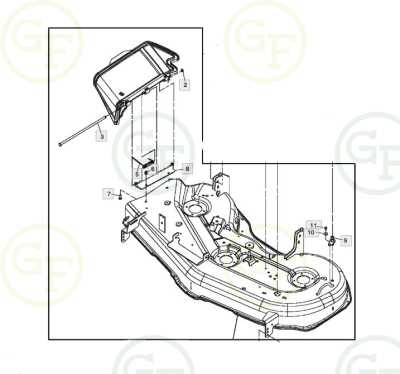

When delving into the intricacies of mechanical assemblies, having a clear representation of individual elements is crucial. Such illustrations serve as a roadmap, guiding users through the various functionalities and interconnections that contribute to the overall operation of the system. A comprehensive layout enhances both understanding and troubleshooting, enabling effective maintenance and repair.

In this section, we will explore the key features of these representations, highlighting how they simplify the complexities of machinery. By examining the arrangement and relationships among components, users can gain insights into their respective roles. This foundational knowledge is vital for anyone seeking to engage with the equipment more effectively.

Furthermore, understanding these configurations can empower users to identify potential issues before they escalate. Recognizing the significance of each component and its interactions facilitates informed decisions during maintenance and upgrades. By grasping the layout’s nuances, users can enhance their proficiency and confidence when working with the machinery.

This section provides a comprehensive outline for a detailed discussion centered around a specific mechanical assembly. The focus will be on breaking down the essential components and their interrelations, allowing readers to gain a clear understanding of the assembly’s functionality and structure. Each section will be designed to enhance knowledge and facilitate practical application.

Introduction to the Mechanical Assembly

In this segment, we will introduce the overall concept of the mechanical assembly, emphasizing its significance in the broader context of machinery.

Key Components of the Assembly

This part will list and describe the primary elements that constitute the mechanical assembly.

- Element A: Description and function

- Element B: Description and function

- Element C: Description and function

Functionality of Individual Components

Each component plays a vital role in the operation of the assembly. This section will delve into the specific functions performed by each part.

Assembly Process

Detailing the step-by-step process of how the assembly comes together, this section will offer insights into best practices and methodologies.

Maintenance and Care

To ensure longevity and optimal performance, proper maintenance is essential. This part will outline key maintenance tips and routines.

Common Issues and Troubleshooting

Here, we will address typical challenges encountered during operation and provide troubleshooting strategies to resolve them.

Comparison with Similar Assemblies

This section will highlight differences and similarities with related mechanical assemblies, providing context for better understanding.

Historical Context and Evolution

An exploration of how the mechanical assembly has evolved over time, considering technological advancements and design changes.

Applications and Uses

Identifying the various industries and scenarios where the assembly is utilized will be the focus here, showcasing its versatility.

Future Trends and Innovations

Discussing potential advancements and trends in the field, this section will speculate on future developments that could influence the assembly’s design and function.

Conclusion and Summary

Summarizing the key points discussed throughout the article, this section will reinforce the importance of understanding the assembly and its components.

Additional Resources

Providing further reading materials and resources for those interested in deeper exploration of the topic.

Understanding the Z445 Configuration

The configuration of this specific model encompasses various components that work in harmony to achieve optimal performance. Grasping the intricacies of how these elements interact is crucial for effective maintenance and enhancement of functionality. This section delves into the key aspects that define its structure, ensuring users are well-informed about its capabilities and applications.

Key Components and Their Functions

Each element within this assembly plays a pivotal role, contributing to the overall efficiency of the system. For instance, the main unit serves as the core of operations, while auxiliary components facilitate specific tasks that enhance overall output. Understanding the purpose and functionality of each part is essential for troubleshooting and upgrades.

Maintenance and Upgrades

Regular maintenance is vital to ensure the longevity of the system. By familiarizing oneself with the configuration, users can easily identify areas requiring attention. Additionally, recognizing opportunities for upgrades can lead to improved performance and expanded capabilities, allowing the system to adapt to evolving needs.

Key Components of the Z445

The efficiency and functionality of any mechanical system hinge on the critical elements that comprise its structure. Each component plays a vital role, contributing to the overall performance and reliability of the equipment. Understanding these essential elements is crucial for effective maintenance and optimal operation.

One of the primary elements is the engine, which serves as the powerhouse, providing the necessary energy to drive the entire mechanism. Coupled with this is the transmission system, responsible for transferring power seamlessly throughout the assembly. Additionally, the framework offers essential support, ensuring stability and durability under various operating conditions.

Moreover, control mechanisms are integral to regulating operations, allowing for precise adjustments based on user input or environmental factors. Lastly, safety features are indispensable, safeguarding both the machine and its operator from potential hazards during use.

Detailed Functionality of Each Part

In this section, we delve into the intricate workings and purposes of every component within the system, elucidating their specific roles and interactions. Each element contributes uniquely to the overall functionality, ensuring seamless operation and optimal performance.

Main Components Overview

- Analyzed elements

- Functions of various components

- Diagrams demonstrating the process

- Regular Inspections: Schedule routine examinations to identify wear and tear early. Check for any signs of damage or misalignment.

- Cleanliness: Keep all components free from dirt and debris. Use appropriate cleaning agents that won’t harm the materials.

- Lubrication: Apply suitable lubricants to moving parts to reduce friction and prevent overheating. Ensure to use the manufacturer’s recommended products.

- Proper Storage: When not in use, store components in a dry, clean environment to avoid corrosion and damage from environmental factors.

- Replacement Schedule: Follow a planned replacement timeline for consumable parts. This proactive approach minimizes the risk of failures during operation.

practical

Common Issues with Z445 Parts

In the realm of machinery, various components may encounter challenges that hinder optimal performance. Understanding these prevalent difficulties can assist users in identifying and addressing potential problems early on, ensuring smooth operation and longevity of the equipment.

Wear and Tear: Over time, continuous use can lead to gradual deterioration of crucial elements. This wear can result in decreased efficiency and may necessitate replacement to restore functionality.

Incorrect Installation: Proper setup is essential for any mechanical system. Mistakes during the installation process can lead to malfunctions, which may require disassembly and reinstallation to rectify.

Compatibility Issues: Using components that are not designed for specific models can cause significant problems. It is vital to ensure that all parts are compatible to avoid operational failures.

Maintenance Neglect: Regular upkeep is necessary for the longevity of any machinery. Failing to perform routine checks and maintenance can lead to unpredicted breakdowns and costly repairs.

Environmental Factors: External conditions, such as temperature fluctuations and humidity levels, can adversely affect component integrity. Protecting machinery from harsh environments is essential for maintaining functionality.

By being aware of these common issues, users can take proactive measures to ensure their equipment operates efficiently and effectively.

Maintenance Tips for Z445 Components

Proper upkeep of essential elements is crucial for ensuring optimal performance and longevity of machinery. Regular attention to these components can prevent unexpected breakdowns and enhance efficiency. Below are key strategies to maintain these vital parts effectively.

By implementing these maintenance practices, you can significantly extend the lifespan of essential machinery elements and ensure smooth operation.

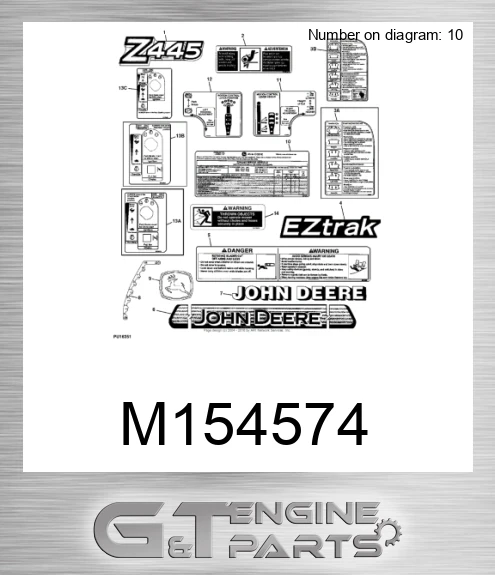

How to Identify Z445 Parts

Understanding the components of a specific model can greatly enhance maintenance and repair efforts. Recognizing individual elements is crucial for effective troubleshooting and replacement procedures. Here, we explore methods to accurately discern various elements associated with this particular device.

One effective approach to identifying components involves familiarizing yourself with the common characteristics and functions of each item. Below are steps to assist you in this process:

- Refer to Documentation: Consult user manuals or technical documentation to gain insights into the specifications and layout of the elements.

- Visual Inspection: Carefully examine the exterior of the device to identify any labels or markings that indicate specific functions or characteristics.

- Utilize Online Resources: Access forums or websites dedicated to equipment enthusiasts for diagrams and detailed descriptions of the components.

- Engage with Professionals: Seek advice from experienced technicians who can provide valuable insights based on their knowledge of similar models.

By employing these strategies, you can enhance your understanding and proficiency in identifying the various components associated with this model.

Tools Required for Z445 Repairs

When embarking on the repair process for complex machinery, having the right tools is essential for achieving optimal results. Utilizing appropriate equipment not only enhances efficiency but also ensures the longevity of the device. Below is a comprehensive list of tools that are vital for effective maintenance and troubleshooting.

| Tool | Description |

|---|---|

| Socket Set | A collection of sockets and ratchets for loosening and tightening bolts and screws. |

| Screwdriver Set | Various screwdrivers to accommodate different types of screws found in the assembly. |

| Wrench Set | Open-end and box-end wrenches to provide leverage for nuts and bolts. |

| Pliers | Tools for gripping, bending, and cutting wires or other small components. |

| Multimeter | A device for measuring electrical values, essential for diagnosing electrical issues. |

| Torque Wrench | A specialized wrench that ensures bolts are tightened to the correct specifications. |

Upgrading Z445 Parts Effectively

Enhancing the components of a device can significantly improve its performance and longevity. Understanding the appropriate upgrades ensures optimal functionality while maintaining compatibility. This section focuses on strategies to effectively enhance various elements within the system, allowing for an improved user experience.

When considering upgrades, several factors should be taken into account:

- Compatibility: Ensure that new components are compatible with existing systems to avoid functionality issues.

- Quality: Invest in high-quality replacements that offer durability and enhanced performance.

- Cost: Evaluate the budget for upgrades, balancing cost against the potential benefits of improved components.

- Supplier Reputation: Choose reputable suppliers to guarantee the quality and reliability of the components.

Furthermore, the installation process is crucial for successful upgrades:

- Preparation: Gather all necessary tools and components before starting the upgrade.

- Guidelines: Follow manufacturer instructions carefully to ensure proper installation.

- Testing: After installation, conduct thorough testing to verify that the upgrades function as intended.

By following these guidelines, users can effectively enhance their devices, resulting in improved performance and satisfaction.

Safety Precautions During Maintenance

Ensuring a secure working environment is essential when conducting upkeep on machinery. Adhering to safety protocols not only protects the technician but also prolongs the lifespan of the equipment. Awareness of potential hazards and implementing necessary precautions can mitigate risks associated with maintenance tasks.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is crucial during maintenance activities. This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp edges, and ear protection when working in noisy environments. Proper attire minimizes the risk of injury and enhances overall safety.

Tool and Equipment Safety

Before commencing any maintenance work, it is vital to inspect tools and equipment for defects. Ensure that all tools are in good condition and suitable for the tasks at hand. Additionally, keep work areas organized to prevent accidents, and always follow manufacturer guidelines when operating machinery. Proper handling and storage of tools contribute significantly to a safe working atmosphere.

Comparing Z445 with Other Models

This section aims to explore the distinctions and similarities between the specified model and its counterparts. By examining various aspects such as functionality, design, and performance, we can gain insights into how each version stands in relation to the others. This analysis will provide a clearer understanding of the unique features that set the discussed unit apart in its category.

Key Features and Innovations

When comparing different units, one of the primary considerations is the innovative features each brings to the table. The examined model showcases advanced technology that enhances efficiency and user experience. In contrast, other models may focus on different strengths, such as ease of maintenance or cost-effectiveness. Understanding these differences can aid potential users in making informed decisions based on their specific needs.

Performance Metrics

Performance is another critical aspect when evaluating these units. The reviewed model demonstrates notable capabilities in various conditions, often outperforming its peers in certain tasks. However, some alternative models might excel in other areas, such as energy consumption or operational speed. By analyzing performance metrics, users can determine which model aligns best with their operational requirements.

Where to Find Replacement Parts

Locating suitable components for machinery can often be a challenging task, yet various resources are available to assist in the search. Whether you need items for repairs or upgrades, understanding where to look is crucial for ensuring optimal performance and longevity.

Online Retailers

Numerous online platforms offer a vast selection of components suitable for various machines. Here are some popular options:

- Manufacturer’s Official Website: Always check the brand’s site for authentic components.

- Specialized E-commerce Stores: Websites dedicated to machine components often provide a wide range of options.

- General Online Marketplaces: Platforms like eBay or Amazon may have listings from various sellers, including new and used items.

Local Suppliers

In addition to online resources, local suppliers can be invaluable for acquiring necessary components. Consider the following:

- Authorized Dealers: These businesses specialize in specific brands and offer genuine components.

- Automotive or Machinery Repair Shops: Often, these establishments have connections to suppliers and may assist in locating the required items.

- Surplus Stores: Stores that focus on excess inventory can sometimes have hidden gems at discounted prices.

Understanding the Z445 Wiring Diagram

The intricacies of electrical layouts are crucial for efficient operation and maintenance of machinery. A comprehensive representation of connections and components serves as a guide, facilitating troubleshooting and repairs. By examining these layouts, users can enhance their understanding of how various elements interact and function together.

In any electrical layout, certain key components typically play vital roles:

- Power Supply: The source of energy that powers the system.

- Connectors: Essential links that join different parts of the circuit.

- Switches: Devices that control the flow of electricity.

- Sensors: Instruments that detect changes in the environment and relay information.

- Load Devices: Components that utilize electrical power to perform tasks.

Understanding the layout not only assists in identifying the purpose of each component but also aids in recognizing potential issues. Familiarity with these connections can lead to more effective maintenance and quicker resolutions when challenges arise.

By carefully studying the layout, users can follow the flow of electricity and gain insights into how the system operates. This knowledge empowers technicians and engineers to implement changes, optimize performance, and ensure safety throughout the operational lifespan of the equipment.