Maintaining outdoor tools is essential for keeping them in optimal condition, and this holds true for your grass trimmer. Whether you’re dealing with minor repairs or simply trying to understand how your device functions, knowing the key elements is important for smooth operation. Every piece plays a role in ensuring your equipment works efficiently and safely.

In this guide, we will explore the crucial components that make up your trimming device. From essential mechanisms that drive the machine to smaller elements that ensure precision and control, each part has a specific function. By becoming familiar with these elements, you’ll be able to maintain your tool effectively, troubleshoot common issues, and extend its lifespan.

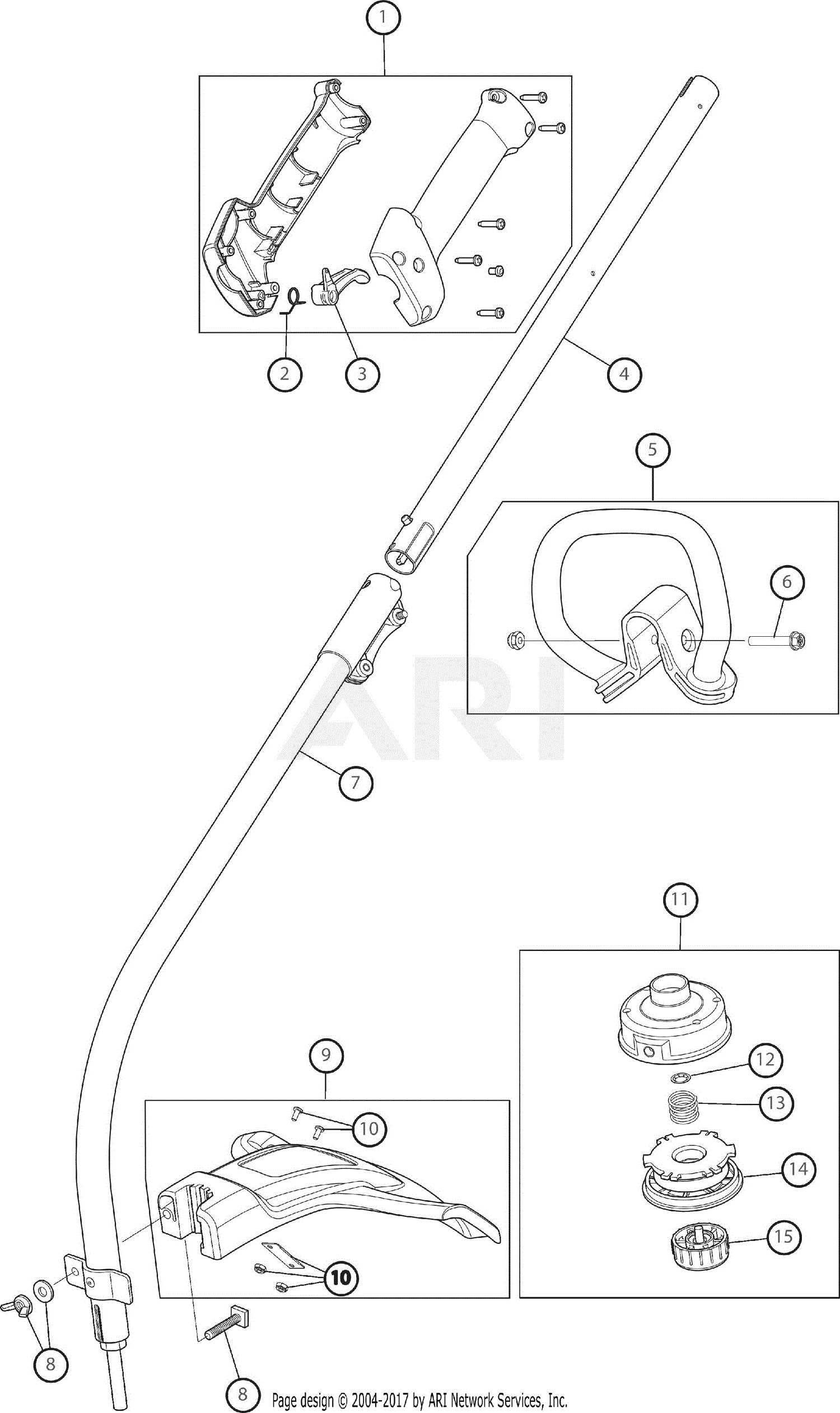

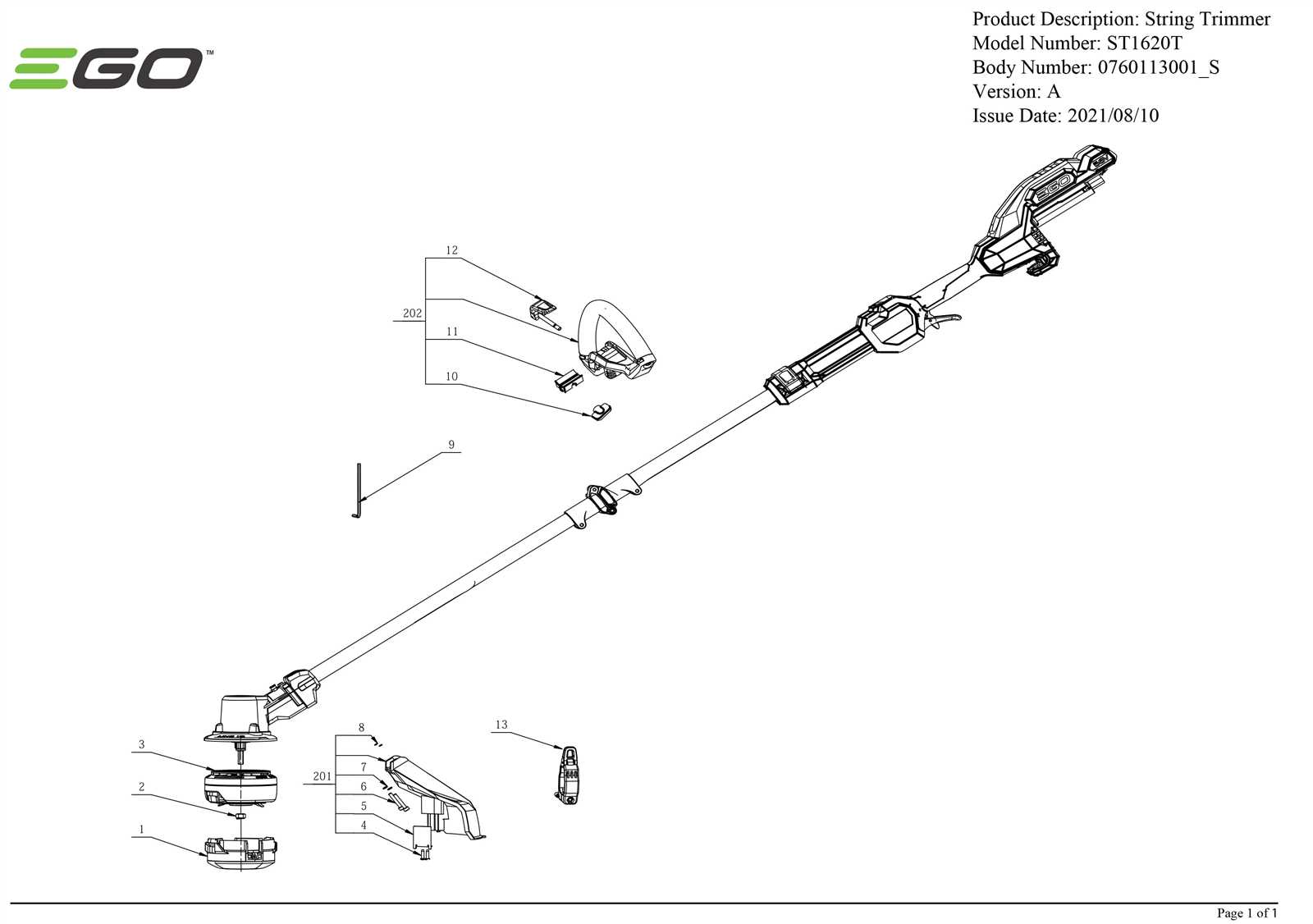

Weed Eater Parts Diagram Guide

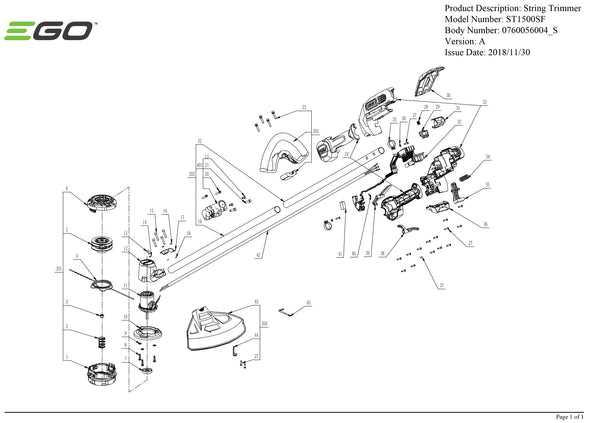

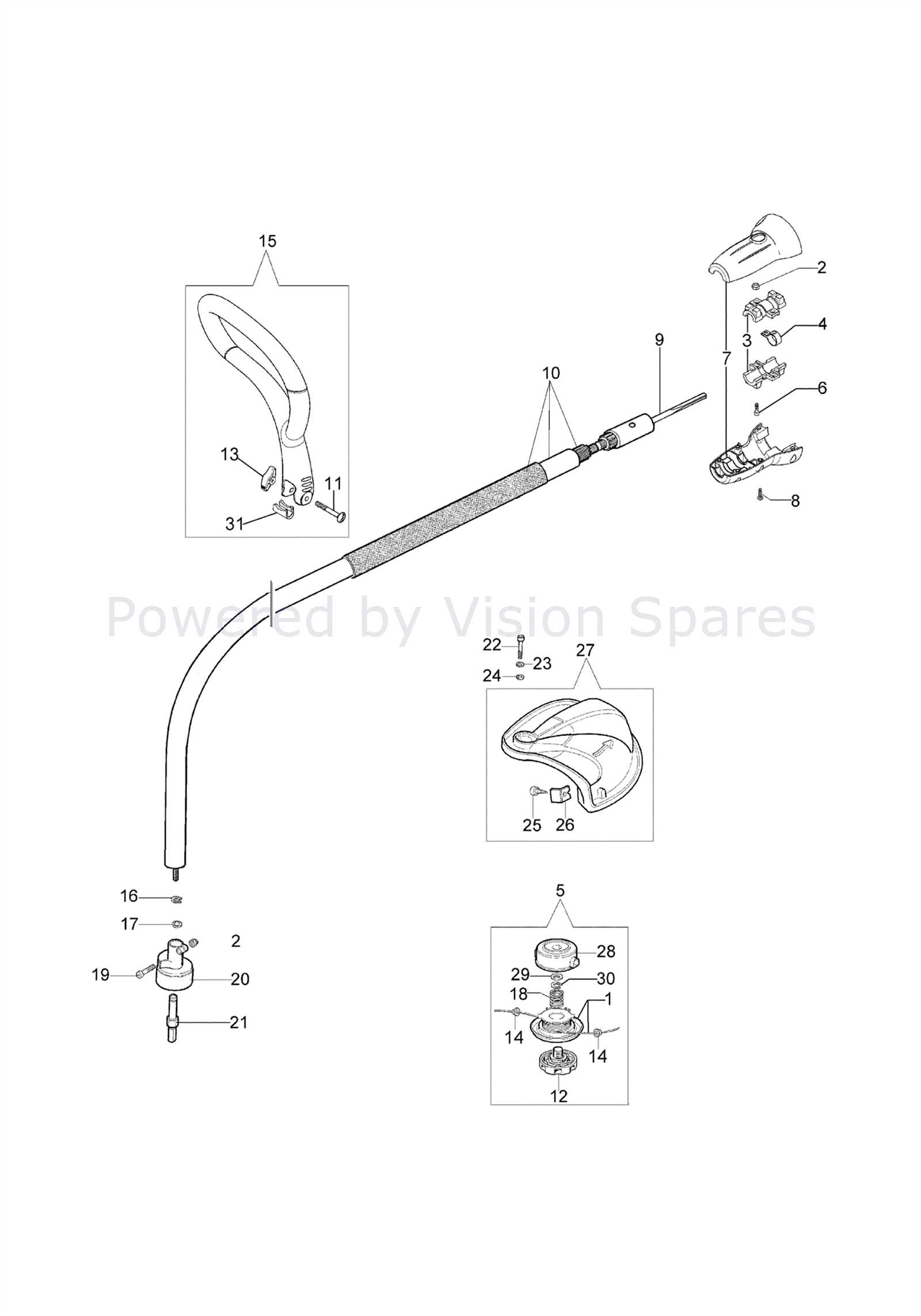

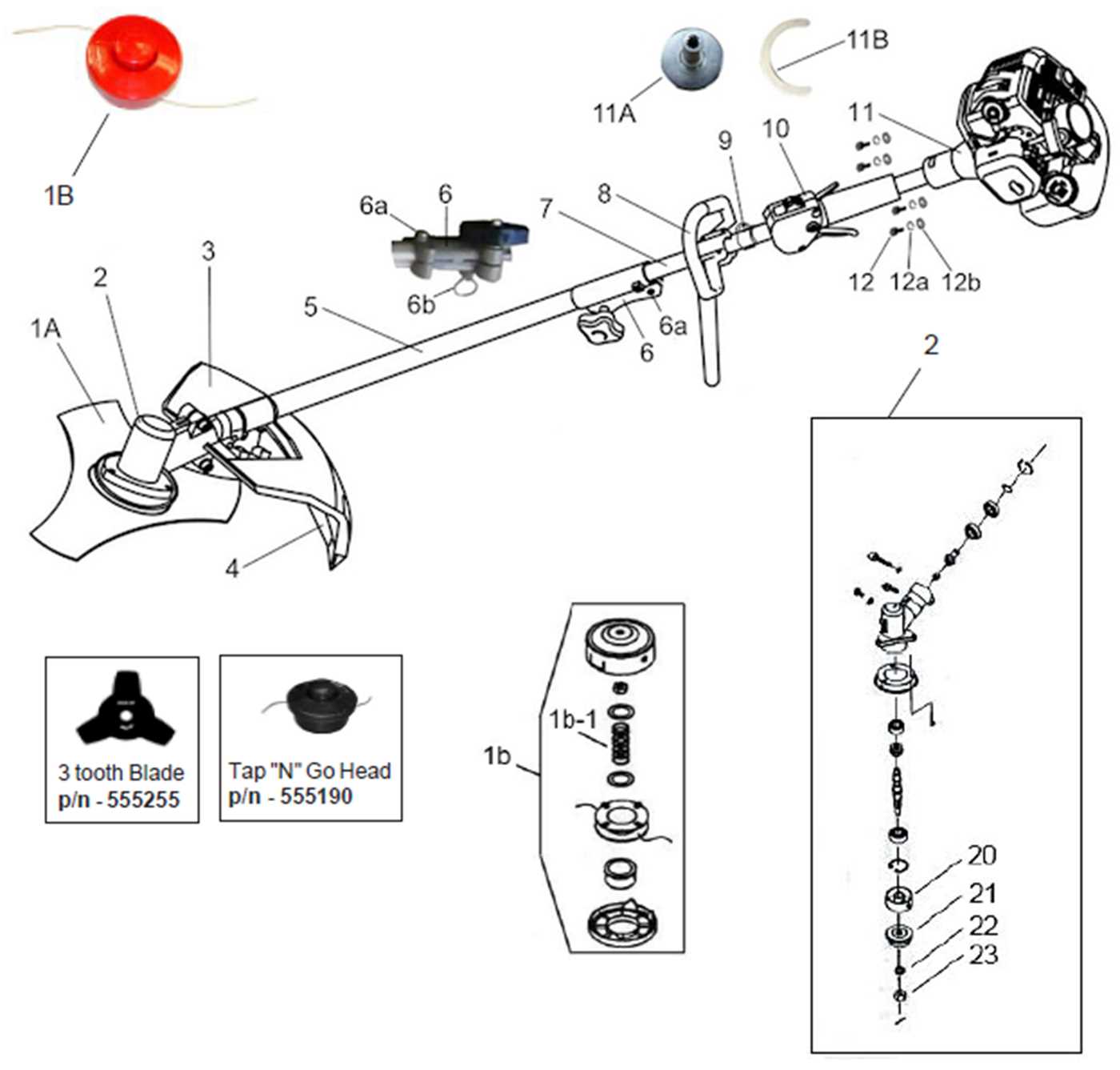

Understanding the layout of essential components is crucial for efficient maintenance and repair of your outdoor equipment. Knowing where each element is positioned can significantly enhance your ability to identify potential issues and replace faulty parts with ease.

The structure of your tool consists of several key segments that work together to ensure smooth operation. Recognizing these segments helps in diagnosing issues quickly and effectively.

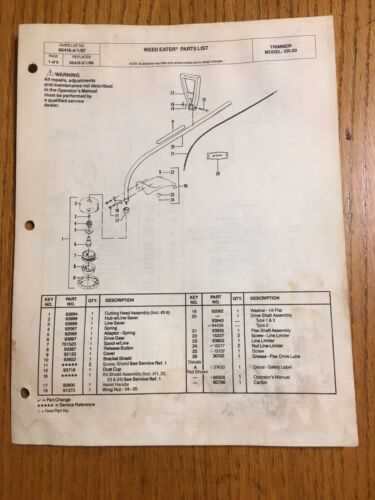

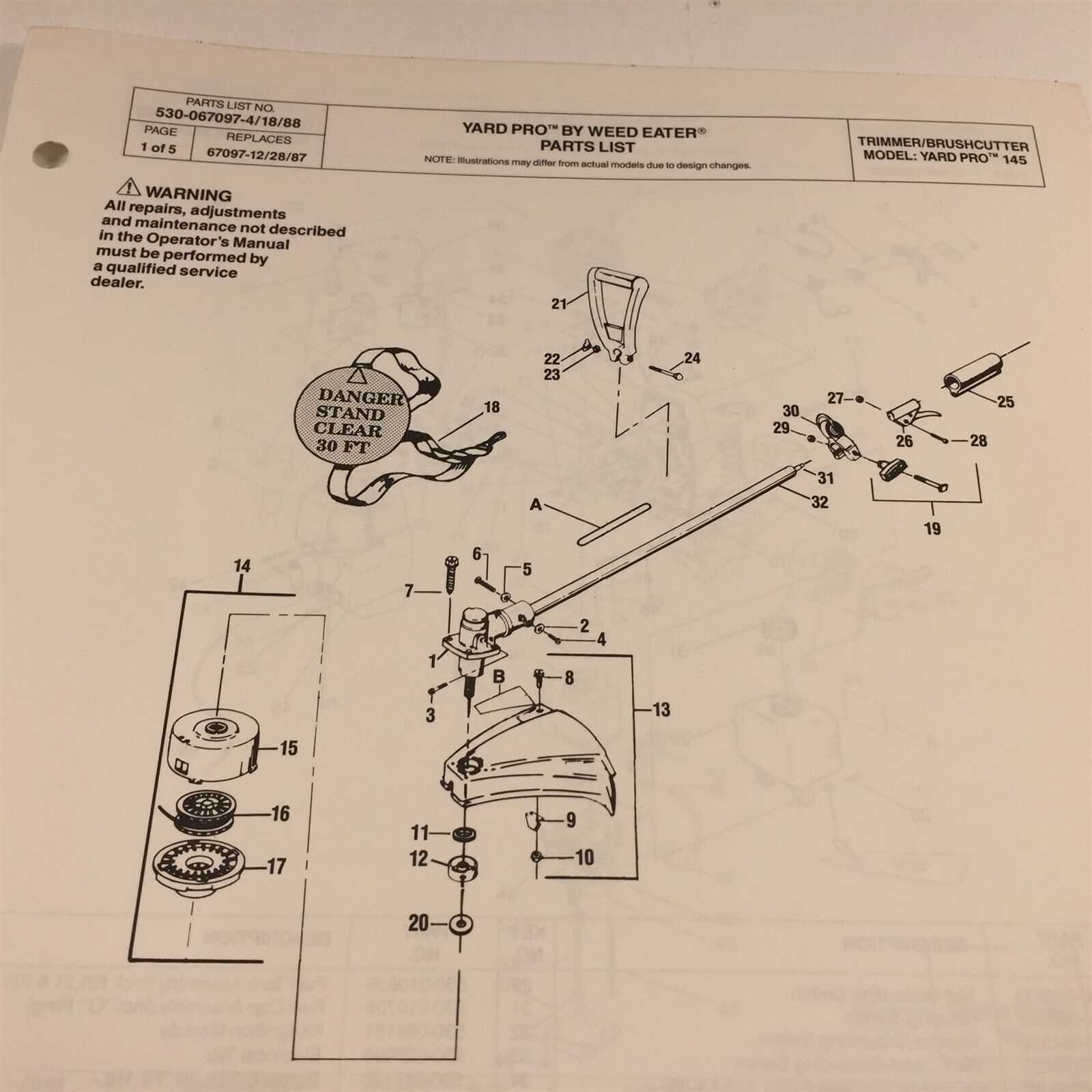

- Motor Assembly – the powerhouse driving all functions, ensuring proper operation of the tool.

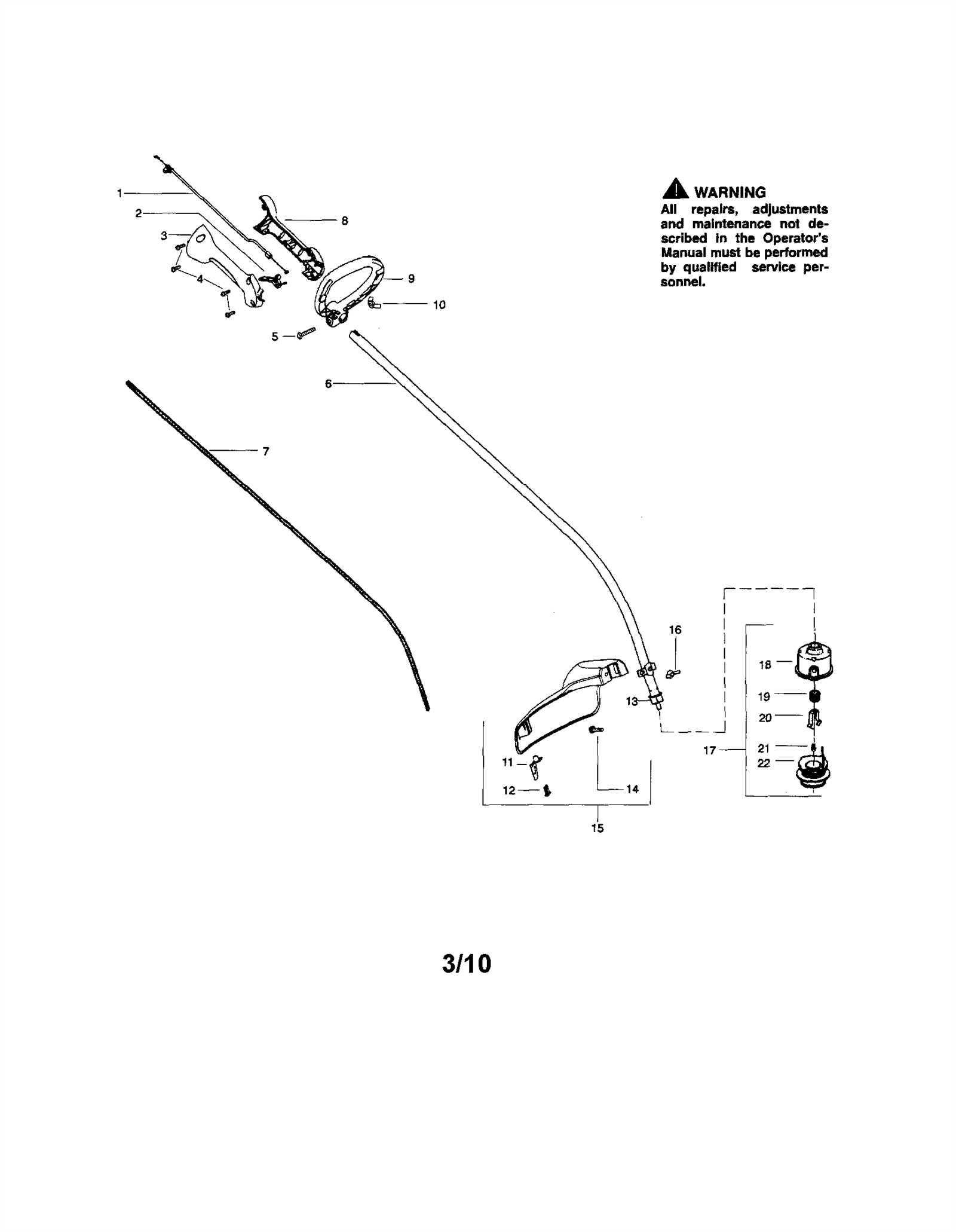

- Handle and Controls – provide ergonomic support and allow the operator to adjust settings easily.

- Cutting Mechanism – designed to trim efficiently, this section includes rotating elements that perform the actual cutting task.

- Shaft Assembly – connects different sections and transmits power from the motor to the cutting elements.

- Guard – shields the operator from debris and protects the surroundings during operation.

Each of these segments plays a critical role in maintaining optimal performance. Familiarizing yourself with their placement will simplify both routine maintenance and repairs.

Understanding the Weed Eater Components

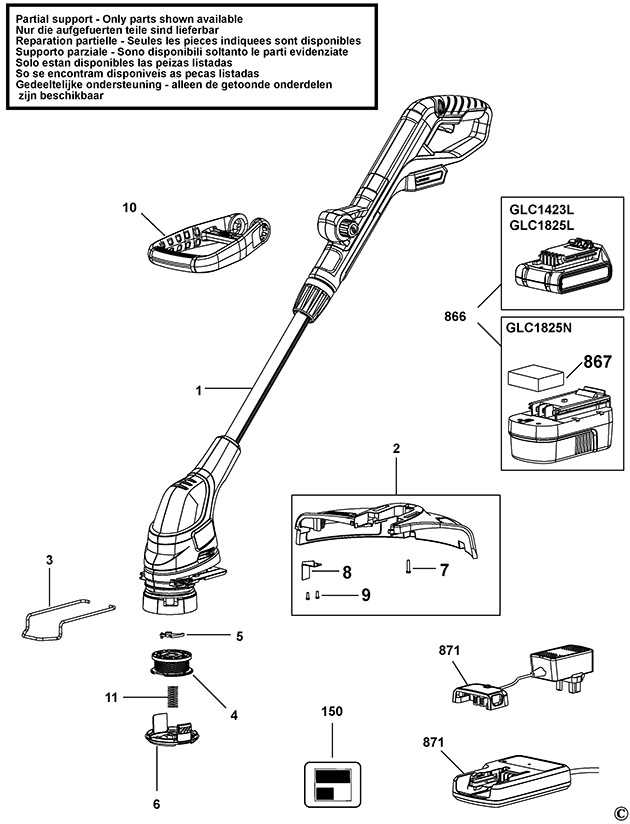

The device used for cutting and trimming vegetation consists of several essential elements working together to deliver optimal performance. Each part of this tool plays a specific role in ensuring smooth operation and efficient cutting. Understanding the main components can help you maintain and troubleshoot your equipment effectively.

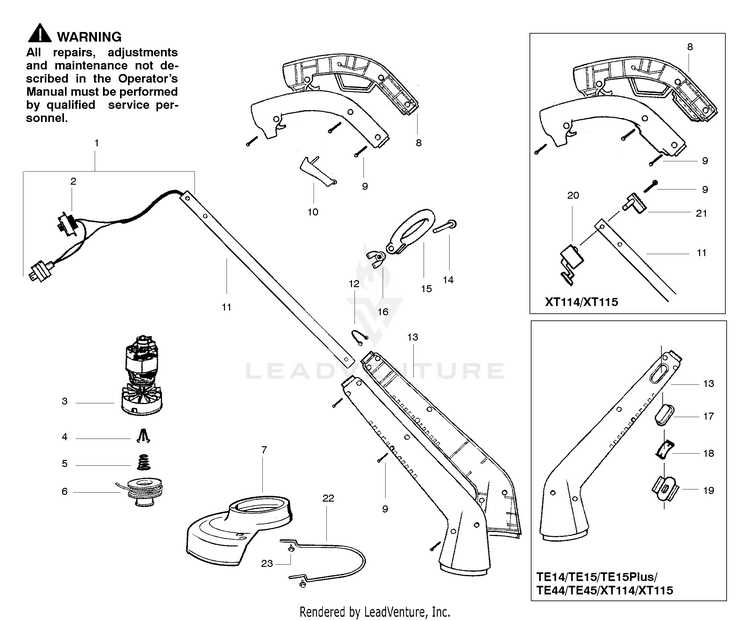

Main Functional Elements

The core sections of the machine are designed for easy handling, precision cutting, and durability. Here are the key elements that make up its structure:

- Motor: The power source of the tool, either electric or fuel-driven, responsible for generating the force needed for the cutting action.

- Shaft: A long, straight or curved piece that connects the motor to the cutting head, providing balance and reach during use.

- Cutting Head: The part that holds the cutting line or blade, rotating at high speed to trim grass and other growth.

Additional Components for Operation

- Handle: This element allows the user to grip and control the machine, typically

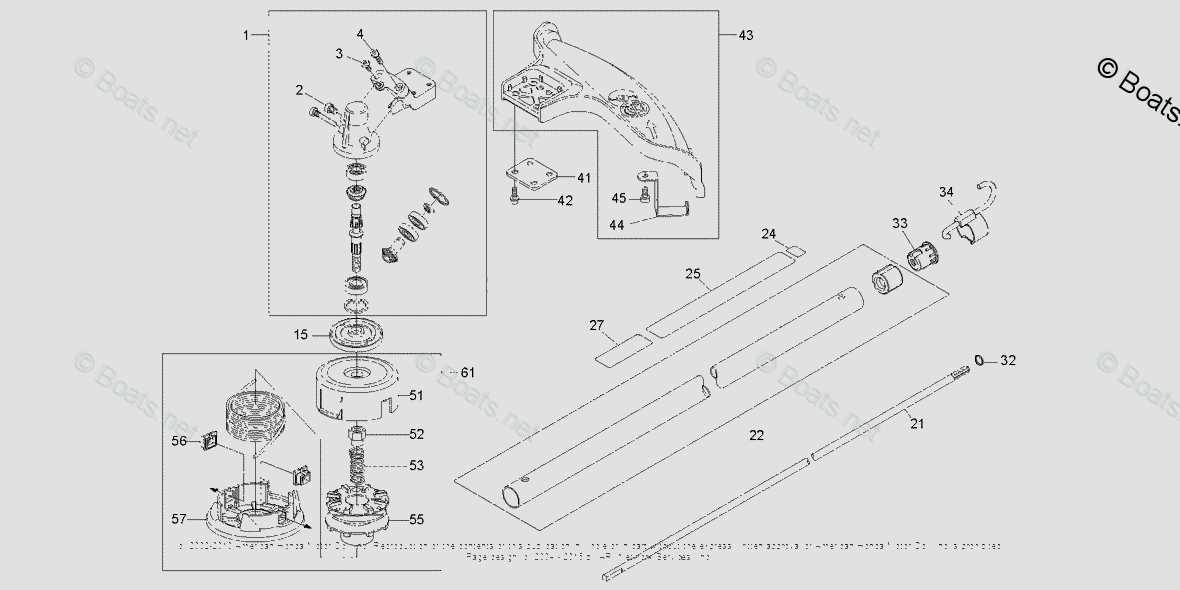

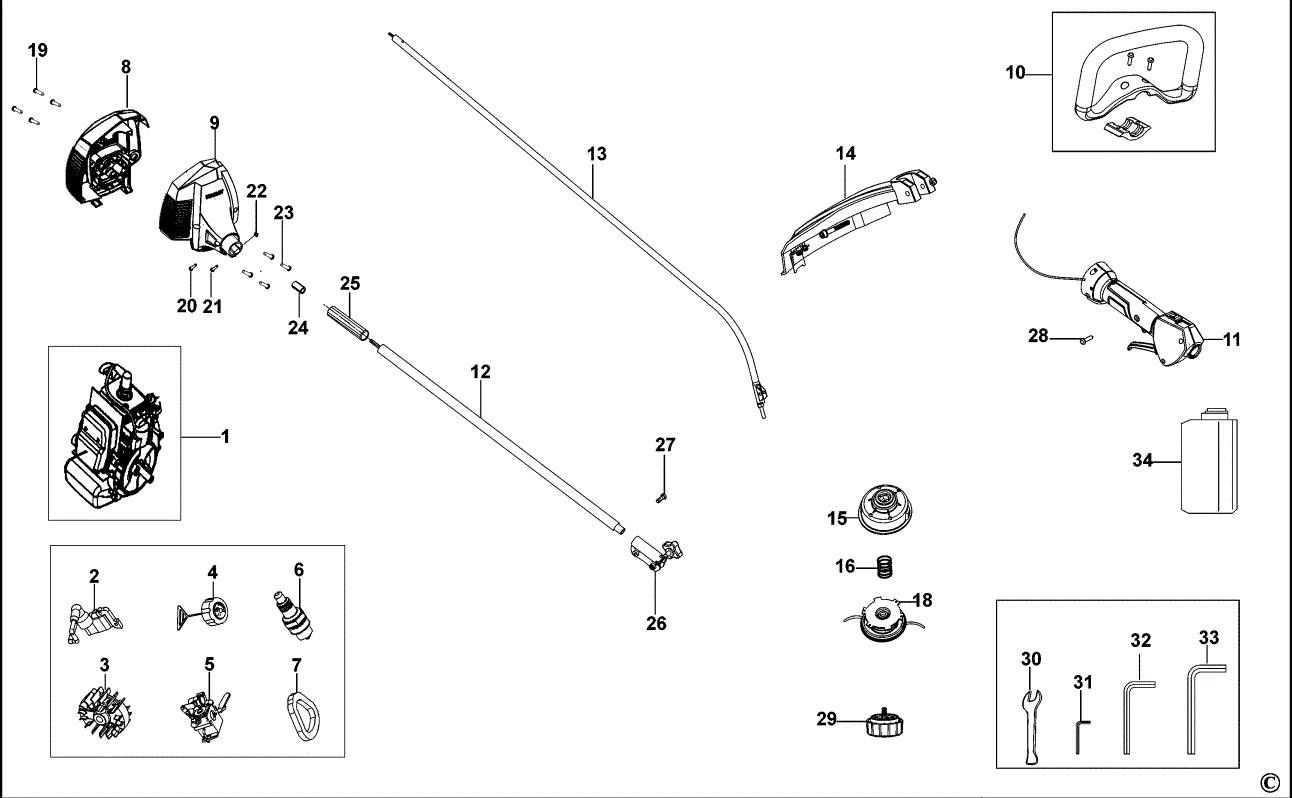

How to Identify Key Parts

Understanding the main components of your equipment is essential for proper maintenance and repairs. By recognizing the individual elements, you can ensure smoother operation and quicker troubleshooting when issues arise. This section will guide you through the process of identifying critical elements without needing a detailed technical drawing.

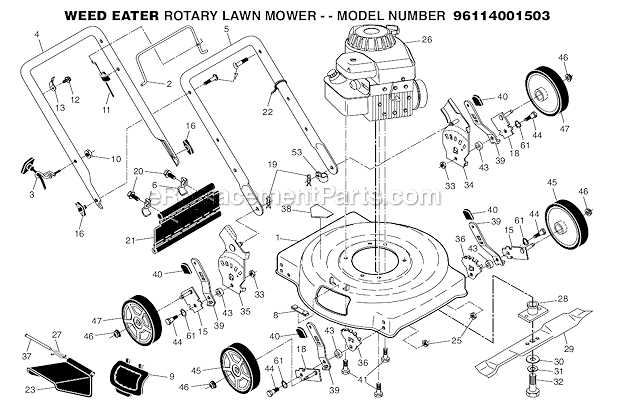

Locating the Main Components

The essential elements of your machine can typically be found in specific areas designed for power delivery, cutting efficiency, and operational control. Each serves a distinct purpose, contributing to the overall function. Below is a breakdown of how to find these core elements:

- Power Source: This component is usually located at the rear and supplies energy to the tool. It could be a motor or an engine depending on the model.

- Drive Shaft: Positioned centrally, this part transfers power from the motor to the working section.

- Cutting Head: Found at the end of the shaft, this is responsible for performing the cutting action and is typically detac

Proper Maintenance of Weed Eater

To ensure the longevity and optimal performance of your trimming tool, regular upkeep is essential. By taking the time to clean, inspect, and adjust various components, you can prevent wear and tear and avoid potential issues during operation. Consistent care will help maintain cutting efficiency and extend the life of your machine.

Cleaning is crucial after every use, especially around the cutting area and the engine. Dirt and debris can accumulate, affecting performance. Use a brush or cloth to remove any build-up.

Check the blades or strings regularly for signs of damage or wear. Replace them as needed to maintain cutting precision. Additionally, inspect the fuel and oil levels, ensuring the correct balance to avoid engine problems. Changing the air filter periodically will also enhance engine performance.

Lastly, make sure all moving parts are properly lubricated. This reduces friction and minimizes the risk of damage to key mechanical components. By following these steps, you can keep your tool running smoothly for years to come.

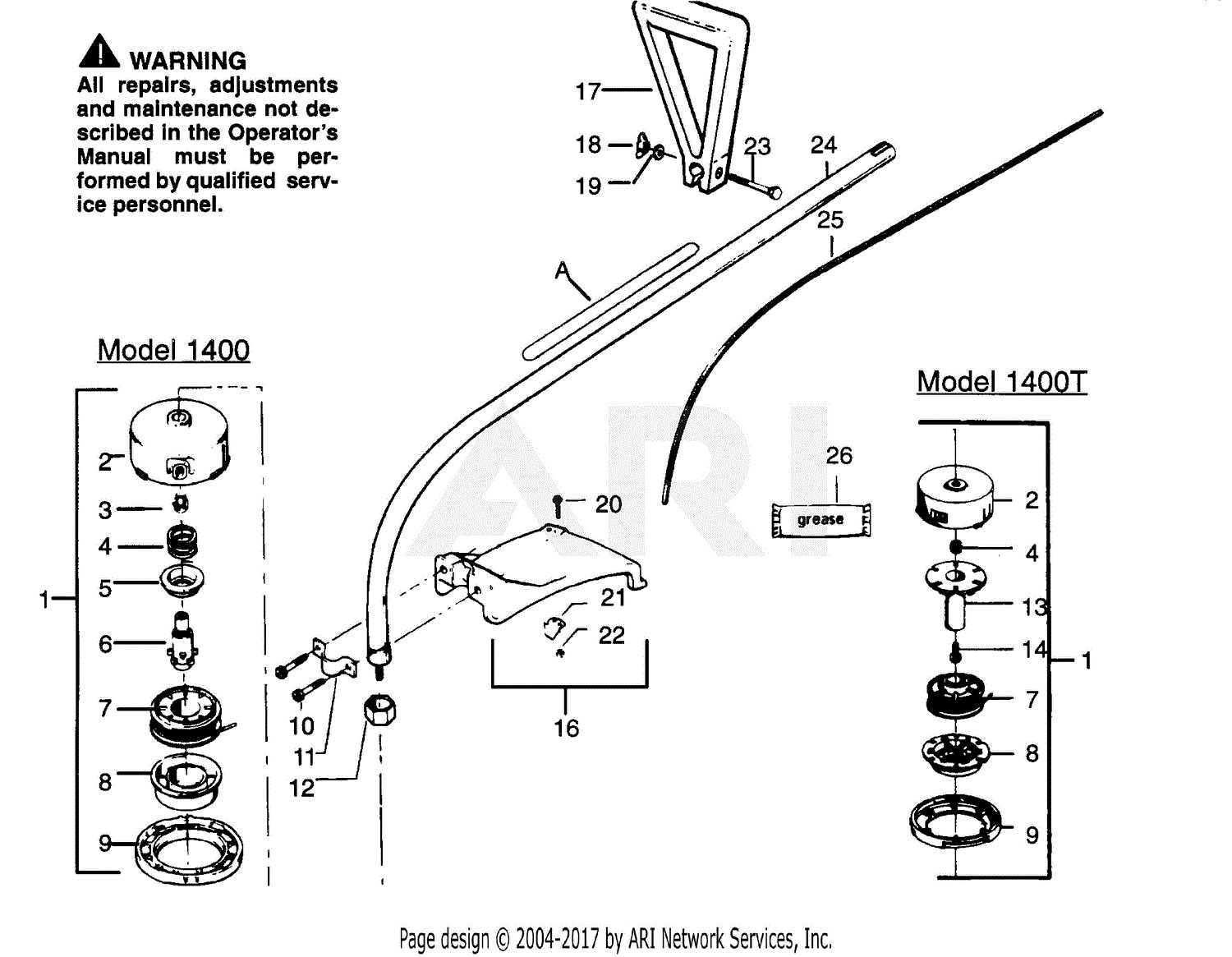

Replacing Damaged Components

Over time, certain mechanical components of your trimmer may wear out or become damaged, affecting the overall performance of the machine. To ensure the tool continues to function efficiently, it’s important to inspect and replace any faulty parts promptly. Regular maintenance can help prevent larger issues from arising, but when damage occurs, knowing how to replace specific elements can extend the lifespan of the equipment.

Before starting any repair, make sure the machine is turned off and disconnected from any power source. Identify the malfunctioning component and consult the manual for detailed instructions on removing and installing the replacement. You will likely need basic tools like screwdrivers or wrenches, depending on the type of assembly. Carefully follow the steps to disassemble the housing and access the damaged area.

Once the damaged part is removed, ensure the replacement matches the original specifications. Install the new piece by reversing the disassembly process, paying attention to screws, bolts, and fasteners to ensure everything is securely in place. After the replacement, test the equipment to confirm it is operating correctly before resuming regular use.

Essential Tools for Part Replacement

When it comes to maintaining and repairing outdoor power equipment, having the right tools is crucial for efficient and effective replacements. A well-equipped toolbox can make all the difference in ensuring smooth operations and preventing potential issues down the line.

- Wrench Set: A variety of wrenches will help in loosening and tightening bolts and nuts securely.

- Screwdriver Set: Both flathead and Phillips screwdrivers are essential for removing covers and securing components.

- Pliers: These are useful for gripping, twisting, and cutting wires or small parts.

- Socket Set: A comprehensive socket set can provide the necessary leverage for difficult-to-reach fasteners.

- Utility Knife: Handy for cutting through materials or trimming excess components during replacement.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Safety Gear: Always wear gloves and goggles to protect yourself from debris and sharp objects during repairs.

By having these essential tools on hand, you can confidently tackle the challenges of replacing components and ensure your equipment operates at its best.

Troubleshooting Common Issues

Addressing typical challenges that arise with outdoor maintenance tools can enhance their efficiency and longevity. Understanding these common problems can lead to quicker resolutions and ensure your equipment operates smoothly. Below are some prevalent issues users encounter and potential solutions to rectify them.

Identifying Performance Problems

Performance issues can manifest in various ways, such as difficulty starting or inconsistent power. These problems may stem from several factors, including fuel quality, spark plug condition, or air filter cleanliness. Regular maintenance checks can help identify and rectify these issues promptly.

Maintenance and Care Tips

Proper upkeep is essential for optimal operation. Routine inspections and cleaning of essential components can prevent most issues from escalating. Keeping the equipment well-maintained not only enhances its performance but also extends its lifespan.

Issue Possible Cause Solution Difficulty Starting Poor fuel quality Replace fuel with fresh, high-quality gasoline. Inconsistent Power Clogged air filter Clean or replace the air filter. Excessive Vibration Loose components Tighten any loose screws or bolts. Strange Noises Worn parts Inspect and replace worn components. Choosing the Right Replacement Parts

When it comes to maintaining your outdoor equipment, selecting the appropriate components is crucial for optimal performance and longevity. Understanding the different types of elements available can help ensure that your machinery operates smoothly and efficiently.

Assessing Compatibility

Before purchasing any new components, it is essential to evaluate their compatibility with your specific model. Consult the user manual or manufacturer’s website to identify the correct specifications. This step is vital, as using incompatible components can lead to performance issues or even damage.

Quality and Durability

Investing in high-quality replacements is always advisable. Look for options that are known for their durability and reliability. While it may be tempting to choose the cheapest alternatives, this can often result in more frequent replacements and higher costs over time. Opting for reputable brands or genuine components can provide peace of mind and enhance the longevity of your machinery.

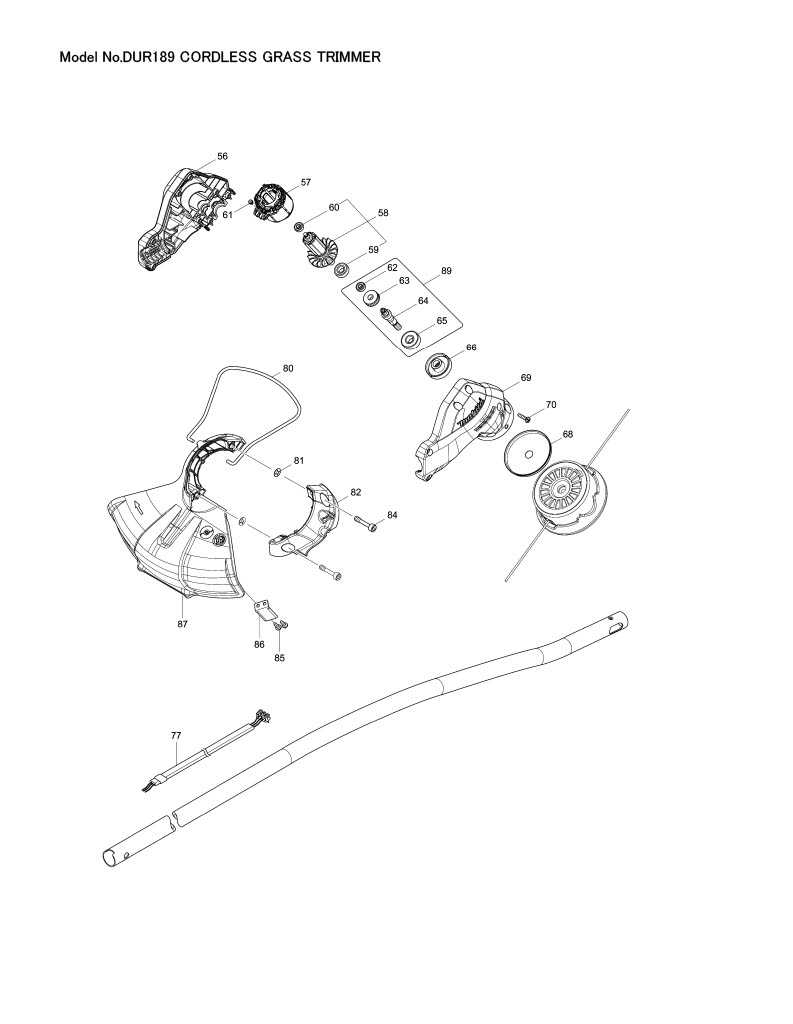

Assembly Instructions for Beginners

Assembling garden tools can be a straightforward task if you follow clear guidelines. This section provides essential steps for beginners to ensure a smooth assembly process, helping you to understand how to connect various components effectively.

Before you begin, gather all necessary components and tools. Familiarizing yourself with each piece will facilitate the assembly process. Below is a simple overview of the assembly steps:

Step Instructions 1 Lay out all components on a flat surface for easy access. 2 Refer to the manual to identify each item and its corresponding location. 3 Begin by attaching the base unit to the handle, ensuring a secure fit. 4 Next, connect any additional attachments as specified in the guide. 5 Tighten all screws and bolts to prevent any loosening during use. 6 Finally, perform a quick check to ensure everything is securely assembled. By following these straightforward instructions, you will be well on your way to successfully assembling your gardening equipment, making your outdoor tasks more efficient and enjoyable.

Ensuring Long-Term Part Durability

Maintaining the longevity of equipment components is crucial for optimal performance and reliability. Adopting specific practices can significantly extend their lifespan, ensuring that they function efficiently over time. By focusing on quality care, regular inspections, and timely replacements, users can minimize wear and tear, ultimately saving on costs and improving productivity.

Regular Maintenance Practices

Implementing routine maintenance is essential for preserving the integrity of the components. Simple actions like cleaning, lubricating, and adjusting settings can make a notable difference. Moreover, adhering to the manufacturer’s recommendations for maintenance schedules can help in identifying potential issues before they escalate.

Quality of Replacement Components

When it becomes necessary to replace any component, opting for high-quality alternatives is vital. Investing in superior materials will ensure that the replacements can withstand the rigors of use, providing better performance and longer service life.

Maintenance Action Frequency Benefits Cleaning After each use Prevents build-up and corrosion Lubrication Weekly Reduces friction and wear Inspection Monthly Identifies wear and potential failures Replacement As needed Ensures continued optimal performance Safety Tips for Handling Parts

When working with various components of outdoor tools, it is essential to prioritize safety. Proper handling techniques can significantly reduce the risk of injury and ensure a smooth maintenance process. This section outlines vital precautions and practices to keep in mind while dealing with these items.

Personal Protective Equipment

Always wear appropriate protective gear to shield yourself from potential hazards. This may include gloves, safety goggles, and sturdy footwear to prevent injuries from sharp or heavy elements.

Proper Tool Usage

Using the correct tools for assembly and disassembly is crucial. Incorrect tools can lead to damage or accidents. Ensure that your workspace is organized and free from distractions.

Safety Measure Description Wear Gloves Protects hands from cuts and abrasions. Use Eye Protection Prevents debris from entering the eyes. Maintain Clean Workspace Reduces the risk of accidents and improves efficiency. Follow Instructions Ensures correct handling and reduces errors. Weed Eater Motor Breakdown

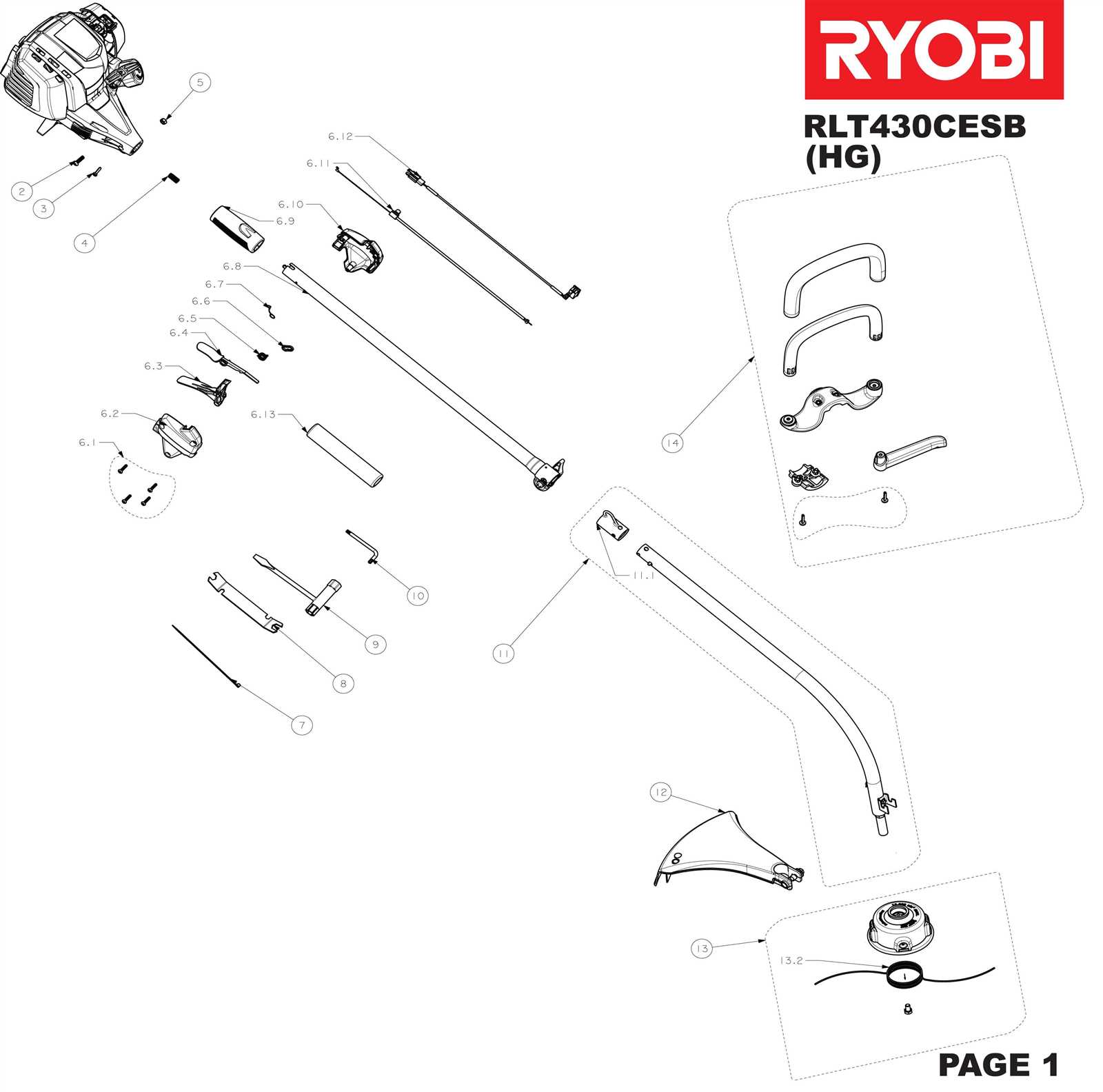

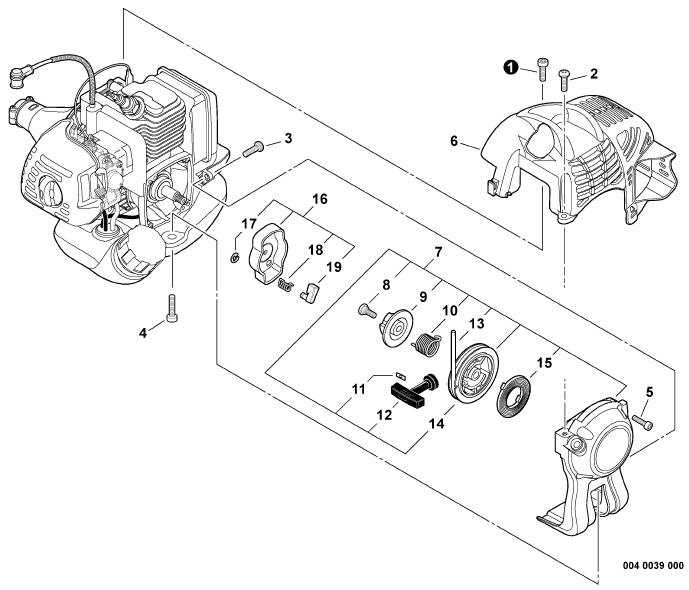

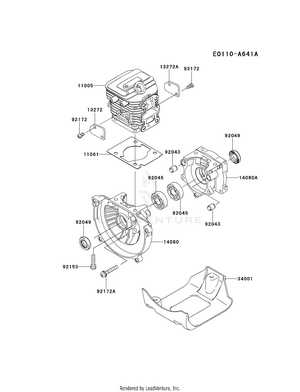

This section provides an overview of the components and functionality of the power unit commonly used in garden trimming devices. Understanding these elements is crucial for effective maintenance and troubleshooting.

Key components of the motor include:

- Engine: The core component responsible for generating power.

- Fuel System: Includes the tank, lines, and carburetor, which manage the flow of fuel.

- Ignition System: Comprises the spark plug and coil, initiating combustion within the engine.

- Cooling Mechanism: Helps to regulate temperature and prevent overheating during operation.

- Drive Shaft: Transfers power from the engine to the cutting attachment.

For effective repair and maintenance, familiarize yourself with the following aspects:

- Regular Inspections: Check for wear and tear on components to ensure smooth operation.

- Lubrication: Regularly lubricate moving parts to minimize friction and prolong lifespan.

- Fuel Quality: Use recommended fuel types to avoid engine damage.

- Replacement Parts: Identify and source quality replacements for any damaged components.

By comprehending these essential elements, users can maintain their devices efficiently and address any mechanical issues that may arise.

Where to Buy Authentic Parts

Finding genuine components for your outdoor equipment is essential for maintaining performance and longevity. Whether you are in need of replacement elements or upgrades, sourcing from reliable suppliers ensures quality and compatibility with your device.

One of the best options for acquiring original items is through authorized dealers. These vendors often have direct access to manufacturer stock, ensuring that what you receive is specifically designed for your model. Additionally, you can check the official website of the manufacturer for recommendations on trusted retailers.

Online marketplaces also provide a vast array of choices. However, it is crucial to verify the seller’s reputation and read customer reviews to avoid counterfeit items. Look for listings that specify authenticity and warranty coverage, which can give you peace of mind in your purchase.

Local hardware stores may carry some components as well. Visiting these shops allows you to inspect items physically and seek assistance from knowledgeable staff who can guide you to the correct selections.

In summary, whether you choose to shop online or visit local establishments, prioritize vendors who offer assurance of authenticity and quality. This approach will ultimately lead to a more satisfying experience and a well-functioning device.