Every complex system comprises various essential elements that work harmoniously to ensure optimal performance. Gaining insights into these individual parts can significantly enhance maintenance and troubleshooting efforts, leading to prolonged longevity and efficiency.

In this section, we will explore the intricate layout of these components, highlighting their interconnections and functionality. Understanding how each piece contributes to the whole is crucial for anyone looking to delve deeper into the mechanics of their equipment.

By familiarizing yourself with the overall structure, you can identify potential areas for improvement or necessary repairs. This knowledge is the ultimate key to mastering your machinery and ensuring it operates at its best.

Overview of Ys4500 Parts

This section provides an insight into the various components that make up the intricate system of the machinery in question. Understanding these elements is essential for maintenance and enhancement, ensuring optimal performance and longevity.

Key Components

Among the critical elements are the drive mechanisms, which facilitate movement, and the control systems that govern functionality. Additionally, the structural framework provides support and stability, while the electrical units ensure seamless operation. Each component plays a vital role in the overall efficiency and effectiveness of the device.

Maintenance Considerations

Regular inspection and timely replacement of worn-out elements are crucial for sustaining operational integrity. Familiarity with the layout and specifications of these components aids in troubleshooting and repairs, ultimately contributing to enhanced performance and reliability.

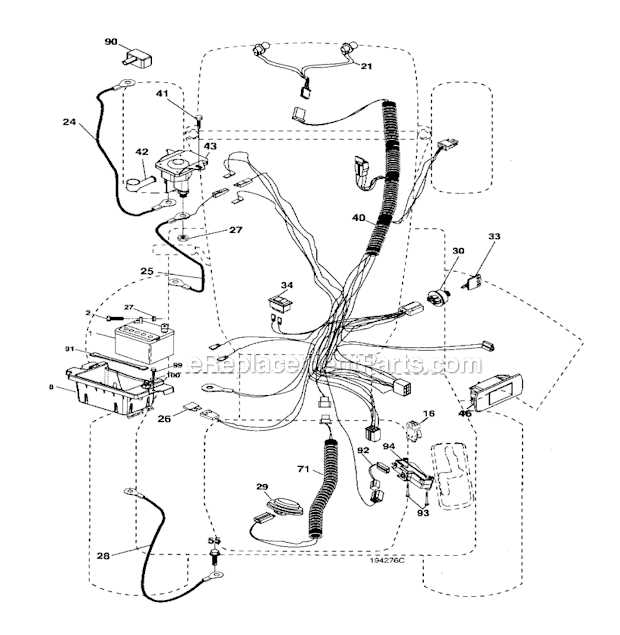

Understanding the Parts Diagram

This section focuses on the importance of visual representations in identifying and organizing components of machinery. These illustrations serve as a crucial reference, simplifying the process of understanding how individual elements fit together and function within the larger system.

Benefits of Visual Guides

- Enhances comprehension of assembly and disassembly processes.

- Facilitates quick identification of necessary components.

- Improves troubleshooting efficiency by highlighting potential issues.

Key Elements to Consider

- Clear labeling of each component.

- Logical arrangement of parts to reflect their relationships.

- Use of color coding to differentiate types of elements.

Key Components of the Ys4500

This section explores the essential elements that contribute to the functionality and efficiency of the machine. Understanding these components is crucial for optimizing performance and ensuring longevity.

Core Functional Elements

Among the primary features are the engine and the transmission. These parts work in harmony to provide power and mobility, making them integral to the overall operation.

Supporting Structures

Another significant aspect includes control systems and hydraulic mechanisms. These systems enhance maneuverability and precision, allowing for effective handling in various tasks.

How to Use the Diagram Effectively

Understanding the layout of components is crucial for any maintenance or repair task. Utilizing a visual reference can significantly enhance your ability to identify and manage different elements, ensuring that you approach your project with clarity and confidence.

Steps for Effective Usage

Follow these simple steps to make the most of your visual reference:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the overall structure presented. |

| 2 | Identify key components and their relationships to one another. |

| 3 | Cross-reference with your project needs to highlight specific parts. |

| 4 | Utilize the visual aid during disassembly or reassembly for accuracy. |

Tips for Maximizing Efficiency

To enhance your experience further, consider these helpful tips:

- Print out the reference for easy access during your work.

- Use markers to denote critical areas or steps that require extra attention.

- Regularly consult the reference as you progress to stay aligned with your goals.

Common Issues with Parts Identification

Identifying components in machinery can often be a challenging task. Various factors contribute to confusion, including overlapping terminologies, lack of visual aids, and inconsistencies in labeling. Addressing these issues is crucial for effective maintenance and repairs.

Challenges in Terminology

- Inconsistent naming conventions can lead to misunderstandings.

- Similar components may have different names across manufacturers.

- Abbreviations and acronyms can cause confusion for users.

Lack of Visual References

- Diagrams may not be available or easily accessible.

- Illustrations can vary in detail and clarity.

- Physical inspections may be necessary but are not always feasible.

Addressing these common challenges can significantly enhance the identification process and ultimately lead to more efficient repairs.

Comparing Ys4500 with Other Models

This section explores the distinctions and similarities between a specific model and its counterparts within the same category. By examining various aspects, we can better understand the advantages and disadvantages each design offers.

Key factors to consider include:

- Performance: How does the efficiency compare across models?

- Features: What unique functionalities set each design apart?

- Durability: Which model demonstrates greater longevity and reliability?

- Cost: How does pricing influence the choice among these options?

In conclusion, a thorough examination reveals the ultimate choice for users based on specific needs and preferences.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficient performance of machinery. Regular attention to key components can significantly extend the lifespan and reliability of your equipment. By adopting a few simple practices, you can prevent premature wear and enhance functionality over time.

Regular Cleaning

Keeping your equipment clean is crucial. Dust, dirt, and debris can accumulate and lead to mechanical issues. Schedule routine cleanings, focusing on critical areas that may trap contaminants. Use appropriate cleaning agents and tools to avoid damage while maintaining optimal performance.

Routine Inspections

Conducting frequent checks on essential elements is vital for identifying potential problems before they escalate. Look for signs of wear, loose connections, or irregularities. Early detection allows for timely interventions, saving both time and resources in the long run.

Where to Find Replacement Parts

Finding the right components for your equipment can be crucial for its maintenance and performance. Fortunately, there are several reliable sources where you can locate the necessary replacements. Understanding where to search can save you time and ensure you get quality items that meet your needs.

Online Retailers are often the most convenient option. Websites specializing in industrial supplies frequently offer a wide selection of components, complete with detailed specifications. Many of these platforms provide user reviews, which can help you make informed decisions about the quality and compatibility of the items you need.

Authorized Dealers are another excellent choice. They typically stock original components and can provide expert advice regarding your specific equipment. Additionally, purchasing through an authorized dealer ensures that you receive items that meet the manufacturer’s standards.

Local Supply Stores can also be a valuable resource. Visiting a store allows you to speak directly with knowledgeable staff who can assist you in finding the right replacements. Moreover, you may be able to inspect items in person before making a purchase.

Finally, online marketplaces such as auction sites or second-hand platforms may offer used components at a reduced price. While this option can be cost-effective, it’s essential to verify the condition and compatibility of these items before making a decision.

Importance of Genuine Parts

Utilizing authentic components in any machinery is crucial for ensuring optimal performance and longevity. Quality replacements not only enhance functionality but also provide peace of mind to the user.

Here are some key reasons to prioritize genuine components:

- Reliability: Original items are designed to meet specific standards, reducing the risk of failure.

- Compatibility: Authentic replacements fit seamlessly with existing systems, ensuring smooth operation.

- Warranty Protection: Using genuine parts often helps maintain manufacturer warranties.

- Safety: Original components typically undergo rigorous testing, minimizing potential hazards.

- Resale Value: Equipment maintained with authentic items often retains higher value in the market.

In summary, opting for original components can significantly impact overall efficiency and safety, leading to a more satisfactory experience.

Upgrading Components for Better Performance

Enhancing the efficiency of your system can lead to significant improvements in overall functionality. By focusing on specific elements, users can experience smoother operations, increased speed, and better reliability. Here are some key areas to consider when seeking enhancements.

- Processor: Upgrading the central processing unit can drastically improve computing speed and multitasking capabilities.

- Memory: Adding more RAM allows for better performance during resource-intensive tasks, enabling smoother transitions and faster load times.

- Storage: Transitioning to a solid-state drive (SSD) from a traditional hard drive enhances data retrieval speeds, reducing boot times significantly.

- Graphics Card: A more advanced graphics unit can elevate visual performance, crucial for gaming and graphic design applications.

By delving into these components, users can unlock the ultimate potential of their systems, ensuring they meet modern demands efficiently.

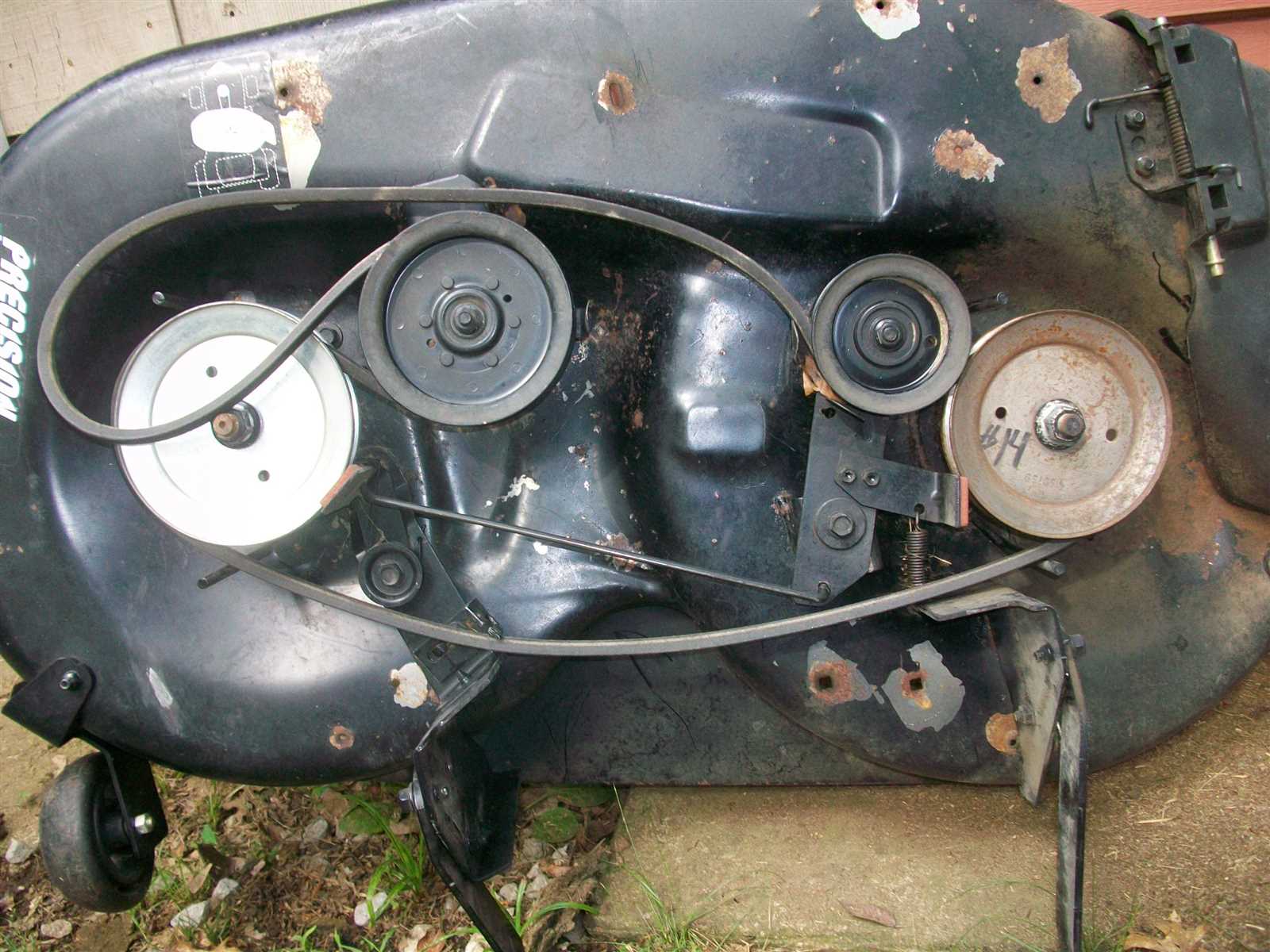

Visual Breakdown of the Parts Diagram

This section aims to provide a comprehensive overview of the intricate layout of components, showcasing how each element interacts within the overall system. By examining the arrangement and relationships, users can gain insights into functionality and maintenance.

Understanding Component Relationships

The layout highlights how various elements connect and operate together. Each section serves a specific purpose, contributing to the ultimate performance of the machine. Recognizing these connections is crucial for effective troubleshooting and repairs.

Key Elements to Focus On

Pay attention to the marked areas that indicate critical components. Identification of these parts can significantly enhance your ability to navigate the system. Familiarity with these sections empowers users to delve deeper into operational efficiency.

Frequently Asked Questions on Ys4500

This section aims to address common inquiries related to a specific model’s components and their configurations. Understanding the nuances can enhance user experience and assist in troubleshooting.

- What is the purpose of the manual?

The manual provides detailed information on assembly, operation, and maintenance of the equipment.

- How can I obtain replacement components?

Replacement items can be sourced from authorized dealers or online retailers specializing in the equipment.

- What tools are required for assembly?

A basic toolkit including screwdrivers, wrenches, and pliers is typically sufficient for assembly and maintenance tasks.

- Are there any common issues I should be aware of?

Users often report problems such as:

- Malfunctioning controls

- Inconsistent performance

- Difficulty in assembly

- Where can I find troubleshooting tips?

Consult the user manual or visit community forums for advice from experienced users.

Resources for Further Information

This section provides valuable insights and references for those seeking a deeper understanding of mechanical components and their assemblies. By exploring various platforms and materials, you can enhance your knowledge and find solutions tailored to your needs.

Online Communities

Engaging with online forums and communities can offer a wealth of shared experiences and expertise. Participants often exchange tips, troubleshooting advice, and guides that can significantly assist in navigating complexities.

Technical Manuals and Guides

Consulting official documentation and user manuals is crucial for accurate information. These resources typically contain detailed explanations, specifications, and maintenance tips essential for optimal performance.