In the world of machinery, comprehending the arrangement of components is crucial for efficient operation and maintenance. A clear illustration of how various elements interact with each other provides invaluable insights for technicians and operators alike. This understanding not only enhances performance but also aids in troubleshooting potential issues.

Accurate schematics serve as a vital resource, offering a visual representation that simplifies the complexities of mechanical systems. By breaking down intricate designs into manageable segments, users can quickly identify individual parts and their functions. This clarity ultimately supports better decision-making regarding repairs and upgrades.

Moreover, familiarity with these layouts fosters a deeper appreciation for the engineering behind the equipment. Recognizing how each segment contributes to the overall functionality can inspire confidence in operating and maintaining the machinery effectively. In this discussion, we will delve into the specifics of these illustrations, focusing on their significance and practical applications.

Understanding Wacker BTS 1035 Components

In any mechanical device, grasping the individual elements and their functions is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring the overall effectiveness and longevity of the machinery. By exploring these elements, one can appreciate their contributions and better understand the workings of the entire system.

Power Source: The energy provider is fundamental, enabling all operations. Without it, functionality is compromised, making it essential to keep it in optimal condition.

Vibration Mechanism: This feature is responsible for enhancing performance during usage. Understanding its design allows for better maintenance and troubleshooting.

Control System: This aspect regulates various functions, ensuring that the device operates smoothly. A keen knowledge of its components can significantly aid in achieving precise adjustments.

Frame Structure: The chassis supports all parts and influences durability. Recognizing its strength and resilience helps in evaluating the overall robustness of the equipment.

By delving into these components, one can gain insights into their interactions and the ultimate performance of the entire apparatus.

Importance of Parts Diagrams

Visual representations of components play a crucial role in various fields, especially in maintenance and repair activities. They provide a clear overview of how different elements are organized and interact with one another. This clarity aids in troubleshooting, assembly, and disassembly tasks, ensuring that users can effectively understand complex machinery.

Benefits of Visual Guides

- Enhanced Understanding: Visual aids simplify the learning process by illustrating how parts fit together.

- Time Efficiency: Quickly locating specific elements can significantly reduce repair time.

- Improved Accuracy: Reduces the likelihood of errors during maintenance tasks.

Application in Various Industries

- Aerospace: Critical for assembly and maintenance of aircraft.

- Automotive: Essential for effective repairs and upgrades of vehicles.

- Manufacturing: Streamlines production processes by clarifying assembly steps.

Overall, these visual resources are invaluable tools that enhance productivity and ensure the longevity of equipment through informed maintenance practices.

Common Issues with Wacker BTS 1035

In the realm of construction equipment, certain challenges tend to arise frequently, impacting both performance and efficiency. Understanding these prevalent problems is essential for ensuring smooth operations and minimizing downtime. Proper maintenance and timely intervention can significantly reduce the likelihood of encountering these issues.

Mechanical Failures

One of the primary concerns is mechanical failure, which often stems from wear and tear over time. Components such as the engine or hydraulic system may experience malfunctions, leading to reduced power output or complete breakdown. Regular inspections and prompt replacements of worn parts can help maintain optimal performance.

Electrical Issues

Electrical problems can also pose significant obstacles, affecting ignition and operational capabilities. Issues may arise from faulty wiring or defective batteries, which can lead to intermittent power supply. It is advisable to conduct thorough electrical system checks and ensure that all connections are secure and functioning properly.

By being aware of these common challenges, operators can take proactive measures to enhance the longevity and reliability of their equipment.

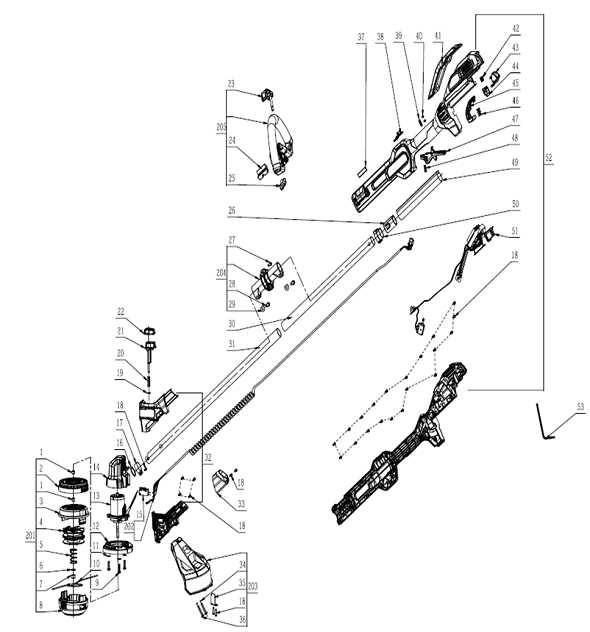

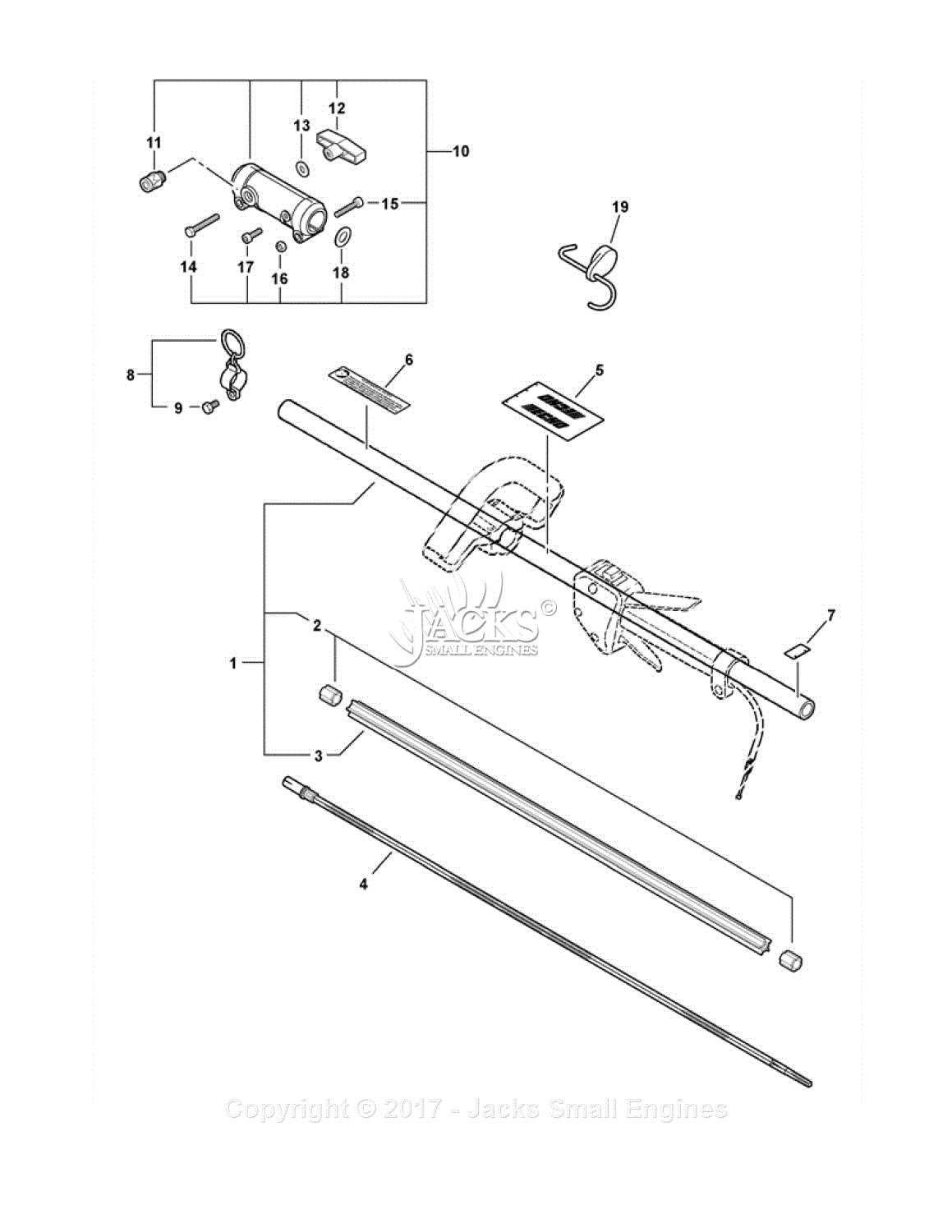

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair of machinery. These visual representations provide a clear overview of the components and their interconnections, allowing users to identify parts quickly and efficiently. Mastering the skill of interpreting these graphics can significantly enhance troubleshooting and assembly processes.

When analyzing a schematic, it’s essential to familiarize yourself with its layout. Typically, these visuals are organized in a way that highlights the relationship between various elements. Components are often labeled with unique identifiers, which correspond to a list of specifications. Here are some key aspects to focus on:

| Element | Description |

|---|---|

| Labels | Each component is usually marked with a specific code or number, making it easier to locate in documentation. |

| Connections | Lines and arrows indicate how parts interact or fit together, showcasing the assembly process. |

| Legend | Many illustrations include a legend or key, explaining symbols and color codes used within the image. |

| Orientation | Pay attention to the orientation of the components; some may need to be positioned in a specific direction to function properly. |

By breaking down these visual tools into manageable segments and understanding the symbolism involved, users can navigate their machinery with greater confidence and precision. This knowledge not only aids in repairs but also fosters a deeper appreciation for the engineering behind the equipment.

Maintenance Tips for BTS 1035

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following some straightforward practices, you can prevent common issues and enhance efficiency. This section outlines key strategies for maintaining your machine effectively.

Routine Inspections

Conduct frequent checks on all components to identify wear and tear early. Focus on critical parts such as hoses, filters, and seals. Regular inspections help in spotting potential problems before they escalate into costly repairs.

Lubrication and Cleaning

Keep moving parts well-lubricated to minimize friction and wear. Use the appropriate lubricant recommended by the manufacturer. Additionally, maintain cleanliness by removing dirt and debris that can hinder performance. Regular cleaning not only extends the life of your equipment but also ensures safety during operation.

Where to Find Replacement Parts

Locating suitable components for machinery can be a crucial task, ensuring that equipment functions efficiently and reliably. Various sources are available to assist users in finding the necessary items, each offering unique advantages. Understanding where to look can save time and effort in the maintenance process.

| Source Type | Description |

|---|---|

| Manufacturer Websites | Official sites often provide catalogs of available components, ensuring authenticity and compatibility. |

| Authorized Dealers | Local or online dealers authorized by the manufacturer can offer genuine items and expert advice. |

| Online Marketplaces | Platforms like eBay or Amazon may have a variety of options, from new to used components, often at competitive prices. |

| Specialty Retailers | Stores focusing on construction or industrial equipment can provide knowledgeable staff and a curated selection of items. |

| Salvage Yards | These locations can offer discounted components from decommissioned machinery, ideal for budget-conscious users. |

Comparison with Similar Models

In the realm of construction equipment, understanding the nuances between various models can significantly impact operational efficiency. This section aims to explore how similar machines stack up against one another, highlighting key features and functionalities that set them apart.

Performance and Capability

When examining the performance metrics, several contenders exhibit comparable power levels and operational capabilities. However, specific aspects such as weight distribution and engine efficiency can lead to differences in performance during intensive tasks. Choosing the right model often depends on the unique requirements of a project.

Maintenance and Durability

Another critical factor to consider is maintenance ease and durability. Some models offer advanced engineering that reduces downtime and enhances longevity, making them more appealing for long-term investments. Assessing user feedback can provide valuable insights into reliability and maintenance costs, guiding buyers towards the ultimate choice for their needs.

Assembly Process of Key Components

The assembly of essential elements in machinery requires precision and a systematic approach to ensure optimal performance and durability. Each component plays a critical role in the overall functionality, and understanding the assembly process is vital for both maintenance and repair. This section will explore the step-by-step methods for correctly integrating these key parts.

Understanding Component Interaction

Before commencing the assembly, it is crucial to comprehend how each element interacts within the system. This knowledge aids in identifying potential issues that may arise during the integration process. Thorough inspection of each part for any defects or wear can prevent complications later on.

Step-by-Step Assembly Guide

1. Preparation: Gather all necessary tools and components, ensuring that everything is clean and free from debris.

2. Alignment: Begin by positioning the primary components in their designated places, making sure they are aligned correctly to avoid misfitting.

3. Securing: Use appropriate fasteners to secure each part, ensuring a snug fit that can withstand operational stress.

4. Testing: After assembly, conduct tests to confirm that all components function harmoniously. Address any issues that arise before finalizing the process.

By following these guidelines, the assembly of critical machine components can be executed efficiently, resulting in enhanced performance and longevity of the equipment.

Tools Needed for Repairs

Conducting maintenance and repair tasks requires a specific set of instruments to ensure efficiency and effectiveness. Having the right tools at your disposal not only simplifies the process but also enhances the quality of the work performed. This section outlines the essential equipment necessary for undertaking such tasks safely and successfully.

Essential Hand Tools

Basic hand tools are fundamental for any repair job. These include screwdrivers, wrenches, and pliers. Each tool serves a distinct purpose, allowing you to tackle various fasteners and components with precision. Additionally, a reliable utility knife can be invaluable for cutting materials or opening packaging.

Power Tools and Safety Equipment

Incorporating power tools into your repair arsenal can greatly expedite the process. Drills, saws, and grinders are crucial for more intensive tasks. However, safety should always be a priority. Equip yourself with appropriate protective gear, including gloves, goggles, and ear protection, to safeguard against potential hazards during operation.

Customer Reviews and Experiences

This section explores the sentiments and feedback shared by users regarding their interactions with a specific piece of machinery. Understanding these insights can help potential buyers make informed decisions based on real-world applications.

Many users have expressed their thoughts on various aspects:

- Performance: Users frequently highlight the efficiency and reliability during operation.

- Durability: Several reviews note the robust construction, which withstands rigorous use.

- Maintenance: Experiences regarding upkeep are varied, with some finding it straightforward and others more challenging.

Common themes in the reviews include:

- High satisfaction with the overall functionality.

- Mixed opinions on the availability of replacement components.

- Positive feedback on customer support responsiveness.

Overall, these experiences provide valuable perspectives for anyone considering this equipment.

Benefits of Regular Maintenance

Routine upkeep of machinery and equipment plays a crucial role in ensuring optimal performance and longevity. By dedicating time and resources to consistent maintenance practices, operators can significantly enhance the reliability and efficiency of their assets. This proactive approach not only prevents unexpected breakdowns but also fosters a safer working environment.

Improved Efficiency

Regular servicing helps identify and rectify potential issues before they escalate, leading to smoother operation. Well-maintained machines typically exhibit better fuel efficiency and reduced wear and tear, resulting in lower operational costs over time. This efficiency translates into increased productivity, allowing businesses to meet demands more effectively.

Extended Equipment Lifespan

Consistent attention to maintenance can greatly extend the useful life of machinery. By replacing worn components and adhering to recommended service intervals, operators can prevent significant damage that could necessitate costly repairs or premature replacement. This longevity not only protects investments but also enhances overall return on investment.