In the realm of heavy machinery, comprehending the intricate relationships between various elements is crucial for effective maintenance and operation. Each unit comprises numerous components, each playing a pivotal role in ensuring optimal performance. By delving into these individual parts, one can gain a clearer understanding of the entire system’s functionality.

Illustrations of component arrangements serve as invaluable resources for technicians and operators alike. They provide a visual reference that simplifies the identification and troubleshooting processes. Such guides not only enhance familiarity with the machinery but also promote efficient repairs and adjustments.

Moreover, an in-depth exploration of the specific elements involved allows for better preparation and planning when it comes to servicing. Recognizing how each part interacts within the larger mechanism can lead to improved reliability and longevity of the equipment. Thus, mastering this knowledge is essential for anyone engaged in the field.

Understanding the Wacker BS50-4

The compact and efficient machine is designed for various applications in construction and landscaping. It provides a reliable solution for soil compaction, making it an essential tool for professionals seeking to achieve optimal results in their projects.

This device is known for its durability and ease of use, featuring a robust engine that powers its performance. Operators appreciate its ergonomic design, which enhances comfort and control during operation, allowing for extended use without fatigue.

Maintenance is crucial for longevity, and familiarizing oneself with the inner workings of this equipment ensures that it runs smoothly and efficiently. Understanding its components will ultimately lead to improved performance and reduced downtime.

Overview of Wacker BS50-4 Features

This section provides a comprehensive look at the key characteristics of a highly efficient compacting machine designed for optimal performance. Its innovative design integrates powerful components, ensuring reliability and ease of use in various applications.

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a robust engine that delivers exceptional compaction force. |

| Ergonomic Design | Features an ergonomic handle for user comfort and better control during operation. |

| Durability | Constructed from high-quality materials, ensuring longevity even in tough conditions. |

| Versatile Applications | Suitable for a wide range of tasks, from soil compaction to asphalt preparation. |

| Easy Maintenance | Designed for straightforward maintenance, reducing downtime and enhancing productivity. |

Importance of Parts Diagrams

Understanding the intricate details of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for technicians, providing clarity on the various components and their interrelations. These illustrations enhance comprehension, enabling users to identify specific elements quickly and efficiently.

Facilitating Maintenance

Regular upkeep is vital for the longevity and performance of equipment. Having a visual guide allows professionals to pinpoint wear and tear, ensuring that they can address issues before they escalate. This proactive approach not only saves time but also reduces costs associated with extensive repairs.

Streamlining Repairs

When a breakdown occurs, the ability to reference an illustration can significantly speed up the troubleshooting process. Technicians can locate malfunctioning parts swiftly, facilitating targeted interventions. Moreover, these guides often include exploded views that simplify the assembly and disassembly processes, promoting greater efficiency in repairs.

In summary, these visual resources are indispensable for anyone involved in the upkeep and restoration of machinery, leading to improved functionality and reduced downtime.

Common Parts for the Wacker Model

This section focuses on the essential components commonly found in various models, highlighting their functions and significance in ensuring optimal performance. Understanding these elements can aid in maintenance and troubleshooting, making it easier to keep machinery running smoothly.

Key Components

Among the vital elements, the engine plays a crucial role in providing power and efficiency. It is often accompanied by a fuel system that ensures proper delivery and combustion. Additionally, the transmission system is essential for converting power into motion, while the vibration mechanism enhances operation effectiveness in various applications.

Maintenance Essentials

Regular upkeep of components such as filters, belts, and seals is necessary to prolong the lifespan of the machinery. Attention to wear and tear can prevent potential breakdowns and costly repairs, ensuring that each part functions seamlessly within the overall system.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of equipment. These visuals serve as guides, showing components and their arrangement within a machine, enabling users to identify necessary elements easily. Familiarity with these representations can enhance efficiency when seeking replacements or performing assembly tasks.

Start by examining the layout, which typically features labeled sections. Each part is often numbered or marked, corresponding to a reference list that provides further details. Pay attention to any accompanying notes or legends, as they offer valuable context regarding the functionality or specifications of the individual components.

When navigating through these illustrations, it’s helpful to understand common symbols used to represent different types of parts, such as fasteners, electrical elements, and hydraulic components. Recognizing these can streamline the process of locating and ordering the correct items.

Ultimately, a thorough grasp of these technical visuals will empower users to tackle repairs confidently, minimizing downtime and ensuring optimal performance of their machinery.

Key Components of the BS50-4

This section explores the essential elements that contribute to the effective operation of the equipment, highlighting their roles and interconnections.

- Engine: The power source, crucial for delivering the necessary energy for performance.

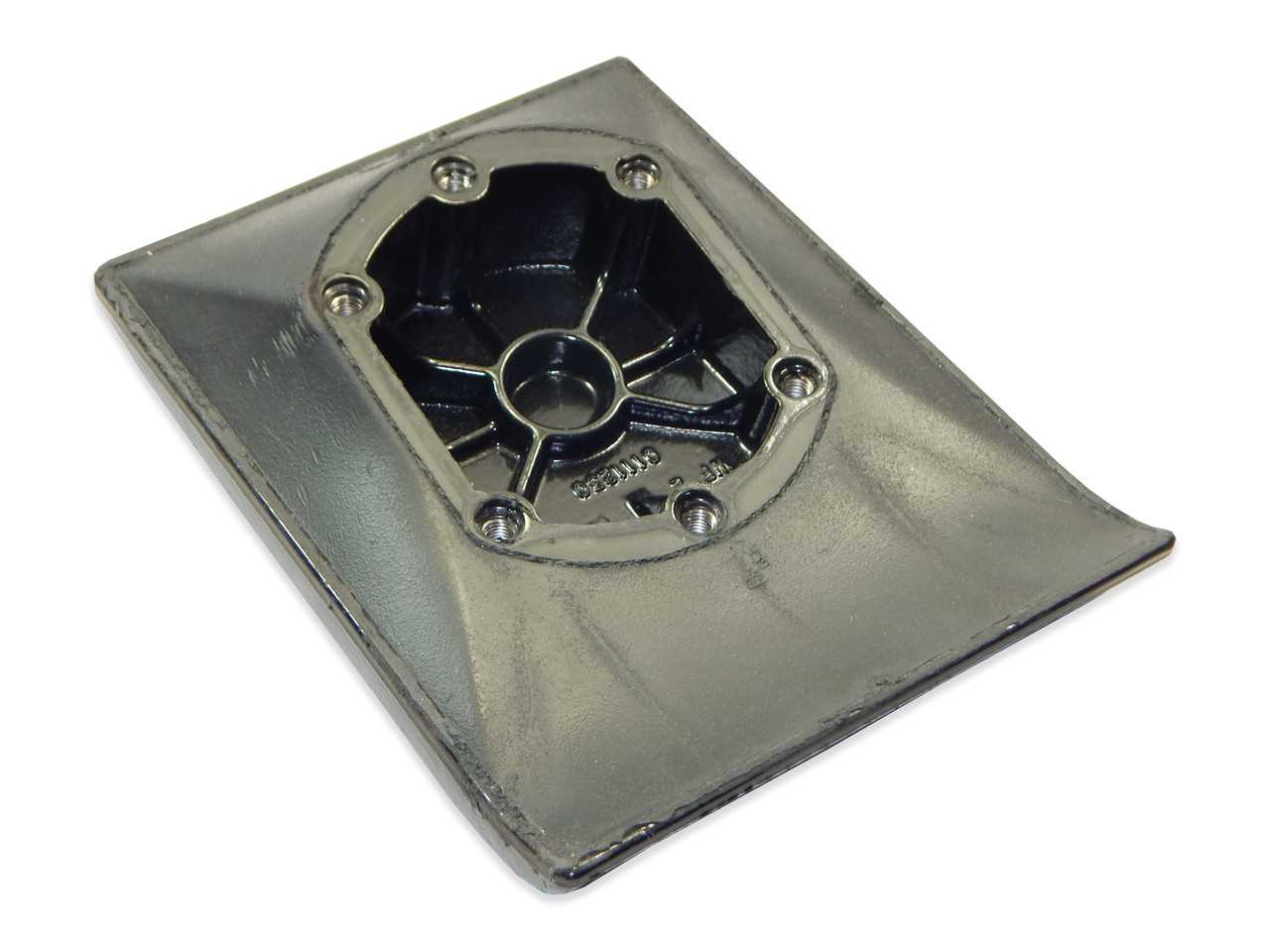

- Base Plate: The foundation that provides stability and support during operation.

- Handle: Designed for easy maneuverability, ensuring operator comfort.

- Vibration System: A mechanism that optimizes performance and minimizes operator fatigue.

- Fuel System: Essential for maintaining engine functionality, including the tank and delivery components.

Understanding these components allows users to appreciate how they interact and contribute to the ultimate efficiency of the machinery.

Maintenance Tips for Longevity

Ensuring the durability and efficient operation of your equipment requires consistent care and attention. Implementing regular maintenance practices can significantly extend its lifespan and enhance performance.

- Regular Inspections: Conduct frequent checks for wear and tear, and address any issues immediately.

- Cleaning: Keep all components free from dirt and debris to prevent clogging and damage.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and prevent corrosion.

- Storage: Store equipment in a dry, sheltered environment to protect it from environmental factors.

- Follow Manufacturer Guidelines: Adhere to recommended maintenance schedules and practices outlined in the user manual.

By following these tips, you can delve into proactive care strategies that contribute to the ultimate functionality and lifespan of your machinery.

Where to Find Replacement Parts

Locating the necessary components for your equipment can be a straightforward task if you know where to look. Accessing the right resources is essential for ensuring optimal performance and longevity of your machinery. Here are some effective avenues to consider when searching for alternatives.

Online Retailers

The internet provides a wealth of options for sourcing components:

- Specialized Websites: Numerous platforms cater specifically to machinery, offering a wide selection of items.

- General E-commerce Sites: Major online retailers often stock a variety of replacement items.

- Auction Sites: These can be valuable for finding rare or discontinued components at competitive prices.

Local Suppliers

Sometimes, a visit to a nearby store can yield faster results:

- Hardware Stores: Many carry basic components and may order specific items upon request.

- Equipment Dealers: Authorized sellers can provide genuine replacements and valuable insights.

- Salvage Yards: Often overlooked, these locations can have hidden gems at a fraction of the cost.

By exploring these options, you can enhance your chances of finding the necessary components quickly and efficiently.

Identifying Wear and Tear Signs

Recognizing the indicators of degradation is crucial for maintaining equipment efficiency and longevity. Early detection of these signs can prevent further damage and costly repairs. This section focuses on common manifestations of wear and tear, providing insights on how to identify them effectively.

Common Indicators

- Visual Damage: Look for cracks, chips, or discoloration on surfaces.

- Unusual Noises: Pay attention to any irregular sounds during operation, such as grinding or rattling.

- Decreased Performance: Notice any reduction in power or efficiency during use.

- Vibrations: Excessive shaking can indicate misalignment or damaged components.

Regular Maintenance Checks

- Inspect equipment regularly for any visible signs of damage.

- Listen for abnormal sounds during operation.

- Monitor performance metrics to identify any declines.

- Check for vibrations and ensure all components are secure.

By staying vigilant and conducting routine inspections, operators can catch issues early and ensure their equipment operates smoothly for years to come.

Tools Needed for Repairs

When it comes to maintaining and fixing machinery, having the right instruments on hand is crucial. The proper tools not only streamline the process but also ensure that repairs are performed safely and effectively. Familiarizing yourself with essential equipment will make tackling any maintenance task much easier.

Basic Hand Tools: A good set of wrenches, screwdrivers, and pliers is fundamental. These tools allow for easy access to various components, enabling adjustments and replacements without hassle. Having both metric and standard sizes on hand is advisable.

Power Tools: Electric drills and impact wrenches can significantly speed up the repair process. They are particularly useful for tasks that require more force or precision, such as loosening stubborn bolts or drilling new holes.

Specialized Equipment: Depending on the specific machinery, certain specialized tools may be necessary. This could include items like torque wrenches for precise tightening or alignment tools to ensure that all parts fit correctly.

Safety Gear: Don’t forget about personal protective equipment. Safety goggles, gloves, and ear protection are essential to keep you safe while working. Prioritizing safety helps prevent accidents and ensures a smoother repair process.

In summary, equipping yourself with the right tools and safety gear is essential for efficient and effective maintenance. By having these instruments at your disposal, you can approach any repair task with confidence and skill.

FAQs About Wacker BS50-4 Parts

This section addresses common inquiries related to components and their maintenance, providing clarity for users and technicians alike. Understanding these aspects can enhance the performance and longevity of your equipment.

- What are the most common issues?

Frequent problems include wear and tear on key components, leading to reduced efficiency. Regular inspection can help identify these issues early.

- Where can I find replacement components?

Replacement items can be sourced from authorized dealers, online retailers, or specialty shops that focus on construction equipment.

- How do I maintain my equipment?

Routine checks and timely replacements of worn parts are essential. Always refer to the user manual for specific maintenance guidelines.

- Are there any upgrades available?

Yes, many suppliers offer enhanced components that can improve functionality. Research compatibility before making upgrades.

Comparing with Other Models

When assessing various machinery within the same category, it is essential to identify the distinguishing features that set each model apart. This comparison not only highlights the strengths and weaknesses of each unit but also assists users in making informed decisions based on specific needs and applications.

Performance can vary significantly among different models, influencing factors like power output and operational efficiency. Some units may excel in compactness and maneuverability, while others prioritize durability and heavy-duty performance.

Features such as vibration control, weight distribution, and user-friendly controls can greatly impact usability. A model that offers enhanced safety features may appeal more to operators who prioritize workplace safety over raw power.

In addition, maintenance requirements often differ, with certain designs allowing for easier access to components, thus reducing downtime. Understanding these variations can help operators choose a machine that aligns with their operational preferences.

Customer Reviews and Experiences

This section highlights the feedback and personal stories from users who have interacted with the equipment in question. Their insights provide valuable information regarding performance, reliability, and overall satisfaction. By examining these experiences, potential buyers can make informed decisions based on real-world usage rather than just specifications.

Many users appreciate the machine’s efficiency and robustness, often noting how it has significantly improved their workflow. Common themes in the reviews include ease of use, maintenance requirements, and the quality of customer support received.

| Reviewer | Experience | Rating |

|---|---|---|

| John D. | Reliable and easy to operate, perfect for construction sites. | 4.5/5 |

| Sarah L. | Powerful performance but requires regular maintenance. | 4/5 |

| Mike R. | Great support team, quick response to queries. | 5/5 |

| Emily T. | Excellent build quality, handles tough jobs with ease. | 4.8/5 |

Overall, the consensus among users suggests a high level of satisfaction, particularly regarding the product’s performance and customer service. These shared experiences offer a comprehensive overview for anyone considering making a purchase.