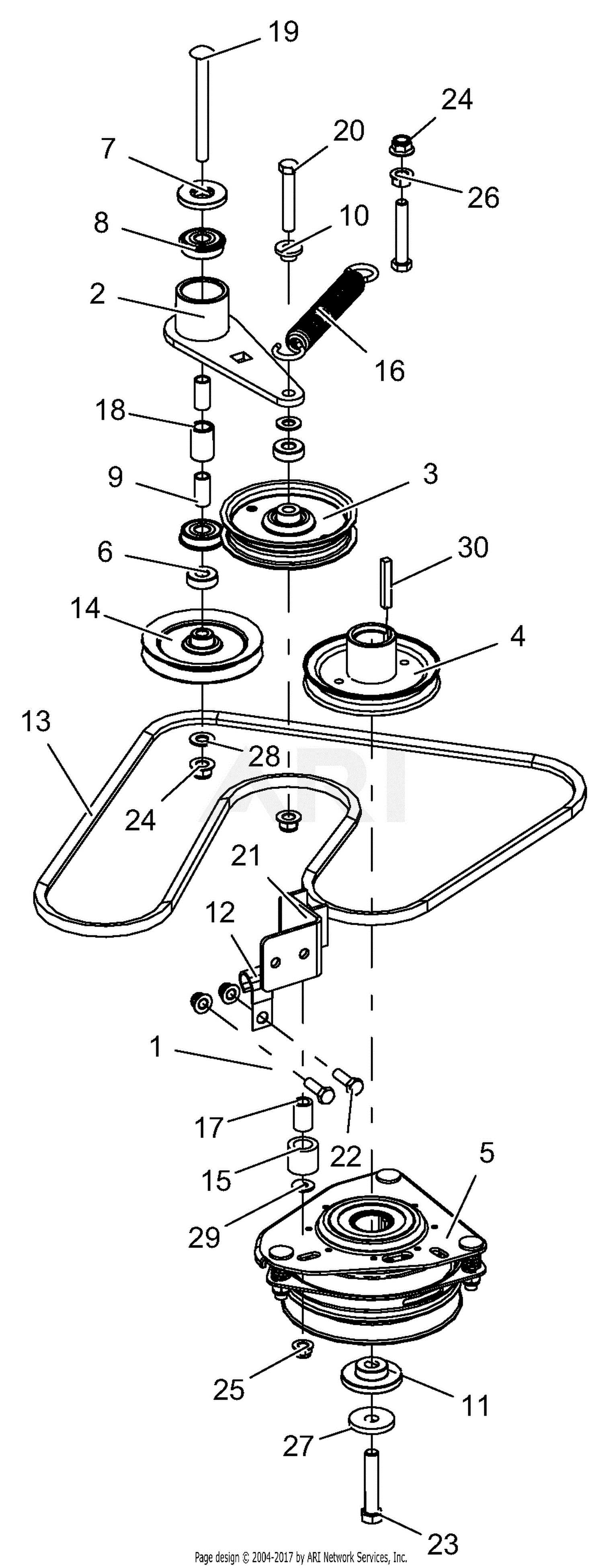

The intricate machinery behind the 52 series offers a fascinating glimpse into engineering precision and functionality. Each component plays a pivotal role, ensuring optimal performance and reliability in various applications. By exploring the assembly of these elements, users can gain valuable insights into their operation and maintenance.

In this section, we will delve into the essential pieces that constitute this sophisticated system. Analyzing these components not only enhances user knowledge but also aids in troubleshooting and repairs. Whether you are a seasoned technician or a curious enthusiast, understanding these intricacies will lead to a more informed experience.

Ultimately, a comprehensive examination of the series’ configuration empowers users to appreciate the design’s innovation and functionality. This exploration will illuminate the path to effective utilization and care, ensuring longevity and efficiency in every task undertaken.

Understanding Wright Stander 52 Components

To appreciate the intricacies of this unique equipment, it’s essential to delve into its various elements and how they contribute to overall functionality. Each component plays a vital role in ensuring optimal performance and user experience, making it crucial to understand their individual characteristics and interactions.

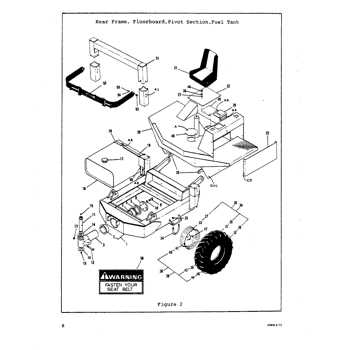

The chassis serves as the backbone, providing structural integrity and stability during operation. Its design enhances maneuverability, allowing for efficient navigation across different terrains. Additionally, the drive system is pivotal, as it translates user input into movement, ensuring responsiveness and control.

Equally important are the cutting mechanisms, which are engineered for precision and efficiency. The arrangement and sharpness of blades can significantly affect the quality of the finished surface. Furthermore, the engine powers the entire system, with specifications that dictate performance levels, fuel efficiency, and maintenance requirements.

Understanding the control features is also crucial, as they dictate how the operator interacts with the machinery. Ergonomic placements enhance comfort, while intuitive layouts facilitate ease of use. Lastly, the safety systems integrated into the design are essential for protecting both the user and the machine during operation.

Key Features of the Wright Stander

This innovative equipment offers a range of standout characteristics designed to enhance performance and user experience. Built with efficiency in mind, it combines robust engineering with ergonomic design, making it a preferred choice for professionals in landscaping and lawn maintenance.

Exceptional Maneuverability: One of the primary attributes is its ability to navigate tight spaces effortlessly. The compact design allows for sharp turns and easy handling, ensuring that operators can tackle various terrains without hassle.

Operator Comfort: Comfort is paramount during prolonged use. This model features an adjustable platform and cushioned controls that reduce fatigue, enabling users to work longer without compromising their well-being.

Durability and Reliability: Constructed with high-quality materials, this equipment is built to withstand the rigors of daily use. Its robust components ensure longevity, allowing users to depend on it season after season.

Enhanced Cutting Efficiency: The advanced cutting system delivers superior results, providing a clean and even finish. This feature not only improves aesthetics but also promotes healthier grass growth, making it a vital tool for maintaining landscapes.

Ease of Maintenance: Maintenance is simplified through accessible components, making it easy for users to perform routine checks and repairs. This design consideration minimizes downtime, ensuring that the equipment is always ready for action.

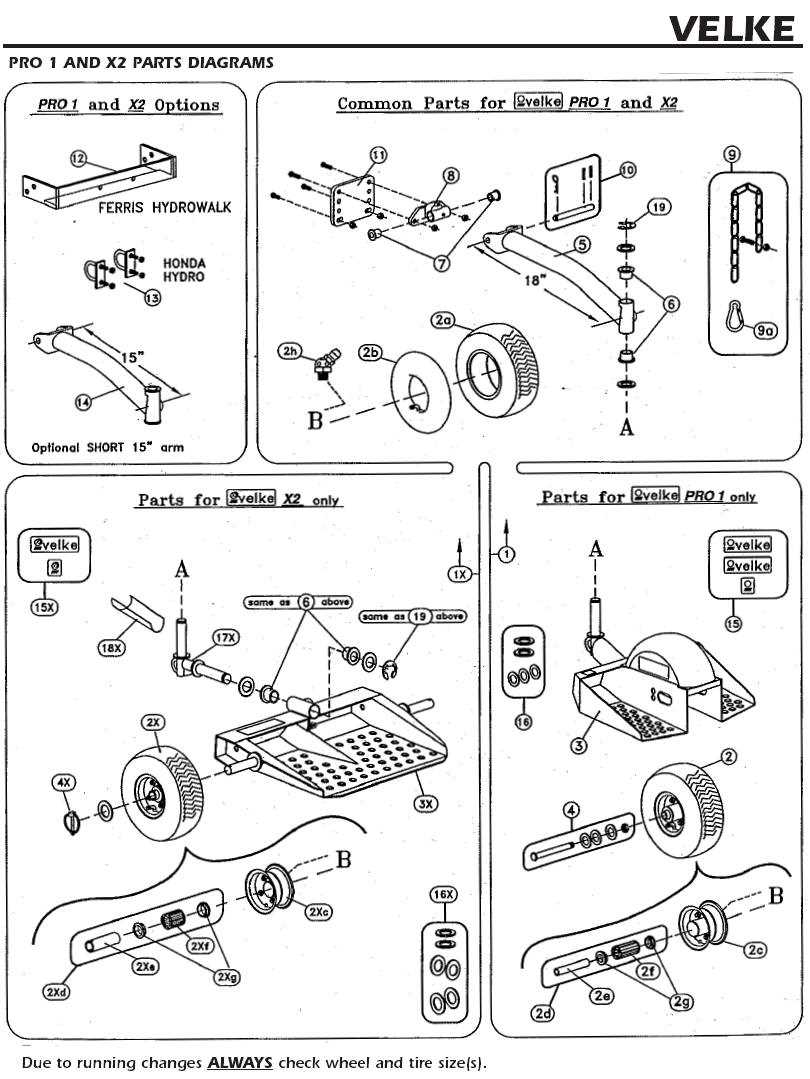

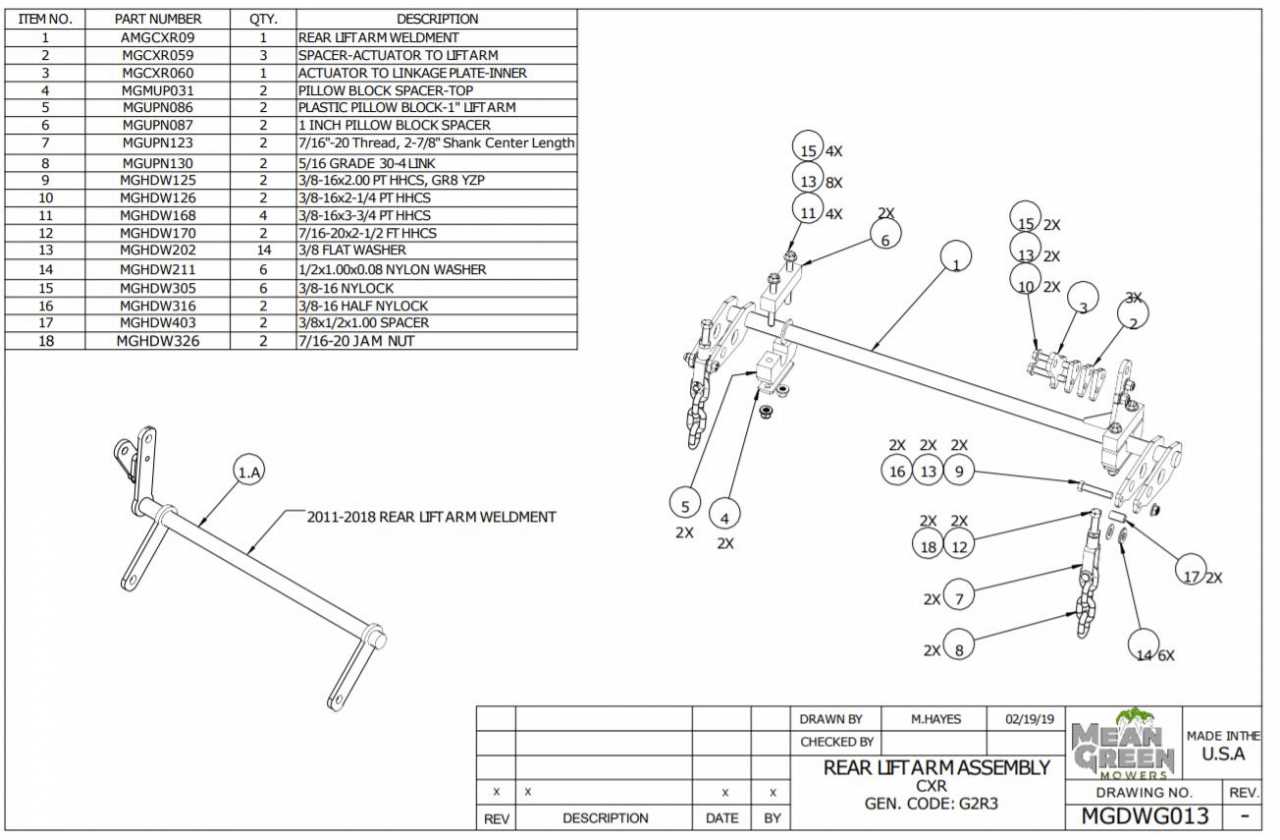

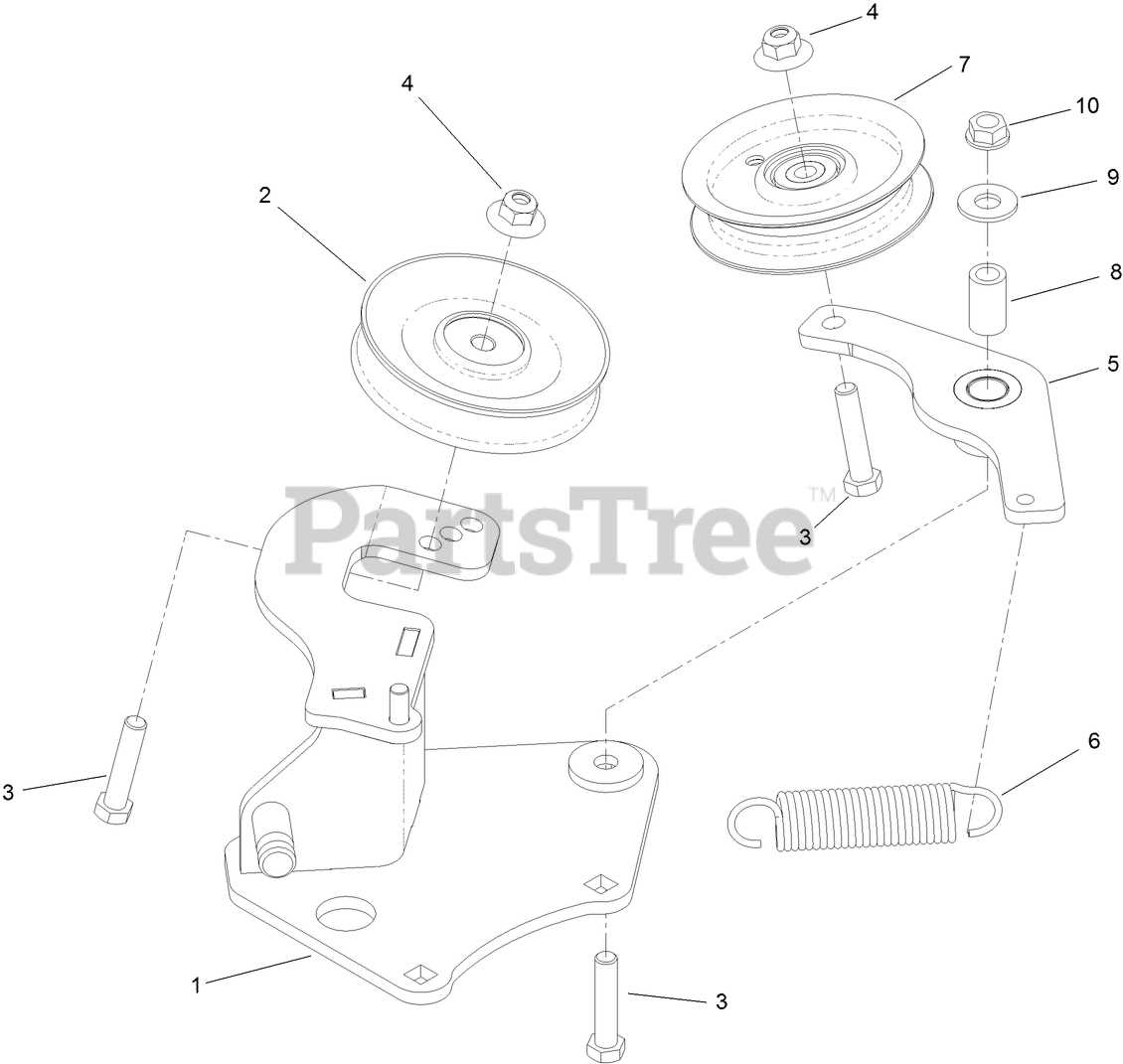

Importance of Parts Diagrams

Understanding the intricate components of machinery is essential for effective maintenance and repair. Visual representations serve as valuable tools, enabling users to identify individual elements, their functions, and how they interact within a system. This clarity helps streamline processes and reduces the likelihood of errors during assembly or disassembly.

Facilitating Efficient Repairs

By providing a clear overview, these visual aids enhance troubleshooting capabilities. When technicians can easily pinpoint issues, they can address problems more swiftly, minimizing downtime and ensuring optimal performance.

Enhancing User Knowledge

Such illustrations also foster a deeper understanding of machinery among users. Familiarity with various components empowers individuals to make informed decisions regarding upgrades or replacements, ultimately contributing to the longevity and efficiency of the equipment.

Identifying Major Assembly Parts

Understanding the primary components of a mechanical structure is essential for effective maintenance and troubleshooting. Each element plays a critical role in the overall functionality, and recognizing them can enhance operational efficiency. This section aims to clarify the key assemblies that form the backbone of the system.

Key Components Overview

The following table outlines the significant assemblies along with their respective functions and characteristics:

| Component Name | Function | Characteristics |

|---|---|---|

| Base Frame | Supports the entire structure | Durable, rigid, stable |

| Control Unit | Manages operations and settings | Intuitive interface, programmable |

| Support Legs | Provides stability and balance | Adjustable height, sturdy material |

| Power Supply | Delivers energy to the system | Reliable, efficient, low-maintenance |

Importance of Each Assembly

Each major component contributes to the seamless operation of the overall mechanism. Familiarity with these assemblies not only aids in quick identification during inspections but also assists in informed decision-making for repairs and upgrades. Recognizing the interplay between these parts is crucial for optimal performance and longevity of the entire system.

Common Maintenance Tips

Proper upkeep is essential for ensuring longevity and optimal performance of your equipment. Regular attention to specific areas can prevent major issues and enhance efficiency, making your investment more reliable.

Regular Inspection

Frequent checks for wear and tear can help identify potential problems early. Look for signs of damage or malfunction, such as unusual noises or vibrations, and address them promptly to avoid costly repairs.

Cleaning and Lubrication

Keeping your machinery clean and well-lubricated is vital. Remove debris and buildup to maintain airflow and prevent overheating. Apply the appropriate lubricants to moving parts to ensure smooth operation.

How to Use the Diagram Effectively

Understanding visual representations is crucial for anyone looking to assemble or maintain complex equipment. By leveraging these illustrations, users can gain insights into the arrangement and functionality of various components, ultimately enhancing their efficiency and precision during the process.

Here are some tips for maximizing the utility of such visuals:

| Tip | Description |

|---|---|

| Familiarize Yourself | Study the entire visual to grasp the overall layout before focusing on individual sections. |

| Cross-Reference | Use additional resources to confirm details and ensure comprehensive understanding. |

| Follow Sequential Steps | Adhere to the order suggested by the illustration for more efficient assembly or troubleshooting. |

| Highlight Key Areas | Mark important components or connections to avoid confusion during the process. |

Repairing Your Wright Stander

When it comes to maintaining your outdoor equipment, understanding its components and how to fix them can greatly extend its lifespan. Regular maintenance and timely repairs ensure optimal performance and prevent minor issues from escalating into major problems.

Common Issues and Troubleshooting

Identifying frequent problems can help you take proactive measures. Common issues include engine difficulties, wheel malfunctions, and electrical failures. Start by examining the fuel system and ensuring all connections are secure. For wheel-related concerns, check for wear and tear, ensuring proper alignment and inflation. Electrical components should be inspected for loose wires and corrosion.

Essential Tools for Repairs

Having the right tools at your disposal can make repairs more efficient. Basic tools such as wrenches, screwdrivers, and pliers are essential. Additionally, specialized tools may be necessary for more intricate repairs. Investing in a good repair manual can provide valuable guidance on specific procedures, ensuring you approach each task with confidence.

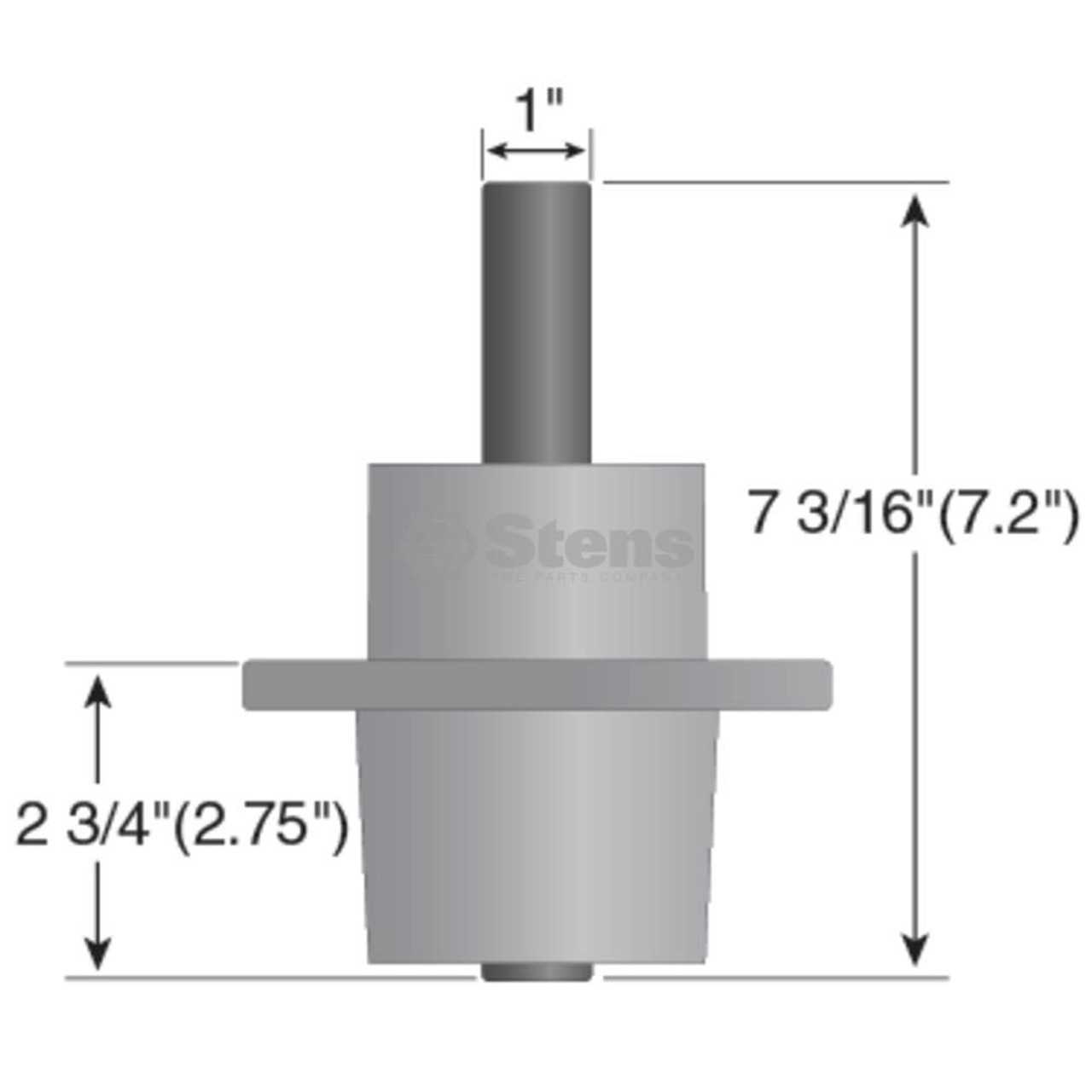

Parts Replacement Best Practices

Ensuring longevity and optimal performance of your equipment often hinges on the correct substitution of components. Adopting the right strategies can not only enhance functionality but also prevent premature failures. Understanding the significance of each element within the system is crucial for effective maintenance and repair processes.

Assessment and Compatibility

Before initiating any replacement, thorough evaluation is essential. Identify the specific component that requires attention and verify its compatibility with existing elements. Utilizing original specifications or consulting the manufacturer’s recommendations can significantly mitigate risks associated with mismatched items.

Quality Over Cost

When selecting replacements, prioritize quality to ensure durability and reliability. While opting for budget-friendly alternatives might be tempting, such choices can lead to additional expenses in the long run due to frequent malfunctions. Investing in high-quality components will provide peace of mind and consistent performance.

Documentation of the replacement process is also vital. Keeping a detailed record helps in tracking maintenance history, which can be beneficial for future reference and troubleshooting.

By following these guidelines, you can enhance the efficiency and lifespan of your equipment, ensuring it operates at its best for years to come.

Where to Find Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for ensuring longevity and optimal performance. There are several avenues to explore when looking for quality replacements, and each offers unique benefits.

| Source | Description |

|---|---|

| Manufacturer’s Website | The most reliable source, providing a comprehensive range of genuine components and detailed specifications. |

| Authorized Dealers | Trained professionals who can guarantee authenticity and offer expert advice on compatibility. |

| Online Marketplaces | Reputable platforms where you can find a variety of options, though it’s important to verify the seller’s credibility. |

| Local Retailers | Physical stores often carry essential items and can provide immediate assistance. |

Choosing the right source can make all the difference in maintaining the integrity and performance of your machinery.

Impact of Regular Maintenance

Consistent upkeep of equipment plays a crucial role in ensuring optimal performance and longevity. Neglecting routine care can lead to various issues, impacting efficiency and safety.

- Enhanced Performance: Regular checks and adjustments keep machinery running smoothly.

- Increased Lifespan: Timely maintenance reduces wear and tear, extending the life of the equipment.

- Cost Savings: Preventative measures minimize costly repairs and unexpected breakdowns.

- Safety Assurance: Regular inspections identify potential hazards, ensuring user safety.

Ultimately, maintaining equipment not only preserves its functionality but also safeguards the investment made in it.

Frequently Asked Questions

This section aims to address common inquiries and provide clarity on various topics related to maintenance and components. Here, you’ll find answers to help guide your understanding and troubleshooting efforts.

General Inquiries

- What are the main features of this equipment?

- How can I identify the components I need?

- Are there specific maintenance tips for longevity?

Troubleshooting

- What should I do if I notice unusual noises?

- How can I resolve performance issues?

- Where can I find replacement components?

Resources for Further Learning

Exploring additional materials can greatly enhance your understanding and skills in a specific field. Access to various educational tools, manuals, and community forums can provide invaluable insights and support for both beginners and seasoned enthusiasts. This section highlights several resources that will help you deepen your knowledge and improve your practical abilities.

Online Tutorials: Numerous platforms offer step-by-step guides that cover a wide range of topics. Websites such as YouTube or specialized educational sites provide visual aids and expert advice, making complex concepts more accessible.

Books and Manuals: Comprehensive texts can serve as excellent reference points. Look for guides that offer detailed explanations, illustrations, and troubleshooting tips relevant to your interests.

Community Forums: Engaging with online communities can provide support and shared experiences. Platforms like Reddit or dedicated discussion boards allow users to ask questions, share tips, and learn from others’ experiences.

Workshops and Courses: Participating in hands-on workshops or online courses can be particularly beneficial. These opportunities often include practical exercises and direct feedback from instructors, facilitating a deeper understanding of the subject matter.

Manufacturer Resources: Many manufacturers provide official documentation and resources tailored to their products. These materials can include maintenance tips, usage guidelines, and safety information that are essential for effective handling.