The efficient operation of woodworking machinery relies on a comprehensive understanding of its components and their arrangement. This section aims to illuminate the intricate structure of these essential tools, ensuring users can effectively identify and utilize various elements. Recognizing how each piece fits into the larger system enhances both performance and maintenance practices.

Exploring the configuration of these machines not only aids in troubleshooting common issues but also empowers operators to optimize functionality. Familiarity with the layout and connections among different sections promotes a more productive workflow and extends the lifespan of the equipment.

In this discussion, we will delve into the various segments of these devices, highlighting their roles and interactions. By enhancing knowledge of the configuration, users can tackle repairs and adjustments with confidence, fostering a more efficient and rewarding woodworking experience.

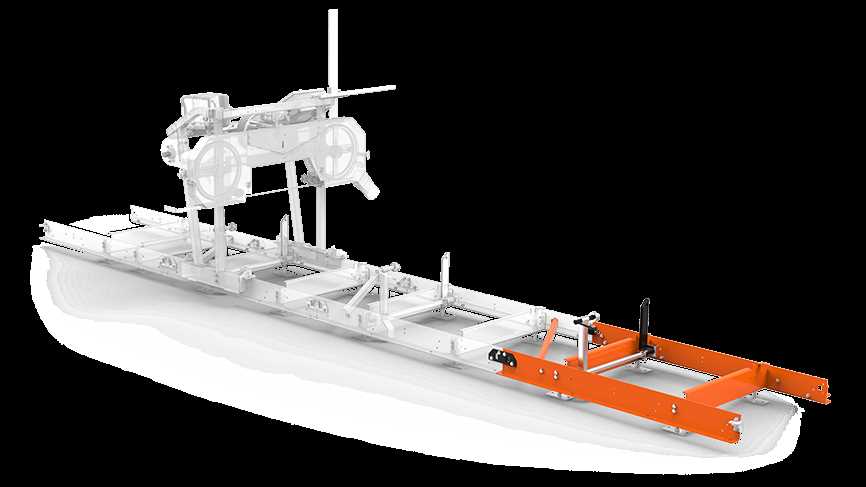

Understanding the Structure of a Wood-Mizer Saw

The design of a timber cutting machine is a remarkable fusion of engineering and functionality, aimed at achieving optimal efficiency in lumber production. Each component plays a crucial role in the overall performance, contributing to the precision and speed of the sawing process. A clear comprehension of these elements enhances the user’s ability to maintain and operate the equipment effectively.

At the heart of this machinery lies the cutting mechanism, designed to deliver smooth and accurate slices through various types of wood. Coupled with robust support structures, it ensures stability and minimizes vibrations during operation. The drive system, consisting of powerful motors and belts, provides the necessary torque to keep the blade moving at high speeds, allowing for quick and clean cuts.

Moreover, the frame and chassis are meticulously crafted to withstand the rigors of heavy-duty usage, ensuring longevity and durability. Accessories such as feeding systems and alignment guides further enhance usability, making the entire setup user-friendly. Understanding these components not only aids in effective operation but also empowers users to identify and resolve potential issues, ensuring continuous productivity.

Key Components of a Wood-Mizer Machine

The effectiveness of a milling system largely depends on its essential elements, each designed to enhance functionality and performance. Understanding these fundamental components is crucial for maximizing efficiency and achieving superior results during wood processing.

Frame: The foundation of the equipment provides stability and strength, supporting all other components during operation. A robust structure ensures longevity and reliable performance in various working conditions.

Cutting Unit: This critical section contains the saw blade and related mechanisms, responsible for transforming logs into usable timber. The design of the cutting unit plays a significant role in the precision and speed of the milling process.

Feed System: This assembly controls the movement of the material through the cutting area. Efficient feed mechanisms are essential for maintaining consistent operation and enhancing productivity by optimizing the speed at which logs are processed.

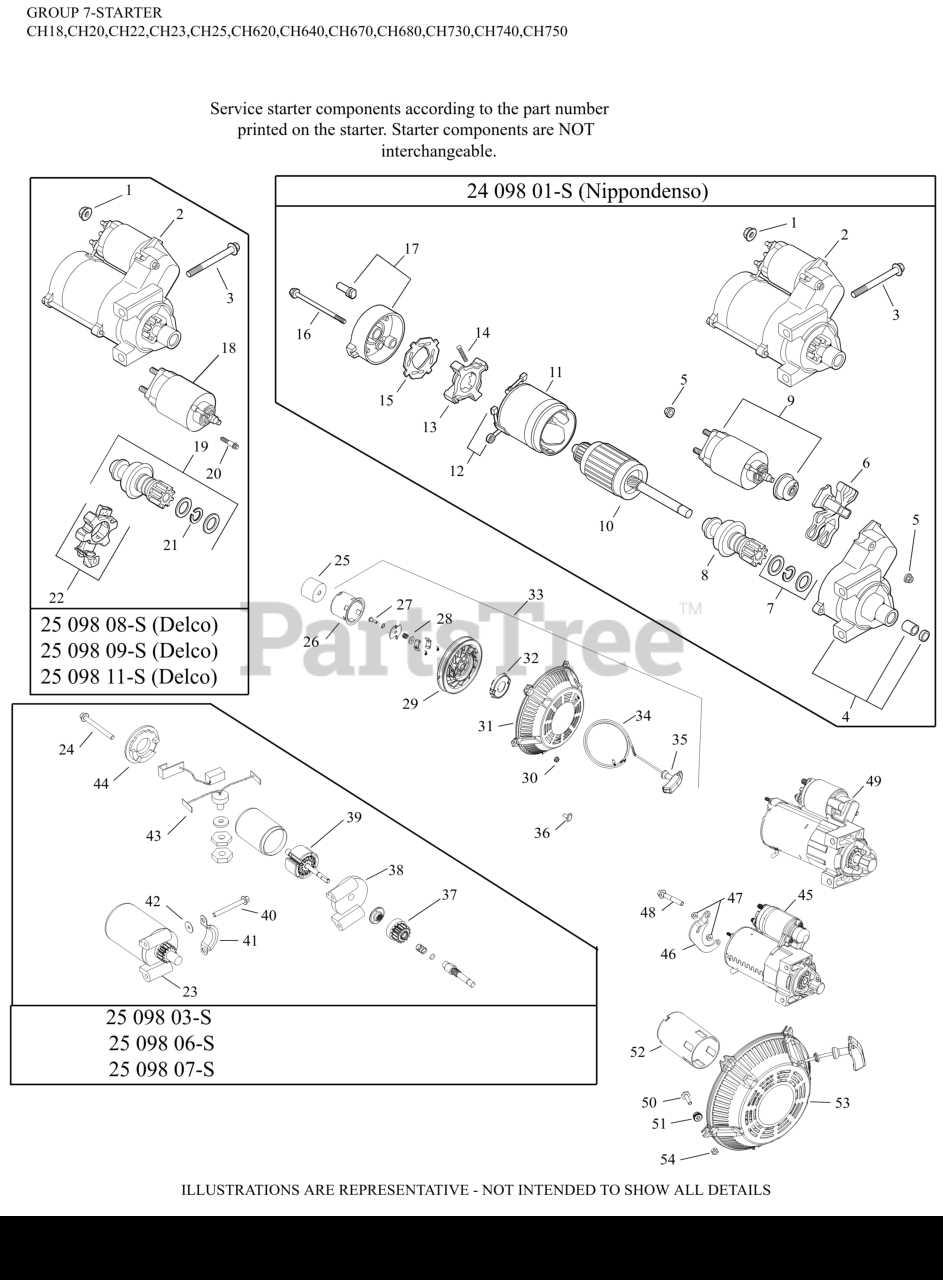

Power Source: Whether it’s electric or gas, the energy supply is vital for driving the entire system. A reliable power source ensures smooth operation and the ability to tackle various milling tasks effectively.

Control Panel: This interface allows the operator to manage and monitor the machine’s functions. An intuitive control panel improves usability and helps in adjusting settings for different milling requirements.

Each of these key elements contributes to the overall performance of the milling system, making it essential for users to be familiar with their functions and maintenance requirements.

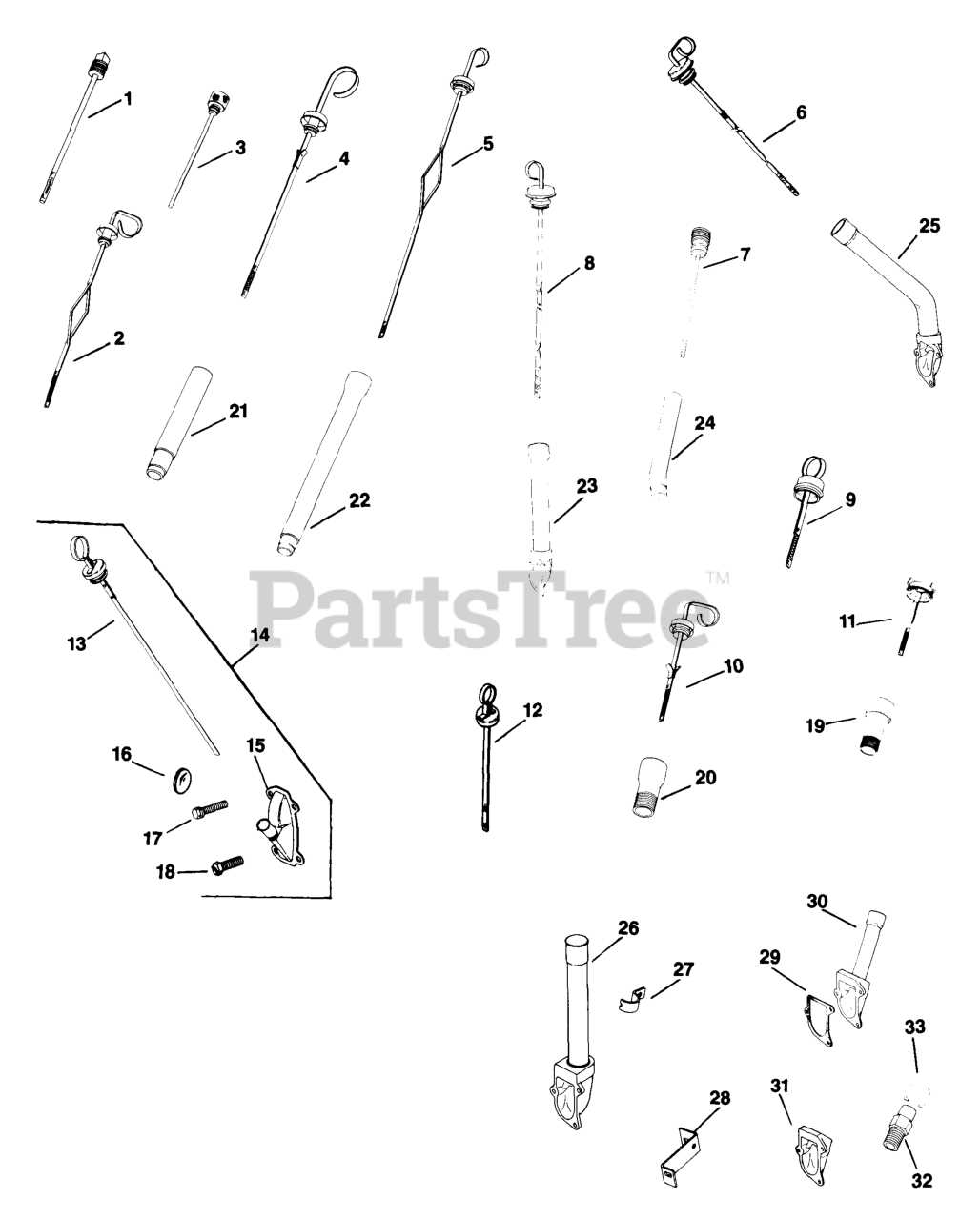

Guide to Identifying Blade Parts

Understanding the components of a cutting tool is essential for efficient operation and maintenance. Familiarizing oneself with each element enhances performance and ensures longevity. Below are the key elements to recognize and comprehend their functions.

- Cutting Edge: This is the sharp section that directly engages with the material being processed, allowing for clean cuts.

- Body: The main structure of the tool, providing support and stability during operation.

- Teeth: These protrusions help in slicing through materials; their shape and spacing can affect cutting efficiency.

- Hub: The central part that connects the blade to the driving mechanism, ensuring proper alignment and rotation.

- Kerf: The width of the cut made by the blade, which can influence the amount of material wasted during the process.

By gaining a clear understanding of these components, operators can troubleshoot issues, make informed decisions about replacements, and optimize their workflow.

How the Tension System Works

The tension mechanism is a crucial element in the operation of cutting machinery, ensuring that the blades maintain optimal pressure during use. This system plays a vital role in enhancing the efficiency of the cutting process by stabilizing the movement and preventing unnecessary wear on the components.

The tension system utilizes a series of adjustable components to regulate the tightness of the blades. By applying appropriate force, it ensures that the blades remain securely in place, which is essential for achieving precise cuts. This setup not only improves the accuracy of the cuts but also prolongs the lifespan of the blades by minimizing vibrations and reducing the chances of misalignment.

Regular maintenance of the tension system is necessary to guarantee its functionality. This includes checking the tension levels and making adjustments as needed to accommodate changes in blade wear or operational conditions. A well-maintained tension mechanism contributes to overall performance, ensuring that the machinery operates smoothly and effectively.

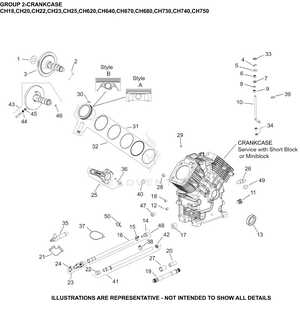

Exploring the Drive System Mechanism

The drive system is a crucial component in the operation of cutting machinery, ensuring efficient power transmission and optimal performance. This mechanism converts energy from the motor into motion, enabling various functions essential for effective processing.

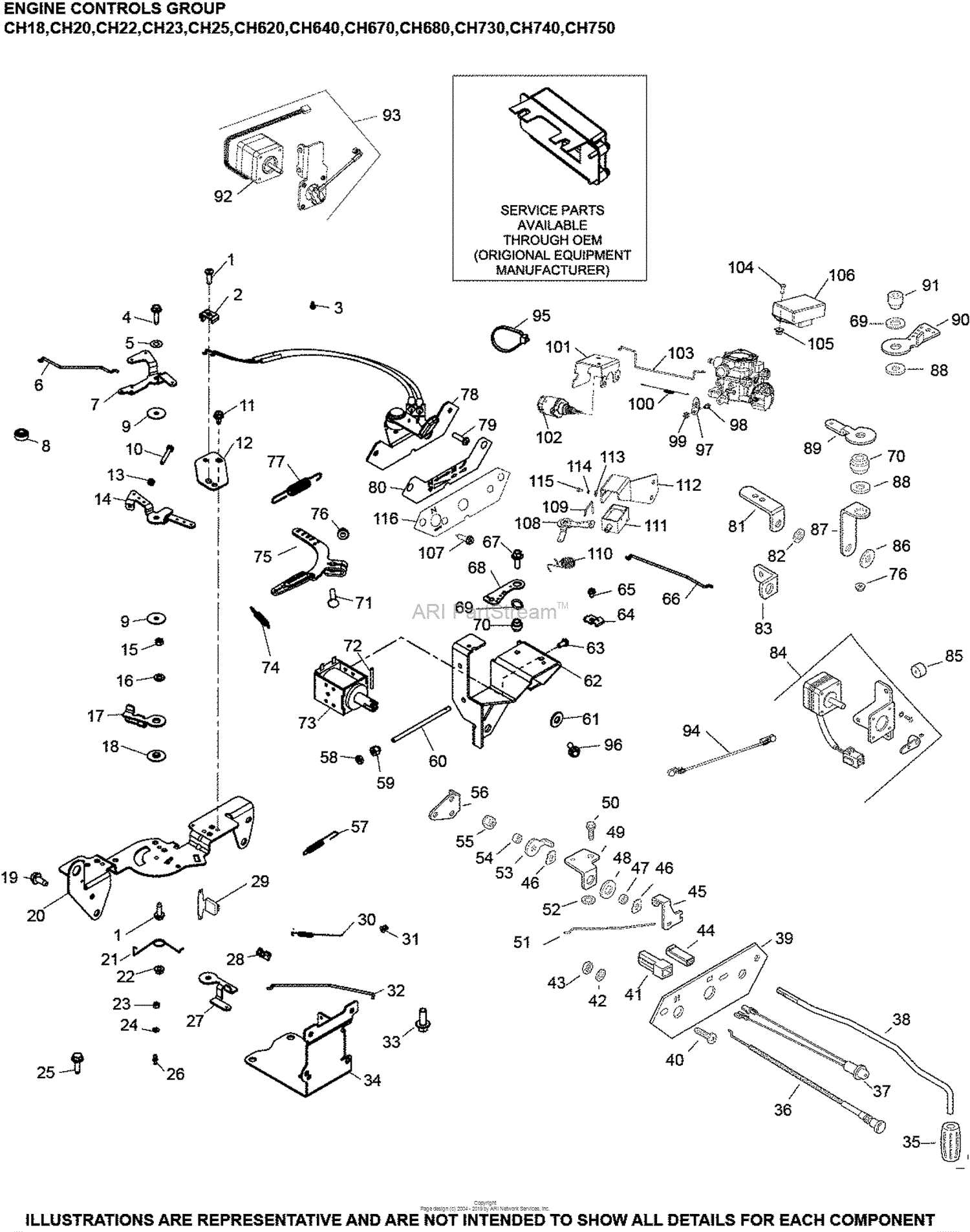

Understanding the key elements of this mechanism helps in maintaining and troubleshooting the equipment. The following components are integral to the drive system:

- Motor: The primary source of power, driving the entire mechanism.

- Belts: These flexible components transfer motion between different parts of the system.

- Gears: Critical for altering torque and speed, allowing the equipment to operate under various conditions.

- Chain Drives: Often used to enhance the efficiency of power transfer over longer distances.

- Bearings: Provide support and reduce friction, ensuring smooth movement of rotating parts.

Each of these components plays a significant role in the overall functionality of the machine, contributing to its performance and longevity. Regular inspection and maintenance of the drive system can prevent breakdowns and enhance operational efficiency.

Replacing Commonly Worn-Out Elements

In the world of machinery, certain components are prone to wear and tear over time. Regular maintenance and timely replacements can significantly enhance the efficiency and longevity of equipment. Understanding which elements typically need attention is crucial for any operator aiming to maintain optimal performance.

Here are some commonly affected components that may require replacement:

- Blades: The cutting edges are essential for smooth operation and may dull or chip with extensive use.

- Drive Belts: These components can stretch or fray, leading to decreased power transfer and potential system failure.

- Rollers: Often subjected to constant pressure, rollers can become worn, affecting material movement.

- Bearings: These parts support rotational motion and may develop play or roughness, impacting performance.

- Filters: Clogged filters can hinder airflow and cooling, necessitating regular replacement to ensure efficiency.

Identifying the signs of wear early can prevent more significant issues down the line. Regular inspections and maintenance schedules are vital in addressing these common replacements effectively.

Detailed Look at Control Panel Functions

The control interface of a machine plays a crucial role in its operation, offering various features to enhance user experience and efficiency. Understanding these functionalities is essential for optimal utilization and maintenance of the equipment. Each button, dial, and display serves a specific purpose, enabling operators to monitor and adjust settings according to their needs.

Key Features of the Control Interface

Operators can manage multiple aspects of the machinery through an intuitive layout. This includes speed adjustments, operational status indicators, and safety features. Familiarity with these components allows users to troubleshoot issues swiftly and ensure smooth performance.

| Control Element | Description |

|---|---|

| Power Switch | Initiates or halts the machine’s operations, ensuring safety when maintenance is required. |

| Speed Control Dial | Allows users to set the operational speed, adapting to different material types and sizes. |

| Status Indicators | Displays operational status, alerting users to any malfunctions or required attention. |

| Emergency Stop Button | Immediately ceases all operations in case of an emergency, enhancing operator safety. |

Understanding Operational Settings

Being proficient in adjusting the operational settings is vital for maximizing productivity. Users can tailor the performance of the machinery to align with specific project requirements. This adaptability not only enhances efficiency but also extends the lifespan of the equipment.

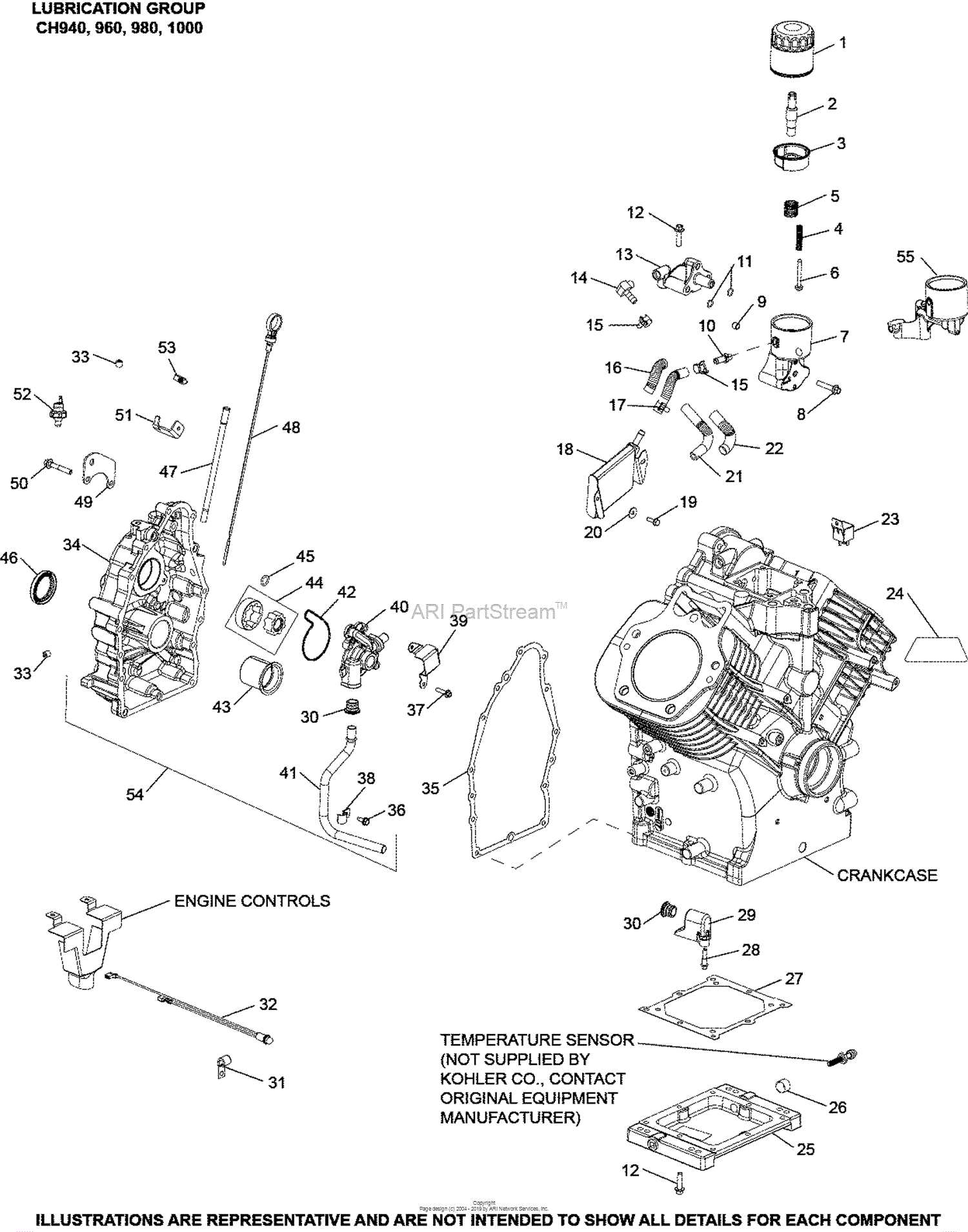

Understanding Hydraulic System Components

The hydraulic system is a vital part of many machinery, utilizing fluid power to perform various tasks efficiently. This mechanism relies on a series of interconnected elements that work together to convert energy into movement, providing enhanced performance and control in operations.

At the heart of this system lies the pump, which generates the necessary pressure to move the hydraulic fluid through the network of tubes and valves. Valves play a crucial role in regulating the flow and direction of this fluid, allowing operators to control the speed and force applied in different applications.

Additionally, actuators, such as cylinders and motors, convert the fluid’s pressure back into mechanical motion, enabling the machinery to carry out its intended functions. Understanding these components and their interactions is essential for optimizing performance and ensuring longevity in equipment operation.

How to Maintain the Cutting Head

Proper upkeep of the cutting mechanism is essential for optimal performance and longevity. Regular maintenance ensures that the equipment operates smoothly, reducing the risk of unexpected breakdowns and enhancing the quality of the cuts produced.

Here are some key practices to follow for effective maintenance:

- Regular Inspection: Frequently check the cutting head for signs of wear or damage. Look for dull blades, cracks, or any irregularities.

- Blade Sharpening: Keep the blades sharp to ensure efficient cutting. Dull blades can strain the motor and reduce cutting quality.

- Cleaning: After each use, clean the cutting area to remove sawdust and debris. This helps prevent overheating and maintains accuracy.

- Lubrication: Apply appropriate lubricants to moving parts as per the manufacturer’s recommendations. This reduces friction and extends the life of the components.

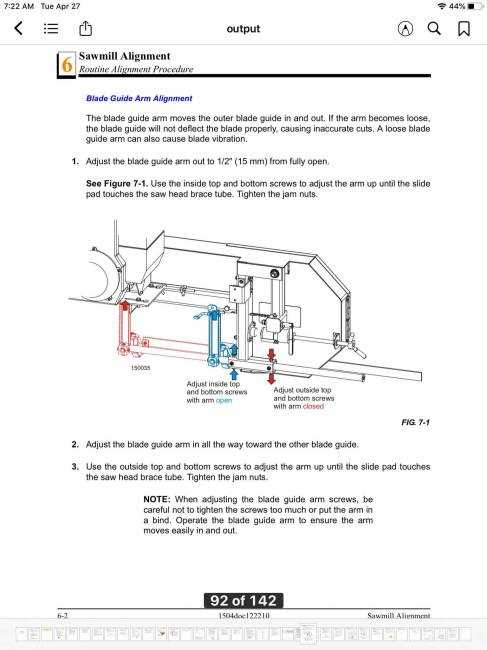

- Alignment Checks: Ensure that the cutting head is properly aligned. Misalignment can lead to uneven cuts and increased wear.

- Replacement of Worn Parts: Replace any worn or damaged components promptly to prevent further issues and ensure safe operation.

By following these guidelines, operators can significantly enhance the performance and lifespan of the cutting apparatus, ensuring that it remains an effective tool for any sawing tasks.

Tips for Finding the Right Spare Parts

When maintaining machinery, acquiring the correct components is essential for ensuring optimal performance and longevity. Knowing where to look and how to evaluate your options can greatly enhance your chances of finding what you need.

1. Identify the Specific Requirements: Start by understanding the exact specifications of the component you need. This includes model numbers, dimensions, and any relevant performance criteria. Being precise helps narrow down your search and avoids costly mistakes.

2. Consult the Manufacturer’s Resources: Utilize official resources provided by the manufacturer, such as user manuals or online catalogs. These documents often contain valuable information on compatible items, helping you make informed decisions.

3. Explore Reliable Suppliers: Look for established vendors known for their reliability and quality. Reading reviews and seeking recommendations can lead you to trustworthy sources that offer authentic components.

4. Consider Aftermarket Options: While original equipment can be ideal, many aftermarket alternatives can perform just as well. Research these options and weigh their pros and cons to find the best fit for your needs.

5. Verify Compatibility: Ensure that the selected item is compatible with your machinery. Double-checking specifications and consulting with experts can save time and prevent frustration.

6. Keep an Eye on Prices: Pricing can vary significantly between suppliers. Compare costs and consider any warranties or return policies before making a purchase to ensure you’re getting the best deal.

By following these guidelines, you can streamline the process of locating the appropriate components, ensuring your machinery operates smoothly and efficiently.