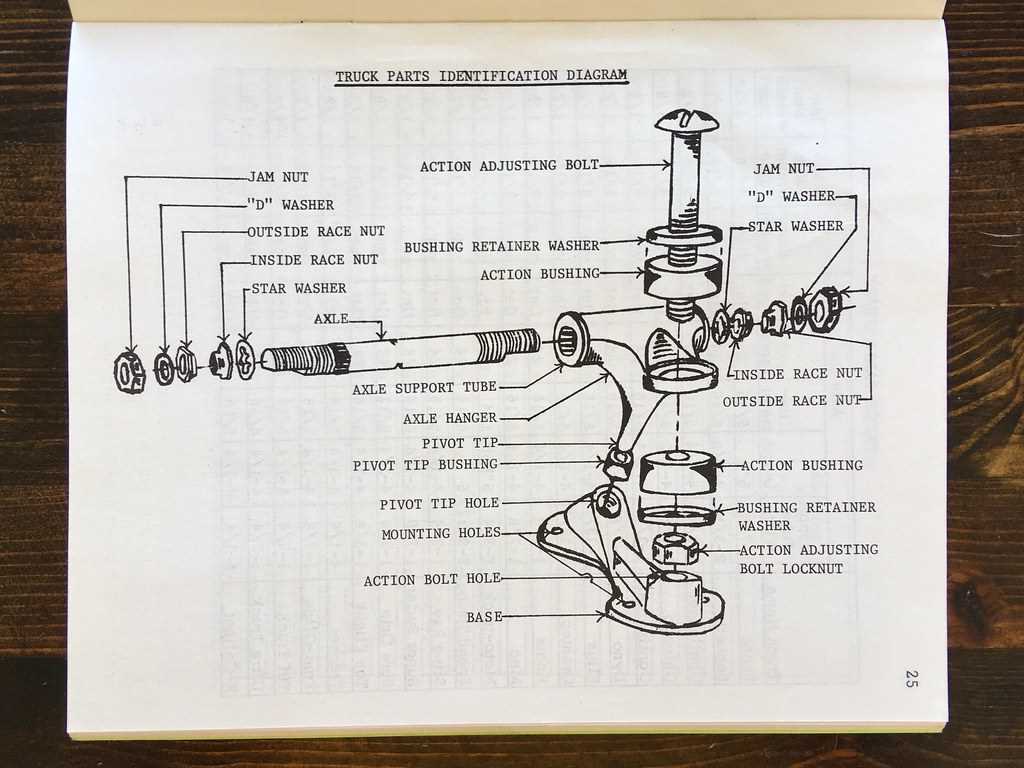

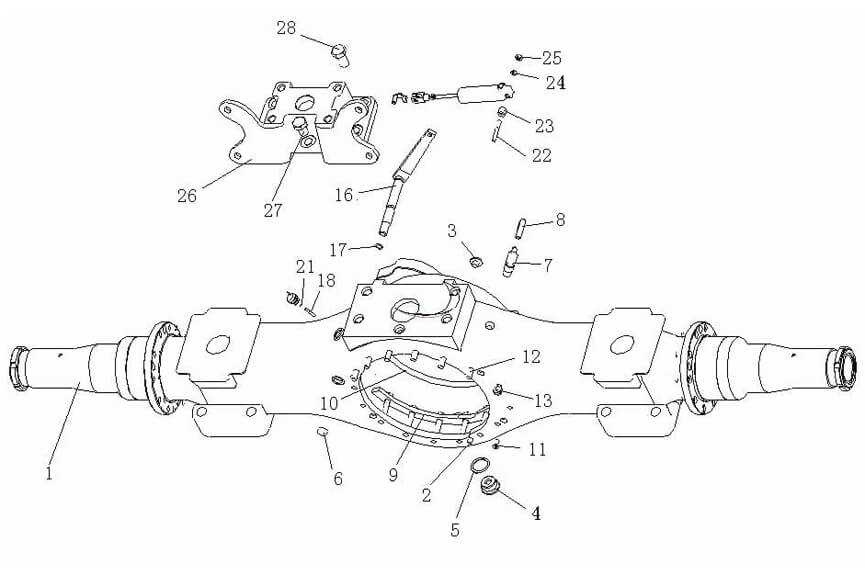

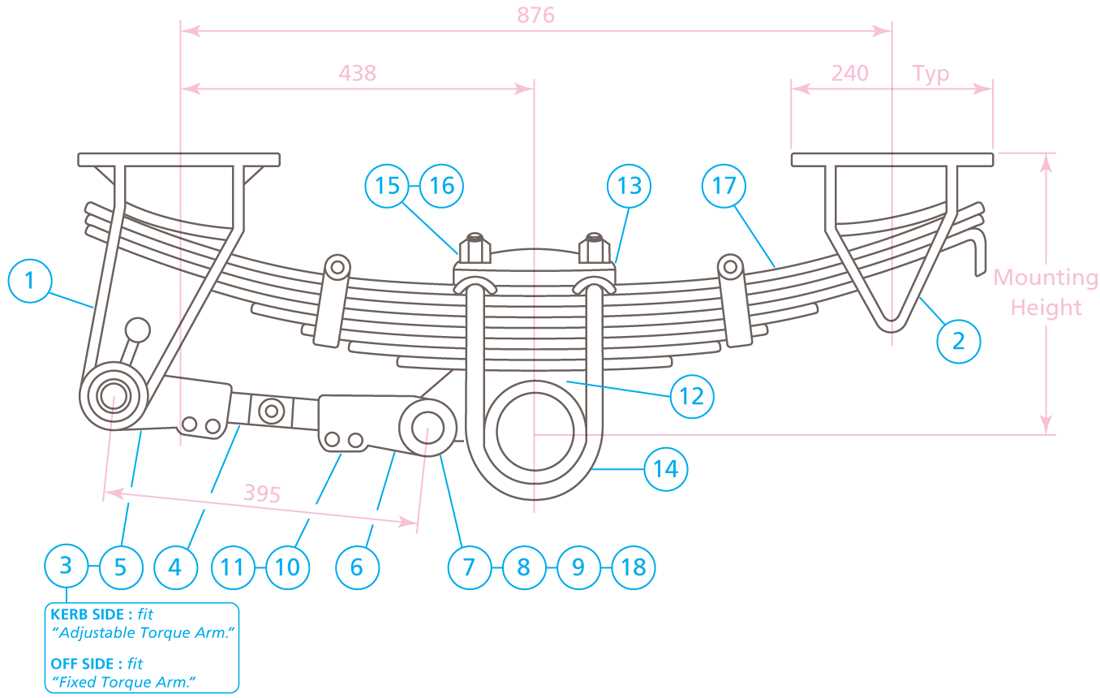

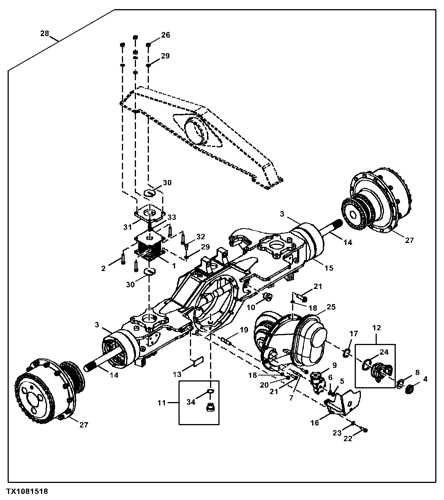

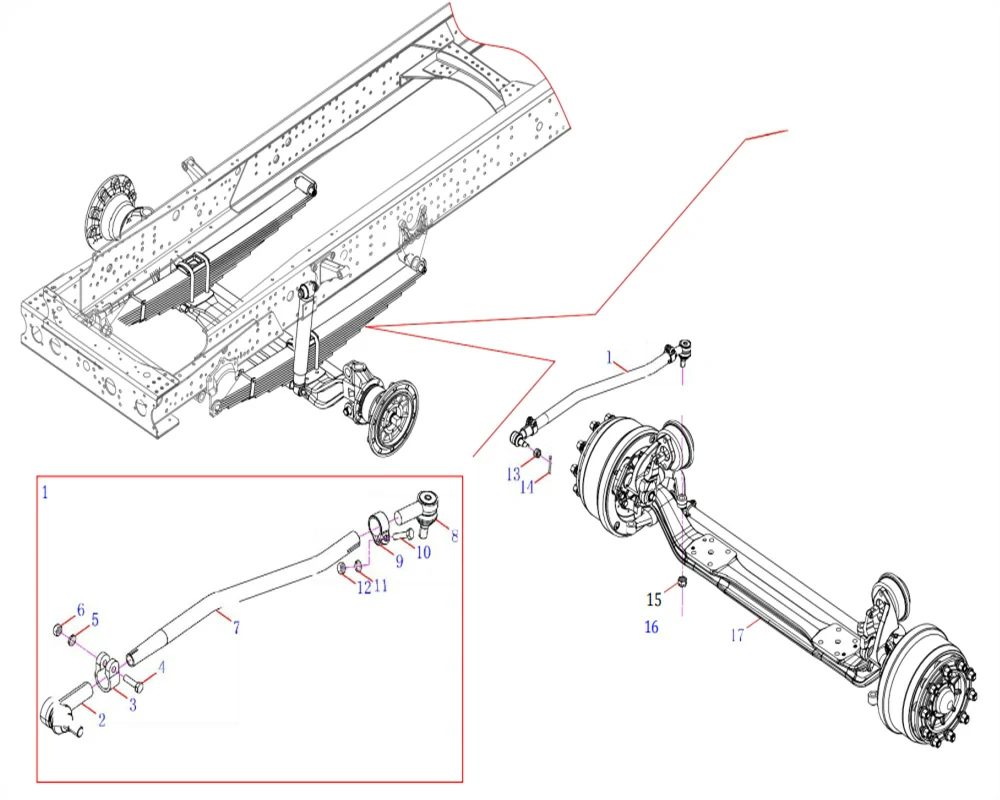

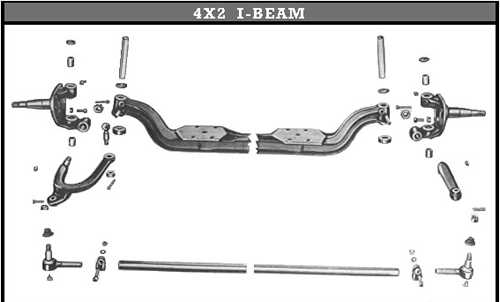

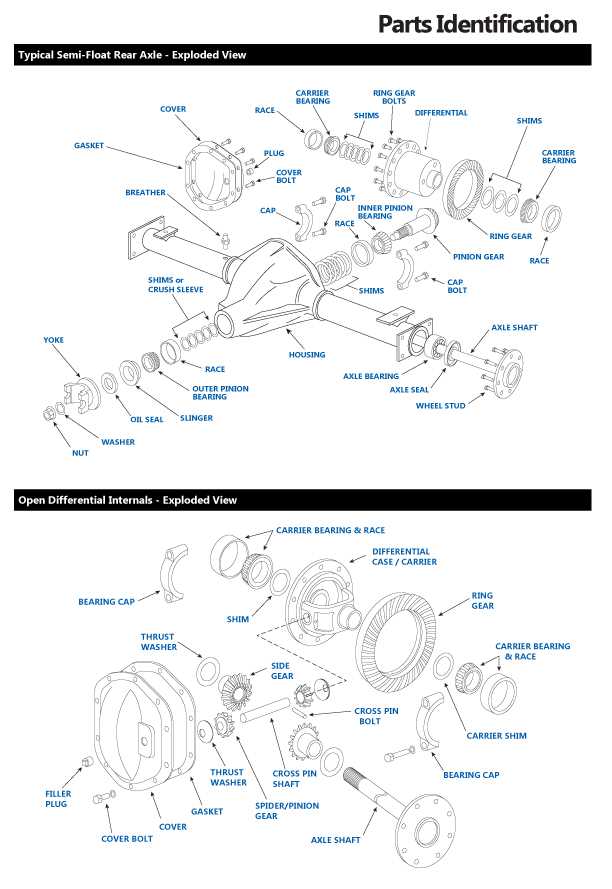

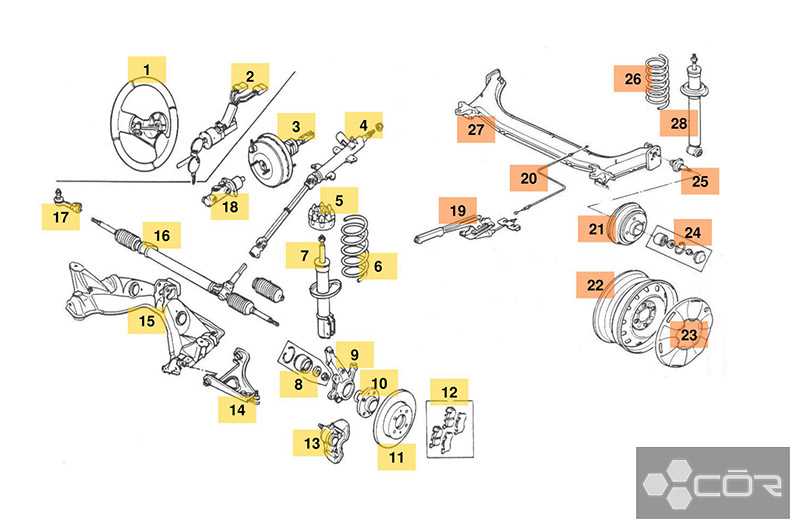

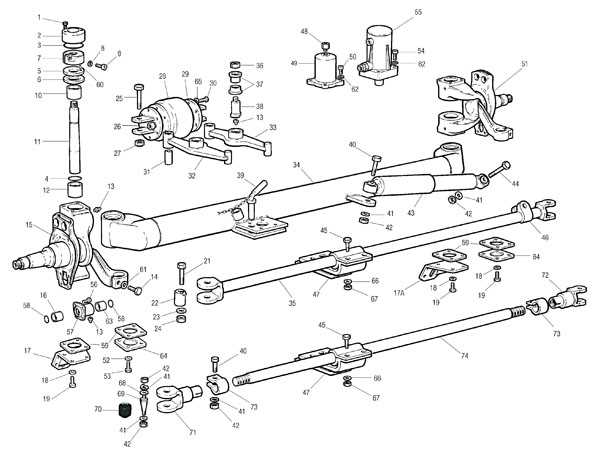

Visual Representation of Axle Systems

A comprehensive visual guide can significantly enhance the understanding of intricate components within a vehicle’s support structure. By illustrating these systems, we gain insights into their functionality and interrelations, making it easier to grasp their roles in overall performance.

Effective visual representations serve several purposes:

- Clarify complex mechanical relationships

- Highlight the arrangement and connection of essential elements

- Facilitate learning for both novices and professionals

When exploring these illustrations, consider the following key aspects:

- Component Identification: Each element is typically labeled, providing clarity on its specific function.

- Flow of Force: Arrows or lines often depict how forces are transmitted through the structure, aiding in understanding dynamics.

- Material Specifications: Annotations may indicate the materials used, which influence performance and durability.

Utilizing such visual tools empowers users to make informed decisions regarding maintenance and upgrades, ultimately contributing to better operational efficiency.

Importance of Axle Maintenance

Regular upkeep of critical components in vehicles is essential for ensuring safety, performance, and longevity. Proper attention to these elements not only enhances operational efficiency but also minimizes the risk of unexpected breakdowns and costly repairs.

Safety Considerations

Neglecting routine maintenance can lead to significant safety hazards. Issues such as:

- Increased wear and tear

- Poor handling and control

- Higher chances of accidents

Addressing these concerns proactively is crucial for the protection of drivers and passengers alike.

Economic Benefits

Investing in the maintenance of essential vehicle components offers various financial advantages:

- Reduced repair costs over time

- Improved fuel efficiency

- Extended lifespan of the vehicle

By prioritizing upkeep, owners can ensure their vehicles remain reliable and cost-effective in the long run.

Common Issues with Axle Components

Various components responsible for vehicle stability and movement can encounter several common challenges. Recognizing these issues early can prevent significant damage and ensure safe operation. Understanding the potential pitfalls is crucial for effective maintenance and repair.

Below are some prevalent problems associated with these essential elements:

| Issue | Description | Possible Causes |

|---|---|---|

| Wear and Tear | Gradual deterioration affecting performance and safety. | Heavy loads, poor maintenance, lack of lubrication. |

| Misalignment | Improper positioning can lead to uneven wear and handling issues. | Accidental impact, incorrect installation. |

| Corrosion | Rust and deterioration caused by exposure to moisture and elements. | Environmental factors, inadequate protective measures. |

| Noise and Vibration | Unusual sounds and vibrations may indicate underlying problems. | Loose components, worn bearings, imbalance. |

Addressing these concerns promptly can enhance the longevity and reliability of the vehicle, ensuring optimal performance in all conditions.

Choosing the Right Axle Type

Selecting the appropriate component for your vehicle’s suspension system is crucial for optimal performance and safety. Various options are available, each tailored to specific requirements, such as load capacity, maneuverability, and terrain adaptability. Understanding the distinct characteristics of each type will help you make an informed decision that enhances both functionality and reliability.

Factors to Consider

When determining the most suitable option, several factors come into play. Load capacity is a primary consideration, as it dictates how much weight the vehicle can safely transport. Additionally, the operating environment should influence your choice; for instance, if traversing rough terrains, a more robust design may be necessary. Furthermore, consider the maneuverability required for your specific applications, especially if tight turns or limited spaces are involved.

Common Types

There are several common configurations, each with unique benefits. For example, a single configuration is typically lighter and offers better fuel efficiency, while a dual configuration provides increased stability and load-bearing capabilities. Assessing your specific needs against these options will guide you in selecting the best fit for your vehicle.

Impact of Axle Design on Performance

The configuration and structure of wheel support systems play a critical role in the overall functionality and efficiency of heavy vehicles. Variations in design influence not only the load distribution but also the handling, stability, and durability of the vehicle under various operating conditions.

Key Factors in Design

- Load Capacity: The ability to support significant weight directly affects performance and safety.

- Material Selection: Different materials offer varying levels of strength, flexibility, and resistance to wear.

- Geometry: The shape and arrangement of components can enhance or hinder maneuverability and traction.

Effects on Performance

- Stability: A well-engineered configuration improves balance and reduces the likelihood of tipping.

- Fuel Efficiency: Streamlined designs can minimize drag and optimize energy consumption.

- Maintenance Needs: Robust designs often require less frequent servicing, leading to reduced operational costs.

In summary, the design of wheel support systems is fundamental to the operational efficiency and reliability of vehicles, influencing various performance metrics that are vital for effective transportation.

Materials Used in Axle Manufacturing

The choice of materials in the construction of essential components is critical for ensuring durability, performance, and safety. Various substances are employed to achieve the desired balance of strength, weight, and resistance to environmental factors. This section explores the primary materials utilized in the production of these vital mechanical elements.

Metals and Alloys

Steel is the most common material due to its high tensile strength and ability to withstand heavy loads. Various alloys are formulated to enhance specific properties, such as chromium-molybdenum for increased toughness and wear resistance. In certain applications, aluminum is favored for its lightweight characteristics, offering a significant reduction in overall weight while maintaining adequate strength.

Composite Materials

In recent years, composite materials have gained popularity for their ability to combine lightweight properties with exceptional strength. Fiber-reinforced plastics and other advanced composites provide corrosion resistance and can be engineered to meet specific performance criteria. These materials are particularly beneficial in reducing overall system weight without compromising safety or reliability.

Upgrading Axle Parts for Efficiency

Enhancing the components that support the weight and movement of heavy vehicles can lead to significant improvements in performance and longevity. By focusing on the quality and compatibility of these crucial elements, operators can achieve better fuel efficiency and overall operational reliability.

Consider the following upgrades to optimize functionality:

- High-Performance Bearings: Investing in advanced bearings can reduce friction and improve load handling, leading to smoother operation.

- Enhanced Lubrication Systems: Implementing superior lubrication techniques minimizes wear and ensures that all moving parts function seamlessly.

- Lightweight Materials: Utilizing lighter yet durable materials can decrease overall weight, enhancing speed and efficiency without compromising strength.

- Advanced Suspension Systems: Upgrading to more sophisticated suspension components can improve stability and handling, resulting in a more comfortable ride.

- Smart Monitoring Technology: Installing sensors to monitor performance in real-time allows for proactive maintenance, preventing breakdowns and extending service life.

By prioritizing these enhancements, vehicle operators can experience significant improvements in operational efficiency and reduce maintenance costs over time.

Safety Considerations for Axle Systems

Ensuring the integrity and reliability of critical components in heavy machinery is paramount for operational safety. Proper maintenance, inspection, and understanding of potential hazards can significantly reduce the risk of accidents and enhance performance.

Regular Maintenance

Routine upkeep is essential for the longevity and safety of essential mechanisms. Key practices include:

- Conducting periodic inspections to identify wear and tear.

- Lubricating moving elements to minimize friction.

- Replacing worn components before they fail.

Understanding Load Capacities

Comprehending the limitations of each system is critical for safe operation. Important aspects include:

- Adhering to the manufacturer’s specifications for weight limits.

- Avoiding overloading, which can lead to premature failure.

- Monitoring load distribution to prevent undue stress on individual elements.

Future Trends in Axle Technology

The evolution of vehicular support systems is paving the way for innovative advancements that enhance performance, sustainability, and efficiency. As industries adapt to new demands, the focus on improving these essential components is intensifying.

One significant trend is the integration of smart technologies. These innovations include:

- Real-time Monitoring: Sensors that track performance metrics and detect wear and tear.

- Predictive Maintenance: Algorithms that analyze data to anticipate failures before they occur.

- Connectivity: Systems that communicate with other vehicle components for optimized functionality.

Another important development is the shift towards sustainable materials. This encompasses:

- Lightweight Alloys: Reducing overall weight to enhance fuel efficiency.

- Recyclable Materials: Using substances that can be repurposed at the end of their lifecycle.

- Advanced Coatings: Enhancing durability and resistance to environmental factors.

Additionally, the push for automation is transforming design and manufacturing processes. Key elements include:

- 3D Printing: Facilitating rapid prototyping and customized designs.

- Robotic Assembly: Improving precision and efficiency in production.

- Virtual Testing: Utilizing simulations to evaluate performance under various conditions.

As these trends converge, the future of vehicle support systems looks promising, promising increased reliability and environmental responsibility for the automotive industry.