Understanding the intricate relationships between various elements of machinery is essential for effective maintenance and repair. This section delves into a visual representation of essential components, providing a clear guide for enthusiasts and professionals alike. Each illustration serves as a valuable resource for identifying and comprehending the individual parts and their functions.

By examining these visual aids, readers can enhance their knowledge of mechanical assemblies and ensure proper handling during service procedures. This exploration aims to simplify complex concepts, ultimately contributing to a deeper appreciation of the machinery’s design and functionality.

Ttr 110 Parts Diagram Article Plan

This section outlines the structure for an article focused on the components of a specific model. It aims to provide a comprehensive understanding of each element, detailing its function and significance within the assembly. By breaking down the various parts, readers will gain insights into maintenance, repair, and overall functionality.

Introduction to Components

The initial segment will introduce the various elements that make up the assembly, highlighting their importance and interconnectivity. This overview sets the stage for a deeper exploration of individual components.

Detailed Analysis of Each Element

This part will delve into a thorough examination of each component, discussing specifications, potential issues, and replacement tips. This analysis will assist users in understanding how to effectively manage and maintain their machinery.

Understanding the Ttr 110 Structure

The framework of this model showcases an intricate assembly that plays a crucial role in its overall functionality. Each component is meticulously designed to work harmoniously, contributing to the machine’s performance and durability. A comprehensive grasp of this structure not only enhances operational efficiency but also aids in maintenance and troubleshooting.

The core elements include the engine assembly, transmission, and suspension systems, each designed with precision to ensure optimal power transfer and stability. Familiarity with these components allows for better insights into the machine’s behavior under various conditions, making it easier to identify areas for improvement or necessary repairs.

Moreover, understanding the interconnections between these elements is vital. The synergy between the engine and transmission, for instance, significantly influences acceleration and handling. This interconnectedness underscores the importance of viewing the structure as a cohesive whole rather than as isolated parts.

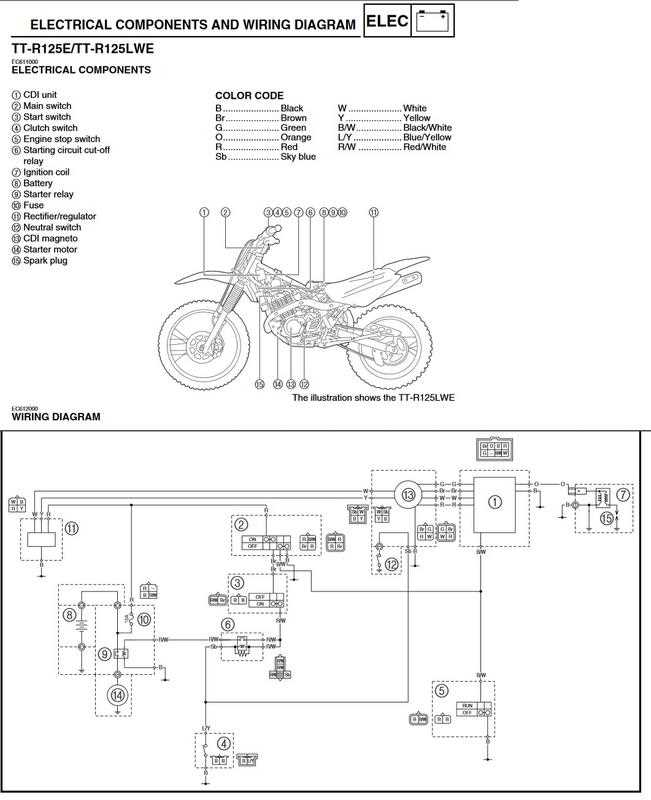

Importance of Parts Diagrams

Visual representations of component arrangements serve as essential tools for understanding complex machinery. They provide clarity on how various elements interact and fit together, which is crucial for effective maintenance and repairs.

Utilizing these illustrations can significantly enhance the troubleshooting process. When a technician encounters an issue, these visuals can quickly point out the exact location and identification of components, facilitating faster and more accurate diagnoses.

Moreover, such representations can aid in inventory management. By knowing the specific parts that make up a system, individuals can ensure that necessary replacements are readily available, minimizing downtime during repairs.

In educational contexts, these visuals serve as valuable learning aids. They help students and new technicians grasp the intricacies of machinery, promoting a deeper understanding of mechanical systems and their operations.

Common Components of the Ttr 110

This section explores the essential elements found in a popular off-road motorcycle, focusing on their functionality and significance in enhancing performance and reliability.

- Engine: The heart of the machine, responsible for providing power and torque for various terrains.

- Transmission: This system ensures smooth gear shifting, allowing for better control during rides.

- Suspension: A crucial feature that absorbs shocks and provides stability, contributing to a comfortable riding experience.

- Brakes: Essential for safety, these components ensure effective stopping power under different conditions.

- Wheels: Designed for durability, they support traction and handling on various surfaces.

Understanding these key components aids in maintaining and enhancing the overall performance of the motorcycle, ensuring a better riding experience.

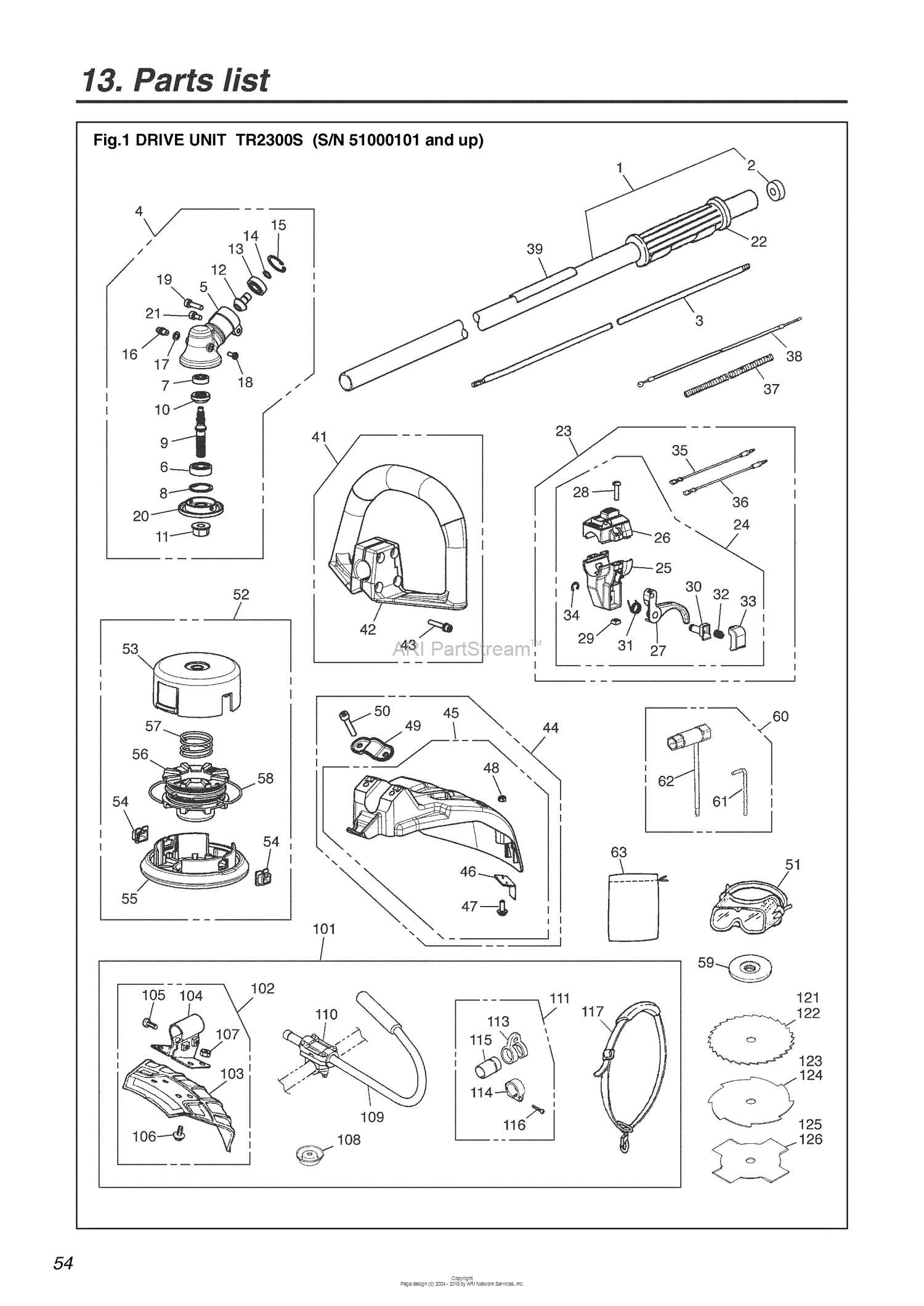

Step-by-Step Assembly Guide

This section provides a comprehensive approach to assembling the essential components of a specific vehicle model. Following these steps will ensure a smooth and efficient process, leading to optimal performance.

Preparation and Tools

Before starting, gather all necessary tools and components. Having everything organized will make the assembly process more efficient. Ensure your workspace is clean and free of distractions.

Assembly Steps

Begin the assembly by following these detailed steps:

| Step | Description |

|---|---|

| 1 | Attach the main frame components securely. |

| 2 | Install the engine and ensure proper alignment. |

| 3 | Connect the electrical wiring carefully. |

| 4 | Fit the suspension parts for stability. |

| 5 | Finalize the assembly by tightening all screws and bolts. |

Following this guide will help achieve a well-assembled unit ready for use. Pay attention to each step to ensure reliability and safety.

Troubleshooting Common Issues

When dealing with mechanical devices, it’s common to encounter a variety of challenges that may hinder optimal performance. This section aims to provide a comprehensive approach to diagnosing and resolving frequent problems that users may face. Understanding these issues can lead to effective solutions and enhance the overall functionality of the equipment.

Identifying Performance Problems

One of the first steps in addressing any malfunction is to observe how the machine operates under various conditions. If it fails to start or runs inconsistently, check for any signs of wear or damage in key components. Regular maintenance can significantly reduce these occurrences.

Addressing Mechanical Failures

In cases where physical components are not functioning correctly, it is crucial to inspect connections and alignments. Loose or misaligned parts can cause significant disruptions. Consulting the user manual for specific maintenance recommendations can often clarify the necessary adjustments or replacements needed.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of any mechanical device. Regular attention and care not only enhance performance but also prevent potential issues before they arise. Here are some key strategies to consider for maintaining your equipment effectively.

Regular Inspections

Conducting frequent evaluations helps identify wear and tear early on. Make it a habit to check the following components:

- Tires: Look for signs of damage or uneven wear.

- Brakes: Ensure they respond well and show no signs of excessive wear.

- Fluid Levels: Check oil, coolant, and other essential fluids regularly.

Scheduled Maintenance

Adhering to a routine maintenance schedule can significantly extend the life of your machinery. Consider implementing these practices:

- Change oil and filters according to the manufacturer’s recommendations.

- Clean air filters and replace them as necessary.

- Lubricate moving parts to reduce friction and wear.

By following these maintenance tips, you can ensure that your machinery remains in optimal condition, ultimately leading to a longer and more reliable service life.

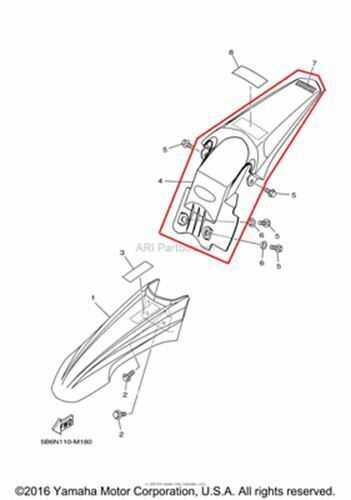

Identifying Parts by Number

Understanding components through their numerical designations is crucial for effective maintenance and repairs. This approach allows users to pinpoint specific elements within their machinery, ensuring accurate identification and sourcing. By referencing a numerical system, individuals can streamline the process of locating the required components, enhancing overall efficiency.

Each number corresponds to a distinct element, often outlined in a reference guide. These guides serve as valuable resources, offering clarity and preventing confusion during the identification process. Users can quickly navigate to the desired item, making informed decisions when purchasing or replacing components.

Moreover, utilizing numerical identifiers promotes consistency across various platforms and suppliers. This standardization aids in minimizing errors and misunderstandings, ultimately contributing to a smoother workflow. Embracing this systematic approach can significantly enhance the effectiveness of maintenance tasks.

Replacing Worn Components

Regular maintenance of mechanical systems is crucial for optimal performance and longevity. Over time, certain elements may show signs of wear, which can affect the overall efficiency of the equipment. Addressing these issues promptly ensures smooth operation and prevents further damage.

Identifying components that require replacement involves a thorough inspection of the system. Look for signs such as unusual noises, decreased performance, or visible deterioration. Once worn parts are pinpointed, selecting high-quality replacements is essential to maintain the integrity of the machine.

The replacement process typically involves disassembling relevant sections to access the worn components. Following the manufacturer’s guidelines is vital for proper installation and alignment. After replacing the parts, conducting a test run is recommended to confirm that the system operates smoothly and effectively.

Upgrades and Modifications Available

Enhancing your vehicle’s performance and aesthetics can significantly improve your riding experience. Various options allow enthusiasts to customize their machines, focusing on both functionality and style. Below are some popular upgrades and modifications that can elevate your ride.

Performance Enhancements

- Exhaust System: Upgrading to a high-performance exhaust can increase horsepower and improve sound quality.

- Air Filter: Installing a premium air filter improves airflow, enhancing engine efficiency.

- Suspension Kit: A better suspension setup provides improved handling and comfort on rough terrain.

Aesthetic Modifications

- Custom Graphics: Unique decals and graphics can personalize the appearance of your vehicle.

- LED Lighting: Adding LED lights can enhance visibility and give a modern touch.

- Seat Upgrade: A more comfortable seat not only looks better but also enhances rider comfort during long rides.

Where to Find Replacement Parts

Finding suitable components for your vehicle is essential to maintain its performance and longevity. Various options are available for sourcing these necessary items, ensuring you can keep your machine in optimal condition.

Online Retailers

The internet offers a vast array of shops specializing in vehicle components. These platforms often provide detailed descriptions and customer reviews to help guide your purchasing decisions.

- Search for dedicated automotive websites.

- Utilize auction sites for used components.

- Explore e-commerce giants for competitive pricing.

Local Dealerships and Repair Shops

Local businesses can be a reliable source for quality components. Building a relationship with these establishments can offer additional benefits, such as personalized service and expert advice.

- Visit nearby dealerships for original items.

- Consult with mechanics for recommendations on trusted suppliers.

- Check local repair shops for inventory or referrals.

Visual Aids for Assembly

Effective visual aids play a crucial role in the assembly process, enhancing understanding and improving efficiency. These resources simplify complex instructions and provide clear representations of components and their arrangements.

- Diagrams: Detailed illustrations showcasing each element’s placement and connections.

- Charts: Organized tables that outline assembly steps in a sequential manner.

- Videos: Visual demonstrations that guide users through the assembly process in real-time.

- Interactive Tools: Software applications that allow users to explore 3D models and visualize the assembly.

By incorporating these tools, users can navigate the assembly process with greater confidence and accuracy, ultimately leading to successful outcomes.

Safety Precautions During Repairs

When engaging in maintenance or restoration tasks, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to recommended guidelines ensures a secure environment for both the technician and the equipment being serviced.

Personal Protective Equipment

Utilizing appropriate protective gear, such as gloves, goggles, and masks, is essential. This equipment safeguards against potential hazards, including sharp edges and harmful substances, thereby enhancing overall safety during the repair process.

Workspace Organization

A well-organized workspace minimizes risks associated with clutter and disarray. Keeping tools and materials in designated areas not only improves efficiency but also reduces the likelihood of accidents, allowing for a more focused and safer working environment.