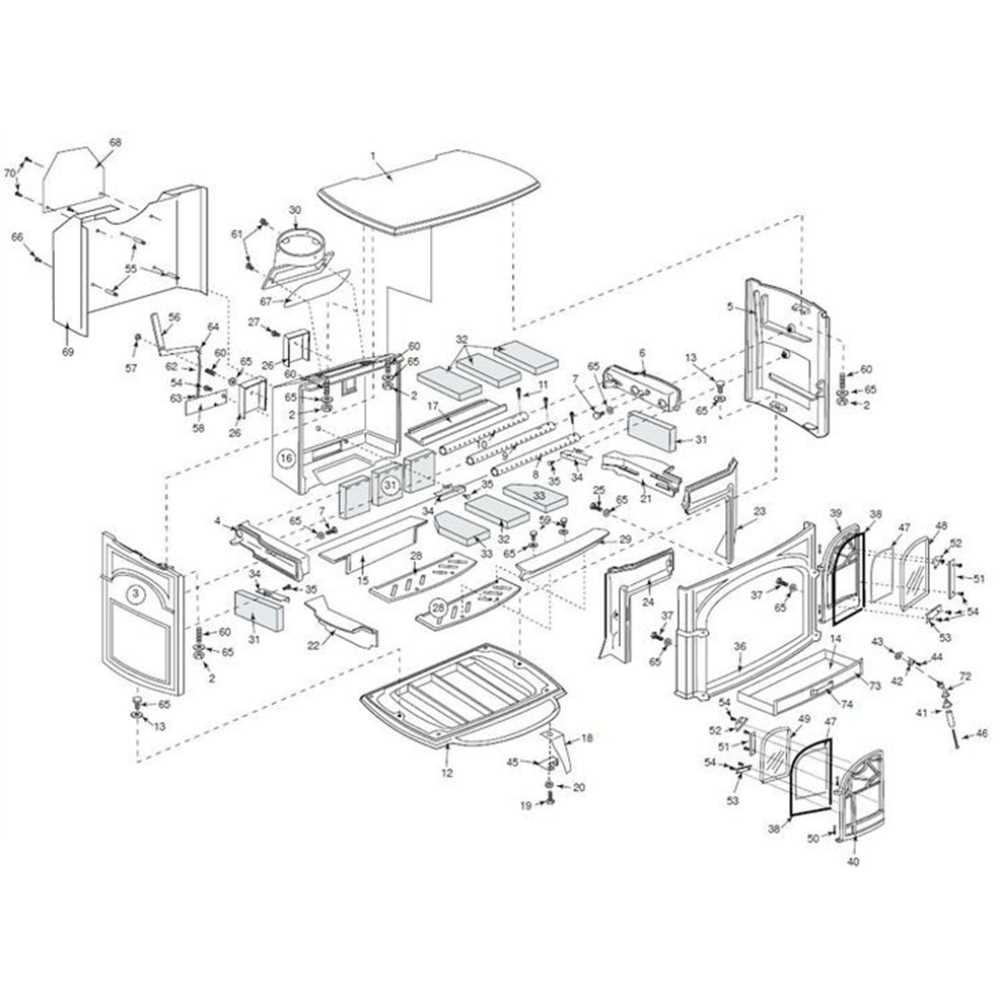

Understanding the intricate construction and organization of heating equipment is crucial for effective maintenance and repair. Each element plays a specific role in ensuring optimal performance, making it essential to familiarize yourself with the internal setup of such systems. Knowing how different parts interact can greatly enhance the longevity and efficiency of the equipment.

This section will delve into the core elements of these systems, offering a clear and detailed breakdown of their structure. By grasping the layout and function of key components, users can navigate troubleshooting and upkeep with greater confidence and precision.

Vermont Castings Defiant Parts Overview

This section focuses on the components that make up the structure and functionality of a premium heating appliance. Each element plays a critical role in ensuring the effective operation and durability of the unit. By understanding the purpose of these pieces, users can maintain and enhance their equipment’s performance.

| Component | Function | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main Chamber | The central area where the fuel is burned to generate heat. | ||||||||||||||||||||

| Firebox Door | A door that provides access to the interior, ensuring safe and controlled combustion. | ||||||||||||||||||||

| Grate | Supports the fuel, allowing airflow from below to promote efficient burning. | ||||||||||||||||||||

| Ash Pan | A removable container designed to collect ash for easy disposal. | ||||||||||||||||||||

| Air Intake Control | Manages the amount of oxygen entering the system, adjusting the intensity of the fire. | ||||||||||||||||||||

| Flue Collar | Connects the stove to the chimney,

Main Components of the Vermont Defiant Stove

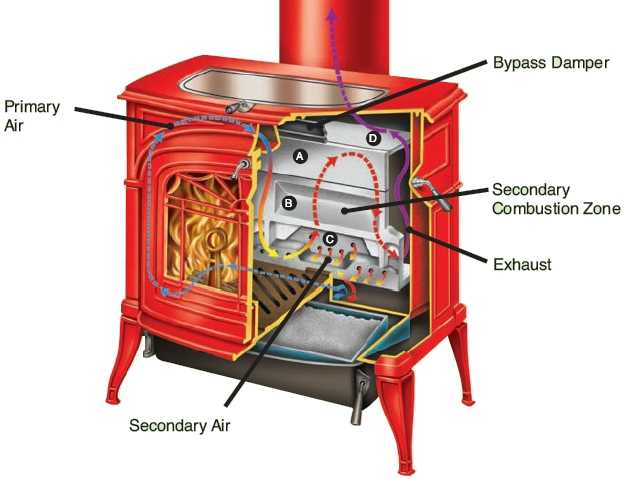

The stove in question is designed with a combination of essential elements that ensure efficient operation and durability. These features work together to manage heat, airflow, and combustion, providing users with a reliable heating solution.

Each of these components is built to withstand high temperatures and ensure long-lasting performance in various environments. Firebox Structure and FunctionalityThe firebox plays a crucial role in the overall operation of a heating system, providing a dedicated space for combustion. It ensures efficient burning by containing and regulating the heat generated. Understanding how this compartment is designed and its purpose helps in maintaining optimal performance of the unit. Construction materials are essential to the durability and heat resistance of the firebox, enabling it to withstand extreme temperatures. These materials often include high-quality metals or refractory elements that enhance the longevity and safety of the unit. In terms of functionality, the firebox is designed to maximize heat retention while minimizing energy loss. Its structure ensures that air circulates properly, contributing to a more efficient burn, which in turn leads to a more consistent heating experience. Overall, a well-maintained firebox ensures both safety and efficiency, making it a vital component of any heating system. Air Control System and Regulation

The air control system is essential for optimizing the performance and efficiency of heating devices. By regulating airflow, it ensures proper combustion and heat distribution, which directly impacts energy consumption and overall operation. Proper adjustment of the air intake allows for better temperature control and reduces emissions, making the system more environmentally friendly.

Understanding the Ash Management System

An effective ash management system plays a crucial role in maintaining the efficiency and cleanliness of your heating appliance. This system is designed to collect and store ash in a way that minimizes user intervention while ensuring the device functions optimally. Proper handling of ash not only simplifies maintenance but also enhances the overall safety of the unit. Key Components of Ash CollectionThe ash management system typically includes a dedicated tray or compartment where ash is gathered during the combustion process. These components are designed for easy removal and cleaning, reducing the need for frequent maintenance. The system ensures that ash is contained securely, preventing it from spreading or obstructing air flow. Safe Ash Disposal and Maintenance

For safe operation, it’s essential to regularly empty the ash collection compartment. Ash should be allowed to cool completely before disposal to avoid safety risks. Additionally, routine checks of the tray ensure that the system remains in proper working order, supporting consistent performance and safety over time. Combustion Chamber Parts BreakdownThe combustion chamber is a crucial component of any heating appliance, as it is where the fuel is ignited to generate heat. Understanding the various elements that make up this space is essential for effective maintenance and troubleshooting. Key Components

Functionality Overview

Gasket and Sealing ElementsIn the realm of heating appliances, the integrity of gaskets and sealing components plays a pivotal role in ensuring optimal performance and efficiency. These elements are designed to create airtight and watertight seals, preventing any leakage of gases or fluids that could compromise the unit’s functionality. Proper maintenance and timely replacement of these components are crucial for the longevity of the system. Types of Gaskets

Various types of gaskets are utilized in heating equipment, each tailored to meet specific operational demands. The choice of material and design is essential for ensuring the longevity and effectiveness of the seals. Below is a table outlining some common gasket types and their applications.

Importance of Proper Sealing

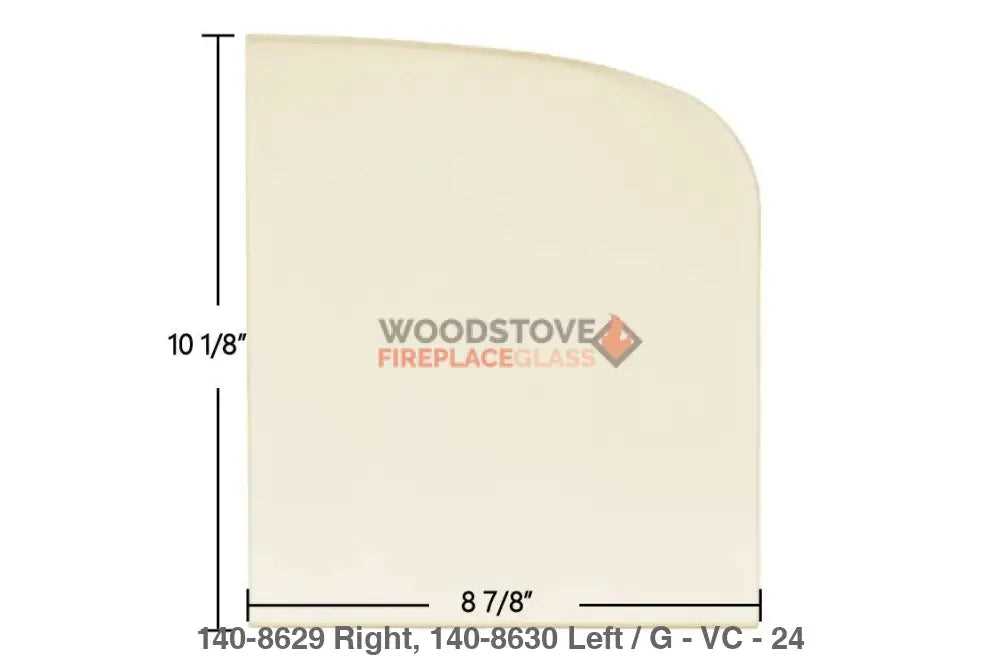

Ensuring the effectiveness of sealing elements is vital for the safe operation of heating systems. A compromised seal can lead to energy loss, increased emissions, and potential safety hazards. Regular inspection and replacement of worn-out gaskets can enhance performance and prevent costly repairs in the long run. Glass Door and Viewing Window

The transparent panel and access entry play a crucial role in enhancing both the aesthetic appeal and functionality of a heating appliance. These components not only provide a glimpse of the internal fire activity but also contribute to the overall design, allowing users to enjoy the warmth and ambiance of the flames. Constructed from high-quality materials, the viewing section is designed to withstand high temperatures while ensuring safety. The innovative design facilitates easy operation, allowing for effortless opening and closing, thereby maximizing convenience during use. Additionally, the framework surrounding the glass elements often includes features that help maintain efficiency, reducing heat loss while providing a clear view of the fire. Regular maintenance of the glass and surrounding framework is essential for optimal performance. Cleaning the surface periodically ensures clarity and enhances the visual experience. It is important to inspect for any wear or damage, as maintaining the integrity of these components directly affects the overall functionality and safety of the appliance. Exploring the Grate and Hearth Plate

The interaction between the components within a heating appliance plays a crucial role in its overall efficiency and functionality. One of the key elements in this system is the support structure that holds the fuel and facilitates the combustion process. Understanding this area can enhance the performance and longevity of the unit. Grate serves as the foundation for fuel placement, allowing for optimal airflow and combustion. It is essential to ensure that this component is in good condition, as wear and tear can significantly affect heating efficiency. Regular inspection and maintenance can prevent issues that may arise from a deteriorating grate. Hearth plate, on the other hand, provides a protective barrier between the heat source and the appliance’s structure. It is designed to withstand high temperatures and should be checked periodically for any signs of damage or degradation. A well-maintained hearth plate not only enhances safety but also contributes to the effective distribution of heat within the space. Identifying the Baffle Components

Understanding the elements of the heat regulation system is crucial for optimal performance. The baffle plays a significant role in managing airflow and maintaining efficient combustion within the unit. Familiarizing oneself with these components allows for better maintenance and improved operation.

Recognizing these elements not only enhances the functionality but also contributes to the longevity of the entire heating apparatus. Handle and Door Latch Mechanisms

The operation of entrance closures relies heavily on the functionality of the gripping and securing components. These mechanisms are essential for ensuring that the door operates smoothly while providing security and convenience for users. Understanding the design and role of these elements is crucial for effective maintenance and troubleshooting. Components of Gripping Mechanisms

Gripping devices are designed to allow users to easily open and close doors. They come in various forms, including levers and knobs, each providing different levels of comfort and ease of use. The material and shape of these components can significantly influence the user experience, making it important to choose the right type based on personal preference and aesthetic considerations. Securing Mechanisms Functionality

Securing devices are vital for maintaining the safety of an enclosure. These mechanisms engage when the door is closed, preventing unauthorized access and ensuring that the door remains in place during use. Proper installation and maintenance of these securing elements are necessary to guarantee their reliable operation over time. Heat Shields and Insulation Features

Effective thermal management is essential in any heating appliance. Properly designed components ensure that heat is retained where needed while preventing excess warmth from escaping to unintended areas. These features play a crucial role in maintaining efficiency and safety.

By integrating these elements, heating appliances can operate more effectively, providing optimal warmth while safeguarding the integrity of the surrounding environment. Replacement Parts and Maintenance Tips

Ensuring optimal performance of your heating appliance requires a solid understanding of its components and how to care for them. Regular upkeep not only prolongs the lifespan of the device but also enhances efficiency. This section provides essential insights into acquiring necessary components and practical suggestions for maintaining your unit. Identifying Necessary Components: When considering replacements, it is crucial to accurately identify which elements require attention. Consult the user manual for specific references and use online resources or expert consultations to assist in selecting the right items. Reliable suppliers often provide high-quality alternatives that meet or exceed original specifications. Routine Maintenance Practices: Implementing a consistent maintenance schedule is vital. Regularly check for signs of wear or damage, such as cracks or discoloration. Cleaning the internal mechanisms and external surfaces helps maintain efficiency. Additionally, ensure that all seals and gaskets are intact to prevent heat loss. Professional Inspections: It is advisable to engage professionals for periodic assessments. Experts can identify potential issues before they become significant problems, saving time and resources. Consider scheduling these inspections at the start of each heating season for optimal performance. Documentation and Records: Keeping detailed records of all replacements and maintenance tasks aids in tracking the history of the appliance. This information can be invaluable for future repairs or when seeking assistance from service providers. |