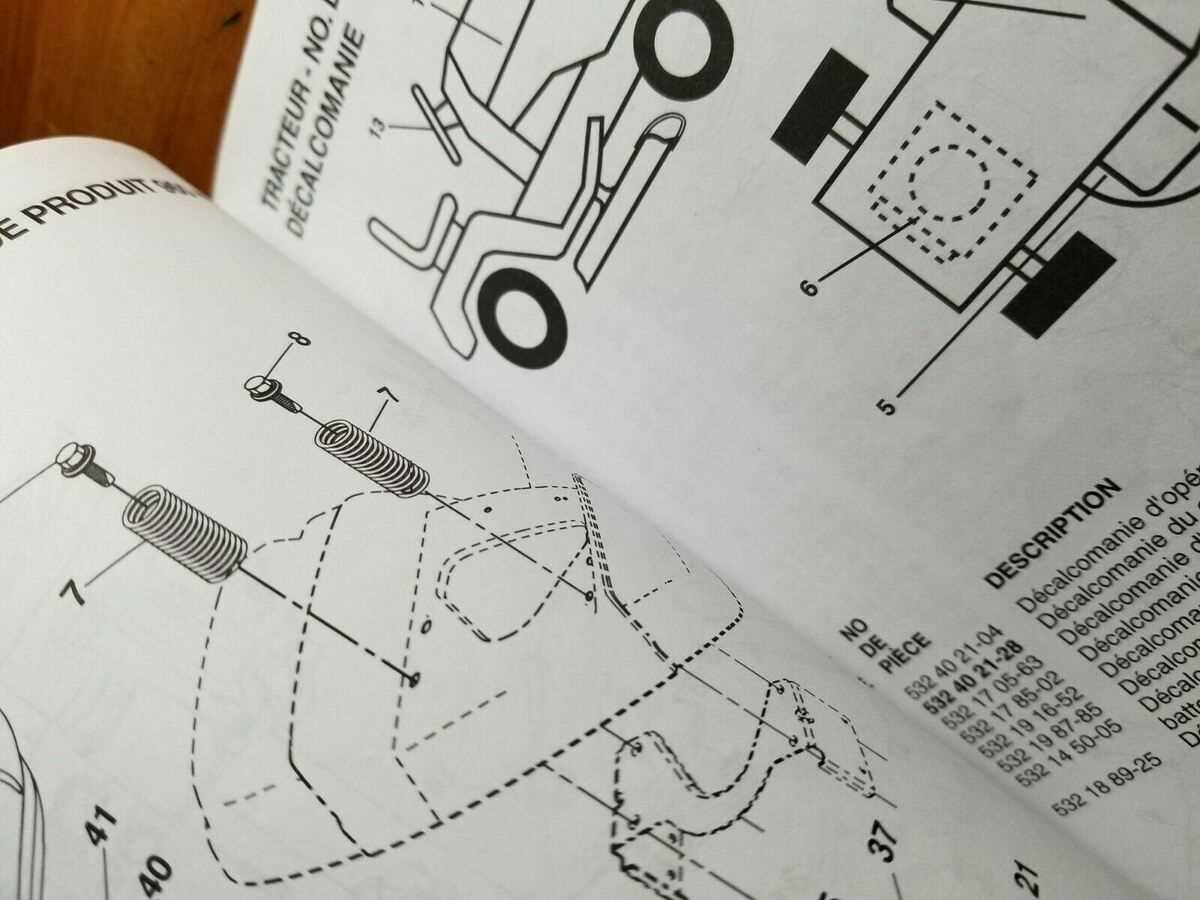

Understanding the internal structure of complex machines can greatly enhance their maintenance and functionality. By examining the arrangement of key elements, users can gain valuable insights into how various mechanisms operate and interconnect. This knowledge is essential for troubleshooting and ensuring smooth performance over time.

Detailed breakdowns of mechanical structures help identify specific areas of interest and provide clarity on the system’s overall functionality. Visual representations, alongside thorough explanations, offer a practical guide for those who seek to optimize or repair intricate assemblies.

Exploring individual sections allows for a deeper comprehension of how each component works within the larger framework. This step-by-step approach ensures that even the most complex configurations can be understood, enhancing both the repair process and long-term maintenance.

Understanding the Yth2448t Parts Structure

When exploring the composition of this equipment, it’s essential to recognize how the various elements come together to form a functional system. Each component serves a specific role, working in unison to ensure the machinery operates smoothly and efficiently. By understanding how these elements are connected, one can better maintain and troubleshoot the equipment when necessary.

Key components of the assembly include moving and stationary parts, all designed to support the operation under different conditions. Regular inspection of these elements can prolong the lifespan of the machine and improve its overall performance.

Maintenance and proper handling of the individual pieces are critical to preventing damage and ensuring that the machine continues to run optimally.

Key Components of the Yth2448t Mower

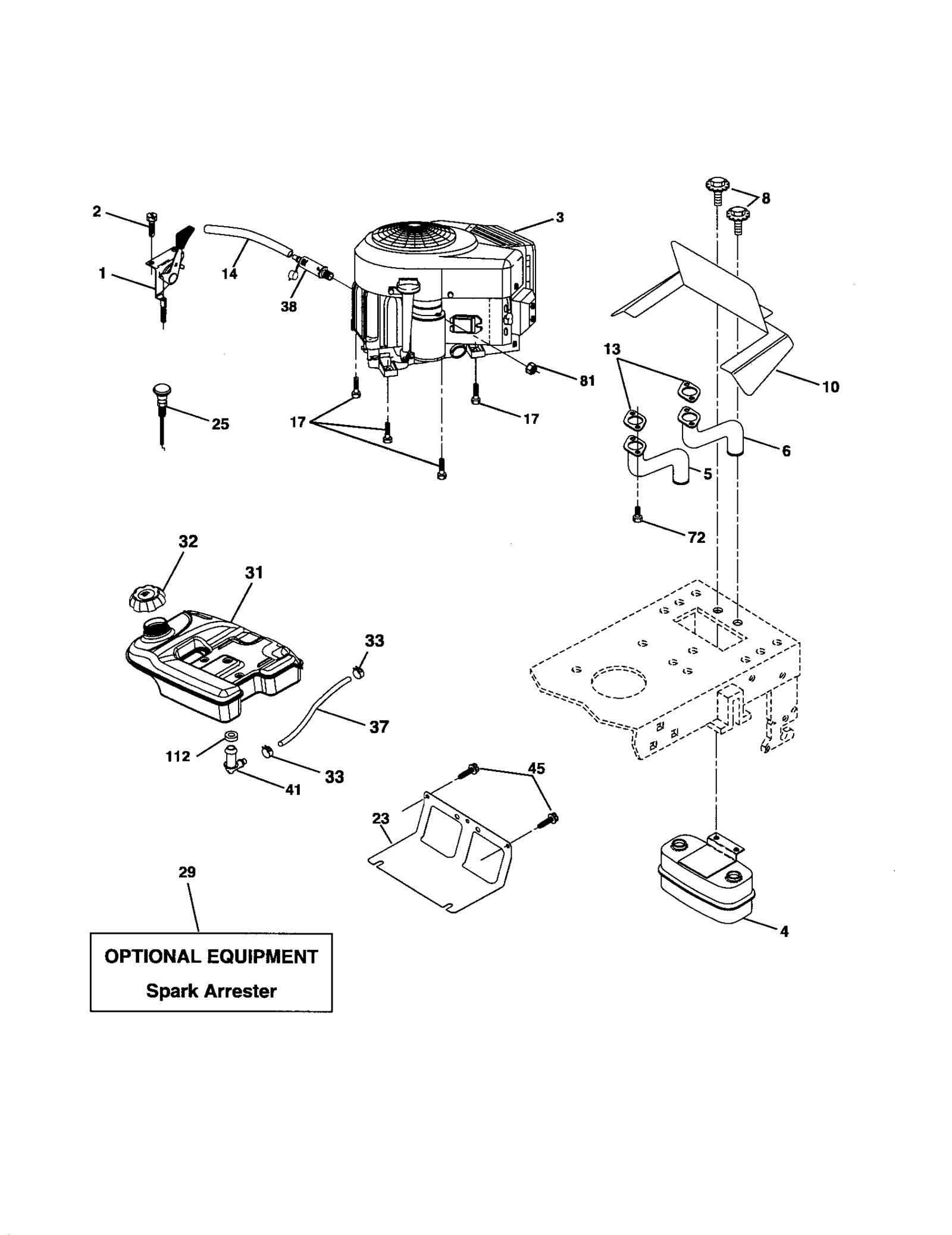

Every lawn tractor is built with several essential mechanisms that ensure its smooth operation and efficiency. Understanding these elements is crucial for maintaining its performance and addressing any issues that may arise during use.

Engine and Power System

The engine serves as the driving force, delivering power to various parts of the machine. A reliable power system is responsible for generating enough energy to handle different tasks, from moving the vehicle forward to powering the cutting blades.

Cutting Deck and Blades

The cutting deck is a fundamental part of the mower, housing the blades that trim the grass. Sharp and well-maintained blades ensure a clean cut and contribute to the overall health of your lawn. Adjusting the height of the deck allows for precision depending on the terrain and grass type.

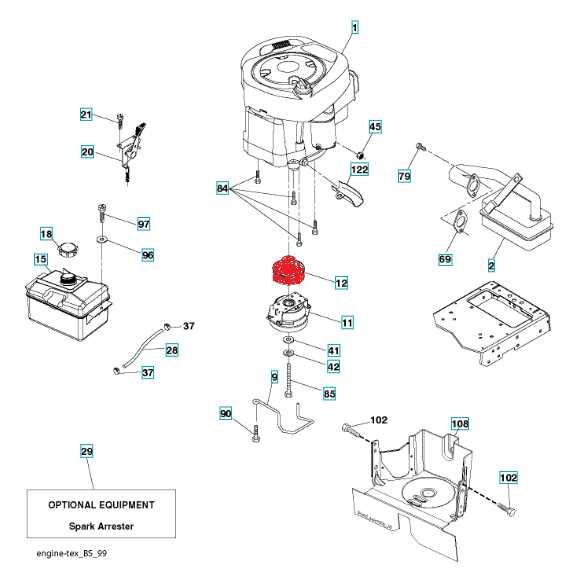

Exploring the Engine Parts of the Yth2448t

The core of any powerful machine lies in its engine. Understanding the key components of this vital mechanism is essential for ensuring smooth performance and maintenance. Each element plays a crucial role in the overall operation, contributing to efficiency, durability, and reliability. By familiarizing yourself with the essential elements, you can enhance the longevity of the equipment and troubleshoot issues effectively.

Key components within the engine work in harmony to deliver consistent power. From the intricate design of the combustion chamber to the sturdy structure of the drive system, each part ensures smooth running under various conditions. Regular upkeep and understanding these elements can prevent unnecessary wear and prolong its lifespan.

Recognizing the importance of these elements allows for timely maintenance and helps in identifying potential issues before they become critical. Familiarity with each section will lead to better performance and more efficient use of your equipment.

Maintenance Guide for Transmission System

Regular upkeep of the transmission system is essential to ensure its smooth operation and longevity. This section covers key maintenance tasks, offering practical steps to help you maintain performance and prevent issues before they arise. Following these guidelines can improve efficiency and prolong the life of your equipment.

Key Maintenance Tasks

- Check the fluid levels regularly to prevent any overheating or excessive wear.

- Inspect the belts and pulleys for any signs of wear or misalignment.

- Ensure that all connections are secure and free from leaks.

Recommended Maintenance Schedule

- Perform a fluid check every month to maintain optimal levels.

- Inspect and adjust belts every three months to ensure proper tension.

- Conduct a full inspection of the system at least once a year, focusing on potential wear and tear.

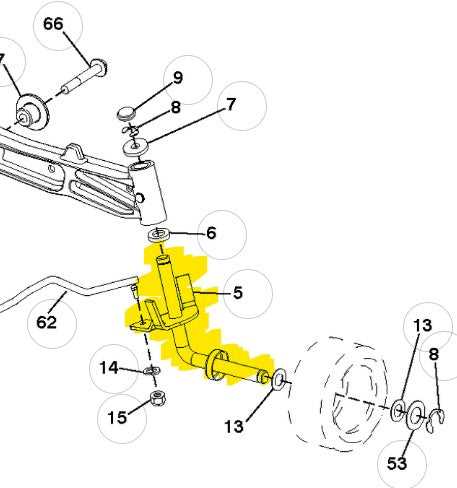

Steering Mechanism Breakdown

The steering system is essential for maneuvering, ensuring smooth and precise control during operation. This section delves into the components involved, providing a detailed overview of how they function together to facilitate direction changes.

- Steering Wheel: The main interface for controlling movement, allowing the operator to guide the equipment effortlessly.

- Linkages: These rods and joints transfer motion from the wheel to the front axle, ensuring responsive direction changes.

- Axle: A crucial part that connects to the wheels, allowing them to pivot based on input from the linkages.

- Bushings and Bearings: These components reduce friction, ensuring smoother steering and prolonging the system’s lifespan.

- Control Rods: Responsible for fine adjustments,

Cutting Deck Assembly for Yth2448t Mower

The cutting deck assembly plays a crucial role in the overall functionality of a mower, contributing to its efficiency and performance. Understanding the components involved and how they fit together is essential for maintenance and repair.

Key Components: The main elements of the assembly include the deck housing, blades, pulleys, and drive belts. Each part serves a specific purpose, ensuring that the mower operates smoothly and effectively.

Assembly Process: To begin the assembly, ensure that all components are clean and free of debris. Position the deck housing securely, then attach the blades using the designated fasteners. Make sure to follow the manufacturer’s guidelines for torque specifications to guarantee proper installation.

Maintenance Tips: Regularly inspect the cutting deck for wear and damage. Replace any worn-out components promptly to maintain optimal performance. Cleaning the deck after each use can also help prevent grass buildup and prolong the life of the assembly.

Yth2448t Electrical System Overview

The electrical framework of this machinery is crucial for its efficient operation and functionality. It comprises various components that work together seamlessly to ensure optimal performance and reliability.

Key Elements of the system include the power source, which supplies energy to the machine, and various circuits that distribute this energy to essential parts. Each component plays a vital role in ensuring that the overall system operates smoothly.

Furthermore, maintenance and troubleshooting are integral aspects of managing the electrical system. Regular checks can prevent malfunctions and enhance the longevity of the equipment. Understanding the layout and function of each element is essential for effective care and operation.

Safety Features and Their Components

Understanding the safety mechanisms in machinery is crucial for ensuring user protection and efficient operation. These systems are designed to minimize risks and prevent accidents during use. Each component plays a significant role in enhancing overall safety.

- Emergency Stop Button: A critical feature that allows operators to halt operations immediately in case of an emergency.

- Safety Guards: Protective barriers that shield users from moving parts, significantly reducing the risk of injuries.

- Operator Presence Control: A system that requires the operator to be in a specific position for the machinery to function, promoting attentive operation.

- Warning Alarms: Audible alerts that signal potential hazards, ensuring users are aware of any safety concerns.

- Stability Features: Components designed to enhance balance and prevent tipping, contributing to safe operation on various terrains.

Each of these elements contributes to a safer working environment, making it essential for users to understand their function and importance.

Blade Mechanism and Replacement Parts

The cutting assembly in lawn care equipment is crucial for efficient operation and performance. Understanding its components and the process for maintaining or replacing them can enhance the longevity and effectiveness of the equipment. This section outlines the essential elements of the cutting mechanism and the steps necessary for replacement when wear occurs.

Key components of the cutting system include:

- Blades: The primary elements that perform the cutting action, available in various designs for different types of vegetation.

- Spindles: These components support the blades and allow them to rotate smoothly, enabling efficient cutting.

- Belt Drive: A mechanism that transfers power from the engine to the cutting assembly, crucial for optimal functionality.

- Bearings: Essential for reducing friction between moving parts, contributing to the overall performance of the system.

When it comes to replacing components, it is vital to follow these steps:

- Ensure the equipment is turned off and disconnected from the power source.

- Remove the old blades by unscrewing them from the spindle assembly.

- Inspect the spindle and other components for wear or damage, replacing any affected parts as necessary.

- Install the new blades securely, ensuring they are aligned properly.

- Reconnect any belts or drive systems and test the equipment to confirm functionality.

Regular maintenance of the cutting assembly not only prolongs the life of the equipment but also ensures optimal performance for all lawn care tasks.

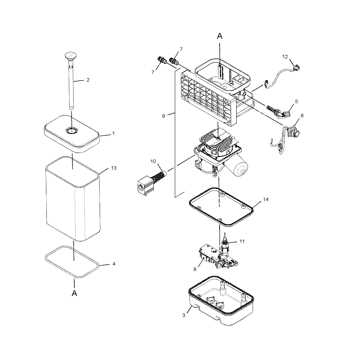

Fuel System Parts and Their Functions

The fuel system is crucial for the efficient operation of any engine, ensuring the right amount of fuel reaches the combustion chamber. Understanding the components involved in this system can enhance maintenance and troubleshooting processes.

Main Components of the Fuel System

- Fuel Tank: Stores the fuel and ensures a steady supply to the engine.

- Fuel Pump: Delivers fuel from the tank to the engine at the necessary pressure.

- Fuel Filter: Cleans the fuel by removing impurities and contaminants before it reaches the engine.

- Fuel Injector: Sprays the fuel into the combustion chamber in a fine mist for optimal combustion.

- Fuel Line: Transports fuel from the tank to the engine.

Functionality Overview

Each component plays a vital role in the overall performance of the fuel system. The fuel tank ensures a reliable source of fuel, while the pump maintains adequate pressure. Filtration prevents damage to engine components, and injectors optimize fuel delivery for efficient combustion. Proper functioning of all these elements is essential for maintaining engine efficiency and longevity.

Troubleshooting Common Yth2448t Issues

When dealing with machinery, it’s not uncommon to encounter various challenges that may hinder performance. Understanding the typical problems that can arise and how to address them is essential for maintaining efficiency and longevity. This section provides insights into common issues, offering practical solutions to help users get back on track quickly.

Identifying Performance Problems

One of the most prevalent concerns is a decline in performance, which can manifest as reduced power or unusual noises. To pinpoint the source, consider checking the fuel system, air filters, and the electrical components. Regular maintenance can prevent many of these issues from escalating.

Starting Difficulties

If the machine struggles to start, several factors could be at play. Inspect the battery condition, ignition system, and safety features that may prevent operation. Troubleshooting these elements can often resolve the issue and restore functionality.

Issue Possible Cause Recommended Action Reduced power Clogged air filter Replace or clean air filter Unusual noises Loose components Tighten bolts and screws Starting issues Weak battery Charge or replace battery