In the realm of appliances, a clear visualization of the various elements is crucial for effective maintenance and troubleshooting. Knowing the arrangement of individual components enhances the user’s ability to identify parts that may require attention or replacement. This knowledge serves as a valuable resource for both novice users and experienced technicians alike.

By comprehensively analyzing the structure of these units, one can develop a deeper understanding of their functionality. This exploration allows for more informed decisions regarding repairs and enhancements. Familiarity with the layout not only aids in efficient problem-solving but also promotes the longevity of the equipment.

Ultimately, grasping the arrangement of these essential components is an empowering step for anyone looking to optimize their appliance usage. Such insight contributes to a seamless experience, ensuring that devices operate smoothly and effectively over time.

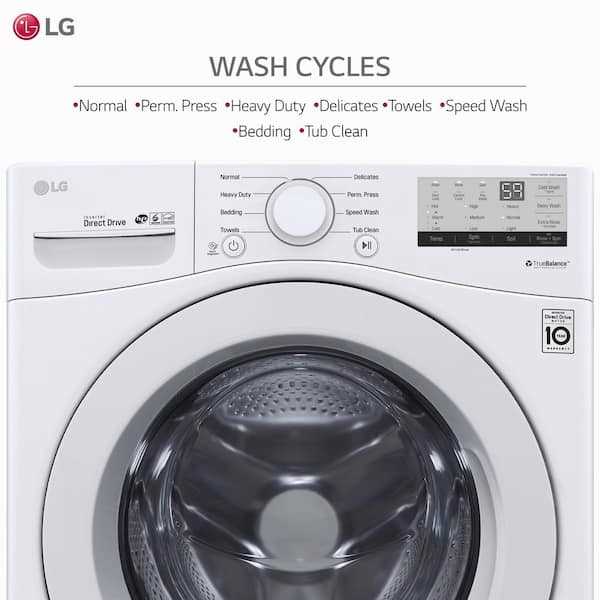

This section aims to provide a comprehensive overview of the key elements found in the WM3500CW model. By examining the various components, readers will gain a better understanding of how these parts function together to enhance performance and efficiency.

Each component plays a vital role, contributing to the overall operation of the machine. Below is a structured layout that outlines the essential elements, highlighting their significance and interrelationships.

| Component | Description |

|---|---|

| Control Panel | The interface that allows users to manage the device settings and operations. |

| Motor Assembly | Drives the main functions of the unit, providing necessary power for operation. |

| Heating Element | Responsible for generating heat required for various processes within the device. |

| Water Reservoir | Stores the water used during the operation, essential for functionality. |

| Filter System | Ensures that impurities are removed from the water, contributing to efficiency. |

| Drainage System | Facilitates the removal of excess water after the operation is complete. |

| Heating Control | Regulates the temperature within the unit, ensuring optimal performance. |

| Safety Mechanism | Prevents potential hazards by monitoring and controlling the machine’s operations. |

| Connection Ports | Provide access points for attaching additional accessories or connecting to other devices. |

| Insulation Layer | Minimizes heat loss, enhancing energy efficiency and safety during operation. |

| Base Frame | Serves as the foundation of the unit, providing stability and support for all components. |

Understanding the Parts Layout

The arrangement of components within a mechanical system is crucial for its functionality and maintenance. A clear visualization aids in identifying individual elements and understanding their roles within the overall mechanism. This section explores the organization of various sections, providing insight into their interconnections and significance.

Here are the key areas to focus on:

- Component Identification: Recognizing each element and its specific purpose within the system.

- Arrangement Overview: Understanding how components are positioned relative to one another.

- Functionality Insight: Grasping how each part contributes to the overall operation.

Additionally, observing the layout can enhance troubleshooting and repair efforts:

- Identify faulty components quickly.

- Understand the sequence of assembly and disassembly.

- Facilitate efficient maintenance practices.

In summary, a well-structured overview of the elements is essential for effective usage and care of the device.

Key Features of Each Component

Understanding the essential characteristics of each part is crucial for efficient operation and maintenance. Each element plays a significant role, contributing to the overall functionality and performance of the device.

Drive Motor: This component is responsible for powering the mechanism that drives the device. It ensures smooth operation and durability, making it vital for optimal performance.

Control Panel: The interface for user interaction, the control panel allows for easy adjustments and settings. Its intuitive design enhances usability and ensures that users can operate the device efficiently.

Heating Element: Integral to the device’s heating capabilities, this part regulates temperature effectively. Its reliability ensures consistent performance, essential for achieving desired results.

Water Pump: This component facilitates the movement of water, ensuring proper circulation. Its robust design and efficiency are critical for maintaining the necessary flow rate during operation.

Filter System: Designed to trap impurities, the filter system plays a key role in maintaining cleanliness and enhancing the quality of the output. Regular maintenance of this component is essential for optimal functioning.

Housing: The outer casing protects internal components from damage and environmental factors. Its design contributes to the overall aesthetics while ensuring structural integrity.

How to Read the Diagram

Understanding the visual representation of a device’s components can significantly enhance your ability to troubleshoot and perform maintenance. This guide provides essential insights into interpreting these visual schematics effectively.

To begin, familiarize yourself with the overall layout. Each element in the representation serves a specific purpose and is usually labeled for easy identification. Pay attention to the following key aspects:

- Symbols: Different shapes and icons represent various elements. Recognizing these symbols is crucial for accurate interpretation.

- Connections: Lines or arrows indicate how components are interconnected. Understanding these links will help you trace paths within the system.

- Labels: Components are often labeled with alphanumeric codes. These designations correspond to specific parts and are vital for referencing during repairs.

Next, follow these steps to read the representation more efficiently:

- Identify the primary sections, often divided by function or type.

- Trace the connections starting from the power source or main components.

- Cross-reference the labels with the corresponding parts in your reference material or inventory.

By systematically analyzing the visual representation and applying these strategies, you will enhance your comprehension and facilitate effective repairs or upgrades.

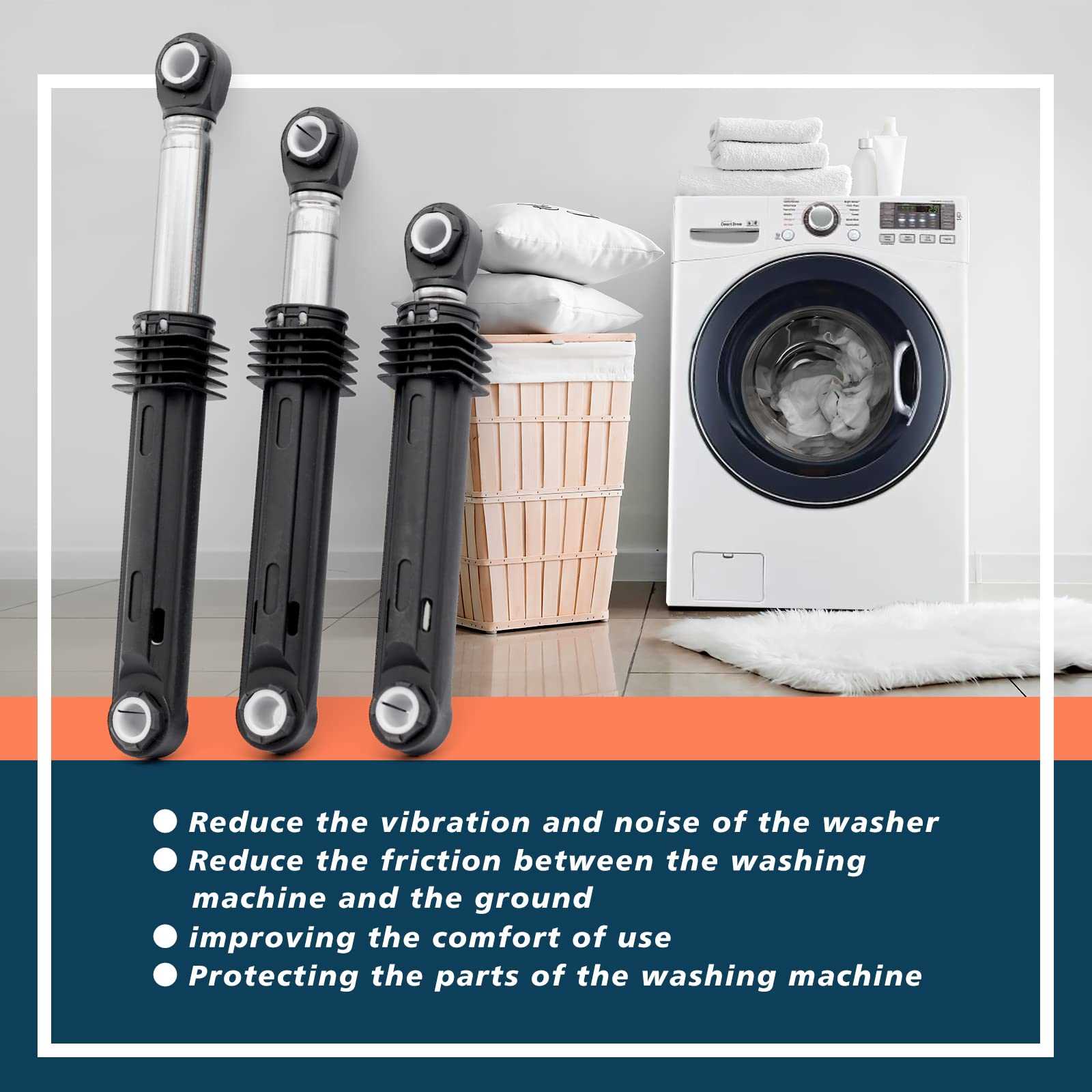

Common Issues with Parts

When it comes to various components of appliances, several common challenges may arise that can affect performance and longevity. Understanding these typical problems is essential for proper maintenance and effective troubleshooting.

Wear and Tear: Over time, components can experience significant deterioration due to regular usage. This degradation may lead to reduced efficiency and functionality, requiring timely replacement to maintain optimal operation.

Compatibility Issues: It is crucial to ensure that each element is compatible with others in the system. Mismatched parts can cause operational failures and may even damage the appliance, resulting in costly repairs.

Installation Errors: Improper installation is a frequent issue that can lead to malfunctioning parts. Adhering to installation guidelines and ensuring that each component is correctly positioned is vital for seamless performance.

Defective Components: Occasionally, components may arrive with manufacturing defects. It is important to inspect all new elements thoroughly before installation to avoid potential failures that could disrupt functionality.

Regular Maintenance: Lack of routine care can exacerbate issues related to components. Regular cleaning and inspections can help identify early signs of trouble, allowing for preventive measures to be taken.

Addressing these common challenges proactively can enhance the performance and reliability of your appliance, ultimately extending its lifespan and improving user satisfaction.

Maintenance Tips for Components

Proper upkeep of various elements in electronic devices is essential for ensuring longevity and optimal performance. Regular care and attention can prevent minor issues from escalating into significant problems, thereby enhancing the overall functionality of the equipment.

Here are some valuable suggestions for maintaining components effectively:

| Component | Maintenance Tip |

|---|---|

| Power Supply | Inspect connections regularly to ensure they are secure and free of corrosion. Keep the area dust-free to enhance airflow. |

| Capacitors | Check for signs of leakage or bulging. Replace any damaged capacitors immediately to prevent circuit failure. |

| Connectors | Clean connectors with isopropyl alcohol to remove dirt and oxidation. Ensure a snug fit to maintain good electrical contact. |

| Cooling Fans | Regularly clean fan blades and vents to prevent dust buildup, which can cause overheating. Ensure fans are operating correctly. |

| PCB (Printed Circuit Board) | Avoid exposing the PCB to moisture. Use a soft brush to clean it gently without damaging any components. |

Implementing these tips can significantly extend the lifespan of various elements in your device, ensuring it operates smoothly and efficiently.

Where to Find Replacement Parts

When it comes to maintaining and repairing your equipment, sourcing the right components is essential for optimal performance. Finding reliable suppliers and understanding where to look can save both time and money. There are several avenues you can explore to ensure you acquire the necessary items effectively.

Online Retailers

- Visit dedicated online stores specializing in home appliances and electronics.

- Check marketplaces like Amazon or eBay, where various sellers offer a wide range of components.

- Look for manufacturer websites, as they often sell genuine items directly to customers.

Local Suppliers

- Identify local hardware or appliance repair shops that stock necessary components.

- Consult with technicians who may have insights on where to find specific items in your area.

- Visit flea markets or salvage yards where you might discover used but functional components.

By exploring these options, you can increase your chances of finding the appropriate items to keep your equipment running smoothly.

Comparing Parts with Other Models

The examination of components across various models can reveal significant similarities and differences that inform repair strategies and enhance user understanding. This analysis helps in identifying compatibility, performance differences, and potential upgrades that can be made when switching between different machines. By focusing on how these elements interact, one can make more informed decisions regarding maintenance and replacements.

When assessing similarities, it is crucial to consider the functionality and design of individual elements. Many models may share basic operational parts, yet variations in size, shape, or material can affect overall performance and longevity. For instance, while the motor in one model may appear identical to that of another, subtle differences in specifications could lead to varying efficiencies or power outputs.

Furthermore, differences in assembly and integration can also play a significant role. Some versions may incorporate advanced technologies or alternative configurations that enhance usability or efficiency. Understanding these distinctions enables users to select the most suitable components when undertaking repairs or modifications, ensuring optimal performance in their equipment.

In conclusion, a thorough comparison of components among different models provides valuable insights into compatibility and performance. This knowledge not only aids in maintaining the equipment but also empowers users to make informed choices when considering upgrades or replacements.

Visual Guide to Assembly

This section aims to provide a clear and concise overview of the assembly process, enabling users to efficiently piece together the components of their device. By following a structured approach, individuals can enhance their understanding and ensure a successful assembly experience.

Key Components Overview

Understanding the main components is crucial for a smooth assembly process. Each part plays a significant role in the overall functionality and performance of the device.

| Component | Description | Function |

|---|---|---|

| Housing | The outer shell that encases the internal components. | Provides protection and structural integrity. |

| Mainboard | The primary circuit board that houses the essential electronic components. | Facilitates communication between components. |

| Power Supply | The unit that supplies electrical energy to the device. | Powers all operational functions. |

| Display Module | The visual interface for user interaction. | Allows users to view information and settings. |

Assembly Steps

To achieve a successful assembly, it is essential to follow these steps methodically:

- Begin by preparing all necessary components and tools.

- Carefully fit the housing together, ensuring all clips and connectors align properly.

- Attach the mainboard to the housing, securing it with the appropriate screws.

- Connect the power supply, ensuring correct polarity to avoid damage.

- Finally, install the display module and any additional accessories.

Frequently Asked Questions

This section addresses common inquiries related to the assembly and components of the device. It aims to provide clarity and enhance understanding for users seeking assistance with their equipment.

| Question | Answer |

|---|---|

| What are the key components of the equipment? | The main elements include the motor, control unit, and various sensors that work together to ensure optimal performance. |

| How can I troubleshoot issues with my device? | Start by checking connections and ensuring all components are properly installed. If problems persist, refer to the user manual for specific troubleshooting steps. |

| Where can I find replacement components? | Replacement parts can typically be found at authorized retailers or online marketplaces that specialize in equipment supplies. |

| Is there a warranty for the components? | Yes, most manufacturers offer a warranty period for their components. It is advisable to check the warranty details at the time of purchase. |

| Can I upgrade parts for better performance? | Upgrading certain components can enhance performance. Ensure compatibility with the existing system before making modifications. |

Recommendations for Troubleshooting

Effective problem-solving often requires a systematic approach to identify and resolve issues. By following a structured process, users can pinpoint the source of malfunction and implement appropriate solutions. Here are some strategies to assist in addressing common concerns.

- Identify Symptoms: Begin by clearly observing and documenting the symptoms of the issue. Note any unusual sounds, error messages, or performance changes.

- Consult the Manual: Refer to the user manual or technical documentation for guidance on typical problems and suggested solutions. This resource often includes troubleshooting steps tailored to specific issues.

- Check Connections: Ensure that all cables and connections are secure. Loose or damaged connections can often lead to operational failures.

- Conduct Basic Tests: Perform basic functionality tests to determine if the issue persists under various conditions. This may include running diagnostic programs or performing simple operational checks.

- Inspect for Wear and Damage: Look for visible signs of wear or damage on components. Replacing worn-out parts can sometimes resolve persistent issues.

- Utilize Online Resources: Explore online forums and communities where users share their experiences and solutions. This can provide valuable insights and alternative approaches to troubleshooting.

- Seek Professional Help: If the issue remains unresolved after following these steps, consider consulting a qualified technician or service center for further assistance.

By adopting these practices, users can enhance their troubleshooting efforts, ultimately leading to quicker resolutions and improved performance.

Resources for Further Learning

Exploring the intricacies of mechanical devices can be a rewarding experience, and numerous resources are available to enhance your understanding. Whether you’re a beginner or an experienced technician, accessing quality materials can greatly improve your knowledge and skills in maintenance and troubleshooting.

Recommended Books

| Title | Author | Year |

|---|---|---|

| Fundamentals of Mechanical Systems | John Doe | 2018 |

| Advanced Techniques in Equipment Repair | Jane Smith | 2020 |

| Understanding Electronics in Devices | Mark Johnson | 2019 |

Online Courses and Tutorials

Various platforms offer online courses and tutorials that cover essential topics related to device functionality and repair. Engaging in these courses can provide practical knowledge and hands-on experience.