The inner workings of small off-road machines involve various elements that ensure smooth operation and reliability. Understanding how these elements interact can offer valuable insights for maintaining and enhancing performance. This section provides an overview of the critical components that come together to form the foundation of such a vehicle, focusing on how each piece contributes to the overall functionality.

Whether you’re involved in regular upkeep or preparing for repairs, having a clear understanding of how the mechanical aspects fit together is essential. By breaking down the essential elements and their roles, we aim to simplify complex technical details, allowing for more effective maintenance and a deeper comprehension of the machine’s design.

As we delve into the specific features and functions of these essential pieces, you’ll gain a better grasp of how to approach different mechanical challenges. This knowledge is crucial for ensuring long-term performance and

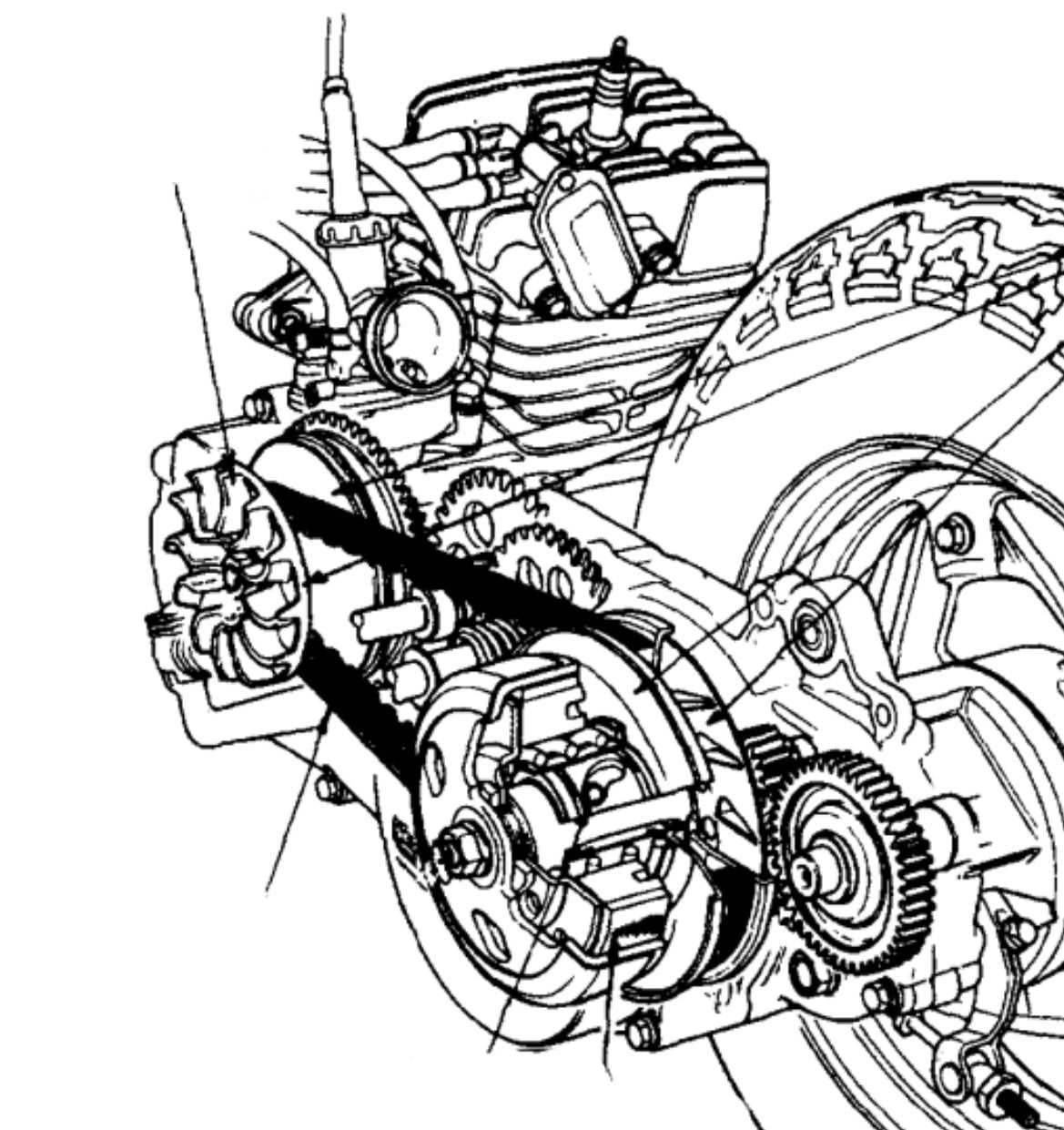

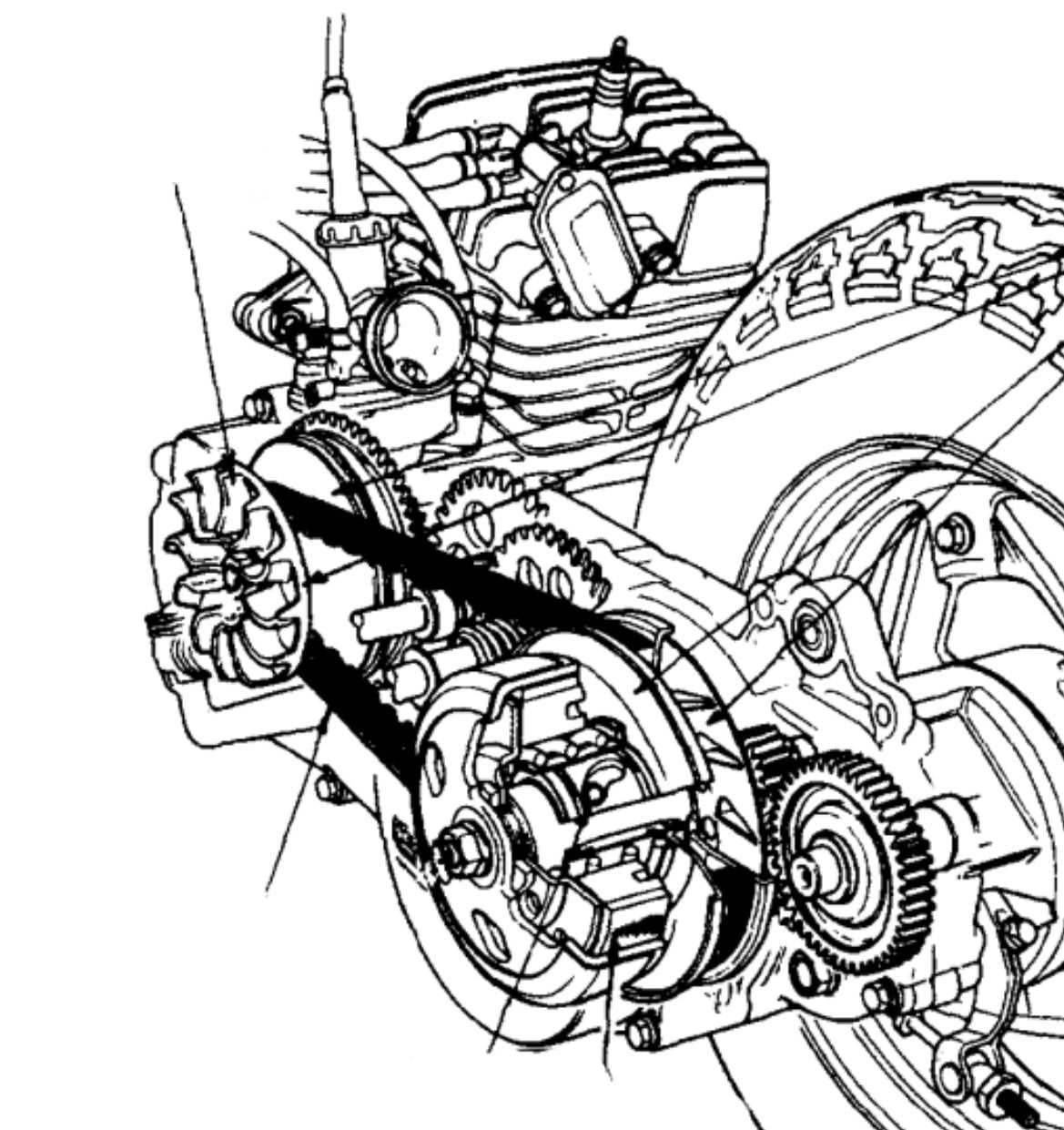

Understanding the Structure of Key Components

The functionality of mechanical systems relies on the interplay between various crucial elements. By examining these integral sections, one can gain insights into how each piece contributes to the overall performance and stability. Each element is meticulously designed to ensure durability, efficiency, and safety, working together to deliver optimal results.

Frame and Support Mechanisms

At the core of the structure lies the frame, which provides essential support and balance. This foundation is crucial as it ensures the system maintains its shape and withstands external forces. Paired with other stabilizing components, the frame enhances both stability and control.

Motion and Control Elements

Key elements responsible for motion and control are designed with precision to ensure smooth and reliable movement. These components interact closely with other parts, translating power into action while maintaining responsiveness and accuracy in operation.

Identifying the Function of Core Elements

Understanding the role of individual components in a system is essential for ensuring optimal performance and maintenance. Each element has a distinct purpose, contributing to the overall functionality of the mechanism. By analyzing the key elements and their interactions, one can gain insight into how the entire system operates and make informed decisions when troubleshooting or performing upgrades.

For instance, mechanical elements are often responsible for movement and stability, while electrical components manage power flow and control. By identifying these core functions, it becomes easier to assess the condition of the entire system and address any potential issues before they escalate.

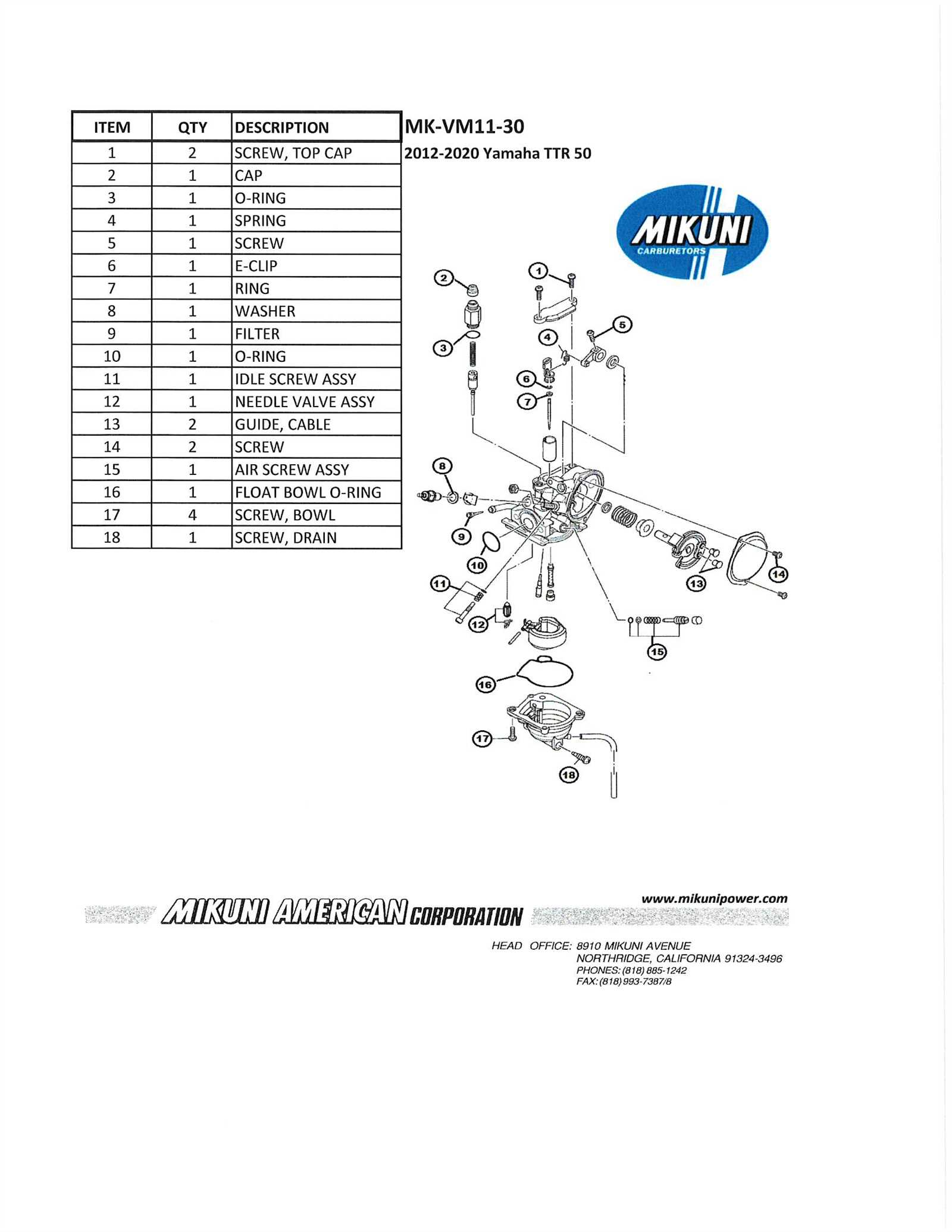

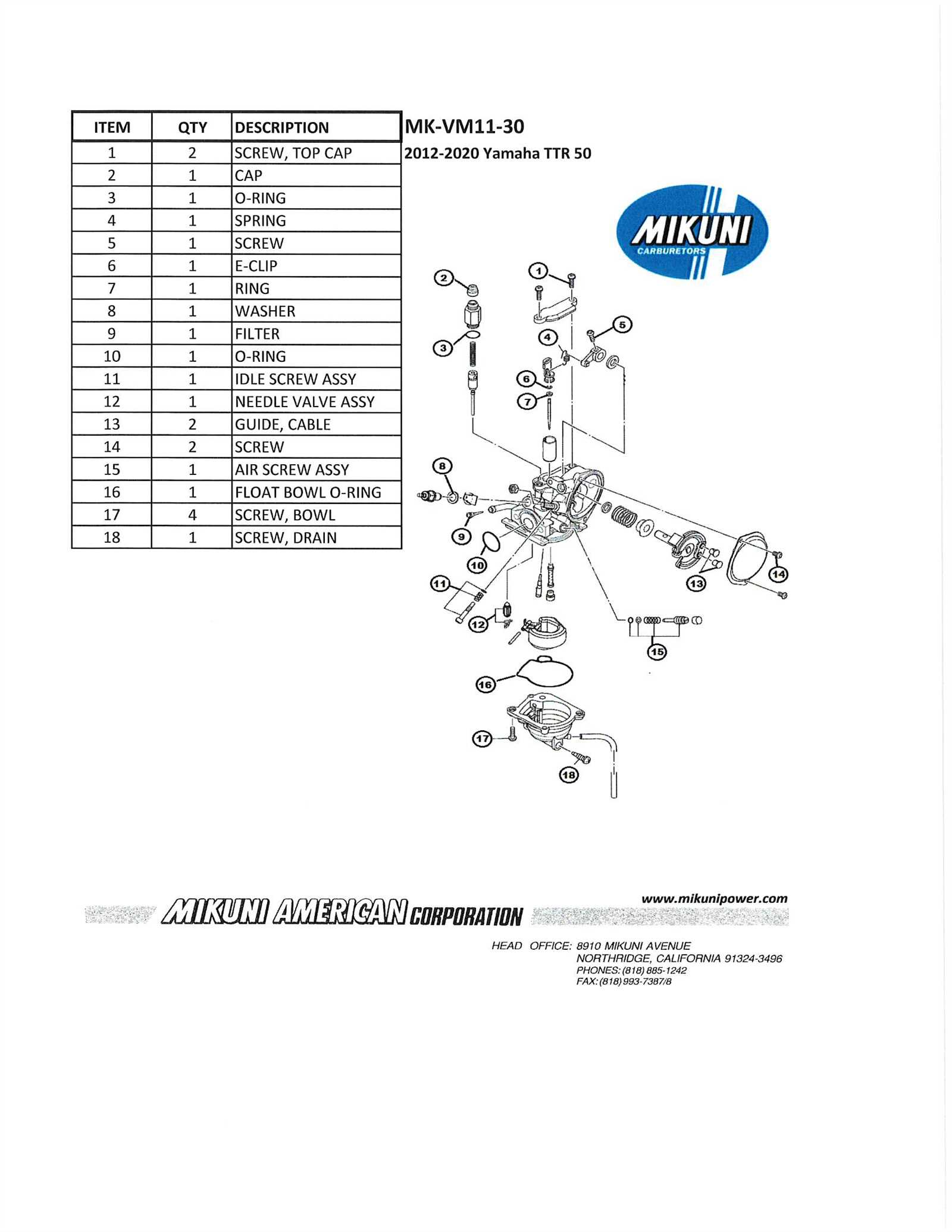

Exploring the Assembly Layout

Understanding how different elements are positioned within a mechanical structure is essential for effective maintenance and troubleshooting. By examining the layout, one can gain insights into the arrangement and interaction of various components, allowing for smoother reassembly and ensuring that all elements function together as intended.

Component Placement Overview

The configuration of individual units within the overall structure provides clarity on how each part supports the others. Identifying key positions within the framework helps pinpoint areas that may require more attention during assembly or repair. This methodical approach reduces the risk of misalignment or improper fitting.

Connecting Elements and Their Role

The precise alignment of connectors and fasteners plays a crucial role in maintaining the integrity of the entire structure. Each link between the parts serves a specific purpose, ensuring stability and seamless operation. Properly understanding the connection points can enhance the durability and performance of the system.

Guide to Critical Mechanical Parts

Understanding key elements of mechanical systems ensures reliable performance and maintenance. This section highlights the most essential components that contribute to functionality and efficiency, providing clarity on their individual roles within the overall framework.

- Engine Assembly: The core unit that drives the system, converting energy into motion. Proper functioning is essential for optimal performance.

- Transmission System: This setup ensures smooth power delivery and controls speed and torque. Key for efficient energy transfer.

- Suspension Mechanism: Vital for managing stability and comfort during operation, helping absorb impacts and maintain balance.

- Brake Configuration: Responsible for controlling motion and providing safety, ensuring the ability to decelerate or stop effectively when needed.

- Exhaust Pathway: Manages the removal of gases and heat, keeping the system running efficiently while minimizing harmful emissions.

Each

Locating Key Fasteners and Connectors

Understanding the placement of critical fasteners and connectors is essential for efficient assembly and maintenance. Identifying these elements ensures a smooth process, minimizing risks of misalignment or improper installation. This section provides a detailed overview of where to find the primary connection points for secure attachment.

Fastener Locations

To ensure the stability of the structure, key fasteners are strategically placed in areas requiring maximum support. These points are typically distributed across the frame to provide balanced weight distribution. Correct identification of each fastener ensures that the assembly remains robust and reliable under various conditions.

| Fastener Type |

Location |

Function |

| Hex Bolt |

Front Mount |

Secures the primary structural component |

| Locking Nut |

Rear Section |

Prevents loosening under vibration |

Analyzing Component Placement and Positioning

Understanding how various elements are arranged is crucial for ensuring optimal functionality and ease of maintenance. The location and orientation of each piece play a significant role in the overall efficiency and performance of the system. A careful examination of their layout can help identify potential areas for improvement or adjustment.

- Strategic alignment contributes to the overall stability and longevity of the system.

- Proper orientation minimizes interference between moving or interacting parts.

- Efficient spacing allows for better heat dissipation and airflow management.

- Well-planned positioning improves accessibility for inspection and maintenance tasks.

By thoroughly analyzing the arrangement, one can optimize the performance and durability of the entire setup, ensuring that all components work harmoniously together.

Breakdown of Moving Parts

In this section, we explore the dynamic components that contribute to the system’s mechanical operation. These essential elements are responsible for ensuring smooth motion and interaction within the assembly. Understanding their arrangement and function is key to maintaining the overall efficiency and performance of the entire mechanism.

Key Components in Motion

The main elements in motion consist of interconnected mechanisms that rely on each other to function properly. Each element plays a crucial role, from managing rotational movement to facilitating proper alignment and interaction. Together, these components create a seamless flow that powers the system.

Ensuring Optimal Performance

For continuous and reliable functionality, regular checks of these elements are essential. Maintaining the correct alignment, lubrication, and condition of the dynamic parts can significantly prolong the life of the system. Paying attention to wear and tear ensures

How Specific Sections Interact

Understanding the relationship between various components is crucial for efficient system operation. Each area of the system plays a distinct role, yet their functions are closely intertwined, contributing to the overall performance. By examining how these elements collaborate, we can gain insights into improving functionality and maintenance.

Collaboration of Mechanical Elements

The interaction between different mechanical elements is essential for ensuring smooth operation. Each section is designed to engage with others, providing support and facilitating movement. Proper alignment and synchronization are necessary to avoid wear and enhance the longevity of the system.

Coordination of Electrical Elements

Electrical components must operate in harmony to ensure consistent power distribution and signal transmission. The proper configuration of these sections allows for efficient energy flow, while any misalignment can lead to system faults. Understanding their dynamic relationship is key to optimizing performance.

Visualizing Electrical Connections

Understanding the layout of electrical pathways is crucial for effective troubleshooting and maintenance. By representing these links in a clear and concise manner, one can easily identify potential issues and comprehend the overall system architecture. This visualization serves as a fundamental tool for technicians and enthusiasts alike, enhancing their ability to navigate complex circuits.

Utilizing schematic representations allows for a straightforward interpretation of how various components interact. Each connection and its respective function become apparent, providing insights into the flow of current and the role of each element within the configuration. Such illustrations facilitate a deeper understanding of electrical systems, enabling more efficient repairs and modifications.

Incorporating color coding and symbols into these representations further aids in the interpretation process. Distinct colors can signify different types of connections or signals, while standardized symbols offer quick recognition of components. This not only speeds up the analysis but also reduces the likelihood of errors during repairs or upgrades, promoting a more systematic approach to working with electrical configurations.

Mapping Fluid and Fuel Systems

Understanding the layout and functionality of liquid transport and energy delivery mechanisms is essential for optimal performance. This section delves into the intricate relationships between various components, highlighting their roles in ensuring efficiency and reliability.

Key Components Overview

- Tanks: Store fluids safely, ensuring that the supply is adequate for operational needs.

- Pumps: Facilitate the movement of liquids through the system, maintaining the necessary flow rate.

- Hoses and Tubes: Provide pathways for fluid transfer, designed to withstand pressure and prevent leaks.

- Filters: Remove impurities, ensuring that only clean fluid reaches critical components.

- Valves: Control the flow and direction of liquids, enabling precise management of resources.

Flow Management and Efficiency

Efficient routing of fluids is crucial for minimizing waste and optimizing performance. Consider the following:

- Regular inspection of components to detect wear and potential failures.

- Use of high-quality materials to enhance durability and prevent leaks.

- Monitoring fluid levels and pressures to ensure proper operation.

- Implementing a systematic maintenance schedule to prolong the lifespan of all systems.

Maintenance Tips for Essential Parts

Ensuring the longevity and optimal performance of your vehicle requires consistent attention to its fundamental components. Regular maintenance not only enhances functionality but also prevents costly repairs down the line. Below are some key practices to keep in mind when caring for these vital elements.

- Regular Inspections: Frequently check for wear and tear. Look for any signs of damage or corrosion, which could indicate a need for replacement or repair.

- Cleanliness: Keep the components free of dirt and debris. Regular cleaning can prevent the buildup of grime that may hinder performance.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction. This will enhance efficiency and prolong the life of the components.

- Tightening Bolts and Fasteners: Ensure all screws and bolts are secure. Loose fasteners can lead to instability and potential failure.

- Follow Manufacturer Guidelines: Always adhere to the maintenance schedules provided by the manufacturer. These recommendations are tailored to optimize performance.

By implementing these practices, you can ensure that essential elements function smoothly, enhancing the overall experience and reliability of your vehicle.

Optimizing Longevity Through Proper Care

Maintaining the functionality and extending the lifespan of your equipment requires regular attention and appropriate maintenance practices. By implementing a few essential care routines, you can ensure optimal performance and reduce the risk of wear and tear. Understanding the components and their roles can significantly enhance the overall reliability of your machinery.

Routine Maintenance Tasks

Establishing a schedule for routine maintenance is vital. Regularly inspecting key areas and performing necessary upkeep can prevent minor issues from escalating into significant problems. Below are some recommended maintenance tasks:

| Maintenance Task |

Frequency |

Description |

| Fluid Check |

Monthly |

Inspect and top up essential fluids to ensure proper operation. |

| Cleaning |

Weekly |

Remove dirt and debris from critical areas to prevent buildup. |

| Part Inspection |

Quarterly |

Check for signs of wear or damage in essential components. |

| Lubrication |

Biannually |

Apply appropriate lubricants to moving parts to reduce friction. |

Storage Recommendations

Proper storage is equally important for preserving the integrity of your machinery. Keeping equipment in a clean, dry environment shields it from moisture and contaminants. Additionally, using protective covers can prevent dust accumulation and potential damage.