When tackling the challenges of winter weather, having a clear understanding of the essential elements that make up your machinery can significantly enhance performance and efficiency. Proper knowledge of these components not only aids in effective operation but also extends the lifespan of the equipment.

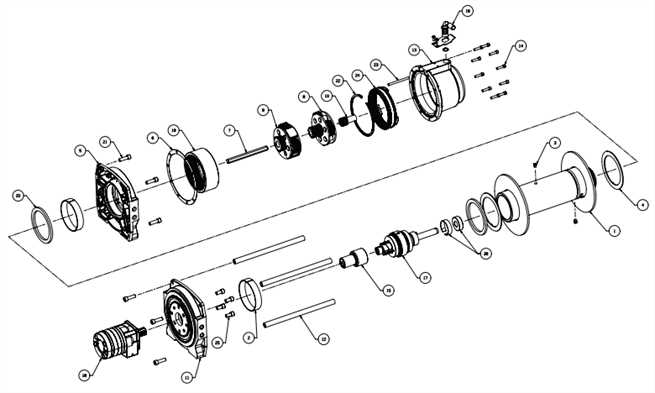

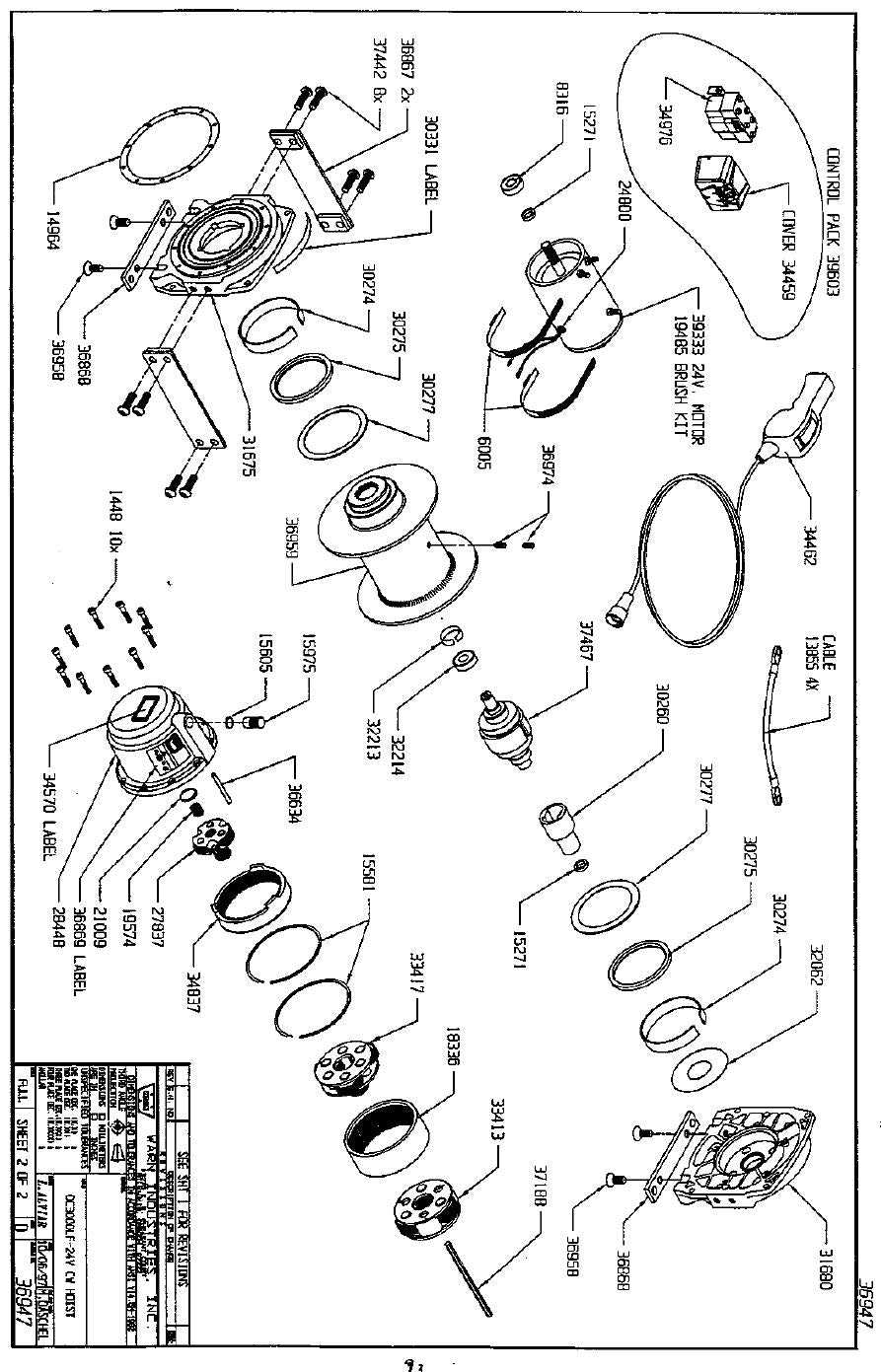

In this section, we will explore the intricate assembly of your snow-clearing apparatus, highlighting the roles and functions of each individual element. By examining the layout and interconnections, users can better appreciate how these pieces work in harmony to achieve optimal results.

Furthermore, familiarity with these configurations enables quick troubleshooting and maintenance, ensuring that you remain prepared for any adverse conditions. Delving into this topic will equip you with the ultimate insight needed to manage your equipment effectively.

Understanding Warn Plow Parts

This section aims to explore the various components that contribute to the efficient functioning of a snow-clearing system. A comprehensive grasp of these elements is essential for optimal performance and maintenance, ensuring longevity and reliability during winter operations.

Key Components

Familiarity with essential elements is crucial. From the attachment mechanisms to the control systems, each part plays a significant role. Recognizing their functions can enhance user experience and facilitate troubleshooting.

Maintenance and Care

Proper upkeep of these components ensures they operate at their peak. Regular checks and timely replacements can prevent potential issues, ultimately prolonging the lifespan and enhancing overall efficiency.

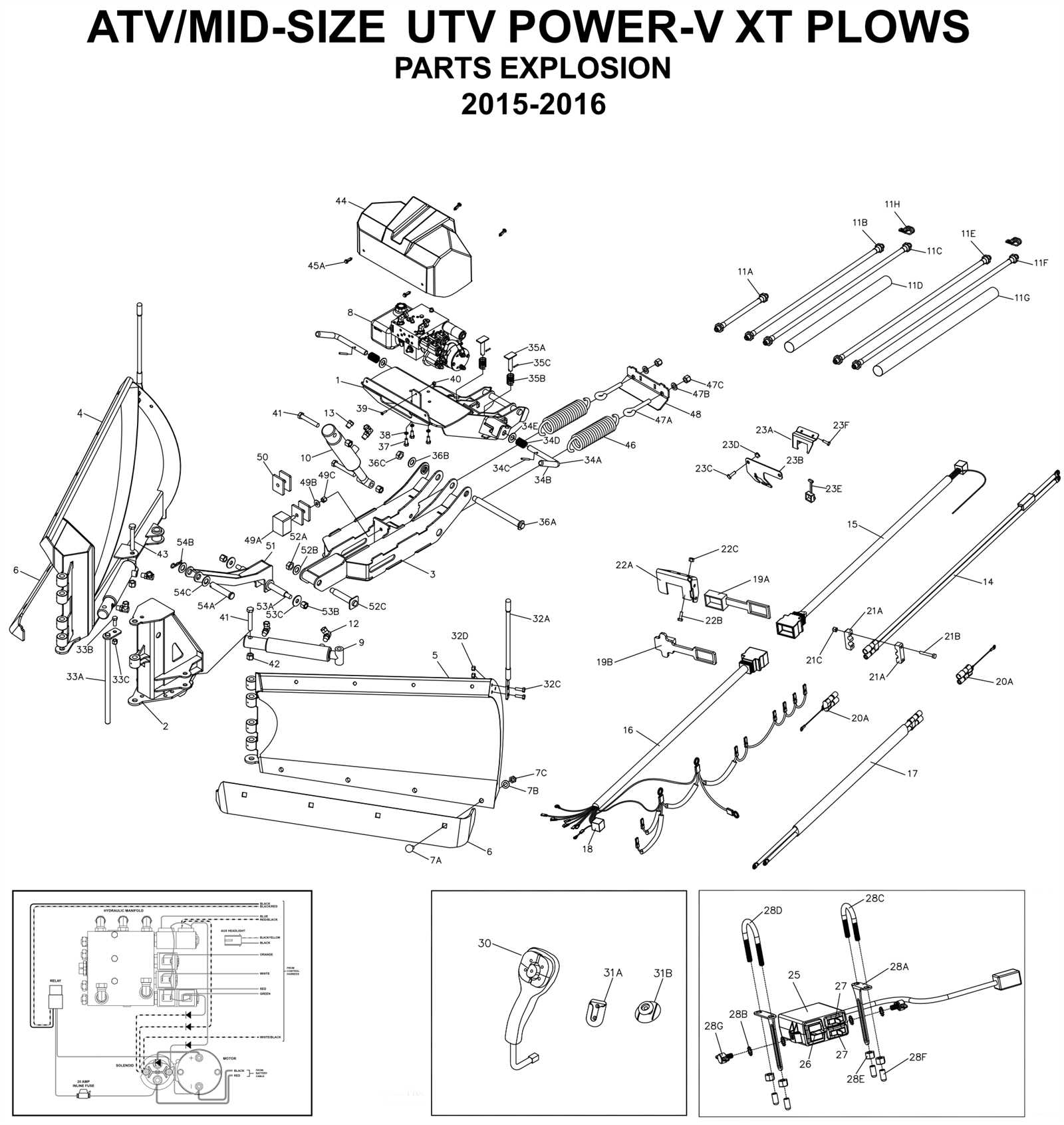

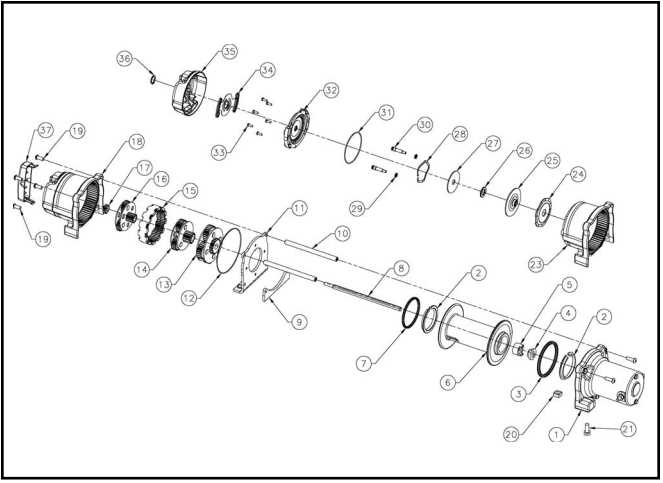

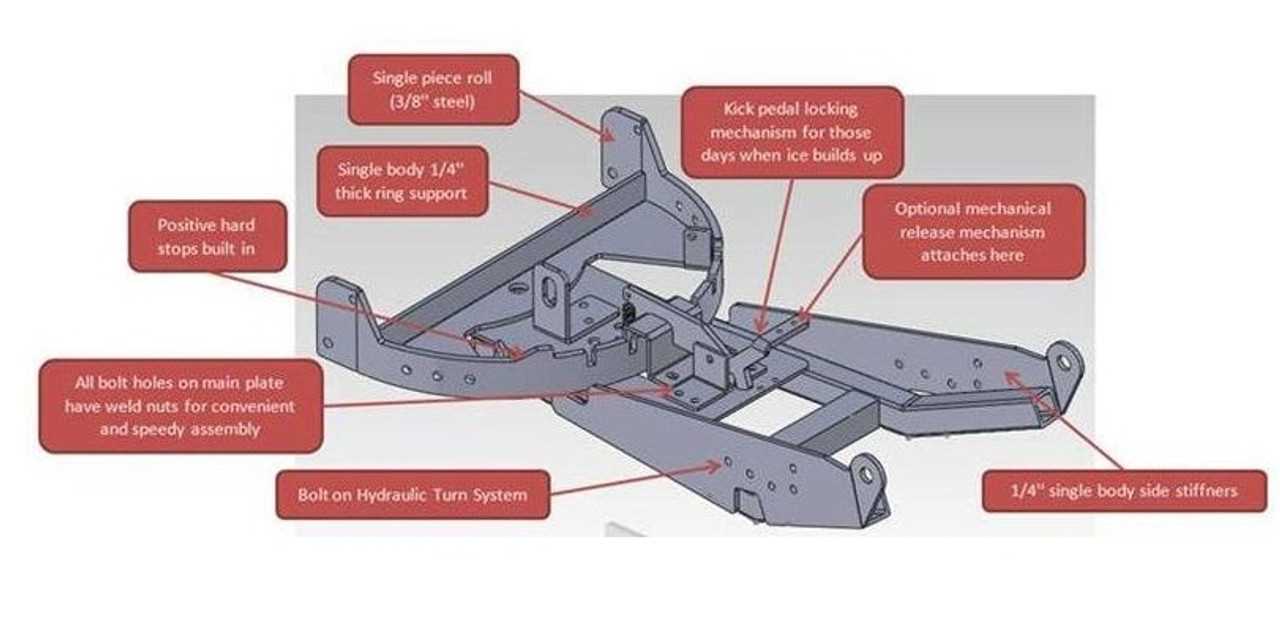

Components of a Warn Plow

This section explores the essential elements that contribute to the functionality and efficiency of a snow removal system, ensuring effective performance in various conditions. Understanding these components is crucial for maintenance and optimal operation.

| Component | Description |

|---|---|

| Blade | The primary tool for moving snow, available in various sizes and shapes for different tasks. |

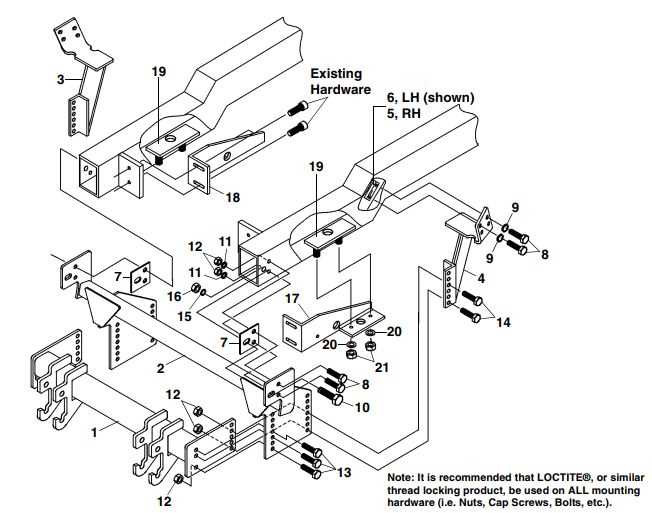

| Mounting Frame | Supports the blade and connects it to the vehicle, providing stability during operation. |

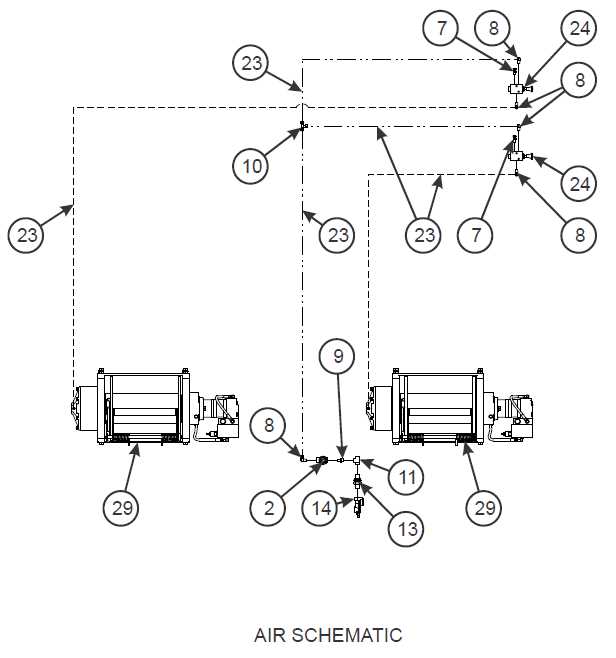

| Hydraulic System | Controls the movement of the blade, allowing for precise adjustments in height and angle. |

| Electrical Components | Facilitates the operation of the hydraulic system and controls, often including switches and relays. |

| Skid Shoes | Protect the blade and allow for controlled contact with the ground, reducing wear. |

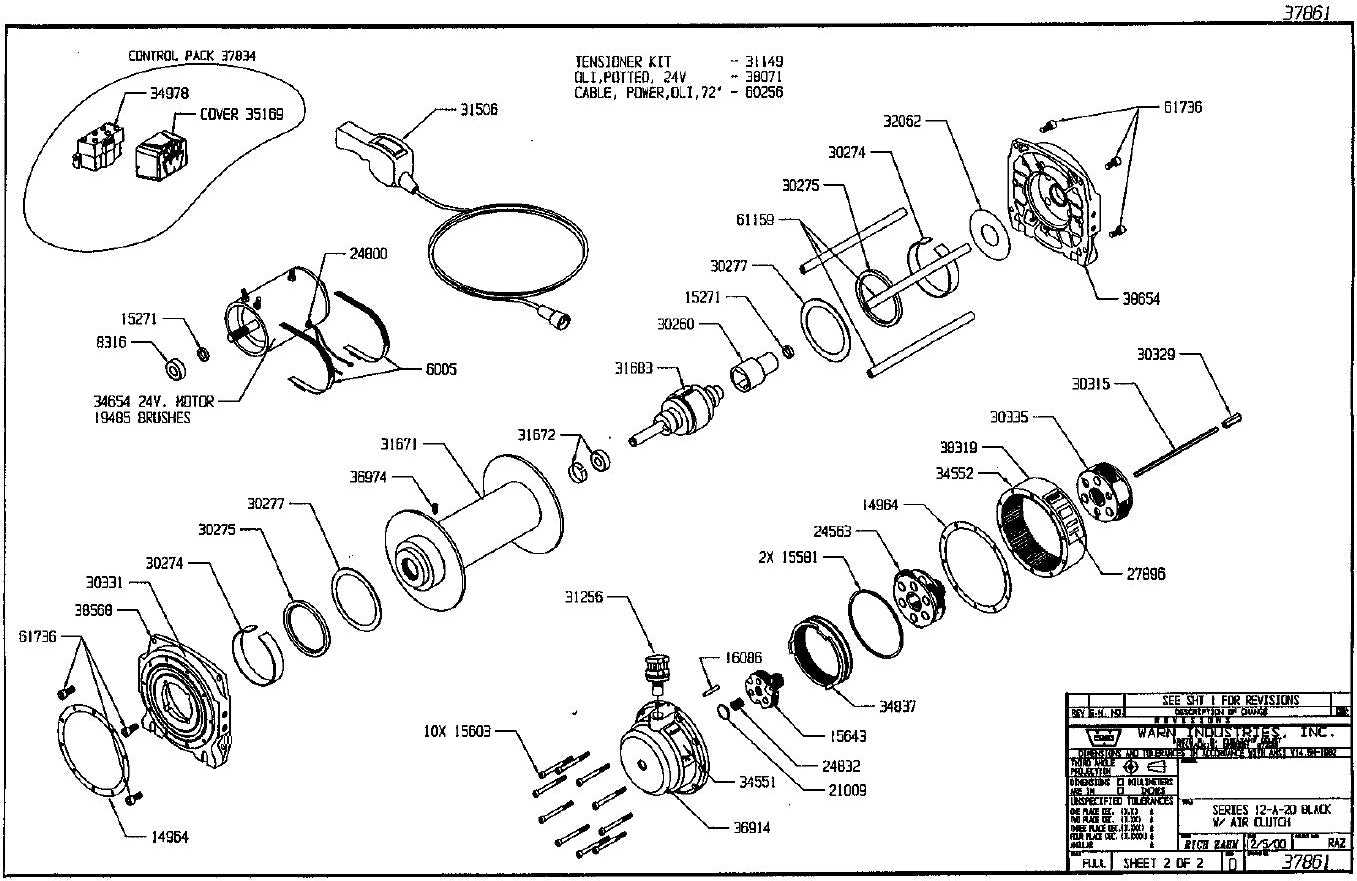

Diagram Overview for Efficient Use

This section provides a comprehensive understanding of the layout and components essential for optimal functionality in snow management equipment. By exploring the visual representation of these elements, users can enhance their operational efficiency and minimize potential issues.

Familiarizing yourself with the configuration is crucial for effective maintenance and troubleshooting. A clear visual reference allows operators to quickly identify key components and understand their roles in the overall system, facilitating better decision-making during usage.

Additionally, this overview serves as a foundation for those seeking to delve deeper into the mechanics, ensuring that users can confidently address any concerns and maximize performance in various conditions.

Common Issues with Plow Parts

When working with snow removal equipment, several challenges may arise that can impact performance and efficiency. Understanding these common issues is crucial for maintaining equipment and ensuring it operates smoothly during harsh weather conditions. Frequent wear and tear, along with occasional misalignment, can lead to significant operational problems if not addressed promptly.

Wear and Tear

Components of snow-clearing machinery often experience extensive wear due to constant exposure to harsh elements and heavy usage. This deterioration can manifest in reduced effectiveness and increased likelihood of failure. Regular inspections and timely replacements are essential to avoid breakdowns and ensure optimal functionality.

Alignment Issues

Another prevalent concern involves the alignment of various elements within the system. Misalignment can lead to uneven distribution of force, causing uneven wear and inefficient operation. Proper setup and periodic adjustments are necessary to maintain alignment and enhance overall performance.

How to Read the Diagram

Understanding technical illustrations is crucial for effective maintenance and repairs. This section will guide you through the essential steps to interpret these visuals accurately, ensuring you can identify components and their functions with ease.

Identify Key Elements

Start by examining the major components highlighted in the visual. Look for labels or symbols that denote specific features, as these will provide clarity on their roles. Familiarizing yourself with these elements will enhance your overall comprehension.

Follow the Connections

Next, trace the lines or arrows that indicate relationships between components. These connections often reveal how parts interact with one another, giving insight into the overall system. Pay attention to any notes or legends included, as they may offer additional context or important details.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment involves consistent care and attention. By implementing a regular maintenance routine, you can significantly extend the lifespan and efficiency of your machinery. Here are some essential strategies to consider.

Routine Inspections

Conducting regular checks allows for the early identification of potential issues. Look for wear and tear, unusual sounds, or fluid leaks that could indicate underlying problems.

Proper Cleaning

Keeping your equipment clean not only enhances its appearance but also prevents the accumulation of dirt and debris, which can hinder functionality. Use appropriate cleaning agents and techniques to maintain surfaces.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect Components | Monthly | Check for signs of damage or wear. |

| Clean Surfaces | Bi-weekly | Remove dirt and debris thoroughly. |

| Lubricate Moving Parts | Quarterly | Use suitable lubricants to reduce friction. |

Upgrading Your Warn Plow System

Enhancing your snow management equipment can significantly improve efficiency and performance. By investing in quality upgrades, you can ensure a smoother operation and better handling during harsh winter conditions. This section explores various options for maximizing the capabilities of your system.

Essential Enhancements

Consider integrating advanced features such as improved blade technology or robust mounting systems. These upgrades can provide better durability and adaptability, allowing you to tackle various terrains with ease.

Maintenance and Care

Regular maintenance is crucial for longevity and optimal performance. Implementing routine checks and timely replacements can prevent potential issues and enhance the overall effectiveness of your setup.

Essential Tools for Repairs

When it comes to maintaining and fixing outdoor machinery, having the right equipment is crucial for efficiency and safety. A well-equipped toolkit not only streamlines the process but also enhances the quality of the work. Essential instruments help in addressing various issues, ensuring that repairs are performed correctly and effectively.

Basic Hand Tools: A collection of wrenches, screwdrivers, and pliers forms the foundation of any repair toolkit. These tools are necessary for loosening or tightening components and making precise adjustments.

Power Tools: Electric drills and saws can significantly reduce the time required for repairs. They offer greater precision and power, allowing for more complex tasks to be completed with ease.

Measuring Instruments: Accurate measurements are vital in ensuring that parts fit properly. Calipers and tape measures help achieve the right dimensions for optimal functionality.

Safety Gear: Never underestimate the importance of personal protection. Gloves, goggles, and masks safeguard against potential hazards while working with machinery.

Equipping yourself with these vital tools empowers you to tackle any repair challenge, ensuring that your equipment remains in peak condition for its ultimate performance.

Identifying Compatible Parts

When seeking components for your equipment, understanding compatibility is crucial for optimal performance. Proper identification of elements ensures seamless operation and longevity of your machinery.

Key Factors to Consider

Before selecting components, evaluate the following aspects:

- Specifications: Check the size, weight, and functionality.

- Brand Standards: Ensure adherence to manufacturer guidelines.

- Material Quality: Assess durability and resistance to wear.

Reference Table for Compatibility

| Component Type | Compatible Models | Notes |

|---|---|---|

| Blade | Model A, Model B | Check for size compatibility. |

| Mounting Kit | Model C, Model D | Verify installation requirements. |

| Control System | Model E | Ensure software compatibility. |

Safety Precautions During Use

Ensuring a safe working environment is crucial when operating heavy machinery. Adhering to safety measures not only protects the operator but also safeguards those nearby. Proper precautions can significantly reduce the risk of accidents and injuries.

- Always wear appropriate personal protective equipment (PPE) such as gloves, helmets, and safety glasses.

- Conduct a thorough inspection of the equipment before use, checking for any signs of wear or damage.

- Ensure that all safety features are functional and in place.

Before starting the machinery, familiarize yourself with its controls and operational guidelines. This knowledge is essential for effective and safe handling.

- Maintain a clear area around the equipment to avoid tripping hazards.

- Keep bystanders at a safe distance during operation.

- Follow all manufacturer recommendations and safety protocols.

In case of any malfunction or irregularity, cease operation immediately and seek assistance. Being proactive about safety can prevent serious incidents and ensure a smooth operation.

Seasonal Maintenance Checklist

Regular upkeep is essential to ensure optimal performance and longevity of your equipment throughout varying weather conditions. A well-structured maintenance schedule can prevent issues and enhance efficiency.

Spring Preparation

- Inspect for any wear and tear from winter usage.

- Clean all components thoroughly to remove debris.

- Check and refill fluids as necessary.

- Sharpen blades or cutting edges for effective operation.

Autumn Readiness

- Examine all mechanical parts for signs of damage.

- Lubricate moving components to ensure smooth functionality.

- Store equipment in a dry, protected area.

- Review safety features and emergency equipment.

Resources for Further Learning

Expanding your knowledge on equipment components and maintenance can greatly enhance your understanding and skills. Here, you will find a variety of resources designed to support your learning journey, from instructional manuals to online forums and expert blogs.

| Resource Type | Description | Link |

|---|---|---|

| Instructional Manuals | Comprehensive guides covering assembly and upkeep. | View Manuals |

| Online Forums | A community for discussions and troubleshooting tips. | Join Forum |

| Expert Blogs | Insights and tips from industry professionals. | Read Blogs |

| Video Tutorials | Visual demonstrations on installation and repair. | Watch Videos |