When it comes to maintaining efficiency in winter conditions, comprehending the various elements that contribute to the functionality of snow clearing tools is essential. These essential components work together to ensure that the machinery operates smoothly, providing effective service throughout the colder months. By exploring the intricate relationships between these parts, users can gain valuable insights into their operations.

Moreover, having a clear understanding of how these elements fit together not only aids in troubleshooting but also enhances the overall maintenance routine. Recognizing potential wear and tear points can prevent breakdowns and extend the life of the equipment. The interplay of these components showcases the ingenuity behind snow removal systems, highlighting their importance in facilitating safe and accessible roadways.

In this section, we will delve into the detailed layout of these crucial mechanisms, offering a closer look at how each element contributes to the overall effectiveness of the snow clearing process. A thorough examination of these configurations enables operators to enhance their understanding and improve their handling of the machinery.

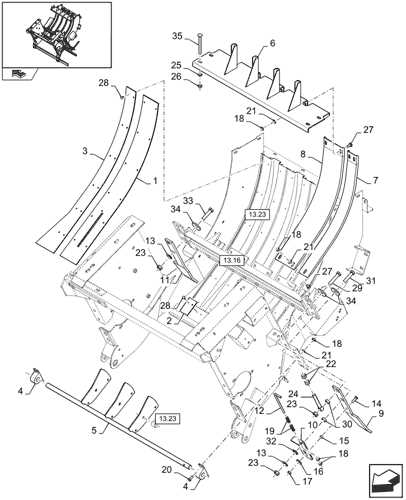

Understanding Western Wideout Plow Components

This section provides insight into the essential elements of a snow removal system designed for efficiency and durability. Understanding these components is crucial for effective operation and maintenance, ensuring optimal performance during winter conditions.

Key Elements of the System

- Frame: The backbone that supports the entire setup, providing stability and strength.

- Blade: The primary component responsible for pushing snow away, available in various shapes and sizes.

- Hydraulic System: Controls the movement of the blade, allowing for adjustments in height and angle.

- Mounting Brackets: Connects the assembly to the vehicle, ensuring a secure fit.

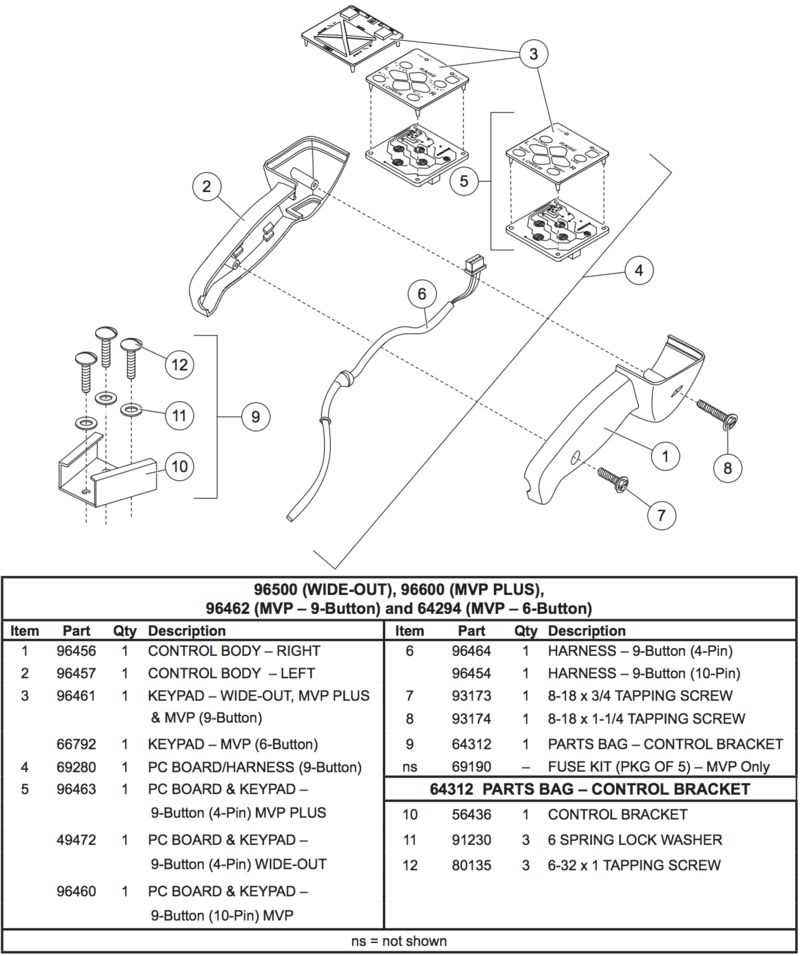

- Electrical Components: Powers the hydraulic system and may include switches and control panels.

Maintenance Considerations

Proper upkeep is vital to enhance the lifespan and functionality of each element. Regular checks should include:

- Inspecting hydraulic fluids for leaks or degradation.

- Ensuring the blade is free of damage and sharp for effective snow removal.

- Checking all electrical connections for corrosion or wear.

- Maintaining the frame for any signs of rust or structural weakness.

By familiarizing oneself with these components, users can ensure efficient snow management and extend the longevity of their equipment.

Essential Parts of the Plow

The functionality of a snow-clearing attachment relies on several key components that work in unison to achieve efficient performance. Understanding these fundamental elements can significantly enhance the effectiveness and maintenance of the equipment.

- Blade: The primary component responsible for pushing snow aside, available in various shapes and sizes to suit different tasks.

- Mounting System: This part connects the clearing device to the vehicle, ensuring stability and proper alignment during operation.

- Hydraulic System: Facilitates the lifting and angling of the blade, allowing for precise control while adjusting to varying snow conditions.

- Wear Bars: These protect the edge of the blade from wear and tear, prolonging its life and maintaining effectiveness.

- Skids: Attached to the blade’s underside, these elements help regulate the height of the attachment, ensuring optimal performance on different surfaces.

- Control Mechanism: Typically includes levers or switches that allow the operator to adjust the blade’s position and angle while driving.

Each of these components plays a critical role in ensuring the reliability and efficiency of the snow-clearing system, making regular checks and maintenance essential for peak performance.

Common Issues with Plow Parts

When utilizing snow removal equipment, users may encounter various challenges that can impact performance and efficiency. Understanding these typical problems is crucial for maintaining optimal functionality and ensuring a smooth operation throughout the winter season.

Wear and Tear: Over time, components can experience significant deterioration due to constant exposure to harsh conditions. Regular inspection and timely replacement of worn items can prevent further complications.

Corrosion: Exposure to moisture and salt can lead to rust and corrosion on metallic components. This can weaken structural integrity and reduce the lifespan of essential elements, necessitating preventive measures such as protective coatings.

Alignment Issues: Improper alignment of equipment can result in uneven performance, leading to inefficient snow removal. Regular adjustments and checks can help maintain proper alignment and enhance overall effectiveness.

Hydraulic Problems: Hydraulic systems are vital for the operation of snow clearing machinery. Leaks or failures in the hydraulic system can cause significant disruptions, making it essential to monitor and maintain fluid levels and check for any signs of leakage.

Electrical Failures: Electrical components, such as switches and lights, may malfunction due to wear or exposure to the elements. Ensuring connections are secure and components are in good condition can help mitigate these issues.

By recognizing and addressing these common challenges, operators can enhance the reliability and performance of their snow removal equipment, ensuring effective operation during the demanding winter months.

Maintenance Tips for Plow Owners

Proper upkeep is essential for ensuring the longevity and efficiency of your snow-clearing equipment. Regular attention to various components can enhance performance and prevent costly repairs. This section provides helpful guidelines for maintaining your equipment effectively.

- Regular Inspections: Check all components for wear and tear. Look for any signs of damage or rust that may compromise performance.

- Lubrication: Keep moving parts well-lubricated to reduce friction and prevent premature wear. Use the appropriate lubricant for each component.

- Cleanliness: After each use, clean the equipment thoroughly to remove snow, dirt, and salt. This helps prevent corrosion and buildup.

- Fastener Tightness: Periodically check all bolts, nuts, and screws to ensure they are securely fastened. Loose components can lead to malfunction or accidents.

- Electrical Components: Inspect wiring and connections for damage or corrosion. Ensure that all electrical parts function properly before the season begins.

By adhering to these maintenance tips, owners can enjoy improved reliability and performance from their snow-removal equipment, ensuring it is ready to handle harsh winter conditions.

How to Identify Plow Components

Understanding the various elements of a snow-clearing attachment is essential for effective maintenance and operation. Each component plays a critical role in ensuring optimal performance during winter tasks. By familiarizing yourself with the different elements, you can enhance your efficiency and prolong the lifespan of your equipment.

Common Components and Their Functions

Many essential parts contribute to the overall functionality of the snow-clearing tool. The blade is typically the most recognizable element, responsible for pushing snow aside. Another vital component is the lift mechanism, which raises and lowers the blade, allowing for adjustable operation based on varying snow depths. Additionally, the frame provides structural integrity, connecting all components securely.

Identifying Specific Features

When assessing individual elements, it is helpful to look for specific characteristics. For instance, the blade may come in various shapes and sizes, designed for different snow conditions. The control system, often located within the operator’s reach, may feature buttons or levers that enable precise adjustments. Familiarity with these attributes can assist in troubleshooting and effective repairs.

Plow Replacement Parts Overview

This section provides an overview of essential components that are crucial for the effective operation of snow removal equipment. Understanding these elements ensures optimal performance and longevity, allowing for efficient clearing of snow during winter months. Familiarity with each component can assist in timely replacements and maintenance, preventing potential breakdowns and enhancing productivity.

Key Components

Maintaining the functionality of your snow clearing equipment involves knowing the main components that may need replacement over time. Each element plays a vital role in ensuring smooth operation, so it’s important to keep track of their condition and address any wear and tear promptly.

Replacement Schedule

Regular inspection and timely replacement of components can greatly improve the efficiency of your equipment. Below is a table outlining typical replacement intervals for various elements:

| Component | Recommended Replacement Interval |

|---|---|

| Blade | Every 1-2 seasons |

| Hydraulic Hose | Every 3-5 years |

| Mounting Hardware | Annually |

| Control Cables | As needed |

Tools Needed for Plow Repairs

Proper maintenance and repair of your snow removal equipment require a specific set of instruments. Having the right tools not only streamlines the repair process but also ensures that the equipment functions effectively throughout the winter season. Below is a list of essential tools to consider when undertaking repairs.

- Wrenches: Various sizes are needed to loosen or tighten nuts and bolts.

- Screwdrivers: Both flathead and Phillips types for different screws.

- Pliers: Useful for gripping and twisting wires or small components.

- Socket Set: Allows for efficient removal of fasteners in tight spaces.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Jack and Jack Stands: For lifting the equipment safely while working underneath.

- Safety Gear: Includes gloves and goggles to protect against debris and sharp objects.

Investing in quality tools will make repairs easier and contribute to the longevity of your equipment. Always ensure that you have the necessary instruments before starting any repair work to avoid interruptions.

Safety Precautions When Repairing

When undertaking maintenance or repair tasks on heavy machinery, it is crucial to prioritize safety to prevent accidents and ensure a smooth workflow. Proper precautions help safeguard both the technician and the equipment from potential hazards associated with mechanical work.

Wear Appropriate Personal Protective Equipment (PPE): Always equip yourself with suitable gear, including gloves, goggles, and sturdy footwear. This protective attire minimizes the risk of injuries from sharp objects, moving parts, or hazardous materials.

Ensure a Clean Work Area: A tidy workspace is essential for safety. Remove any unnecessary tools, debris, or obstacles that could pose tripping hazards. A well-organized environment allows for better visibility and easier access to tools and components.

Disconnect Power Sources: Before beginning any repairs, ensure that the machinery is turned off and disconnected from any power source. This step is vital to prevent accidental activation, which could lead to severe injuries.

Follow Manufacturer Guidelines: Always refer to the specific instructions provided by the manufacturer for the equipment you are working on. Adhering to these guidelines can help you understand the correct procedures and safety measures necessary for effective repairs.

Use Proper Tools: Utilize the right tools for the job to avoid unnecessary strain and potential accidents. Using improper tools can lead to equipment damage or personal injury, so always select equipment designed for the specific task at hand.

Maintain Awareness: Stay vigilant while working on machinery. Being aware of your surroundings, including the position of other workers and equipment, can significantly reduce the risk of accidents. Communicate clearly with colleagues to ensure everyone is informed about ongoing tasks.

Differences Between Plow Models

Understanding the variations among different models is crucial for making informed decisions regarding snow removal equipment. Each design offers unique features tailored to specific needs, performance levels, and operational environments. Recognizing these distinctions helps users select the most suitable option for their requirements.

Design Features

One of the primary differences lies in the construction and design elements. Some models may feature a straight blade for straightforward clearing, while others are equipped with curved edges to enhance maneuverability and efficiency. Additionally, the material quality can vary significantly, affecting durability and overall performance in various conditions.

Functionality and Efficiency

Another significant aspect is the functionality provided by each model. Certain variations are designed for heavy-duty tasks, ensuring they can handle larger volumes of snow effectively. Others may prioritize ease of use, offering simpler controls and lighter weights for more casual users. Efficiency ratings often differ, indicating how well each model can manage diverse winter challenges.

Adjusting Plow for Optimal Performance

Proper calibration of your snow removal equipment is essential for achieving the best results during winter operations. Ensuring that the apparatus is set up correctly can significantly enhance efficiency and prolong its lifespan. This section will cover essential adjustments and best practices to optimize functionality.

Start by verifying the angle and height of the blade. An appropriate angle allows for effective snow distribution and minimizes the chances of excessive wear. Ensure that the cutting edge is positioned at the correct height to effectively scrape the surface without causing damage.

Next, examine the hydraulic system for any signs of leaks or inefficiencies. A well-maintained hydraulic system ensures smooth operation and responsive control. Regularly check fluid levels and replace any worn seals to prevent performance issues.

It is also advisable to adjust the weight distribution on your vehicle. Properly balancing the load can enhance traction and stability, resulting in smoother operations. Utilize weights or ballast as necessary to achieve optimal balance.

Finally, regular maintenance, including cleaning and lubricating moving parts, will contribute to overall performance. Keeping components free from debris and ensuring they are well-lubricated will minimize friction and enhance operational efficiency.

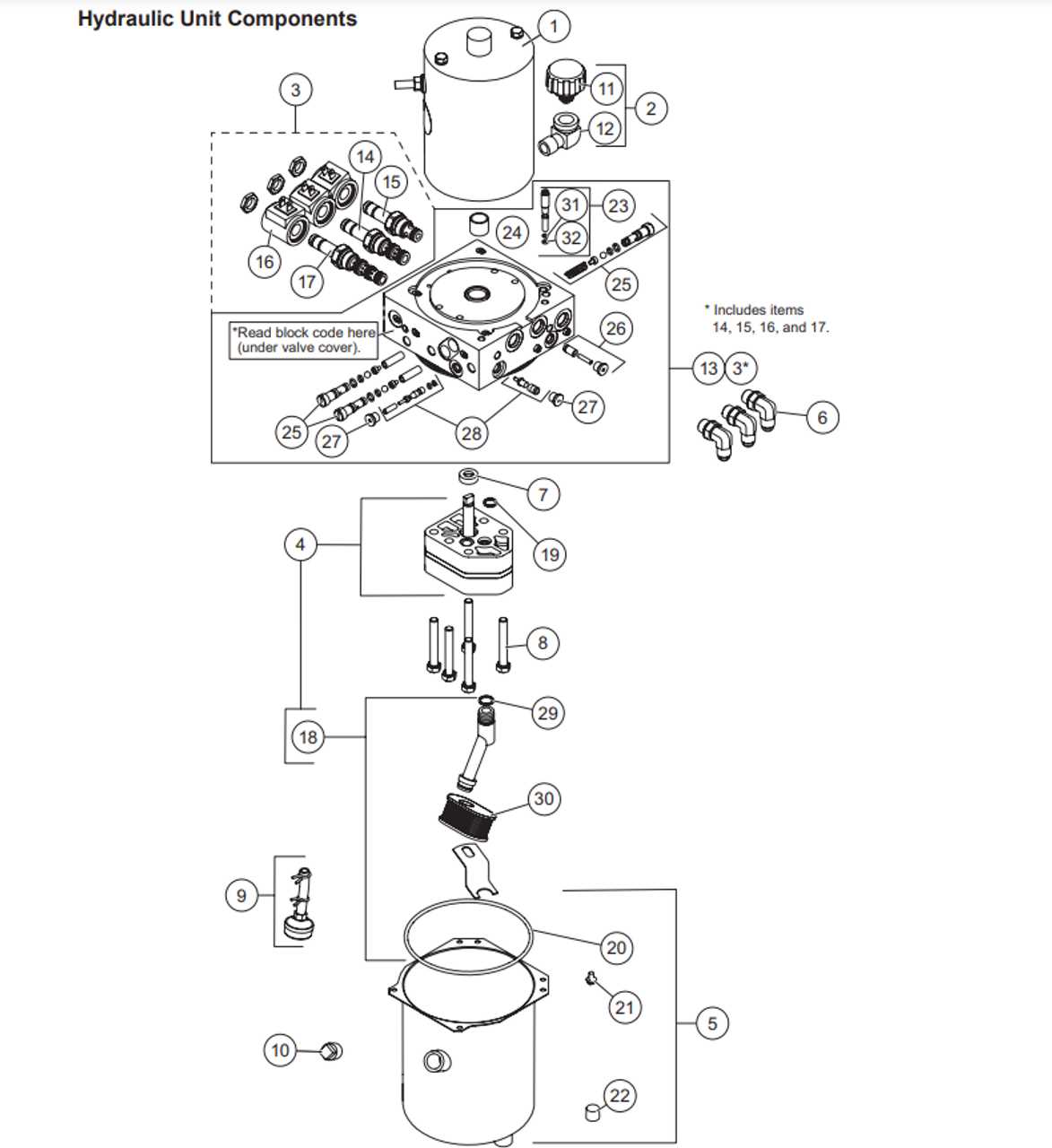

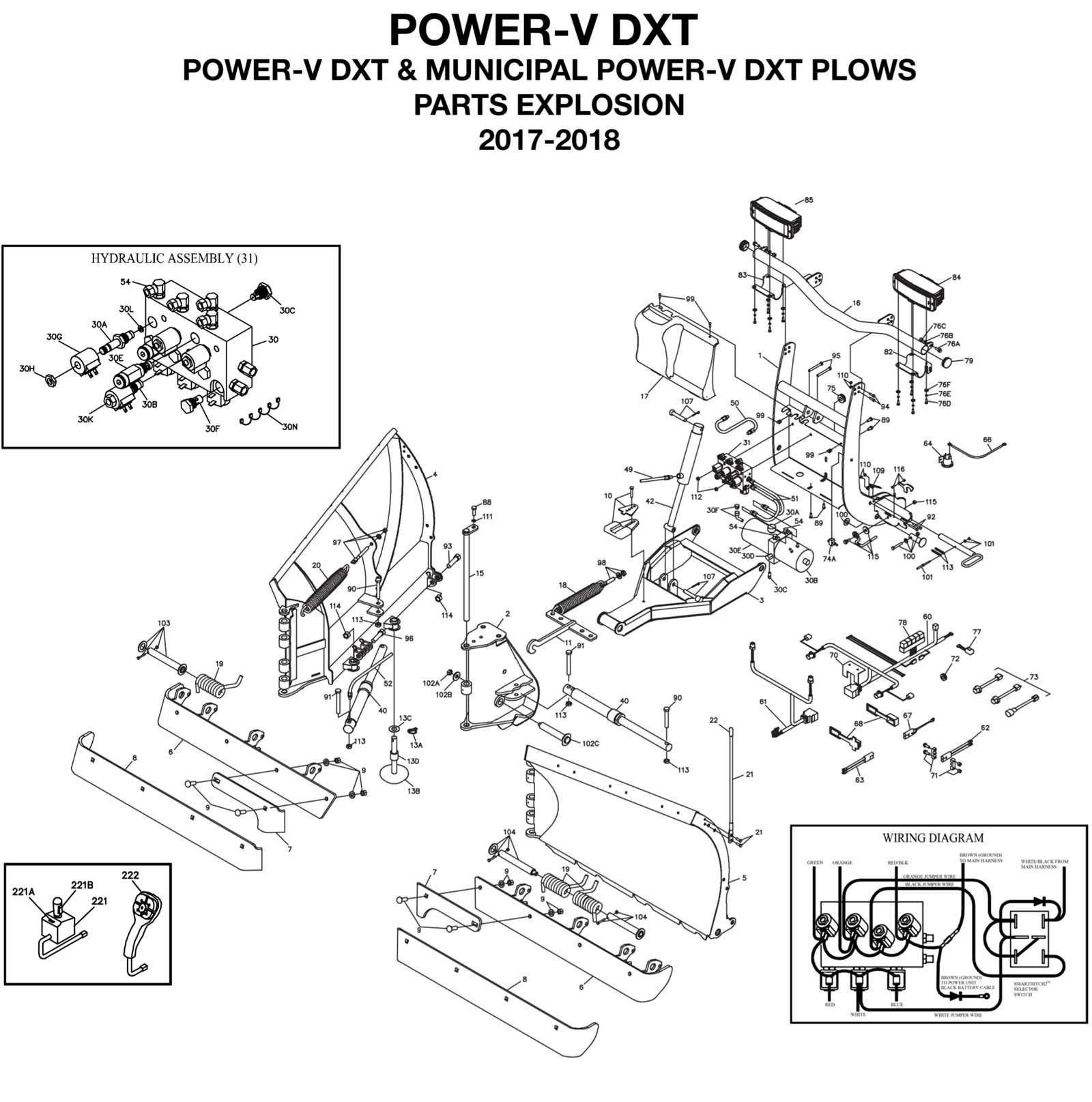

Understanding Hydraulic Systems in Plows

Hydraulic systems play a crucial role in enhancing the functionality of snow removal equipment, providing efficient control and operation. These systems utilize fluid dynamics to generate force, allowing for the manipulation of various components with precision and ease. By comprehending the mechanisms involved, operators can ensure optimal performance and maintenance of their machinery.

Key Components of Hydraulic Systems

Several essential elements contribute to the effective operation of hydraulic systems:

- Hydraulic Fluid: The medium through which force is transmitted, typically a specialized oil.

- Pumps: Devices that create flow and pressure in the system, drawing fluid from the reservoir.

- Valves: Controls that manage fluid flow and pressure, allowing for directional movement and speed adjustments.

- Actuators: Mechanisms that convert hydraulic energy into mechanical movement, enabling the movement of blades and other components.

Working Principles

The operation of hydraulic systems is based on Pascal’s principle, which states that pressure applied to a confined fluid is transmitted equally in all directions. This principle allows for the following:

- The operator engages the pump, generating pressure in the hydraulic fluid.

- Valves direct the flow to specific actuators, controlling the movement of the equipment.

- The actuators respond to the pressure, executing the desired action, such as lifting or angling.

Understanding these principles and components is vital for ensuring the reliability and efficiency of snow management machinery. Proper maintenance and knowledge of the hydraulic system can significantly enhance the lifespan and performance of the equipment.

Where to Buy Plow Parts

When it comes to acquiring essential components for your snow removal equipment, knowing the right sources can make a significant difference. Whether you are looking for replacement items or upgrades, a variety of options are available to ensure your equipment operates efficiently throughout the winter season.

Online Retailers: Numerous online platforms offer a wide selection of components. Websites dedicated to outdoor equipment often have detailed inventories, allowing you to browse and compare various options. Reading customer reviews can also provide insights into the quality and compatibility of the products.

Local Dealers: Visiting local dealerships can be advantageous as they often carry original equipment items. Engaging with knowledgeable staff can help you find the exact components needed for your machinery, and you may also have the opportunity to receive personalized recommendations.

Aftermarket Suppliers: If you’re looking for more affordable alternatives, aftermarket suppliers offer competitive pricing on various items. While quality may vary, many aftermarket options are reliable and meet the necessary standards for effective operation.

Forums and Community Groups: Online forums and community groups dedicated to snow removal equipment can be excellent resources. Members often share their experiences and recommendations on where to find specific components. You may also find classified ads for second-hand items, which can be a cost-effective solution.

By exploring these various avenues, you can find the components that best suit your needs, ensuring your equipment remains functional and effective during the demanding winter months.

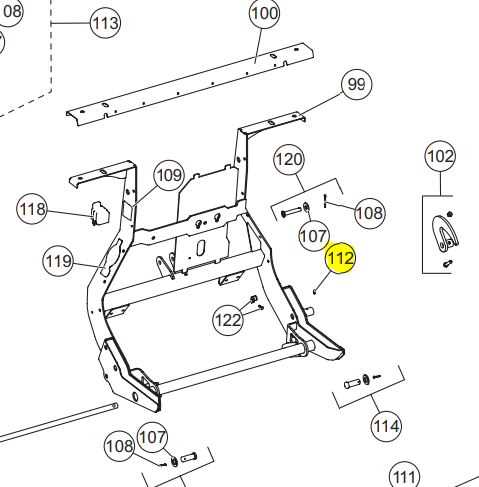

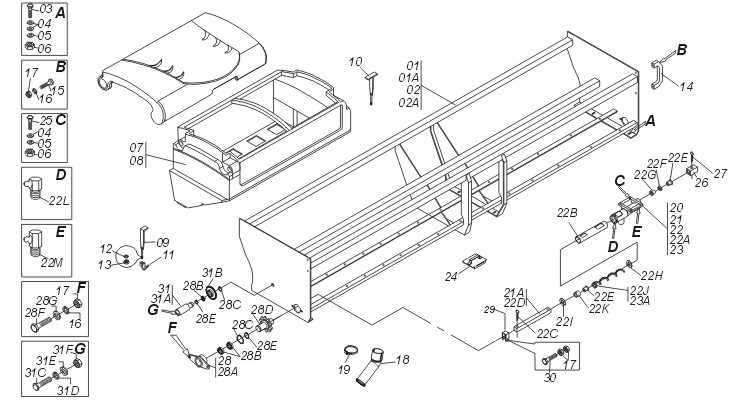

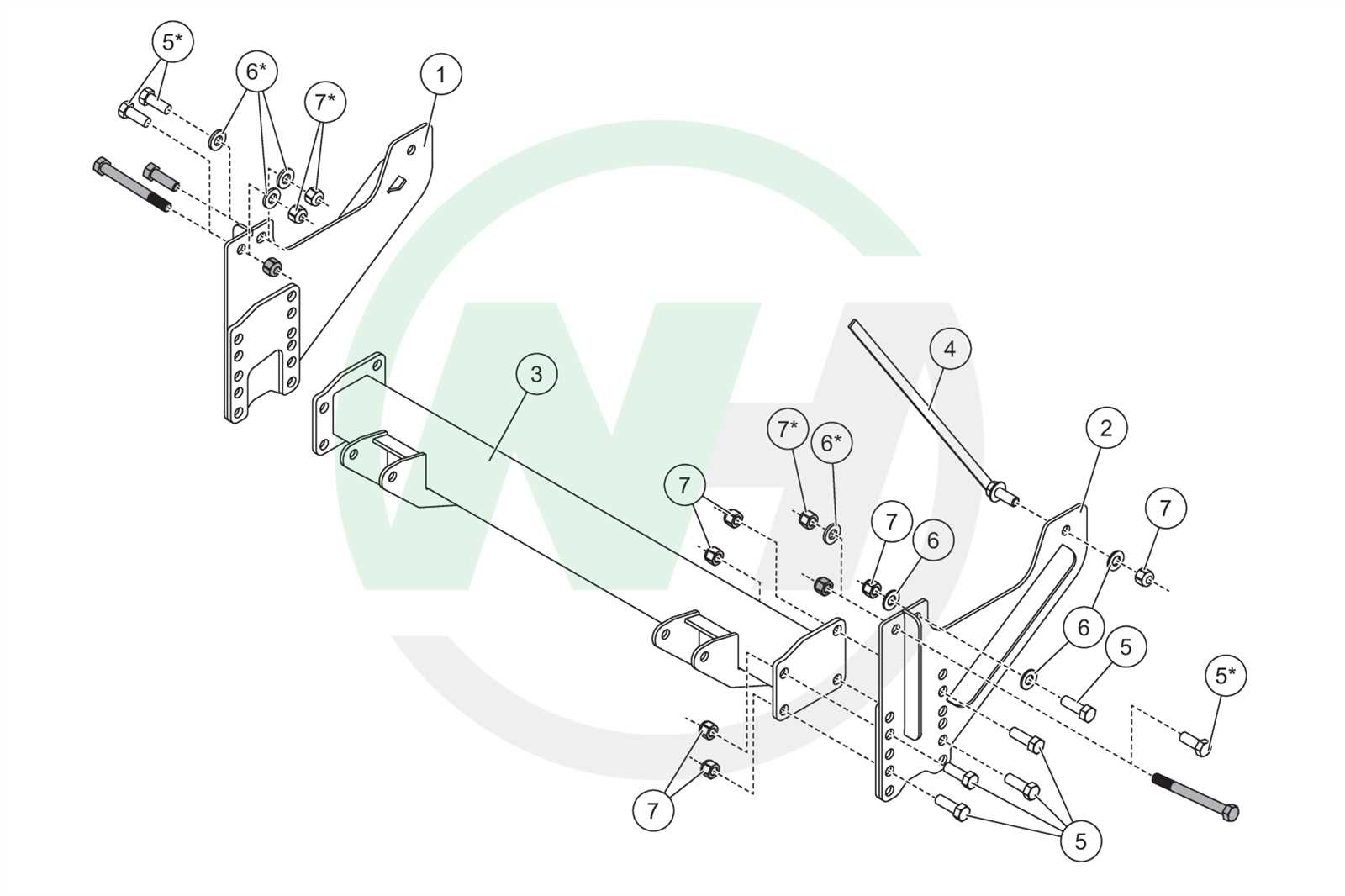

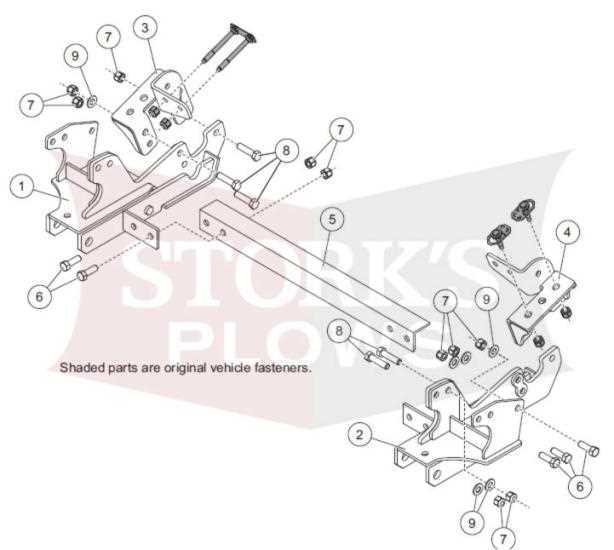

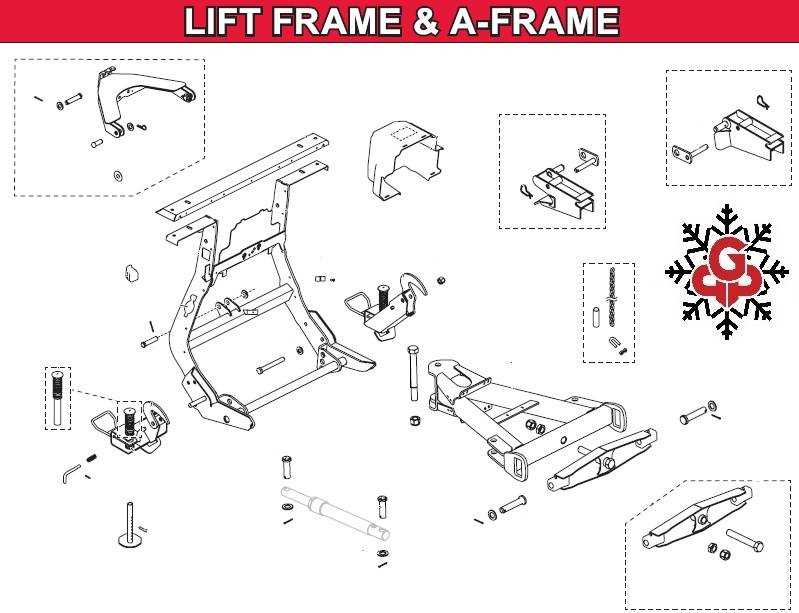

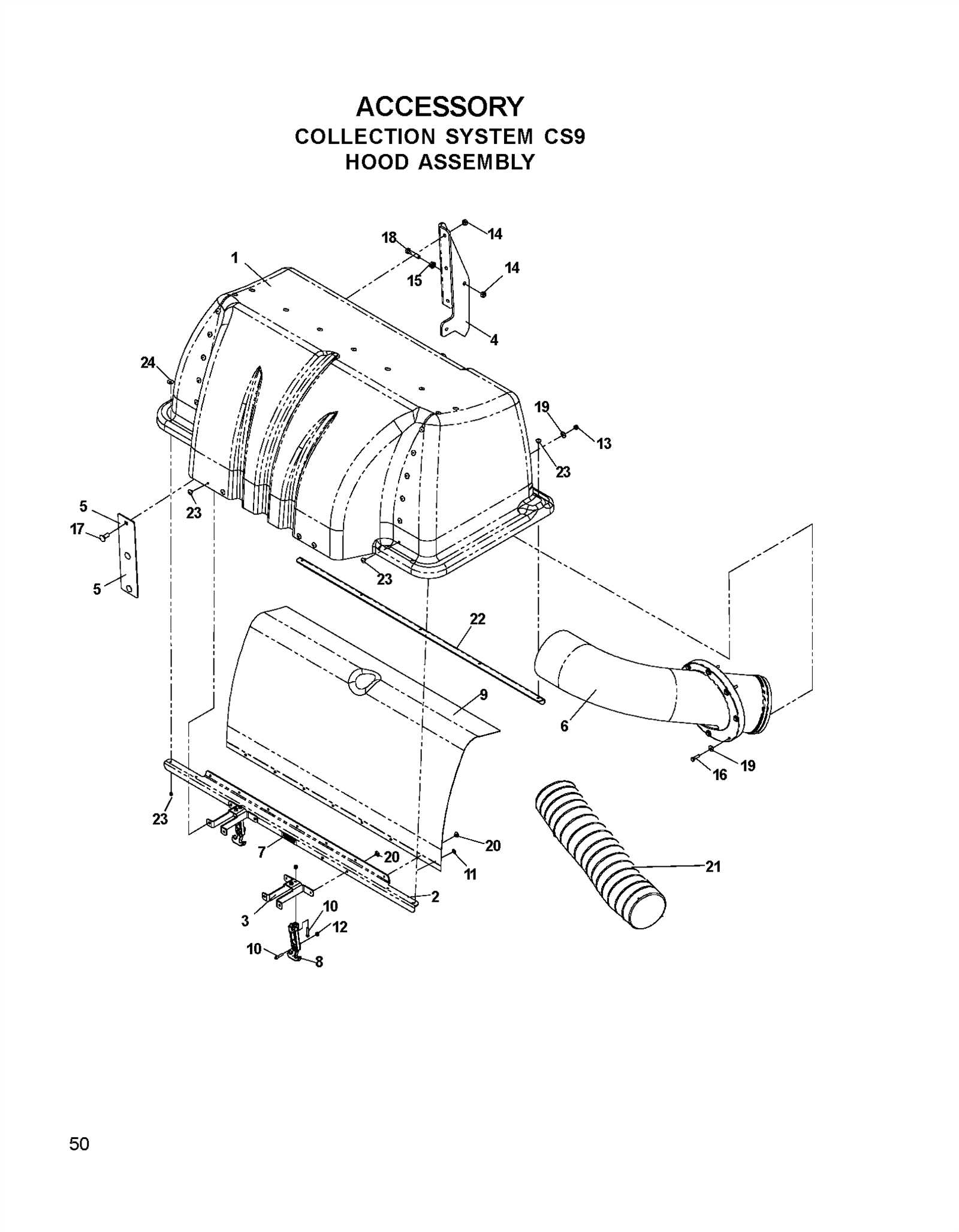

Visual Guide to Plow Assembly

This section provides an insightful overview of the assembly process for snow removal equipment. Understanding the various components and their arrangement is crucial for efficient operation and maintenance. Each element plays a significant role in ensuring optimal performance during winter tasks.

To effectively piece together the unit, it is essential to familiarize yourself with the individual segments. Begin by identifying the primary frame, which serves as the backbone, supporting additional attachments. Next, recognize the lifting mechanisms that enable height adjustments, allowing for versatile use on different terrains.

As you assemble, pay close attention to the connection points between various parts. These joints are critical for stability and should be secured tightly. Use appropriate tools to ensure everything fits snugly, preventing any wobbling during operation.

Incorporating protective elements is also vital. These components help shield the main structure from wear and tear caused by contact with icy surfaces. Regular checks and replacements of these parts will prolong the lifespan of the equipment.

Lastly, refer to any available visual aids that illustrate the assembly steps. These guides can significantly enhance your understanding, making the entire process more manageable and efficient.