Understanding the internal structure and key elements of complex appliances ensures smooth operation and simplifies upkeep. Familiarity with each segment allows for quick identification of malfunctions and streamlines routine servicing. Clear insights into the system’s organization can significantly reduce troubleshooting time.

Each individual element within a mechanism plays a critical role, and knowing their interactions is essential for maintaining optimal performance. Such knowledge aids in identifying

Overview of WM4370HKA Component Layout

This section provides a detailed look at the arrangement and key elements within the machine’s internal structure. Understanding how individual elements are organized helps ensure smooth operation and simplifies troubleshooting when needed.

- Control Panel Assembly: The upper section houses buttons and displays, allowing users to manage various functions and monitor performance.

- Drum and Tub System: At the center, the rotating drum and surrounding tub work together to handle fabric loads efficiently, minimizing vibrations.

- Motor and Drive Mechanism: Located at the base, the motor transfers power to the drum, using belts or

Main Control Board Structure

The main control board serves as the central hub for the operation and coordination of various components within a system. Its design incorporates multiple elements that work together to ensure optimal performance and functionality. Understanding the structure of this board is essential for effective troubleshooting and maintenance.

Key Components

- Microcontroller: This component acts as the brain of the control board, executing instructions and processing data.

- Power Supply Circuit: Converts input voltage to the required levels for other components.

- Communication Interfaces: Facilitate communication between the control board and other devices.

- Input/Output Ports: Allow connection to various sensors and actuators.

- Memory Modules: Store essential data and firmware necessary for operation.

Functional Role

Each component plays a critical role in the overall operation of the system. The microcontroller processes signals and makes decisions based on input data. The power supply ensures all components receive the necessary energy, while communication interfaces enable seamless interaction with external devices. Together, these elements create a reliable and efficient control system.

Water Inlet Valve Configuration

The water inlet valve is a crucial component in any washing appliance, responsible for controlling the flow of water into the system. Its configuration ensures that the correct amount of water is supplied during different cycles, which is essential for optimal washing performance. Understanding the layout and function of this valve helps in troubleshooting and maintenance, leading to better efficiency and longevity of the unit.

Components of the Water Inlet Valve

This valve typically consists of several key elements, including solenoids, filters, and connectors. Solenoids are electrically operated, allowing for precise control over water flow. Filters are included to prevent debris from entering the system, ensuring that the water remains clean and free from contaminants. Connectors play a vital role in linking the valve to the water supply and the control system.

Operational Principles

The operation of the water inlet valve is based on a simple principle: it opens and closes in response to signals from the control module. When a wash cycle begins, the control module activates the solenoid, allowing water to flow through the valve. Once the required water level is reached, the solenoid deactivates, closing the valve and stopping the flow. This cycle repeats as necessary throughout the washing process.

Drain System and Pump Mechanism

The drainage system plays a crucial role in ensuring the efficient removal of water from the appliance, preventing any overflow and maintaining optimal performance. This system is designed to facilitate the smooth transition of water through various channels, ultimately directing it to the appropriate outlet. Understanding the components and functionality of this system is essential for troubleshooting and maintenance.

At the heart of this setup lies the pumping mechanism, which is responsible for moving water through the drainage channels. This mechanism operates using an electric motor, which drives the pump impeller to create the necessary pressure for water movement. Regular inspection of the pump’s condition and functionality can help identify potential issues early, ensuring a seamless operation.

Furthermore, the configuration of the drainage system is designed to minimize the risk of clogs and leaks. Proper alignment and sealing of all components are vital to achieving effective drainage. Routine maintenance, including cleaning filters and checking hoses, is recommended to prolong the lifespan of the pump and enhance overall efficiency.

Dispenser Drawer Assembly

The dispenser drawer assembly plays a crucial role in the overall functionality of modern laundry appliances. It is designed to efficiently hold and distribute detergent, fabric softener, and other additives during the washing process. Understanding the components and their arrangement can help users ensure optimal performance and maintenance of their machines.

Components of the Assembly

The assembly consists of several key components that work together seamlessly. These parts are engineered to provide ease of use and durability, ensuring that the drawer can withstand regular handling and exposure to various cleaning agents.

Component Description Drawer The main compartment that holds the detergent and additives. Separator A divider that ensures different products do not mix before use. Cover The lid that protects the contents from spills and dust. Slides Mechanisms that allow the drawer to open and close smoothly. Maintenance Tips

Regular maintenance of the dispenser drawer assembly is essential for optimal performance. Cleaning the drawer and its components periodically prevents the buildup of residues that can affect dispensing efficiency. Additionally, ensuring that the slides are lubricated will help maintain smooth operation and extend the lifespan of the assembly.

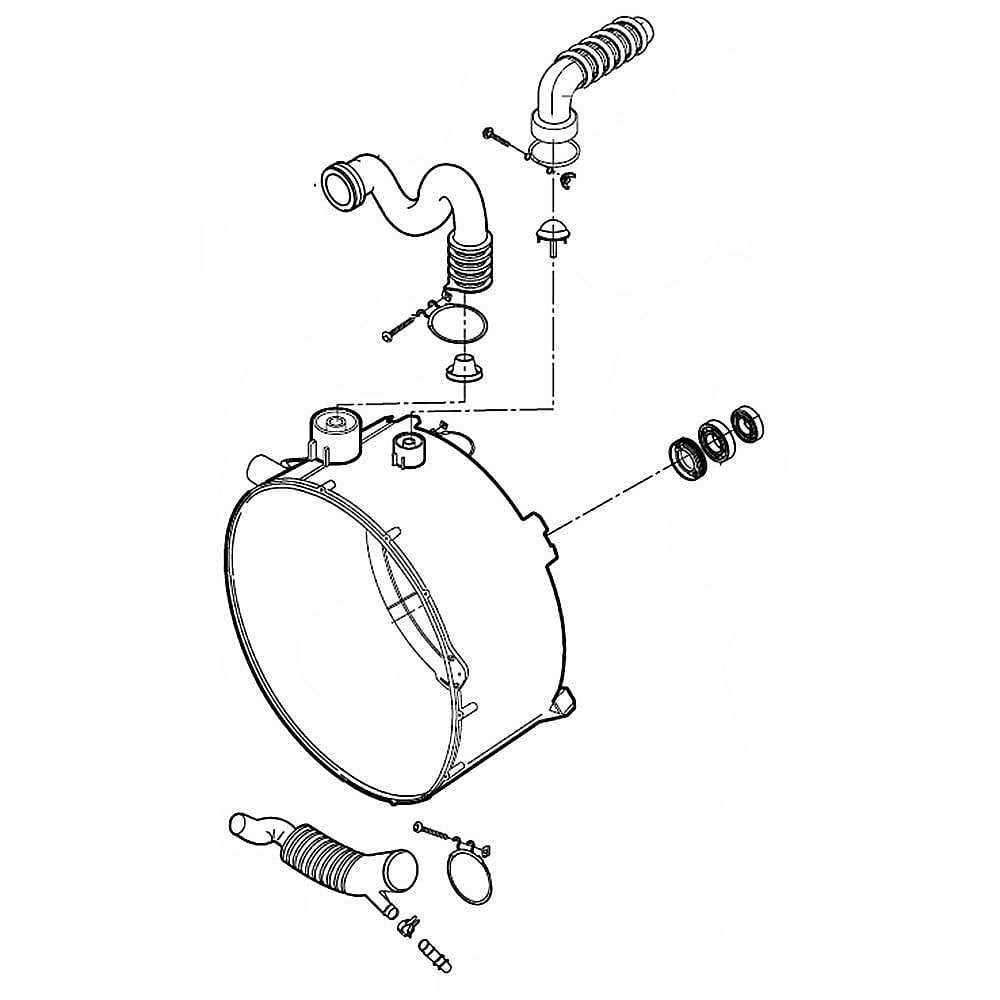

Drum and Tub Housing Details

The housing structure that encloses the drum plays a vital role in the efficiency and performance of laundry equipment. This section delves into the essential aspects of the drum and tub assembly, highlighting their significance in ensuring optimal operation and longevity.

Construction Materials

The drum and tub are typically constructed from durable materials designed to withstand the rigors of frequent use. Stainless steel is commonly employed for its resistance to corrosion and staining, while polymer options may offer lightweight and impact-resistant alternatives. Each material has its advantages, influencing factors such as weight, durability, and thermal conductivity.

Functional Considerations

Proper alignment and sealing between the drum and tub housing are crucial for maintaining efficiency. Any discrepancies can lead to water leaks, increased noise, and potential mechanical failures. Additionally, the design often includes features that enhance water drainage and aeration, contributing to more effective cleaning and drying processes.

Door Seal and Latch Mechanism

The door sealing and locking system is a crucial component in ensuring effective functionality and safety of any appliance. It prevents the escape of moisture and heat, contributing to optimal performance while also enhancing energy efficiency. Understanding the mechanisms involved can help in maintenance and troubleshooting, ensuring longevity and reliability of the unit.

Importance of Proper Sealing

A well-functioning seal is essential for maintaining the internal environment. It minimizes the risk of leaks and improves energy efficiency, reducing operational costs. Regular inspection and timely replacement of worn seals are vital to prevent further issues.

Latch Mechanism Functionality

The latch mechanism serves as a security feature, ensuring that the door remains closed during operation. It provides ease of use while preventing accidental openings. Familiarizing oneself with its operation can aid in identifying potential malfunctions, promoting safe usage.

Motor Assembly and Belt Setup

This section outlines the essential steps for assembling the motor and configuring the belt system in a washing machine. Proper alignment and installation are crucial for optimal performance and longevity of the appliance. Understanding the components involved will facilitate a smoother assembly process and ensure that the system operates efficiently.

Key Components of Motor Assembly

- Motor housing

- Mounting brackets

- Drive belt

- Pulleys

- Wiring harness

Steps for Belt Installation

- Begin by securing the motor housing to the base using the provided mounting brackets.

- Attach the pulleys to the motor shaft, ensuring they are properly aligned.

- Loop the drive belt around the motor pulley and the adjacent pulley, making sure it is snug but not overly tight.

- Check the tension of the belt by pressing down on it; it should have a slight give but remain taut.

- Reconnect the wiring harness to the motor, ensuring all connections are secure.

Temperature Sensor and Heating Elements

The functionality of a heating system relies heavily on its components that regulate temperature and heat distribution. Essential elements within this system ensure optimal performance and safety, allowing appliances to operate efficiently.

Among these components, the temperature sensor plays a crucial role. It monitors the heat levels within the system and sends feedback to the control unit, enabling precise adjustments. This responsiveness is vital for maintaining desired conditions and preventing overheating.

Heating elements, on the other hand, are responsible for generating heat. They convert electrical energy into thermal energy, which is then distributed throughout the appliance. The efficiency and longevity of these elements can significantly affect the overall performance.

- Temperature sensors can be classified into different types:

- Thermocouples: Known for their wide temperature range and durability.

- Thermistors: Provide high sensitivity and accuracy at specific temperature ranges.

- Resistance Temperature Detectors (RTDs): Offer excellent stability and linearity.

- Heating elements can vary in design and material:

- Coiled wire elements: Commonly used for their simplicity and effectiveness.

- Flat panel elements: Often employed for uniform heat distribution.

- Ceramic heating elements: Known for their durability and heat retention.

Understanding the interaction between the temperature sensor and heating elements is essential for troubleshooting and enhancing system performance. Regular maintenance and monitoring can help prolong the life of these components, ensuring reliable operation.