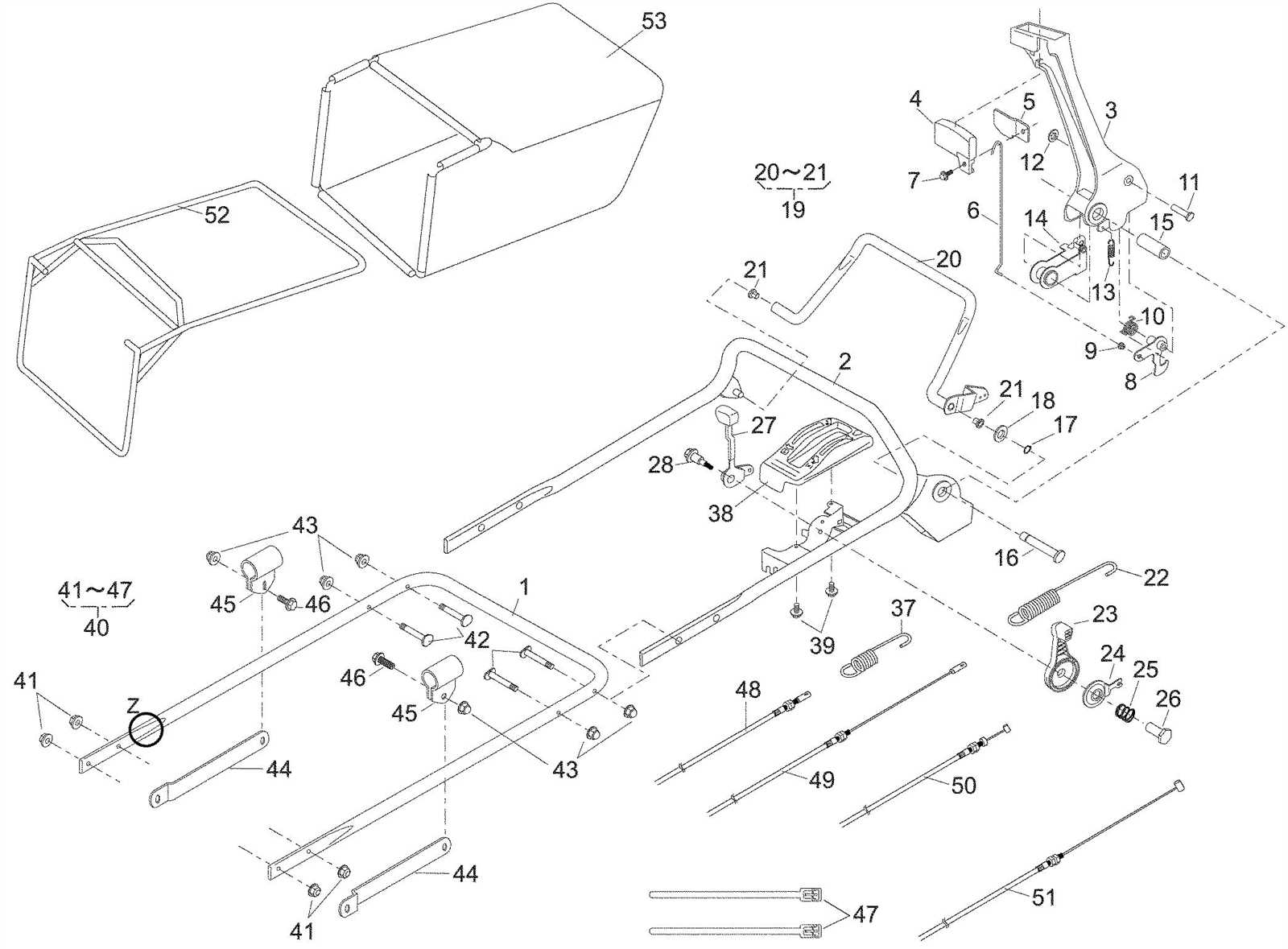

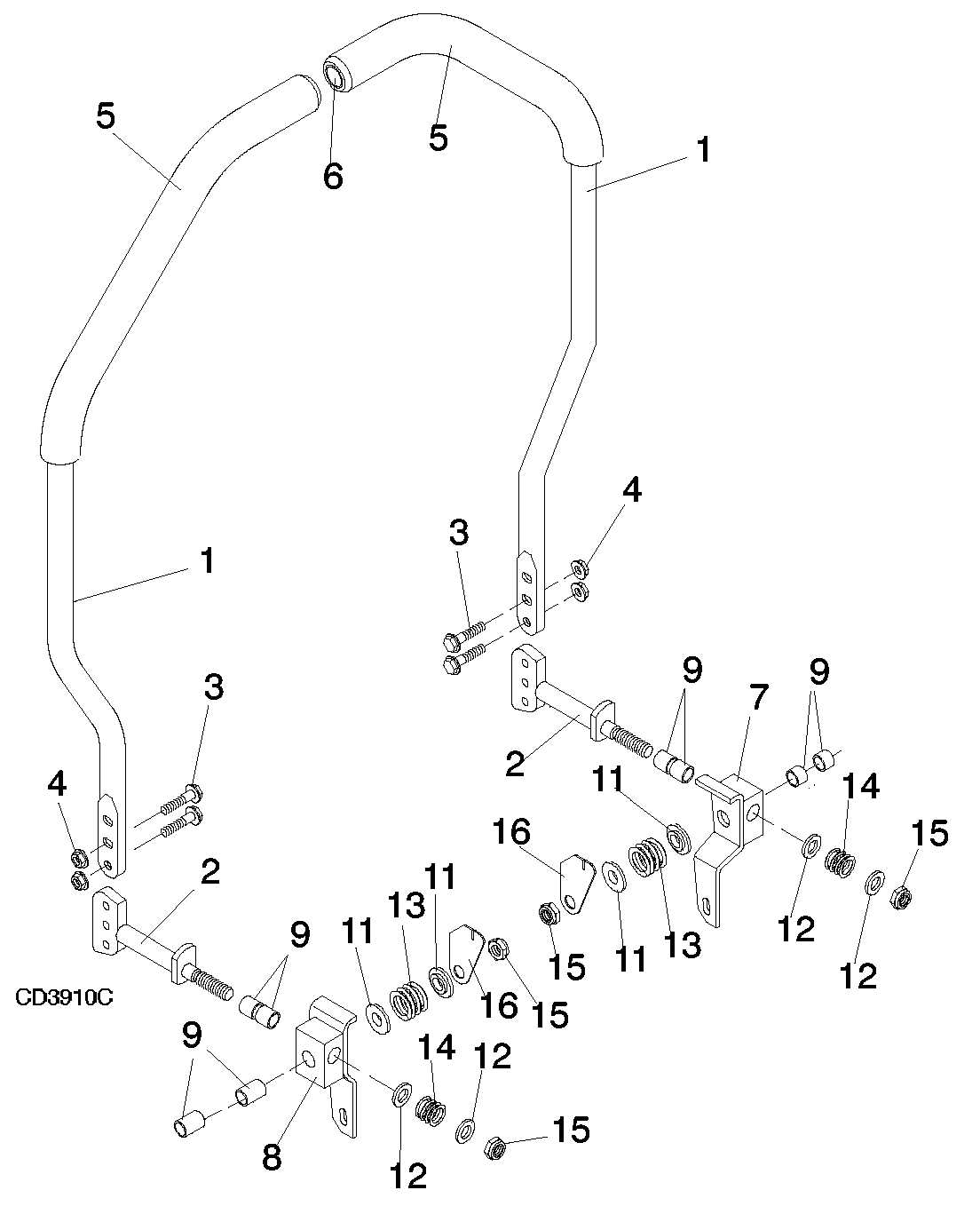

In any mechanical system, comprehending the arrangement of individual elements is crucial for effective maintenance and troubleshooting. A well-structured representation can significantly aid users in identifying each component’s function and location within the overall assembly. This approach not only simplifies repairs but also enhances the efficiency of routine inspections.

Visual representations play a vital role in facilitating an understanding of complex systems. By illustrating the connections and interactions among various elements, users can gain insights into how these parts collaborate to ensure optimal performance. Such clarity is essential for both novice and experienced technicians, allowing them to navigate the intricacies of machinery with confidence.

Furthermore, having a clear reference can prevent potential errors during assembly or disassembly. When individuals can easily locate specific components, the risk of misplacement or damage diminishes significantly. This organized approach fosters a smoother workflow and ultimately contributes to the longevity of the equipment.

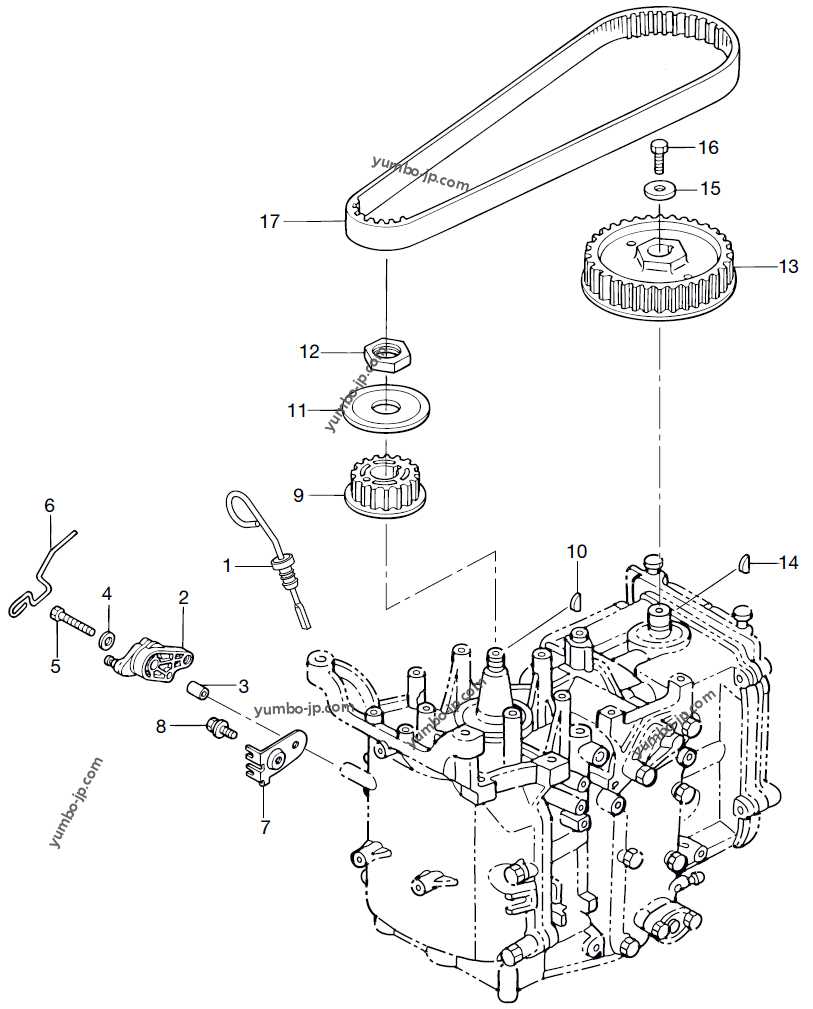

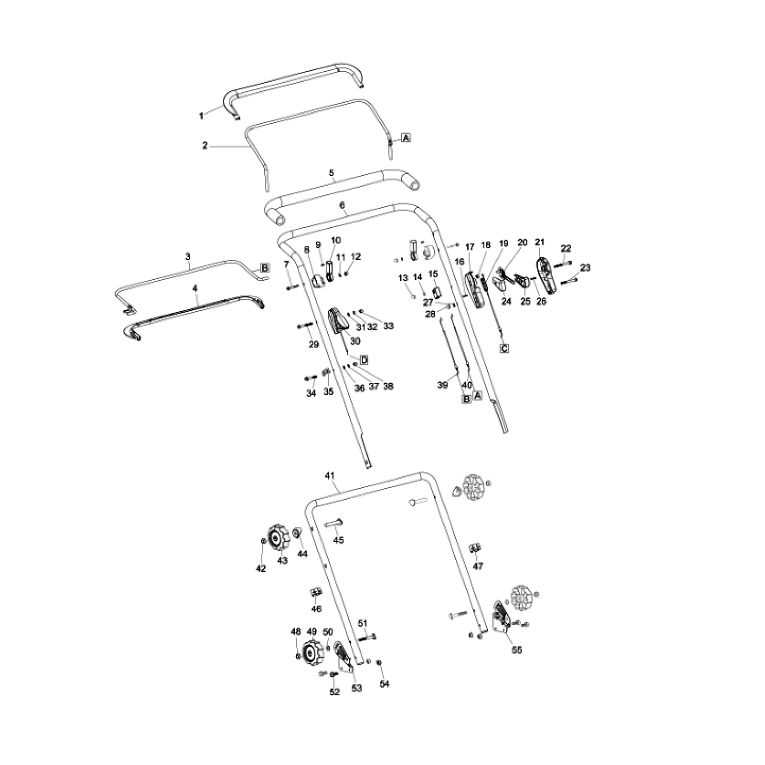

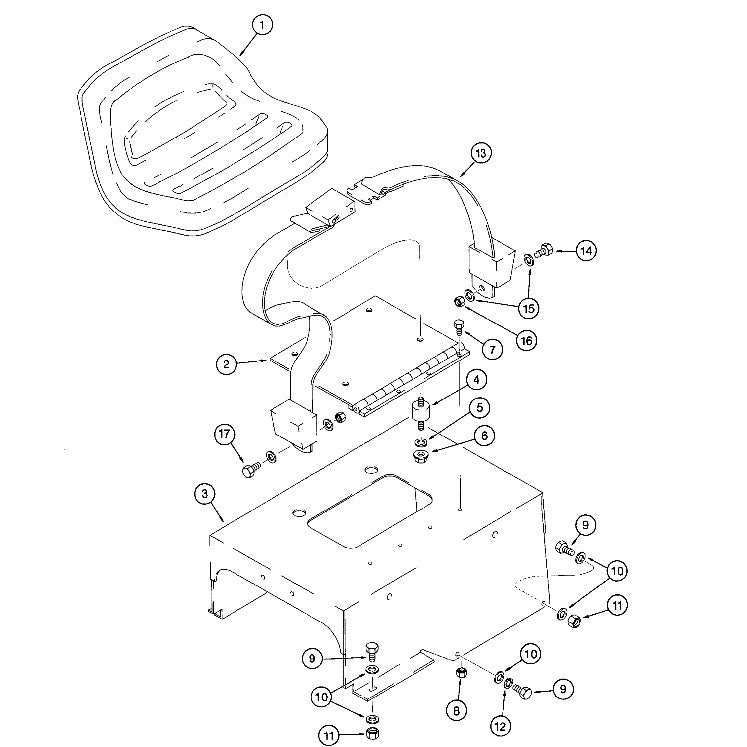

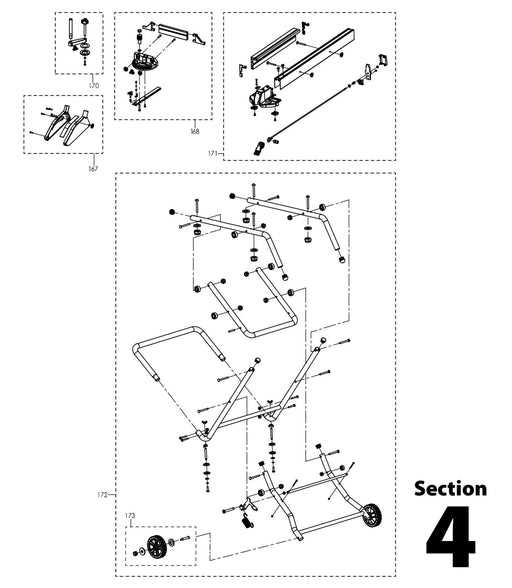

Understanding the Parts Diagram

Comprehending the assembly layout is crucial for effective maintenance and repair. This visual representation aids in identifying various components and their respective functions. By analyzing this information, users can enhance their knowledge of the machinery and ensure proper handling.

Key Components

- Engine

- Chassis

- Transmission

- Electrical System

- Fuel System

Benefits of Familiarity

- Improved Troubleshooting: Recognizing each element facilitates quicker diagnostics.

- Efficient Repairs: Knowing where parts are located streamlines the repair process.

- Enhanced Safety: Understanding how components interact reduces the risk of accidents.

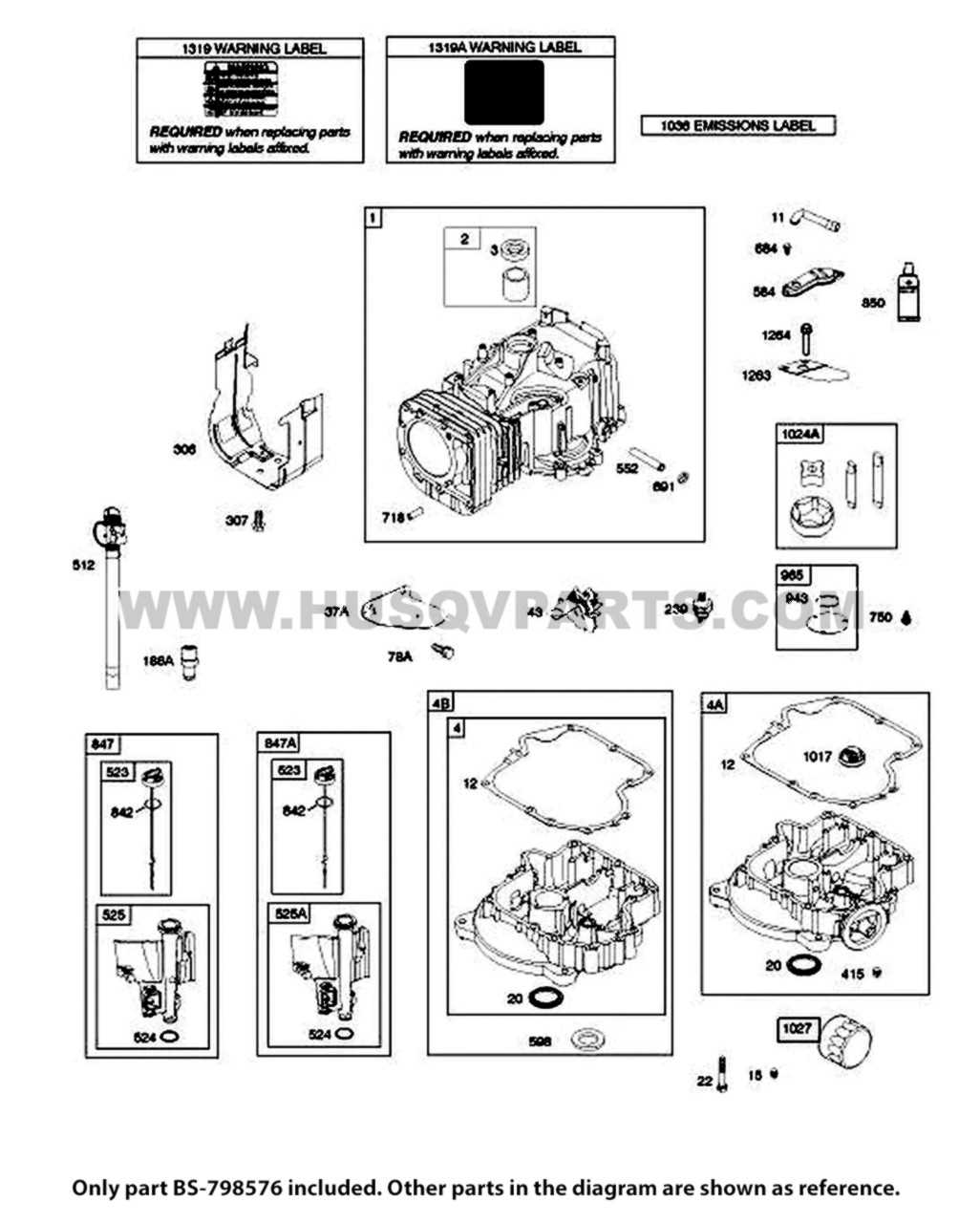

Key Components of Z246

This section focuses on the essential elements that contribute to the functionality and efficiency of the system. Understanding these crucial parts is vital for effective maintenance and operation.

- Engine: The heart of the system, providing necessary power for various operations.

- Fuel System: Responsible for delivering the right amount of fuel to ensure optimal performance.

- Cooling System: Maintains the appropriate temperature to prevent overheating during operation.

- Electrical System: Powers the electronic components and ensures smooth operation of controls.

- Transmission: Facilitates the transfer of power from the engine to the wheels, enabling movement.

Each of these elements plays a significant role in the overall functionality of the system, ensuring reliability and efficiency in performance.

How to Read the Diagram

Understanding the visual representation of components is essential for effective maintenance and repair. This guide aims to simplify the process of interpreting the illustration, ensuring that users can easily identify and locate each element. By familiarizing oneself with the structure and symbols used, one can navigate the information with confidence.

Familiarizing with Symbols

Each symbol in the illustration corresponds to a specific item, providing a quick reference for identification. Take time to study the legend or key, which explains what each representation means. This foundational knowledge allows for faster comprehension when analyzing the layout.

Following the Layout

The arrangement of the elements is designed for logical flow. Start from a designated point, usually marked clearly, and follow the paths indicated by lines or arrows. This approach will guide you through the sequence of components, making it easier to understand their relationships and functions within the system.

Identifying Each Part

Understanding the components of a machine is essential for effective maintenance and troubleshooting. Each element plays a crucial role in the overall functionality, and recognizing them can greatly enhance the efficiency of operations. By familiarizing oneself with these elements, users can ensure optimal performance and longevity of the equipment.

To effectively identify the various components, it is beneficial to consult a comprehensive reference that highlights their specific features and functions. This reference serves as a valuable tool for users, providing clarity on how each segment interacts within the assembly. Furthermore, hands-on experience with the machine can significantly aid in memorizing the locations and roles of each piece.

In addition, visual aids can be instrumental in reinforcing the knowledge of component identification. These resources help users develop a mental map of the assembly, making it easier to locate and understand each part’s significance. This proactive approach not only streamlines maintenance efforts but also contributes to a safer working environment.

Common Issues with Components

In the realm of machinery and equipment, various challenges can arise with individual elements, impacting overall performance and functionality. Understanding these common issues helps in efficient troubleshooting and maintenance, ensuring longevity and optimal operation.

Some frequent problems include:

| Issue | Description |

|---|---|

| Wear and Tear | Over time, components may degrade due to regular use, leading to diminished efficiency. |

| Misalignment | Improper installation can cause elements to misalign, resulting in operational inefficiencies. |

| Corrosion | Exposure to moisture or chemicals may lead to rust or corrosion, affecting integrity. |

| Faulty Connections | Worn or damaged connections can disrupt functionality and create safety hazards. |

| Contamination | Debris or foreign substances can interfere with the proper functioning of individual units. |

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires consistent and thoughtful upkeep. Regular maintenance practices not only extend the lifespan but also enhance efficiency, ultimately saving you time and resources.

1. Regular Inspection: Periodically check for any signs of wear or damage. Early detection of potential issues can prevent more extensive repairs down the line.

2. Cleaning: Keep all components clean from dirt and debris. Regular cleaning helps maintain efficiency and prevents premature deterioration.

3. Lubrication: Apply appropriate lubricants to moving parts as recommended by the manufacturer. Proper lubrication reduces friction and minimizes wear.

4. Seasonal Maintenance: Adapt your maintenance routine according to seasonal changes. Certain tasks may be more critical during specific times of the year.

5. Follow Guidelines: Always adhere to the manufacturer’s maintenance schedule and guidelines. These recommendations are designed to ensure optimal performance and longevity.

Replacement Parts Availability

Accessing components for maintenance and repair is essential for optimal performance and longevity of equipment. Ensuring that these essential items are readily available can significantly reduce downtime and enhance functionality. This section provides insights into the sources and options for obtaining necessary elements for effective servicing.

Source Options

Several avenues exist for acquiring replacement components. Authorized dealers often stock genuine items that meet specific quality standards. Additionally, online platforms offer a diverse selection, enabling users to compare prices and availability. Local suppliers may also carry essential items, providing a convenient alternative for immediate needs.

Considerations for Selection

When choosing components, it is crucial to consider compatibility and quality. Selecting original equipment manufacturer (OEM) items ensures reliability and performance. Furthermore, exploring aftermarket options can yield cost-effective solutions, though it’s important to verify their quality and suitability for your particular equipment.

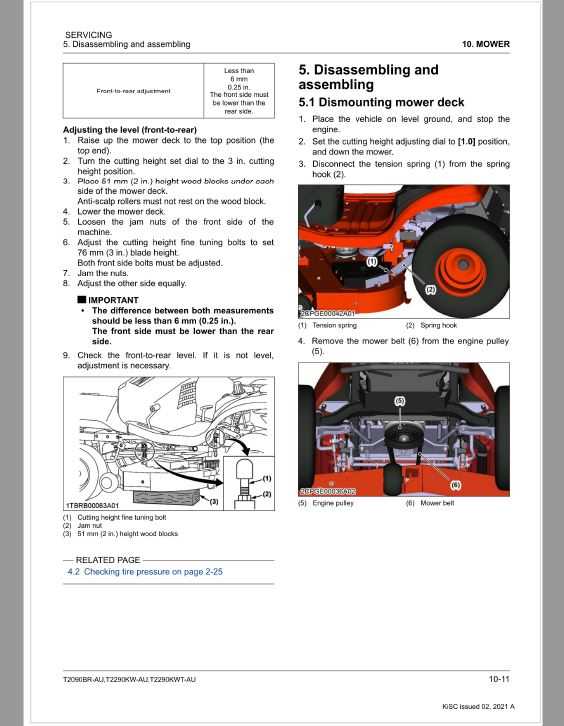

Assembly and Disassembly Guidelines

Understanding the proper techniques for assembling and disassembling equipment is essential for maintenance and troubleshooting. This section outlines important steps and considerations to ensure a smooth process while preventing damage to components.

- Preparation: Before starting, gather all necessary tools and a clean workspace.

- Consult Documentation: Refer to the relevant manuals or resources for detailed instructions.

- Safety First: Always wear appropriate safety gear to protect yourself during the process.

When disassembling, follow these steps:

- Turn off power and disconnect all electrical sources.

- Carefully remove any protective covers or casings.

- Take note of the arrangement and orientation of components for easier reassembly.

- Keep all screws and small parts organized in labeled containers.

For assembly, adhere to the following guidelines:

- Follow the reverse order of disassembly to ensure proper alignment and fitting.

- Use the correct torque specifications for fasteners to avoid over-tightening.

- Test the assembly for proper functionality before finalizing the installation.

By adhering to these guidelines, you can achieve effective assembly and disassembly, extending the lifespan of the equipment.

Safety Precautions During Repairs

When performing maintenance on equipment, ensuring safety is paramount. Taking appropriate measures can prevent accidents and injuries, safeguarding both the technician and the machinery.

General Safety Guidelines

- Always wear personal protective equipment (PPE) such as gloves, goggles, and ear protection.

- Ensure the work area is well-lit and free of clutter to reduce the risk of tripping or accidents.

- Disconnect power sources before starting any repair work to avoid electrical hazards.

- Keep a first aid kit nearby for emergencies.

Handling Tools and Equipment

- Use tools appropriate for the job to prevent damage and ensure efficiency.

- Inspect tools regularly for wear and tear; replace any damaged items immediately.

- Store tools in a designated area after use to prevent accidents and loss.

Tools Required for Maintenance

Proper upkeep of equipment involves a variety of essential tools that facilitate effective service and ensure longevity. Utilizing the right instruments not only streamlines the maintenance process but also enhances performance and safety. Below is a comprehensive list of necessary tools for routine maintenance tasks.

Essential Hand Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Socket set

- Adjustable wrench

Specialized Equipment

- Torque wrench

- Multimeter

- Diagnostic tools

- Grease gun

- Safety gear (gloves, goggles)

Cost Considerations for Parts

When evaluating expenses related to components for machinery, it is essential to assess various factors that can influence overall costs. Understanding these financial implications can lead to more informed decisions and potential savings.

Quality vs. Price: One of the primary considerations is the balance between quality and cost. Higher-quality items often come with a steeper price tag, yet they can provide enhanced durability and performance. In contrast, budget-friendly options may save money upfront but could lead to increased maintenance costs over time.

Supplier Selection: The choice of supplier plays a crucial role in determining expenses. Comparing different vendors can uncover variations in pricing, shipping fees, and warranty options. Establishing a relationship with a reliable provider can also yield discounts and favorable terms.

Bulk Purchasing: Another strategy for reducing overall expenditures is buying components in bulk. Many suppliers offer significant discounts for larger orders, which can lead to substantial savings, especially for items frequently used in maintenance or repairs.

Long-term Investment: It’s important to view expenses as an investment in longevity and efficiency. Selecting higher-quality items may incur a higher initial cost but can result in lower total costs over the lifespan of the machinery due to reduced failure rates and maintenance needs.

Resources for Further Information

For those seeking additional knowledge and insights on components and their configurations, a variety of sources are available. These resources can help deepen your understanding of assembly processes, specifications, and functionality.

Online forums and community websites often provide user-generated content that can be invaluable. Engaging with experienced enthusiasts can lead to discovering practical tips and troubleshooting techniques.

Official documentation from manufacturers is another reliable source. This material typically includes detailed explanations, installation guides, and safety information, ensuring that users have access to accurate data.

Additionally, consider exploring video tutorials on platforms such as YouTube. These visual aids can simplify complex concepts, making them easier to grasp.

Lastly, specialized publications and trade magazines often feature articles on innovations and trends within the industry, providing a broader context for your knowledge.