Maintaining outdoor tools is essential for ensuring their longevity and optimal performance. A comprehensive overview of the various elements that make up your equipment can significantly aid in both troubleshooting and enhancement of functionality. Familiarizing oneself with these components helps users to efficiently address any issues that may arise during operation.

In this section, we will explore a detailed representation of the essential elements involved in your gardening apparatus. By breaking down the different sections and their corresponding functions, users can gain valuable insights into how to effectively service and improve their machinery. Understanding these intricacies not only facilitates repairs but also empowers owners to make informed decisions regarding upgrades or replacements.

With a closer look at the arrangement and interactions of the different components, you will develop a deeper appreciation for the engineering behind your equipment. This knowledge serves as a foundation for enhancing your skills and ensuring that your gardening tasks are executed with efficiency and ease.

This section aims to provide a comprehensive overview of a specific outdoor maintenance tool, highlighting its essential components and their functionalities. By understanding the structure and workings of this device, users can better maintain and troubleshoot their equipment, ensuring optimal performance.

| Component | Description |

|---|---|

| Motor | The heart of the equipment, responsible for generating power and driving the cutting mechanism. |

| Cutting Head | Holds the cutting line and is crucial for trimming and edging tasks. |

| Handle | Provides a grip for maneuvering the tool during operation. |

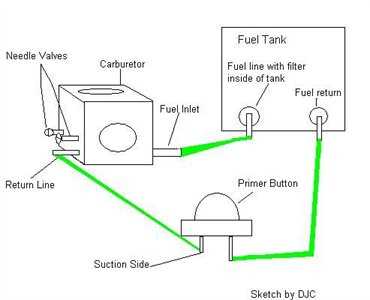

| Fuel Tank | Stores the fuel necessary for the operation of the engine. |

| Starter Mechanism | Facilitates the initiation of the motor, allowing the user to start the device easily. |

Key Features of the Model

This model is designed to deliver optimal performance and user convenience in outdoor maintenance tasks. With a focus on durability and efficiency, it incorporates several innovative elements that enhance its functionality and ease of use.

Enhanced Power and Efficiency

The equipment is equipped with a powerful engine that ensures robust performance even in challenging conditions. Its fuel efficiency allows for extended usage without frequent refueling, making it ideal for larger areas.

User-Friendly Design

Designed with the user in mind, the model features an ergonomic handle that minimizes fatigue during extended use. Additionally, the lightweight construction allows for easy maneuverability, ensuring that users can operate it comfortably for long periods. Safety features such as an automatic shut-off mechanism further enhance its usability, providing peace of mind during operation.

Understanding Parts Functionality

The functionality of components within a mechanical device plays a critical role in its overall performance. Each element contributes uniquely to the system, working in harmony to ensure effective operation. A thorough understanding of these elements helps users maintain and troubleshoot their equipment efficiently.

Core Components and Their Roles

Each individual element serves a distinct purpose, contributing to the machine’s ability to perform its tasks. For instance, the motor is the powerhouse that drives the entire system, while the cutting mechanism is designed to provide precision in operation. Understanding how these core components interact enables users to optimize performance and enhance durability.

Maintenance and Upkeep

Regular maintenance is essential for prolonging the lifespan of the device. Familiarity with the functionalities of various elements allows users to identify potential issues before they escalate. Implementing routine checks on critical parts not only ensures smooth operation but also safeguards against costly repairs.

Common Maintenance Practices

Regular upkeep is essential for ensuring the longevity and efficiency of outdoor power tools. Implementing a few straightforward maintenance habits can prevent issues and enhance performance, allowing users to maximize the benefits of their equipment. This section outlines some key practices that can help maintain the functionality and reliability of your machinery.

Routine Cleaning

Keeping your equipment clean is crucial for optimal performance. After each use, remove any debris, such as grass clippings and dirt, from the exterior and air vents. Regularly inspect and clean the filters to ensure proper airflow and prevent overheating.

Inspection and Replacement of Components

Periodically examine essential components for signs of wear or damage. Pay attention to the cutting mechanism, and replace any dull or damaged parts promptly. Additionally, check fuel lines and spark plugs to ensure they are functioning correctly, replacing them as needed to maintain efficiency.

Tools Needed for Repairs

When it comes to fixing outdoor equipment, having the right tools can significantly ease the process and enhance efficiency. A well-equipped workspace not only allows for a smoother repair experience but also ensures that each component is handled properly. Below is a list of essential implements that will assist in effectively addressing any issues.

Essential Hand Tools

Basic hand tools are indispensable when it comes to maintenance tasks. Common items include screwdrivers, wrenches, and pliers. These tools will help in loosening or tightening various components, making it easier to access internal parts for repairs. Additionally, a ratchet set is often beneficial for working with bolts and nuts that are hard to reach.

Power Tools and Equipment

For more extensive repairs, power tools can save both time and effort. A drill is useful for creating new holes or removing stubborn screws. Furthermore, an angle grinder can come in handy for cutting through metal parts or cleaning up edges. Always ensure that safety gear, such as goggles and gloves, is worn when operating these tools to prevent injury.

Parts Replacement Guidelines

Maintaining the efficiency of your outdoor equipment involves timely replacement of worn or damaged components. Understanding the essential guidelines for component substitution can enhance the longevity and performance of your machinery.

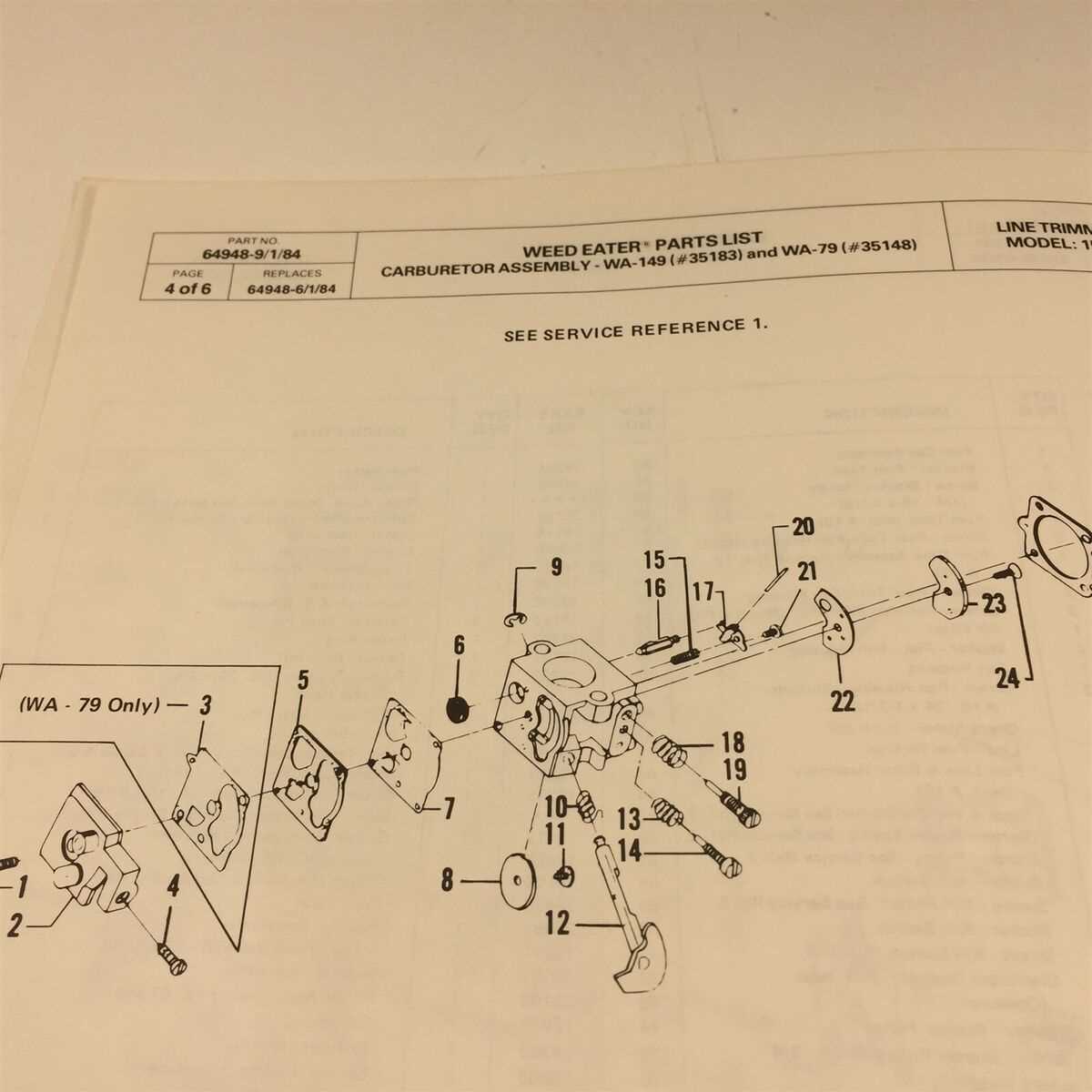

Identifying Necessary Components

Before proceeding with any replacements, it is crucial to identify the specific components that require attention. Referencing a reliable resource can provide valuable insights into the different elements and their respective roles in the overall functionality of the device.

Replacement Procedure

Once the needed elements are identified, follow a systematic approach to replace them. Ensure that you have the correct tools and new components ready. Adhering to the steps outlined below will facilitate a smooth transition:

| Step | Action |

|---|---|

| 1 | Disconnect the equipment from the power source. |

| 2 | Remove any coverings or shields to access the components. |

| 3 | Carefully detach the damaged or worn elements. |

| 4 | Install the new components, ensuring a secure fit. |

| 5 | Reassemble any coverings or shields that were removed. |

| 6 | Reconnect the power source and test the equipment. |

Following these guidelines will not only ensure optimal functionality but also contribute to the overall safety and reliability of your outdoor equipment.

Where to Buy Replacement Parts

Finding suitable components for your outdoor equipment is essential for maintaining its performance and longevity. Numerous retailers offer various options, ensuring you can locate the necessary items to keep your device running smoothly. This section will explore the best places to acquire these vital components.

Online Retailers

Shopping online provides convenience and access to a broader selection. Numerous websites specialize in outdoor equipment, offering detailed catalogs and competitive pricing. Here are some popular online platforms:

| Retailer | Website | Notes |

|---|---|---|

| Amazon | www.amazon.com | Wide variety, user reviews available. |

| eBay | www.ebay.com | Good for finding used or rare items. |

| Home Depot | www.homedepot.com | Local pickup options available. |

Local Retail Stores

Visiting local hardware or specialty stores can be advantageous for immediate needs. These establishments often carry essential components and offer personalized assistance. Consider the following types of stores:

| Store Type | Advantages |

|---|---|

| Hardware Stores | Quick access, knowledgeable staff. |

| Garden Centers | Specialized items for outdoor equipment. |

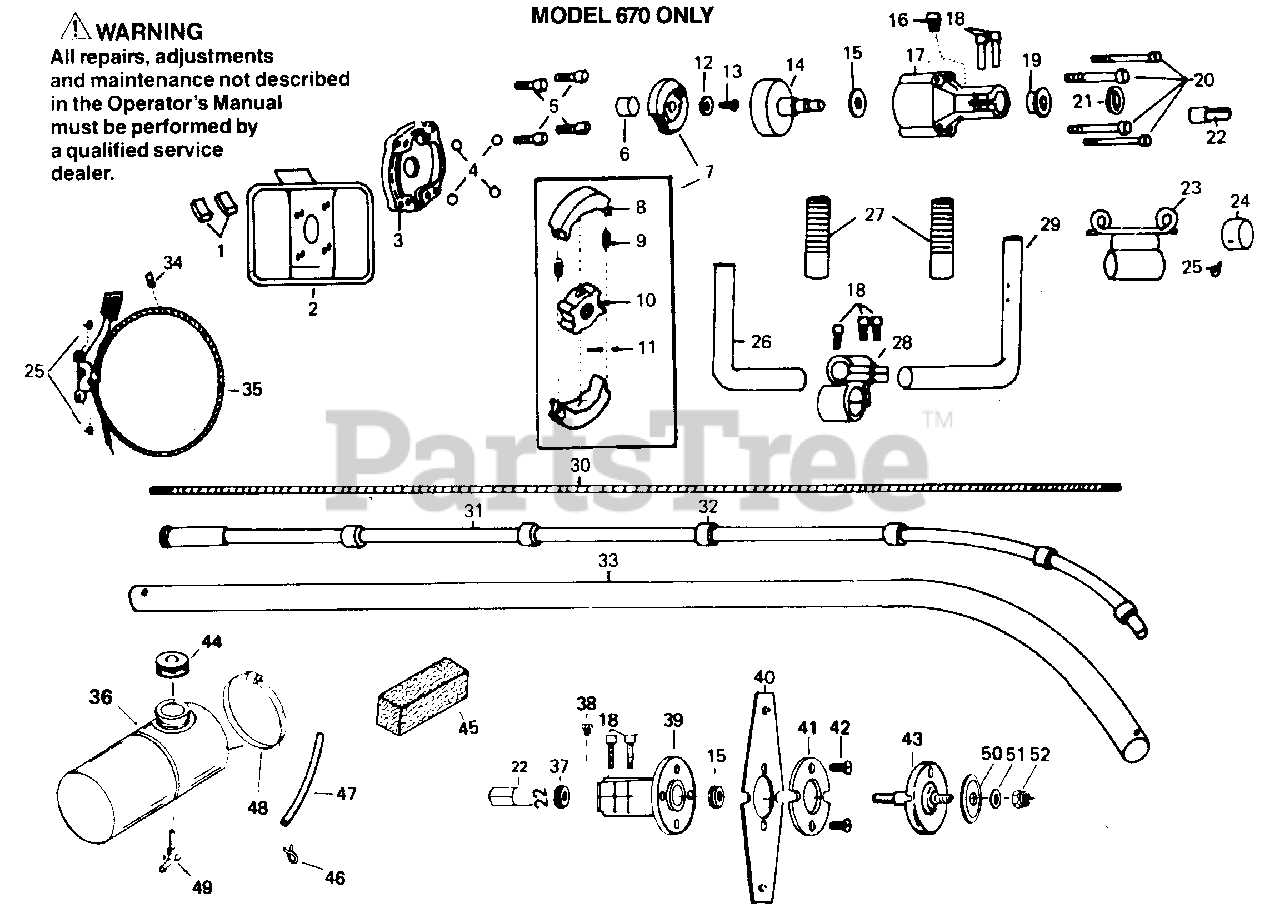

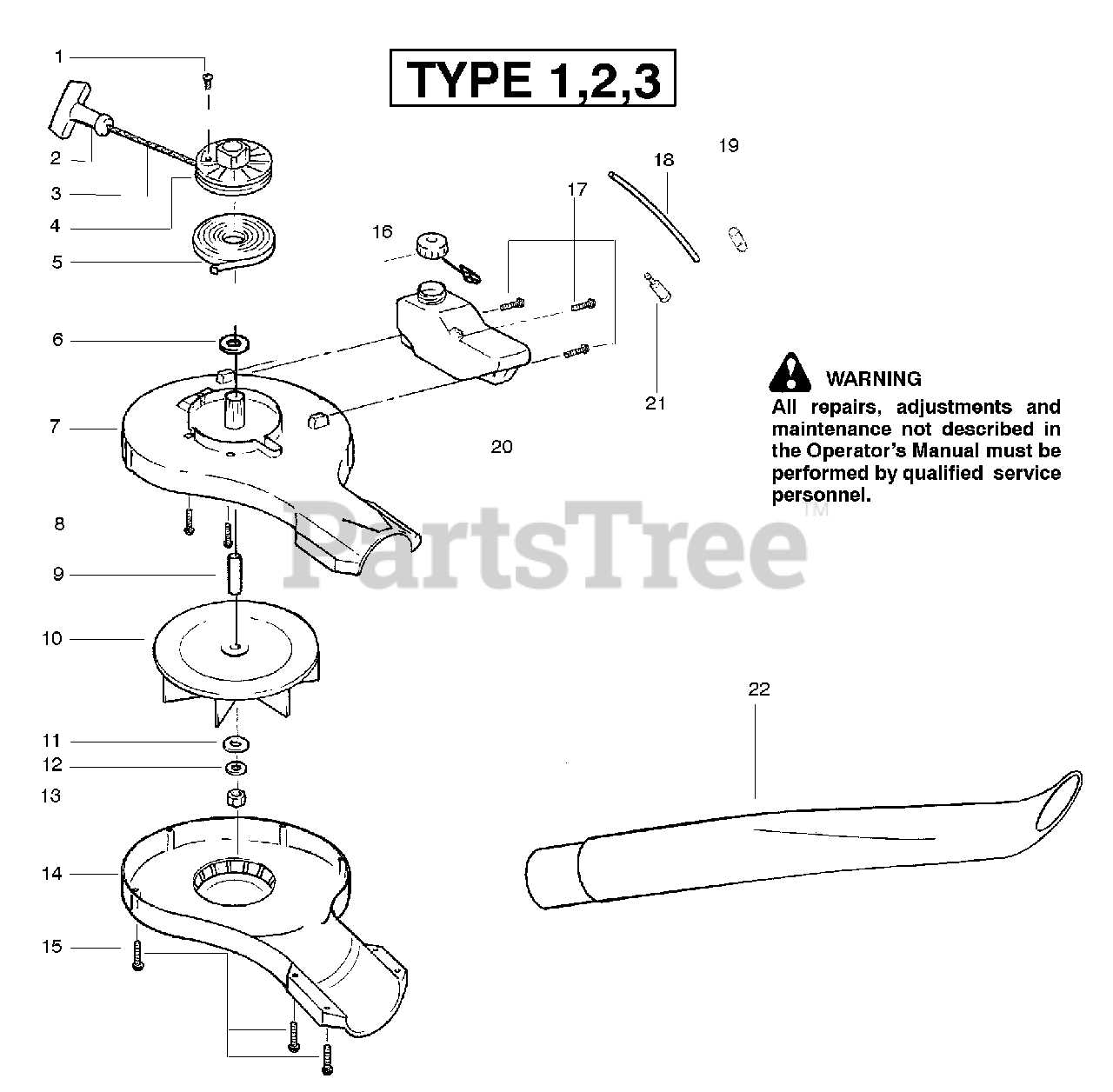

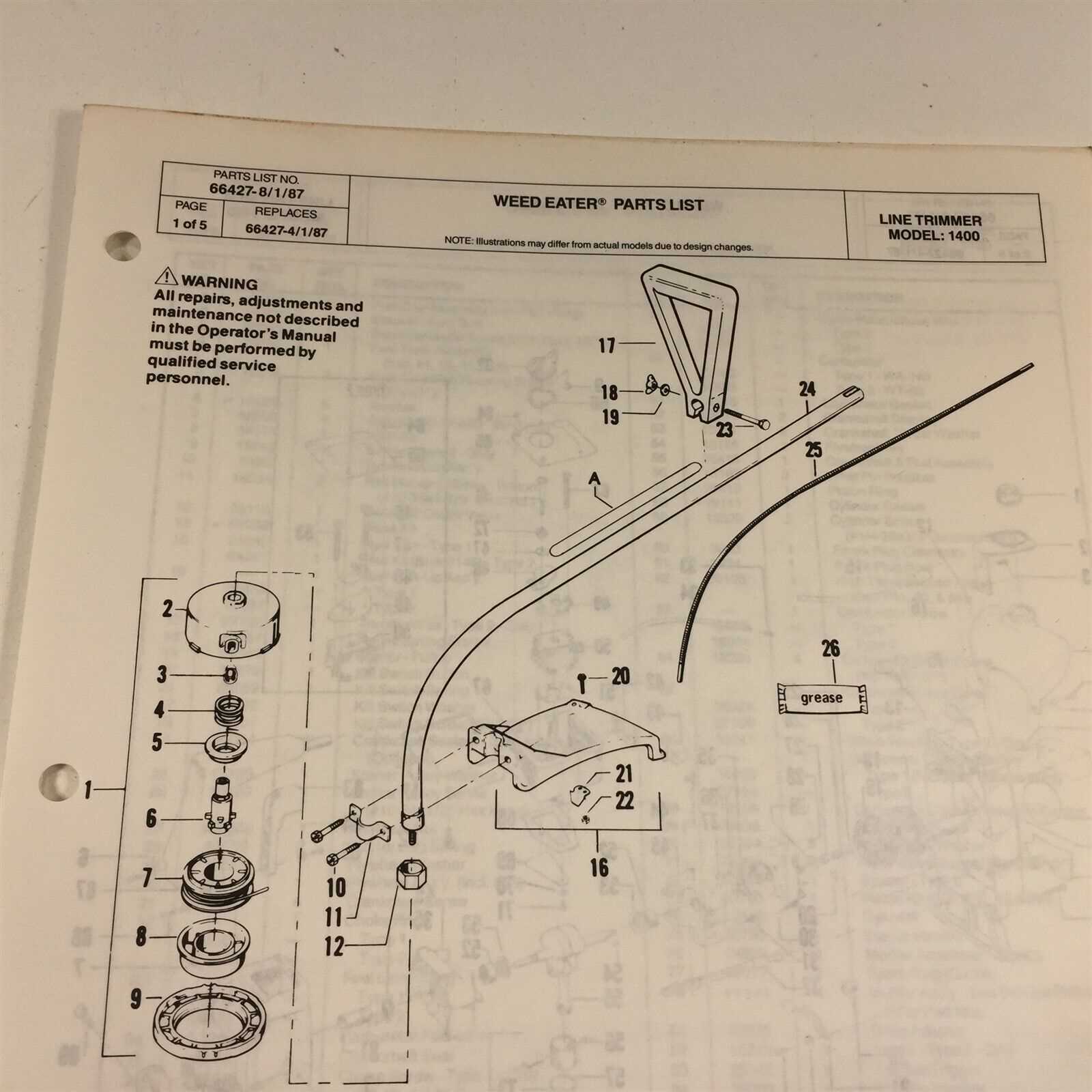

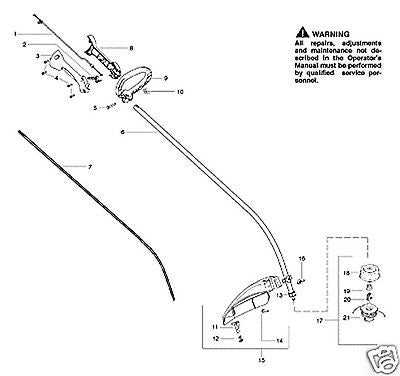

Visual Guide to Assembly

This section offers a comprehensive overview of the assembly process for your device, focusing on key components and their arrangement. Understanding how each element fits together is essential for effective operation and maintenance, ensuring that everything functions as intended. This guide is designed to simplify the assembly process, making it accessible even for those with minimal experience.

Essential Components Overview

Before beginning the assembly, it’s crucial to familiarize yourself with the various elements involved. Each component serves a specific purpose, contributing to the overall functionality of the equipment. Refer to the visual references to identify components such as the power unit, handle, and attachment mechanisms.

Step-by-Step Assembly Instructions

Follow these steps to successfully assemble your equipment:

- Step 1: Start by securing the main unit to the base, ensuring a snug fit.

- Step 2: Attach the handle, making sure it is aligned correctly for ease of use.

- Step 3: Fasten any additional components, checking that they are securely in place.

Taking the time to follow these instructions will lead to a smooth assembly process, allowing you to enjoy the benefits of your equipment efficiently.

Diagnosing Common Issues

Identifying frequent problems with outdoor power equipment can enhance performance and extend lifespan. Understanding typical symptoms and their causes allows for more effective troubleshooting and maintenance.

One common issue involves the unit failing to start. This can be attributed to factors such as insufficient fuel, a clogged air filter, or a faulty ignition system. Checking these components systematically can help pinpoint the problem.

Another prevalent challenge is poor cutting performance. This may arise from dull blades, improper tension, or debris obstructing the cutting mechanism. Regular inspection and maintenance of the cutting elements can resolve these concerns.

Overheating is also a frequent occurrence, often caused by a blocked exhaust or low lubrication levels. Ensuring proper airflow and adequate oil can mitigate this issue and promote efficient operation.

Lastly, vibrations during operation can signal mechanical wear or loose components. Tightening connections and replacing worn parts are essential steps in maintaining stability and safety.

Safety Precautions During Repairs

When undertaking maintenance on any outdoor equipment, ensuring personal safety and the proper functioning of the device is essential. Adhering to basic safety guidelines can help prevent accidents and facilitate a smoother repair process. This section outlines key considerations to keep in mind while performing service tasks.

Personal Protective Equipment

Before beginning any repair work, it is crucial to equip yourself with appropriate protective gear. Items such as safety goggles, gloves, and sturdy footwear can shield against potential injuries from debris and moving parts. Wearing long sleeves and trousers is also advisable to minimize skin exposure.

Work Environment

Maintaining a clean and organized workspace is vital for safe repairs. Ensure that the area is well-lit and free of clutter to avoid tripping hazards. Additionally, it is important to use stable surfaces for placing equipment to prevent slips or falls during the repair process. Always disconnect power sources before initiating any work to eliminate the risk of electrical shock.

Comparative Analysis with Similar Models

This section explores the distinctions and similarities between a specific model and its contemporaries in the market. By examining various features, specifications, and performance metrics, users can make informed decisions about their equipment choices.

Key Features to Consider

- Power Output: Evaluate the engine strength and efficiency.

- Weight and Maneuverability: Compare the ease of handling between different models.

- Cutting Mechanism: Analyze the type of cutting system employed.

- Fuel Efficiency: Consider how much fuel each model consumes during operation.

Performance Metrics

- Assess acceleration rates and maximum speeds.

- Review user feedback on durability and reliability.

- Investigate maintenance requirements and the availability of replacement components.

- Determine warranty offerings and customer support options.

Owner Reviews and Feedback

This section delves into the experiences and opinions shared by users of this outdoor power tool. Customer feedback plays a vital role in understanding the functionality, reliability, and overall performance of the equipment. By examining a range of reviews, potential buyers can gain insights into the strengths and weaknesses as expressed by those who have firsthand experience.

| User | Rating | Feedback Summary |

|---|---|---|

| John D. | 4.5/5 | Highly efficient for light-duty tasks; easy to maneuver. |

| Sarah L. | 4/5 | Great value for the price; reliable performance, but slightly noisy. |

| Mike T. | 3.5/5 | Effective for small jobs, but struggles with thicker vegetation. |

| Emily R. | 5/5 | Excellent product! Lightweight and easy to start. |

Tips for Extended Lifespan

Maintaining equipment longevity is essential for optimal performance and reducing replacement costs. By implementing effective care strategies, users can enhance the durability and functionality of their tools. Below are several recommendations to ensure prolonged operational life.

- Regular Cleaning: After each use, remove debris and residue from the exterior and moving parts. This practice prevents buildup that can lead to wear and tear.

- Routine Inspections: Periodically check components for signs of damage or wear. Identifying issues early can prevent more significant problems down the line.

- Proper Storage: Store the equipment in a dry, sheltered location to protect it from harsh weather conditions that can cause corrosion and other damage.

- Use Quality Fuel: Always utilize recommended fuel types and additives to ensure efficient operation and minimize engine problems.

- Follow Manufacturer Guidelines: Adhere to maintenance schedules and service recommendations provided in the user manual for optimal upkeep.

By following these simple yet effective practices, users can significantly enhance the lifespan and reliability of their tools, ensuring they remain functional for many seasons to come.