Understanding the intricate mechanisms of heavy-duty equipment is crucial for efficient operation and maintenance. This section explores the various elements that contribute to the overall functionality of these machines, focusing on how they interact and perform under different conditions.

By examining a detailed representation of the assembly, operators and technicians can gain insight into each component’s role. This knowledge not only enhances performance but also aids in troubleshooting potential issues, ensuring that machinery remains reliable and effective.

Whether you are a seasoned professional or a newcomer to this field, familiarizing yourself with these critical elements will provide the ultimate advantage. A thorough comprehension of the assembly will empower users to optimize their equipment, leading to improved results and increased efficiency.

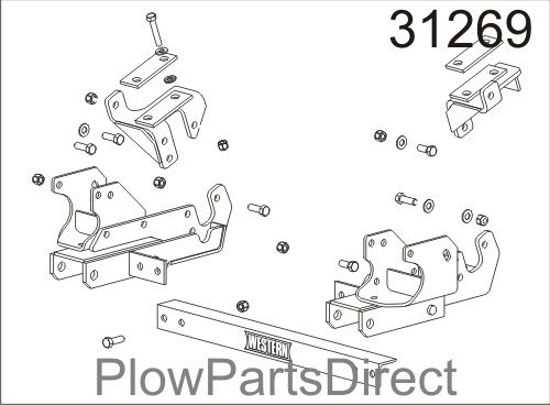

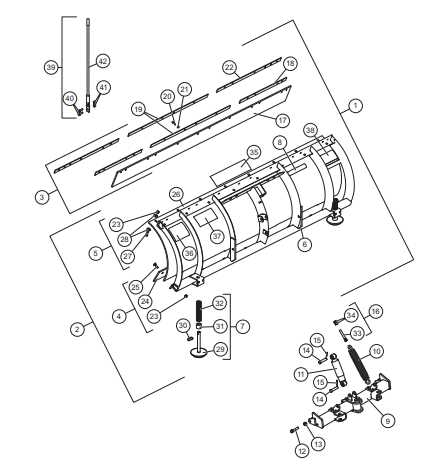

Understanding Western Ultramount Design

This section explores the intricate framework of a specific attachment system designed for efficient surface clearing. By examining its structure and functionality, users can gain insights into its operational benefits and design philosophy.

Core Components

The main elements of this system are engineered to provide stability and ease of use. Each component works in harmony to ensure optimal performance under various conditions, enhancing maneuverability and effectiveness.

Functional Advantages

Emphasizing adaptability, this design allows for seamless integration with different vehicles. Users can expect a robust experience that maximizes efficiency, making it the ultimate choice for maintaining clear surfaces.

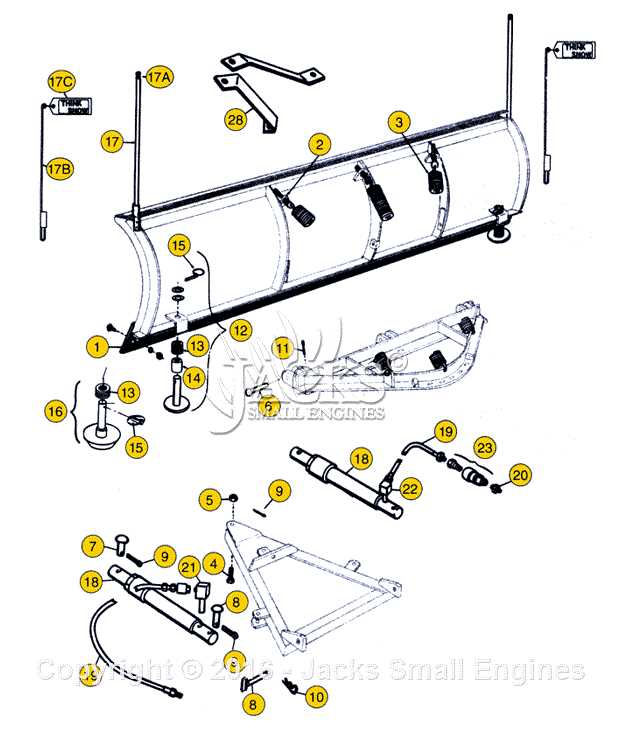

Key Components of Snow Plow Systems

Understanding the essential elements of winter equipment is crucial for effective operation and maintenance. Each component plays a significant role in ensuring efficiency and reliability during challenging weather conditions. This section outlines the main constituents that contribute to optimal performance.

| Component | Description |

|---|---|

| Blade | The primary surface used to clear accumulated ice and precipitation from roadways. |

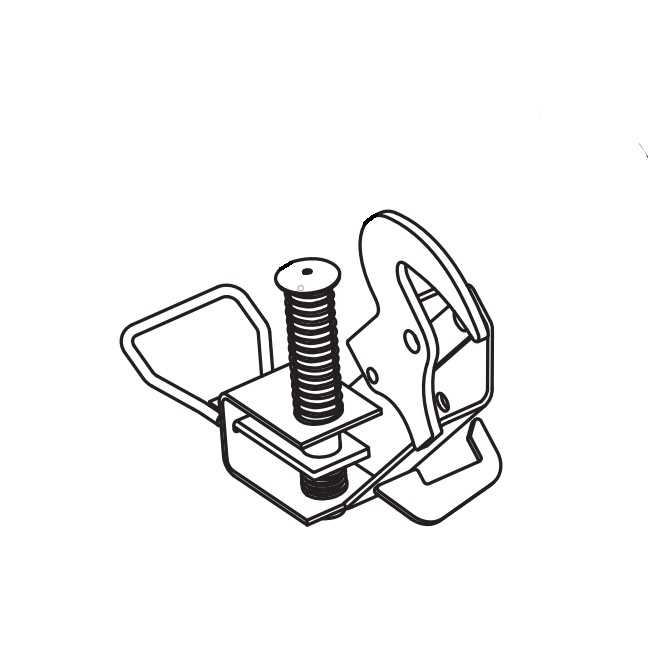

| Mounting System | A framework that attaches the clearing apparatus to the vehicle, providing stability and control. |

| Hydraulic Mechanism | This system facilitates the lifting, lowering, and angling of the clearing device, allowing for versatile operation. |

| Control System | An interface for the operator to manage the various functions of the equipment efficiently. |

| Support Frame | A sturdy structure that reinforces the entire setup, ensuring durability under heavy loads. |

Familiarity with these crucial components allows users to optimize performance and extend the lifespan of their winter machinery.

Maintenance Tips for Ultramount Parts

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By implementing a few key practices, you can enhance efficiency and prevent unexpected breakdowns. This guide outlines crucial strategies for maintaining various components, ensuring they operate smoothly and reliably throughout their use.

Regular Inspection

Frequent checks of your equipment are vital. Look for signs of wear or damage, such as cracks, rust, or loose connections. Identifying these issues early can prevent more significant problems later on.

Lubrication and Cleaning

Proper lubrication minimizes friction and wear. Use the recommended lubricants for each component and clean them regularly to remove debris that can hinder performance. A clean machine runs more efficiently and lasts longer.

| Component | Inspection Frequency | Maintenance Action |

|---|---|---|

| Hydraulic System | Monthly | Check fluid levels and look for leaks |

| Electrical Connections | Bi-weekly | Inspect for corrosion and tightness |

| Mechanical Joints | Weekly | Ensure bolts are tightened and lubricated |

Following these maintenance tips will help prolong the life of your equipment and ensure it operates at peak efficiency. Consistent care is the key to avoiding costly repairs and maintaining reliable performance.

Common Issues and Solutions

When operating a snow removal system, various challenges may arise that can affect performance and efficiency. Understanding these common issues and their respective solutions can help ensure smooth operation during winter conditions.

1. Hydraulic System Failures: One frequent issue is a malfunction in the hydraulic system, which can lead to insufficient blade movement. Regularly check for leaks and ensure that the fluid levels are adequate. If problems persist, consider replacing worn hoses or seals.

2. Electrical Malfunctions: Electrical problems can cause the system to become unresponsive. Inspect connections and fuses regularly. If a component fails, replacing it promptly can restore functionality.

3. Blade Wear: Over time, the cutting edge may become dull or damaged, impacting efficiency. Regular maintenance, including sharpening or replacing the blade, is essential for optimal performance.

4. Mounting Issues: Improper mounting can lead to instability or misalignment. Ensure that all components are securely attached and aligned correctly. Tighten bolts and inspect brackets for wear.

5. Control Malfunctions: If the control system does not respond as expected, check for loose wires or damaged controls. Replacing faulty components can often resolve these issues.

By addressing these common challenges promptly, operators can enhance the reliability and effectiveness of their winter equipment, ensuring they are ready for any snow removal task.

Benefits of Using Quality Components

Utilizing high-grade components significantly enhances the performance and longevity of machinery. When superior materials and craftsmanship are employed, the overall reliability and efficiency of equipment improve, leading to a more productive experience.

Improved Durability

Quality components ensure that equipment withstands harsh conditions and regular use. The advantages include:

- Longer lifespan

- Resistance to wear and tear

- Fewer breakdowns

Enhanced Performance

Superior materials contribute to better functionality. Key benefits include:

- Increased efficiency

- Faster operation

- Reduced maintenance costs

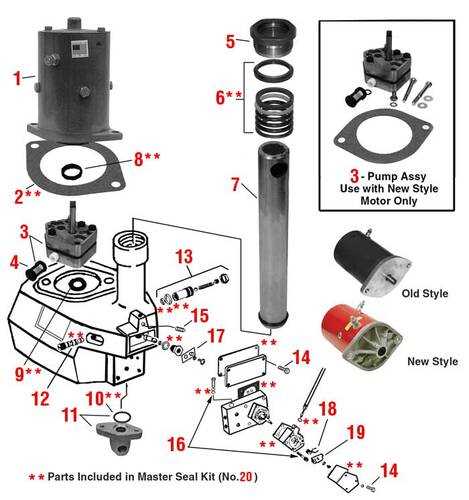

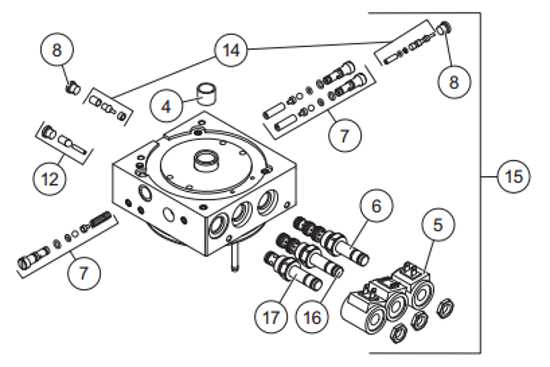

Exploring Hydraulic Mechanisms in Plows

Hydraulic systems play a crucial role in enhancing the efficiency and functionality of equipment designed for clearing surfaces. By harnessing the power of fluid dynamics, these mechanisms allow for precise control and adaptability in various conditions, making operations smoother and more effective.

Key Components of Hydraulic Systems

- Hydraulic Pumps: Generate fluid flow, crucial for system operation.

- Hydraulic Cylinders: Convert fluid pressure into linear motion, enabling movement.

- Valves: Control the direction and flow of hydraulic fluid, ensuring accurate functionality.

- Hoses and Fittings: Facilitate the transfer of hydraulic fluid between components.

Benefits of Hydraulic Mechanisms

- Enhanced Control: Allows for precise adjustments and maneuvers.

- Increased Power: Offers superior force compared to mechanical systems.

- Versatility: Adaptable to different tasks and environments.

- Reduced Wear: Minimizes physical stress on components, extending lifespan.

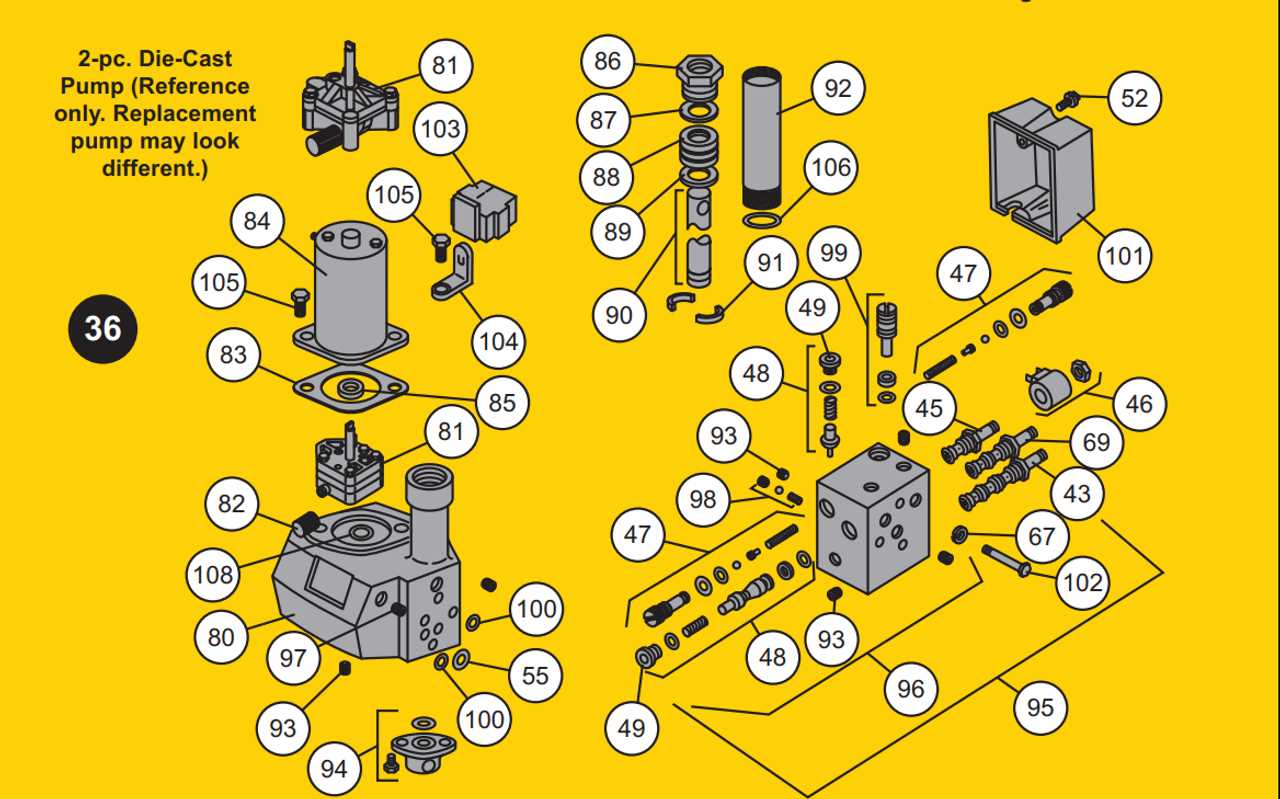

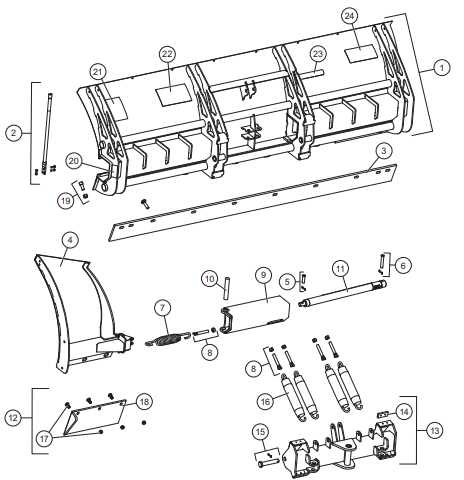

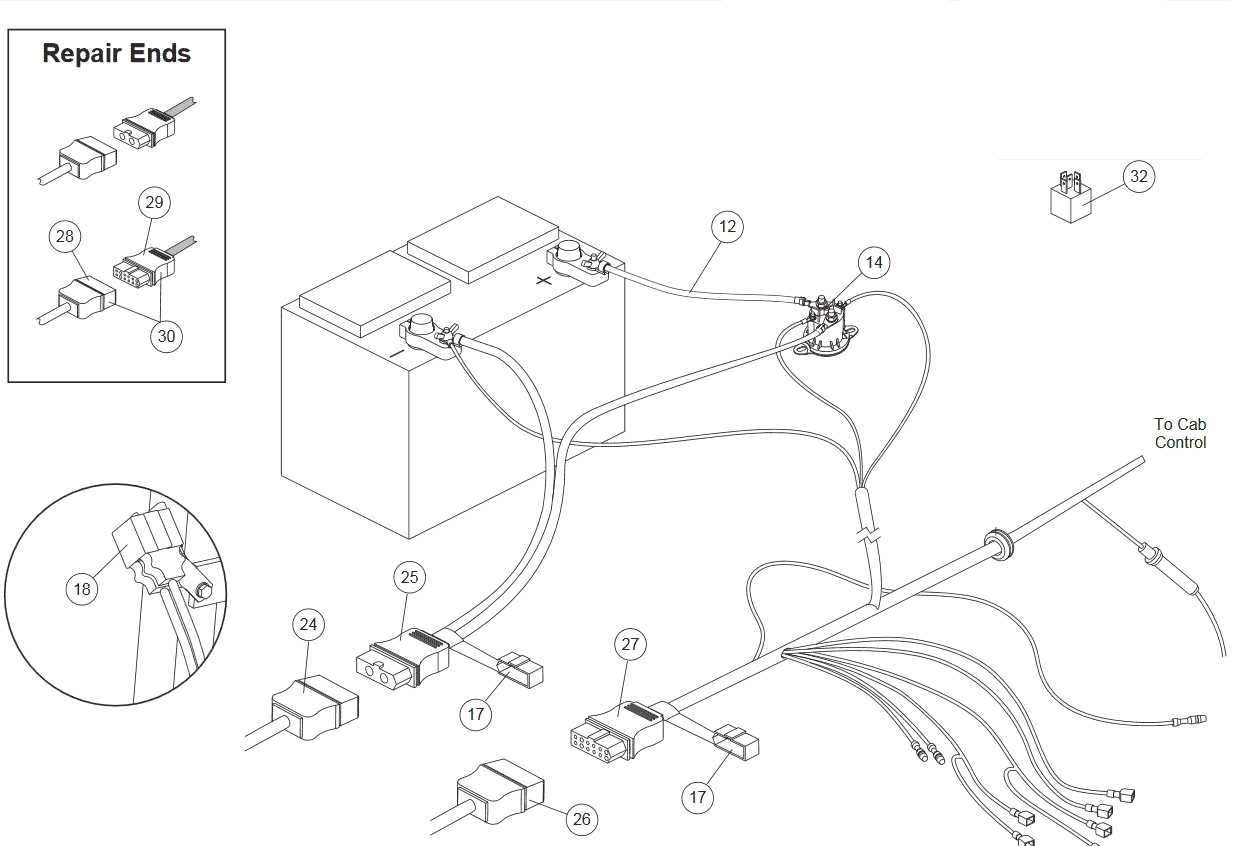

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as a roadmap, guiding you through the various elements and their connections. By familiarizing yourself with the symbols and layout, you can quickly identify necessary items and their functions.

Start with the legend: Most visuals include a key that explains the symbols used. This is crucial for interpreting the specifics of each element.

Pay attention to numbers: Each component typically has a corresponding number that links it to descriptions or lists. This connection aids in finding replacement items accurately.

Look for groupings: Components are often organized by function or location. Identifying these clusters helps you understand how parts interact with one another.

Practice makes perfect: The more you work with these representations, the more intuitive they become. Take time to review them thoroughly to build confidence in your skills.

Upgrading Your Ultramount Equipment

Enhancing your equipment can significantly improve performance and efficiency. By making thoughtful upgrades, you can ensure that your setup meets the demands of various tasks while extending its lifespan.

Consider the following aspects when planning your enhancements:

- Performance Boost: Look for components that can enhance speed and power, allowing for quicker and more efficient operation.

- Durability: Invest in high-quality materials that withstand harsh conditions and reduce wear and tear over time.

- Compatibility: Ensure that new additions are compatible with your existing system to avoid installation issues and maximize functionality.

- Technology Integration: Explore options for integrating advanced technology, such as GPS or remote control systems, to streamline your workflow.

Before making any modifications, evaluate your current setup and identify areas that require improvement. A strategic approach to upgrades can lead to a more efficient and reliable operation.

- Assess your current equipment capabilities.

- Research available upgrades that align with your needs.

- Consult with professionals if necessary to ensure optimal choices.

- Plan for installation and future maintenance.

By focusing on these elements, you can effectively enhance your equipment, ensuring it remains a valuable asset for years to come.

Compatibility with Various Vehicles

This section highlights the adaptability of specific equipment to a range of vehicle models, ensuring optimal performance across different makes and types. Understanding compatibility is crucial for users who seek efficiency and reliability during harsh weather conditions.

Many models are designed to fit a variety of trucks and SUVs, providing flexibility for owners. Adapters and mounting kits are often available, enhancing the versatility of the system. It’s important to verify that the chosen setup aligns with the vehicle’s specifications to achieve the best results.

Users should consider the vehicle’s weight class and front-end configuration when selecting equipment. Certain designs cater specifically to light-duty trucks, while others are tailored for heavier-duty models. Researching compatibility can prevent costly mistakes and ensure a seamless installation process.

Consulting manufacturer guidelines and compatibility charts can aid in making informed decisions. Proper alignment with the vehicle’s capabilities not only maximizes performance but also extends the lifespan of the equipment.

Safety Features in Snow Plows

Ensuring safe operation during winter maintenance is crucial for both the operator and the public. Various mechanisms and technologies are integrated to minimize risks and enhance performance in challenging conditions.

Visibility Enhancements play a vital role in safety. Many units are equipped with high-intensity lights and reflective materials to improve sightlines during low-light conditions, ensuring that operators can navigate effectively.

Emergency Shutoff Systems are essential in mitigating accidents. These systems allow for immediate cessation of operations if an unforeseen issue arises, providing an added layer of protection for both the operator and surrounding pedestrians.

Furthermore, Stability Control Features help maintain balance and traction on slippery surfaces. Advanced technology detects skidding and adjusts power distribution, aiding the operator in maintaining control.

Ergonomic Design is also significant. Controls that are intuitively placed reduce strain and enhance reaction times, allowing for quicker responses to potential hazards.

Lastly, regular Maintenance Checks are crucial. A proactive approach to servicing equipment ensures that all safety features function properly, significantly reducing the likelihood of accidents during operation.