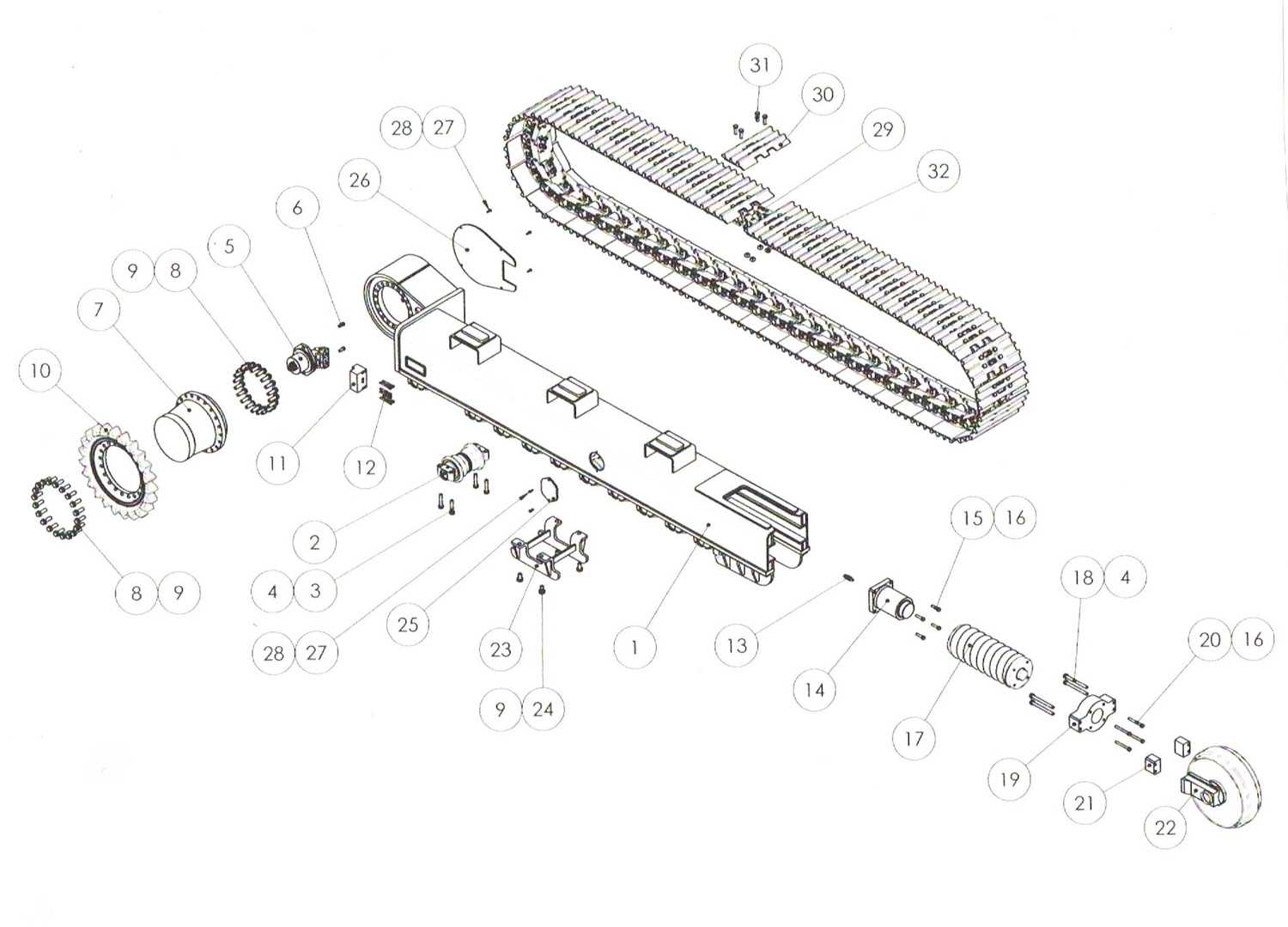

In the world of mechanical engineering and design, visual representations play a crucial role in understanding the intricate relationships between various elements of a machine. A comprehensive layout serves as a valuable tool for enthusiasts and professionals alike, enabling them to grasp the functionality and interconnectivity of different segments.

Such illustrations provide clarity, allowing individuals to identify essential units and comprehend their specific roles within the overall structure. By analyzing these visuals, one can effectively troubleshoot issues, perform maintenance, and enhance the performance of the equipment.

Moreover, detailed representations can assist in the assembly and disassembly processes, ensuring that each component is appropriately aligned and securely connected. This knowledge fosters a deeper appreciation for the engineering behind the machinery, empowering users to engage with it more confidently.

This section outlines the essential elements of a particular model, focusing on its various components and their functions. By delving into the specifics of each section, readers can gain a better understanding of how these elements work together to enhance performance and reliability.

| Section Title | Description |

|---|---|

| Essential Components Overview | An introduction to the main elements that make up the assembly. |

| Engine Specifications | A detailed look at the engine and its crucial features. |

| Transmission System | Insights into how the transmission facilitates power delivery. |

| Suspension Mechanisms | An exploration of the suspension setup for improved handling. |

| Brake Assembly | An overview of the braking system and its safety features. |

| Fuel System | A breakdown of how fuel is delivered and managed. |

| Electrical System | A review of the electrical components that power various features. |

| Frame and Chassis | A discussion on the structural integrity and design of the chassis. |

| Wheels and Tires | Information on wheel types and tire specifications for optimal performance. |

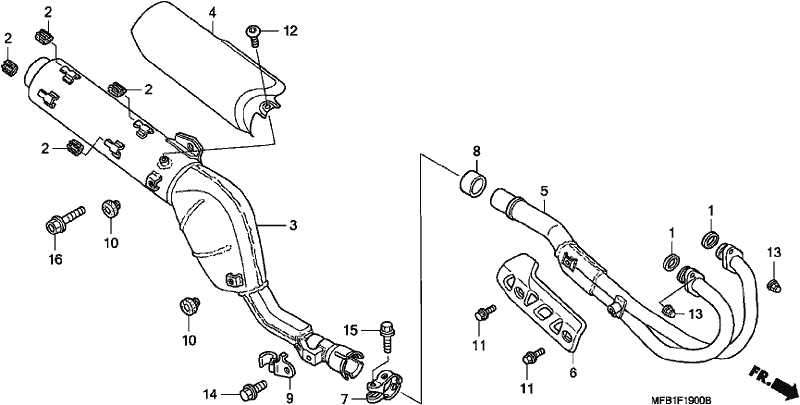

| Exhaust System | An overview of how exhaust components affect efficiency. |

| Cooling Mechanism | An examination of cooling strategies to maintain optimal operating temperatures. |

| Maintenance Tips | Practical advice for keeping the assembly in top condition. |

Key Features of Xr400 Parts

This section highlights the essential characteristics that define the components of this particular model. Understanding these attributes can enhance the overall performance and longevity of the machine, ensuring that it operates efficiently and reliably under various conditions.

Durability is one of the primary aspects to consider. The components are designed to withstand rigorous usage and harsh environments, making them suitable for demanding tasks. Their robust construction ensures they can handle stress without compromising functionality.

Compatibility is another significant feature, allowing these components to seamlessly integrate with a range of systems. This versatility enhances user experience, as it enables easy replacements and upgrades without extensive modifications.

Additionally, the efficiency of these elements contributes to optimal performance. Each component is engineered to minimize energy consumption while maximizing output, leading to better overall operation and reduced operational costs.

Finally, attention to design plays a crucial role in functionality. The thoughtful layout and arrangement of these elements ensure ease of maintenance and access, promoting a user-friendly experience that supports effective management of the equipment.

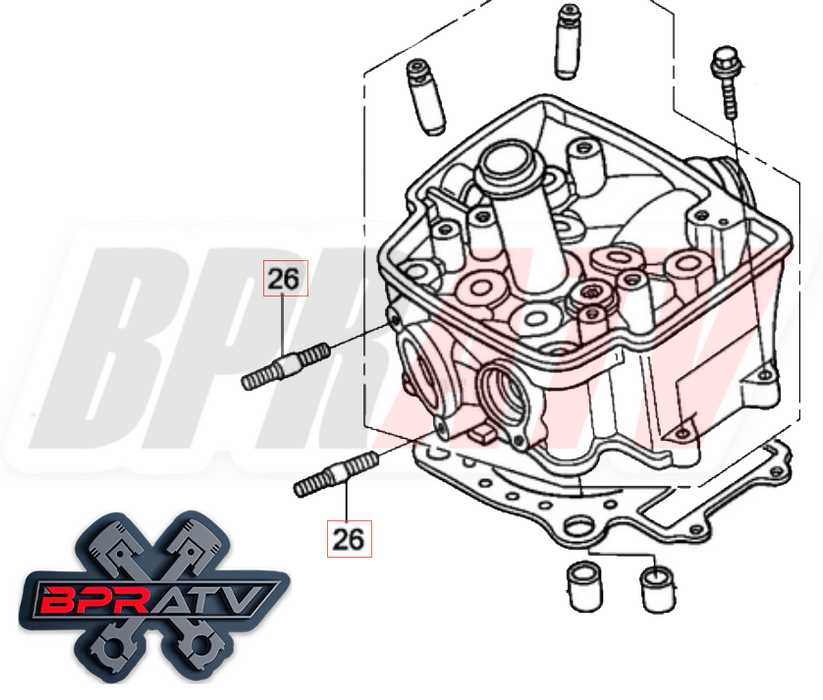

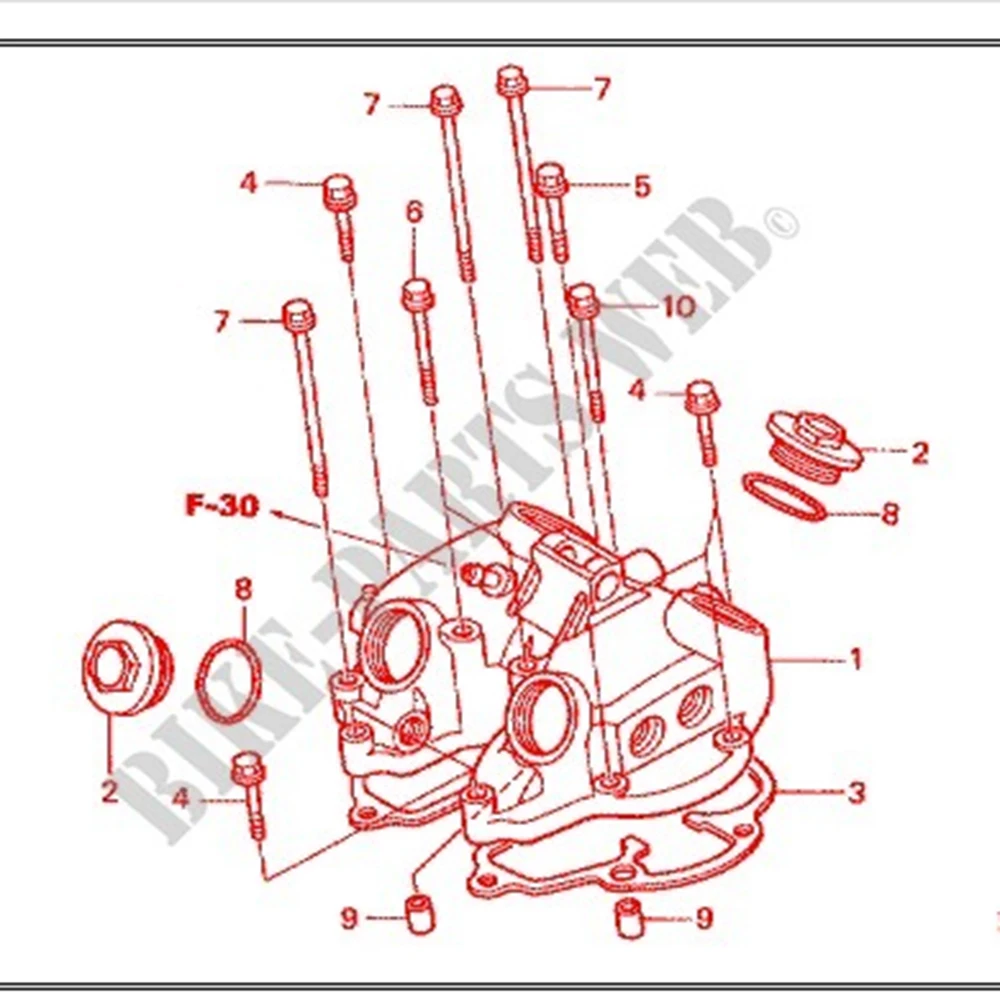

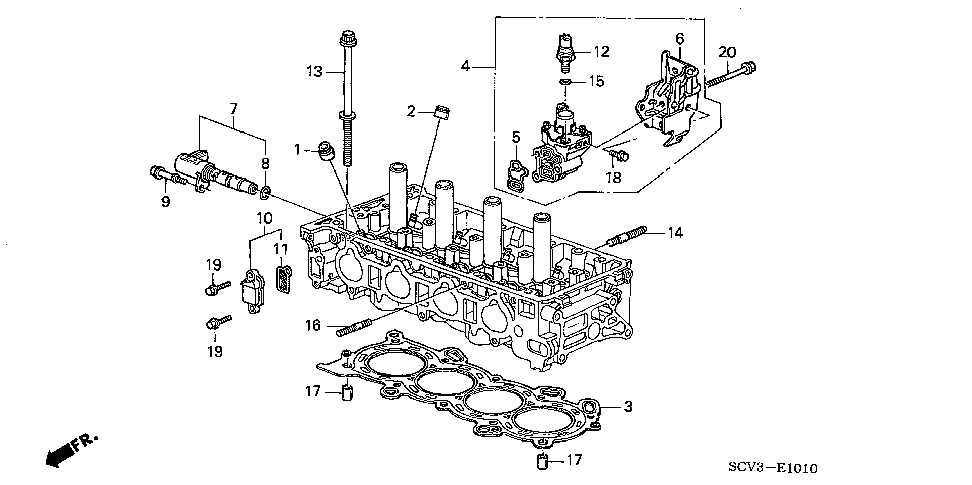

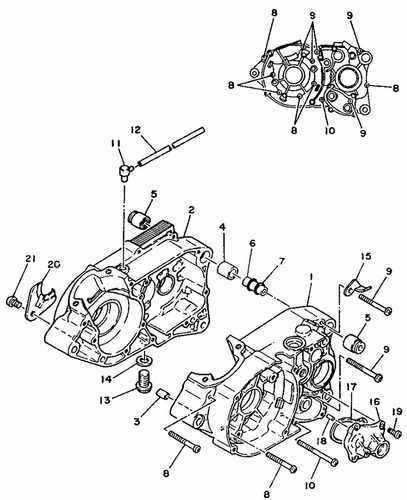

Understanding the Engine Assembly

The engine assembly serves as the heart of any machine, driving its performance and efficiency. This intricate structure consists of various components that work harmoniously to convert fuel into motion. Each part plays a vital role in ensuring optimal functionality, making it essential to understand how these elements interact within the larger system.

Key Components of the Engine

At the core of the assembly lies the cylinder block, which houses the cylinders where fuel combustion occurs. Above this is the cylinder head, responsible for sealing the combustion chamber and containing vital components like valves and spark plugs. Connecting rods link the pistons to the crankshaft, facilitating the transfer of energy generated during combustion. Crankshafts convert linear motion into rotational energy, propelling the vehicle forward.

Importance of Maintenance

Regular upkeep of the engine assembly is crucial for longevity and performance. Neglecting maintenance can lead to wear and tear, affecting the efficiency of each component. Routine inspections and timely replacements of worn-out parts help prevent major failures, ensuring smooth operation and enhancing the overall lifespan of the machine.

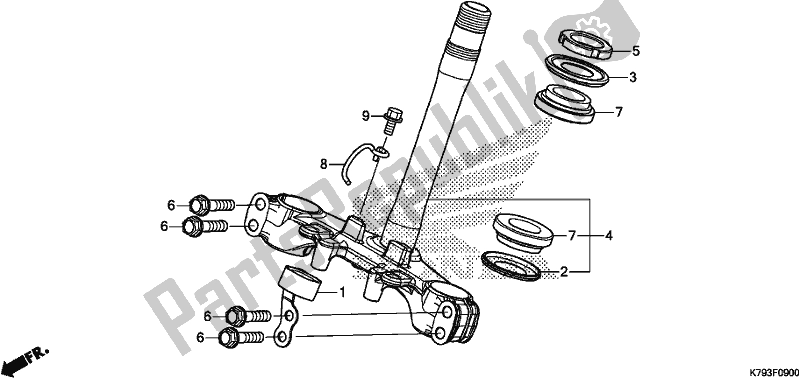

Front Suspension Explained

The front suspension system plays a crucial role in enhancing the overall performance and stability of a vehicle. It serves to absorb shocks and impacts from the road, ensuring a smoother ride for the driver and passengers. This mechanism is designed to maintain tire contact with the ground, which is essential for effective steering and control.

At its core, the front suspension consists of various components that work together to provide optimal handling and comfort. These elements typically include springs, dampers, and control arms. Each part contributes to the system’s ability to manage weight transfer and provide stability during acceleration, braking, and cornering.

Moreover, the configuration of the front suspension can vary depending on the vehicle’s design and intended use. For instance, different types of setups, such as telescopic forks or independent systems, offer unique advantages in terms of performance and ride quality. Understanding these differences is vital for anyone looking to enhance or modify their vehicle’s performance.

In summary, the front suspension is a fundamental aspect of vehicle dynamics, influencing not just comfort but also safety and handling characteristics. A well-designed system can significantly improve the driving experience by ensuring better control and responsiveness on various terrains.

Rear Suspension and Its Role

The rear suspension system plays a critical role in the overall performance and handling of a motorcycle. It is designed to absorb shocks from uneven terrain, providing stability and comfort to the rider. By effectively managing the dynamics of the vehicle, this system contributes to a smoother ride, enhancing both safety and control.

Functionality of Rear Suspension

This system primarily functions to minimize the impact of bumps and irregularities in the road surface. It allows the rear wheel to move independently, maintaining contact with the ground for optimal traction. By doing so, it helps in reducing fatigue for the rider during long rides and improves overall maneuverability.

Components and Their Importance

Key components of the rear suspension include springs and shock absorbers. Springs provide the necessary support and flexibility, while shock absorbers control the rate of compression and rebound. Together, these elements ensure that the motorcycle can handle varying conditions effectively, allowing for a responsive and enjoyable riding experience.

Braking System Components Breakdown

The braking system is essential for safe operation, providing the necessary force to slow down or stop a vehicle. Understanding its individual components helps in ensuring optimal performance and reliability. This section delves into the various elements that comprise this critical system, each playing a significant role in its overall functionality.

Brake Pads: These are the friction materials that press against the braking surface, generating the necessary stopping power. Their quality and condition directly impact the effectiveness of the braking system.

Brake Discs: Often referred to as rotors, these components provide a surface for the brake pads to clamp down on. They are typically made from durable materials to withstand high temperatures generated during braking.

Calipers: The caliper houses the brake pads and is responsible for pushing them against the discs. It contains hydraulic components that allow for the application of pressure, crucial for effective braking.

Brake Lines: These are the conduits through which brake fluid travels, connecting the master cylinder to the calipers. They play a vital role in transmitting force from the brake pedal to the braking components.

Master Cylinder: This part serves as the heart of the braking system, converting the force from the brake pedal into hydraulic pressure. It initiates the braking process by sending fluid through the brake lines.

Each of these components works in harmony to ensure effective stopping power, contributing to overall vehicle safety. Regular maintenance and inspection of these elements are crucial for preventing failures and ensuring reliable operation.

Fuel System Overview and Details

The fuel system plays a crucial role in ensuring the efficient operation of any engine. Its primary function is to deliver the right amount of fuel to the engine, allowing for optimal combustion and performance. Understanding the various components and their interconnections within this system can help in diagnosing issues and performing maintenance effectively.

Key Components of the Fuel System

At the heart of the fuel system are several essential components. These include the fuel tank, which stores the fuel, and the fuel pump, responsible for transporting it to the engine. Additionally, filters are integrated to remove impurities, ensuring that only clean fuel reaches the combustion chamber. Injectors or carburetors then atomize the fuel, mixing it with air for efficient burning.

Functionality and Importance

The proper functioning of the fuel system is vital for maintaining engine performance and longevity. A well-maintained system prevents issues such as fuel leaks, blockages, or improper fuel-air mixtures, which can lead to decreased efficiency and increased emissions. Regular inspection and servicing of the fuel components are essential for keeping the engine running smoothly.

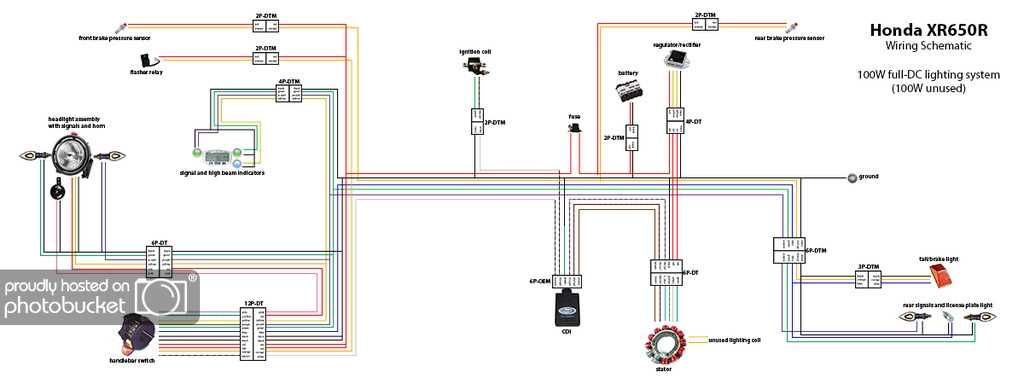

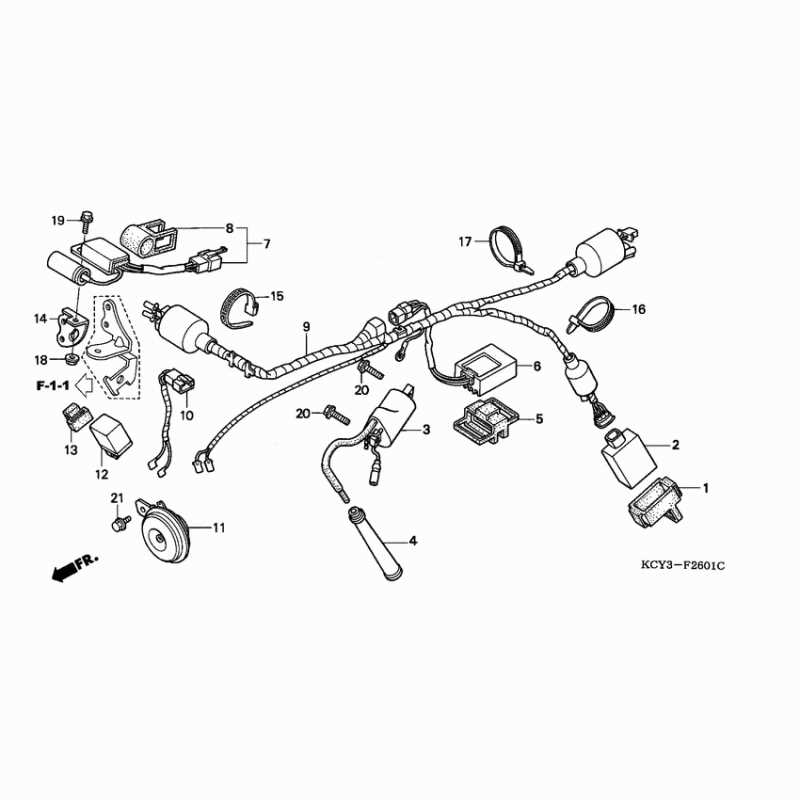

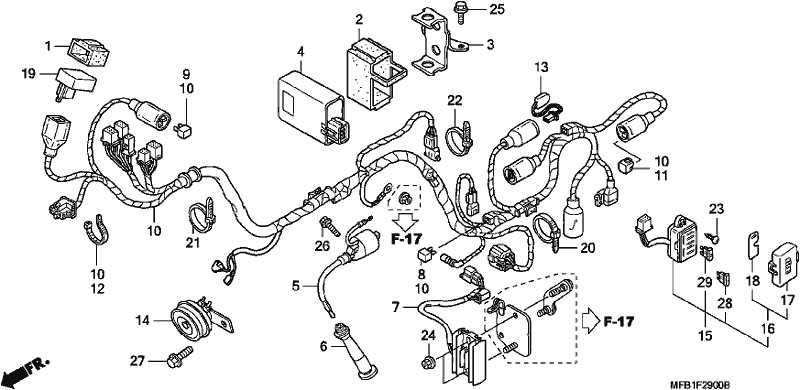

Electrical System Wiring Guide

This section offers a comprehensive overview of the electrical connections essential for efficient functionality. Proper understanding of these linkages is vital for maintaining optimal performance and reliability in any vehicle.

Before embarking on any wiring project, it is crucial to familiarize oneself with the components involved. Each element in the electrical setup plays a significant role in ensuring seamless operation. Clear identification of wiring routes and connections can prevent potential issues and enhance overall efficiency.

Key considerations include understanding the flow of electricity through various circuits. Recognizing the purpose of each wire and its relationship with other components is essential for effective troubleshooting. Adequate insulation and secure connections are paramount to prevent short circuits and electrical failures.

When planning the layout, it is beneficial to create a visual representation that outlines the connections. This approach aids in organizing the wiring and simplifies future modifications or repairs. Additionally, always use quality materials that can withstand the operational environment, ensuring longevity and safety.

Regular inspection of the wiring system is advised to identify any wear or damage. Keeping the electrical system in optimal condition will contribute to the longevity and reliability of the entire assembly.

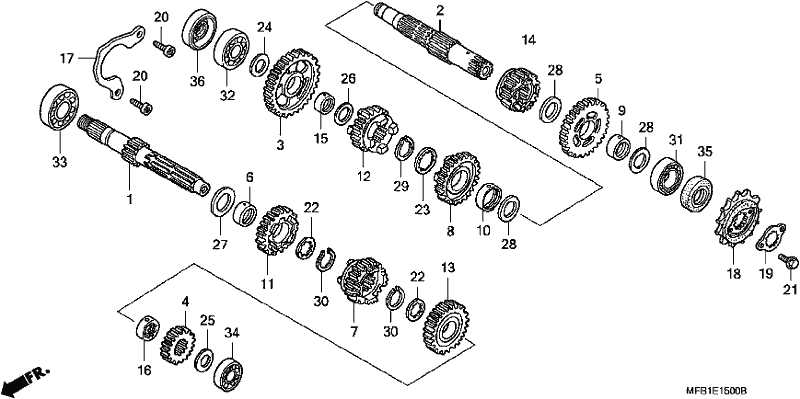

Transmission and Gearbox Insights

This section delves into the crucial aspects of the transmission and gearbox system, which plays a vital role in optimizing performance and efficiency in any vehicle. Understanding how these components function together can significantly enhance the driving experience.

Key Functions of the Transmission

- Facilitates smooth gear shifts

- Ensures power delivery from the engine to the wheels

- Adapts to varying driving conditions

Importance of Gearbox Maintenance

- Regularly check fluid levels to prevent overheating.

- Inspect for leaks that could indicate potential issues.

- Change fluids according to the manufacturer’s recommendations to ensure optimal performance.

Wheel and Tire Specifications

This section provides essential details about the specifications related to wheels and tires, which play a crucial role in ensuring optimal performance and safety. Understanding these specifications can help in making informed choices for replacements or upgrades.

- Wheel Size: The diameter and width of the wheel affect the overall handling and ride quality.

- Tire Type: Options include tubeless and tube-type, each offering distinct advantages for different riding conditions.

- Tread Pattern: This influences traction and stability, essential for various terrains.

Selecting the right combination of these elements enhances the overall riding experience and ensures compatibility with the vehicle’s performance requirements.

- Aspect Ratio: The ratio of the tire’s height to its width impacts ride comfort and handling.

- Load Index: This indicates the maximum load capacity of the tire, ensuring it can support the weight of the vehicle and rider.

- Speed Rating: This denotes the maximum speed at which the tire can safely operate, essential for performance considerations.

Bodywork and Frame Analysis

This section delves into the structural components and exterior elements of the vehicle, highlighting their significance in overall performance and aesthetics. Understanding these features is essential for both maintenance and enhancement, as they contribute to the ride quality and durability.

The outer casing plays a crucial role in protecting internal mechanisms while providing a sleek appearance. Made from various materials, these elements are designed to withstand external forces and environmental conditions. Their design also influences aerodynamics, which can enhance fuel efficiency and handling.

Equally important is the frame, which serves as the backbone of the entire structure. It provides stability and support for all other components, ensuring that they work in harmony. A robust frame can improve handling and safety, making it vital for any vehicle’s longevity.

Regular inspection and maintenance of both the bodywork and frame can prevent wear and tear, ensuring optimal functionality. Understanding the interplay between these components can empower owners to make informed decisions regarding upgrades and repairs.

Maintenance Tips for Xr400 Parts

Regular upkeep is essential for ensuring optimal performance and longevity of any machinery. Adopting a few simple practices can significantly enhance the functionality and reliability of components. Understanding the specific needs of each element will help in preserving their condition over time.

Regular Inspection

Consistent checks on various elements can help identify wear and tear before it becomes a more significant issue. Look for signs of damage, corrosion, or loose fittings. Addressing these concerns promptly will prevent further complications.

Proper Lubrication

Using the correct lubricant is vital for reducing friction and preventing premature wear. Make sure to apply lubricant as specified in the guidelines, focusing on high-friction areas. This practice can lead to smoother operation and extended lifespan of components.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Look for signs of wear or damage. |

| Lubrication | Every 500 miles | Use recommended lubricant type. |

| Replace Filters | Every season | Ensure clean air and fuel flow. |

| Tighten Fasteners | Before each ride | Check for any loose components. |

Replacement Parts and Upgrades

When considering enhancements for your vehicle, understanding the available components is essential for optimal performance. Various elements can be replaced or upgraded to improve functionality, reliability, and overall riding experience. This section explores the options for replacements and enhancements that can elevate your machine to the next level.

Quality components play a crucial role in maintaining efficiency and ensuring durability. Whether you seek improved suspension, better braking systems, or upgraded engines, selecting the right items can significantly influence the riding experience. Performance upgrades often lead to enhanced handling and responsiveness, making your rides smoother and more enjoyable.

Additionally, opting for high-quality replacements can extend the lifespan of your machine, minimizing wear and tear. Regular maintenance and timely upgrades not only boost performance but also contribute to safety. A thorough evaluation of your vehicle’s requirements will guide you in making informed decisions about necessary enhancements and replacements.