The effective operation of a refrigeration unit relies on a variety of essential elements that work in harmony to maintain optimal temperatures. Each component plays a critical role in ensuring that the system functions efficiently, providing reliable cooling in various environments. Grasping the layout and functionality of these components is vital for anyone involved in the maintenance or installation of such systems.

In this section, we will explore the various components that contribute to the overall performance of the cooling system. By understanding how these parts interconnect, users can better appreciate the mechanics behind temperature regulation. This knowledge is particularly beneficial for technicians and operators who are tasked with troubleshooting or enhancing system efficiency.

Recognizing the specific functions of each element enables individuals to make informed decisions regarding repairs or upgrades. As we delve deeper into the intricate workings of the refrigeration unit, you will gain insights that are crucial for ensuring longevity and reliability in your cooling solutions.

This section will provide a comprehensive overview of the essential elements found within a specific refrigerated storage unit. It will explore the various components that contribute to its functionality, emphasizing their roles and interconnections. By breaking down each part, readers will gain a clearer understanding of how this refrigeration system operates effectively.

Key Elements of Refrigerated Storage Systems

Understanding the individual components of these units is crucial for efficient operation and maintenance. Each element serves a unique purpose, contributing to the overall efficiency and performance of the refrigeration system.

Component Overview Table

| Component Name | Description |

|---|---|

| Evaporator | Absorbs heat from the interior, facilitating cooling. |

| Compressor | Circulates refrigerant and maintains pressure. |

| Condenser | Releases heat absorbed from the interior into the environment. |

| Thermostat | Regulates temperature by controlling the cooling cycle. |

| Insulation | Maintains internal temperature by minimizing heat transfer. |

Essential Elements of Walk-in Coolers

Understanding the fundamental components of large refrigeration units is crucial for effective operation and maintenance. These essential elements work together to create a controlled environment for preserving perishable goods, ensuring optimal functionality and efficiency.

Insulation plays a vital role in maintaining temperature. High-quality insulating materials minimize heat transfer, keeping the interior cool and energy consumption low.

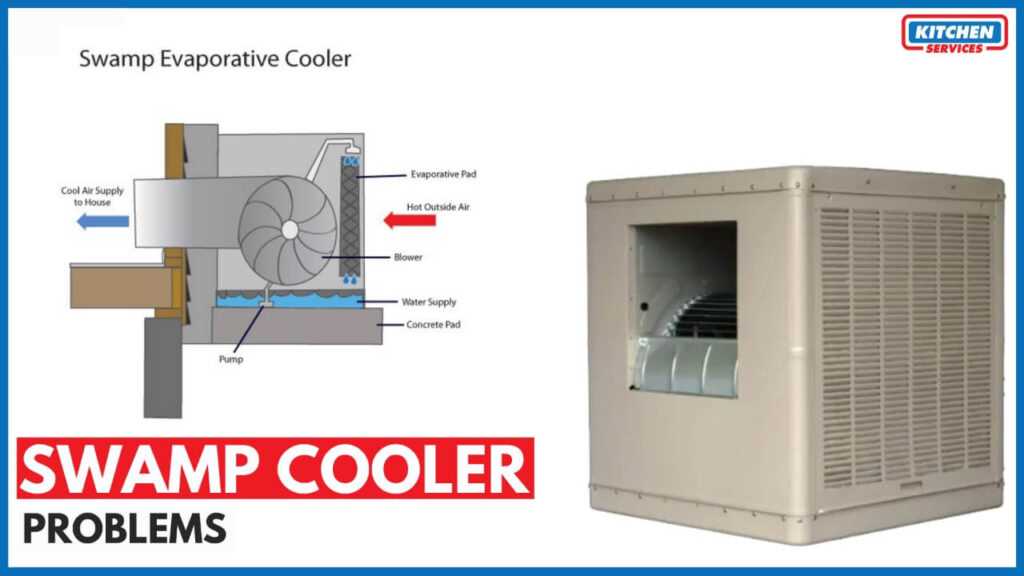

The refrigeration system is the heart of these units, responsible for removing heat and maintaining the desired temperature. This system typically includes a compressor, condenser, evaporator, and expansion valve, each serving a specific function in the cooling process.

Temperature controls and monitoring systems are essential for ensuring that the internal climate remains stable. These devices allow for precise adjustments and provide alerts in case of fluctuations, preventing spoilage and waste.

Air circulation is also critical for even temperature distribution throughout the space. Fans and ventilation systems facilitate airflow, helping to maintain a consistent environment and prevent hot spots.

Finally, the entryway is a key aspect of usability and energy efficiency. Proper sealing and automatic closing mechanisms are important to minimize the loss of cool air and ensure easy access for staff.

Detailed Parts Overview

This section provides an in-depth look at the various components that make up a refrigeration unit designed for large storage spaces. Understanding these elements is crucial for effective maintenance and troubleshooting, ensuring optimal performance and longevity of the system.

The key elements of this cooling system include:

- Refrigeration Unit: The heart of the system, responsible for the cooling process.

- Insulated Panels: Essential for maintaining temperature by minimizing heat exchange with the environment.

- Door Mechanisms: Critical for access, featuring seals that prevent air leakage.

- Evaporator Coils: Facilitate heat absorption, contributing to the overall cooling efficiency.

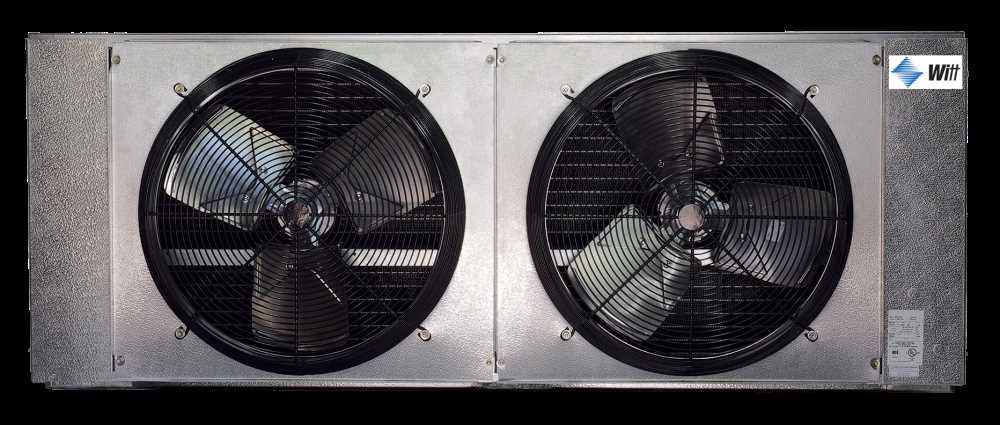

- Condensing Unit: Works in conjunction with the refrigeration unit to expel heat from the system.

- Fans: Aid in air circulation, ensuring even distribution of cool air within the storage area.

- Thermostat: Controls the internal temperature, allowing for adjustments based on specific storage needs.

Each of these components plays a vital role in the overall functionality of the refrigeration system, and a thorough understanding can significantly enhance operational efficiency.

Regular inspections and maintenance of these elements can prevent potential issues and prolong the life of the refrigeration system.

Key Functions of Each Component

This section explores the essential roles played by various elements in a refrigeration system designed for storage. Understanding the functions of each part can enhance operational efficiency and ensure proper maintenance.

| Component | Function |

|---|---|

| Compressor | Compresses refrigerant gas, increasing its pressure and temperature, facilitating heat transfer. |

| Condenser | Releases heat from the refrigerant, causing it to condense into a liquid state. |

| Evaporator | Absorbs heat from the surrounding environment, allowing the refrigerant to evaporate and cool the area. |

| Expansion Valve | Regulates the flow of refrigerant into the evaporator, reducing pressure and temperature. |

| Thermostat | Monitors and controls the temperature, ensuring the system maintains the desired conditions. |

Visual Representation of Parts

This section aims to provide an illustrative overview of the components that make up an insulated refrigeration unit. A clear depiction aids in understanding how each element contributes to the overall functionality and efficiency of the system.

Key Components Overview

Understanding the various elements is essential for effective maintenance and troubleshooting. Below are the primary constituents that play a crucial role:

- Refrigeration unit

- Insulation panels

- Door assemblies

- Condensing unit

- Thermostat

- Evaporator coils

Importance of Visual Guides

Visual aids enhance comprehension and retention of information related to the structure and operation of the system. They facilitate easier identification of components and their respective functions.

- Facilitates quick reference during repairs

- Enhances training for new technicians

- Improves overall efficiency in maintenance tasks

Interconnectivity of Cooler Elements

The intricate relationship between various components in refrigeration systems plays a crucial role in their overall efficiency and performance. Each element serves a specific function while relying on others to operate seamlessly, creating a cohesive unit designed to maintain optimal conditions for preservation and storage.

Understanding the synergy among these components is vital for effective maintenance and troubleshooting. For instance, the evaporator and compressor work in tandem to facilitate the refrigeration cycle, where the former absorbs heat and the latter circulates refrigerant. This interaction underscores the importance of ensuring that all components are functioning properly to avoid disruptions.

Moreover, the condensing unit and expansion device contribute significantly to this interconnected framework. While the condensing unit releases heat from the refrigerant, the expansion device regulates the flow of refrigerant into the evaporator, establishing a balanced system that enhances performance. Regular inspections and timely repairs of these elements are essential to uphold their interdependence.

In conclusion, the successful operation of refrigeration systems hinges on the harmonious interplay among all components. Recognizing the significance of their connections can lead to improved functionality and longevity, ultimately benefiting the efficiency of the entire setup.

Maintenance and Repair Insights

Effective upkeep and troubleshooting of refrigeration systems are essential for ensuring optimal performance and longevity. Regular attention to these units can prevent unexpected failures and enhance efficiency. Understanding the components and their functions will aid in identifying potential issues and implementing timely solutions.

Routine inspections play a critical role in the maintenance process. Regularly checking for signs of wear, leaks, or unusual noises can help detect problems early on. Cleaning coils and ensuring proper airflow are also vital for efficient operation. Additionally, monitoring temperature settings and ensuring they align with operational standards can prevent undue strain on the machinery.

When issues arise, a systematic approach to troubleshooting is beneficial. Begin by isolating the symptoms and assessing the relevant components. Utilize a checklist to guide the evaluation process, focusing on areas such as electrical connections, seals, and refrigerant levels. Documenting findings can assist in pinpointing recurring issues, facilitating more effective repairs.

In cases of significant malfunction, consulting with a qualified technician may be necessary. They possess the expertise to conduct comprehensive diagnostics and implement advanced repairs. Prioritizing both preventive measures and professional assistance will contribute to the reliable operation of refrigeration systems.

Common Issues with Cooler Parts

In refrigeration systems, various components can encounter issues that affect overall performance and efficiency. Understanding these challenges is crucial for effective maintenance and ensuring the longevity of the equipment. Common complications may arise from mechanical failures, environmental factors, or improper usage.

1. Refrigeration Failure: One of the most frequent problems involves inadequate cooling. This can result from refrigerant leaks, faulty compressors, or blocked evaporators. Identifying the source of the issue is essential for timely repairs.

2. Temperature Fluctuations: Inconsistent temperatures can lead to spoilage of stored items. This issue may stem from malfunctioning thermostats, poor insulation, or external heat sources affecting the system’s efficiency.

3. Noise Issues: Unusual sounds, such as rattling or buzzing, often indicate mechanical problems. Loose components or failing motors can generate excess noise, signaling the need for inspection and potential replacement.

4. Ice Build-Up: Frost accumulation on coils can impede airflow and reduce cooling effectiveness. This can occur due to high humidity levels, malfunctioning defrost timers, or inadequate ventilation.

5. Electrical Problems: Power supply issues can disrupt functionality. Faulty wiring, blown fuses, or circuit breaker trips can lead to operational failures and require immediate attention.

By recognizing these common issues, operators can take proactive steps to maintain efficiency and prevent costly repairs.

Choosing Quality Replacement Parts

When it comes to maintaining refrigeration units, selecting high-grade components is crucial for ensuring optimal performance and longevity. Quality elements contribute significantly to the efficiency of the entire system, preventing unexpected breakdowns and minimizing operational costs.

First and foremost, prioritize reliability over cost. While budget-friendly options may seem appealing, they often lack durability and may lead to frequent replacements. Investing in reputable brands can offer peace of mind, knowing that the components will withstand wear and tear, ultimately saving time and resources in the long run.

Additionally, consider compatibility with your existing setup. Mismatched components can lead to inefficient operation and may compromise the overall functionality. Always refer to specifications to guarantee a proper fit, and consult with experts if needed to ensure informed choices.

Lastly, don’t overlook warranties and customer support offered by manufacturers. A solid warranty not only indicates the manufacturer’s confidence in their product but also provides protection against defects. Comprehensive customer service can assist you with installation and troubleshooting, ensuring a seamless experience throughout the process.

Impact of Proper Installation

The significance of correct setup cannot be overstated when it comes to refrigeration systems. Proper installation not only enhances efficiency but also ensures longevity and optimal performance of the equipment. By following recommended guidelines and best practices, users can avoid potential issues that may arise from improper assembly or positioning.

Benefits of Correct Assembly

- Efficiency: Proper installation leads to optimal energy usage, reducing operational costs.

- Durability: Equipment that is installed correctly is less prone to breakdowns and repairs.

- Performance: Adequate positioning allows for better temperature regulation and overall effectiveness.

- Compliance: Adhering to installation standards helps meet safety regulations and industry guidelines.

Common Installation Mistakes

- Improper leveling can lead to drainage issues.

- Insufficient insulation can cause temperature fluctuations.

- Poor placement of components may hinder airflow and efficiency.

- Neglecting manufacturer instructions can result in warranty voids.

In summary, attention to detail during the installation process is essential. Investing time and effort into proper assembly ultimately pays off by enhancing the functionality and lifespan of the refrigeration unit.