The organization of various elements is crucial for understanding how the entire system functions. Each piece works in harmony to ensure the machinery operates efficiently and smoothly. The arrangement allows for easy identification and understanding of how individual components connect and collaborate.

A well-structured guide can greatly assist in maintaining and repairing equipment. By breaking down the arrangement of the different elements, users can quickly locate and manage any issues that arise. Such an approach makes the process of troubleshooting significantly more straightforward.

Whether you are familiar with the equipment or just beginning to explore its workings, understanding the configuration of its various elements will enhance your ability to perform maintenance and repairs with confidence.

Zt7000 Parts Overview

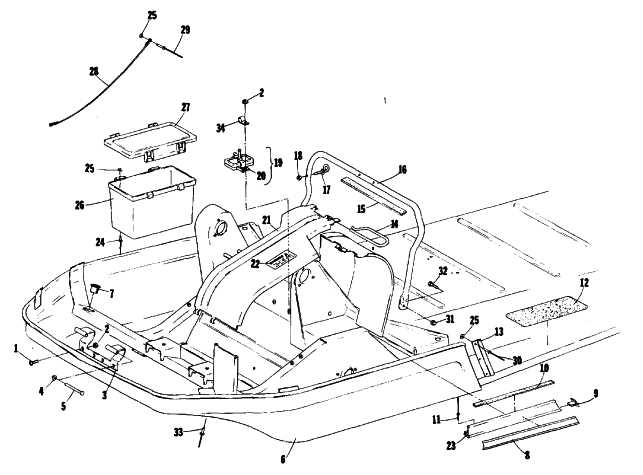

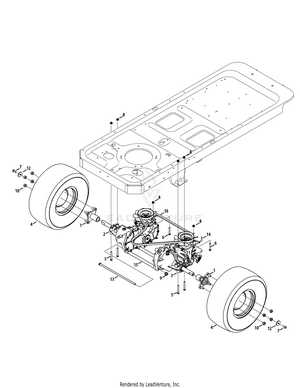

The structure of this model is built on a combination of essential components designed to work seamlessly together. Each element contributes to the overall functionality and ensures optimal performance under various conditions. Understanding how these key segments fit together will help in maintaining and servicing the equipment effectively.

| Component | Description | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main Frame | Provides support and houses other critical sections. | |||||||||||

| Engine | Powers the system, ensuring smooth operation across tasks. | |||||||||||

| Transmission | Transfers power from the motor to the working mechanisms. |

| Specification | Details | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Type | Four-stroke, air-cooled | |||||||||||

| Horsepower | 25 HP | |||||||||||

| Fuel Type | Unleaded gasoline | |||||||||||

| Displacement | 700 cc | |||||||||||

| Fuel Capacity |

| Component | Description |

|---|---|

| Steering Wheel | The main control interface for the driver, allowing them to dictate the vehicle’s direction. |

| Steering Column | Connects the steering wheel to the steering gear, transferring the driver’s input. |

| Steering Gear | Transforms the rotational motion of the steering wheel into lateral motion of the wheels. |

| Linkage System | A series of rods and joints that transmit motion from the steering gear to the wheels. |

| Power Assist | A hydraulic or electric system that reduces the effort needed to turn the steering wheel. |

Functionality Overview

When the driver turns the steering wheel, the steering column rotates and activates the steering gear. This action adjusts the angle of the wheels, guiding the vehicle in the desired direction. The linkage system ensures that this motion is efficiently transferred, while the power assist feature enhances the ease of steering, particularly at low speeds.

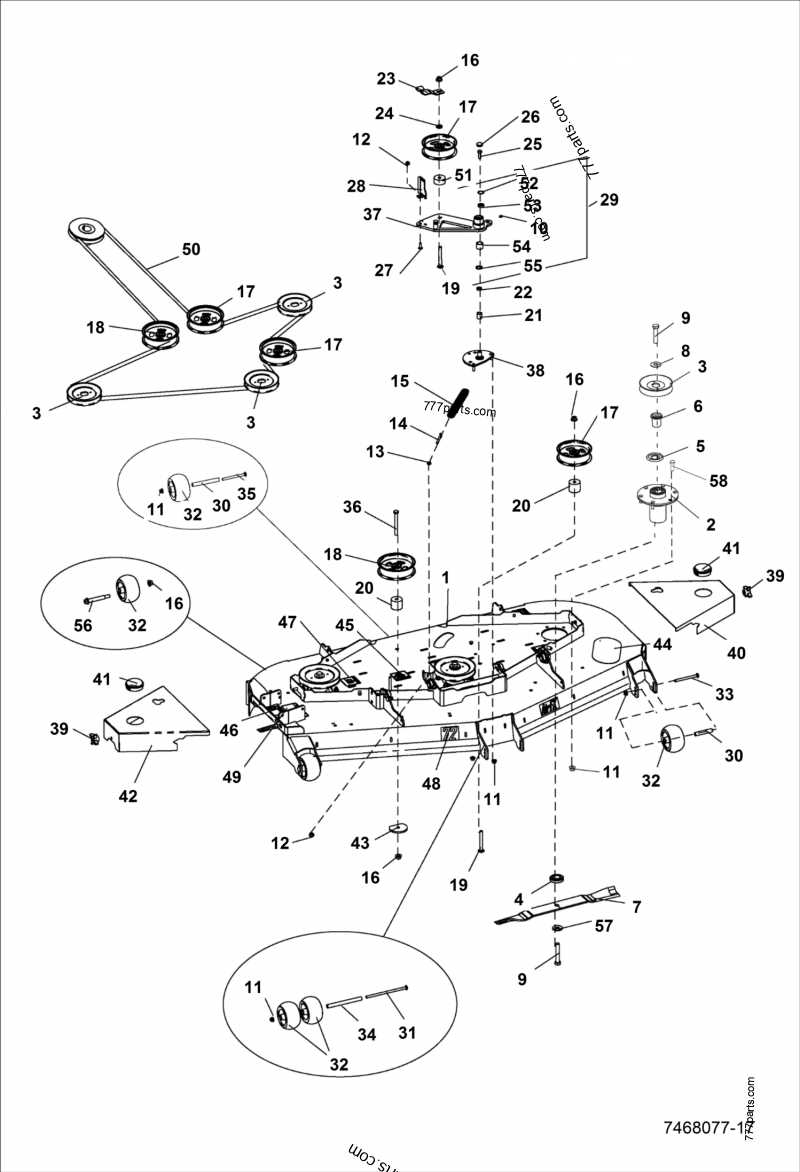

Deck Assembly and Adjustments

The assembly and fine-tuning of the deck are crucial for optimal performance and longevity of the equipment. Proper installation ensures effective operation, while adjustments allow for personalized settings based on specific usage needs. This section outlines essential steps and considerations for assembling the deck and making necessary modifications.

When assembling the deck, follow these steps:

- Gather all necessary components and tools.

- Begin with the main frame, ensuring it is level and stable.

- Attach the cutting mechanism securely, following the manufacturer’s guidelines.

- Ensure all bolts and screws are tightened to avoid any movement during operation.

- Install any additional components, such as guards and belts, as specified.

After assembly, make the following adjustments for optimal performance:

- Height Adjustment: Modify the cutting height based on the type of terrain and desired finish.

- Leveling: Check that the cutting mechanism is level to ensure even trimming.

- Tension Settings: Adjust the tension of belts and cables for efficient operation.

Regular maintenance and periodic checks will help maintain the efficiency and effectiveness of the deck assembly, ensuring that it operates smoothly over time.

Maintenance Tips for Long-Term Use

Ensuring the longevity and optimal performance of your equipment requires regular attention and care. Implementing a consistent maintenance routine can significantly enhance the durability and efficiency of the device over time.

Regular Inspection

Routine checks are essential to identify any potential issues before they escalate. Look for signs of wear and tear, loose connections, or any unusual noises. Addressing minor problems promptly can prevent more significant failures down the line.

Proper Cleaning

Keeping your device clean is crucial for its overall performance. Debris and dirt can accumulate in various parts, leading to inefficiencies. Use appropriate cleaning agents and tools to ensure all components remain in optimal condition. A clean environment contributes to smoother operation and extends the life of your equipment.

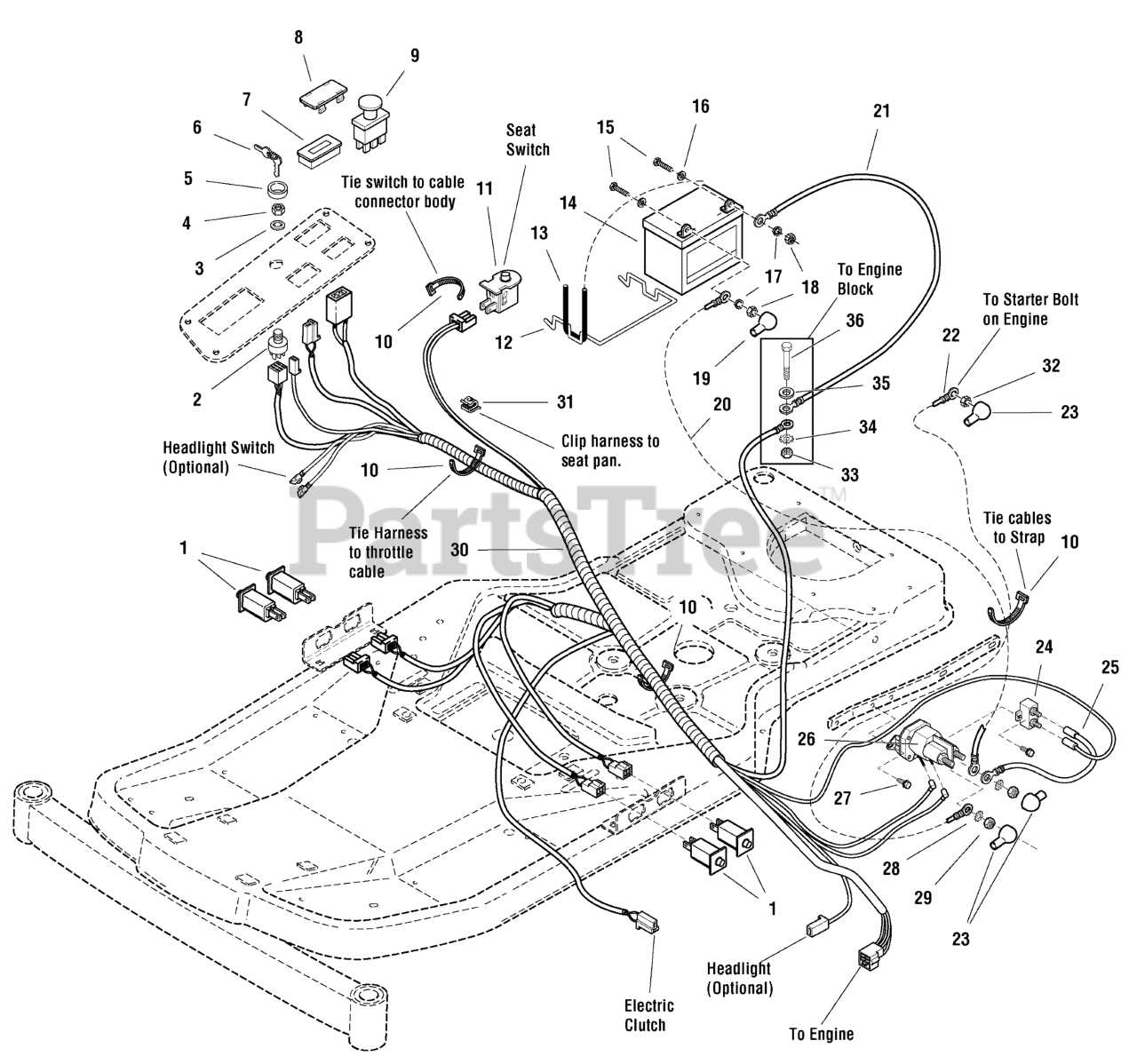

Parts Replacement Guidelines

Ensuring the functionality and longevity of your equipment often requires the timely exchange of specific components. This section provides essential instructions to assist you in efficiently replacing these elements, thereby maintaining optimal performance.

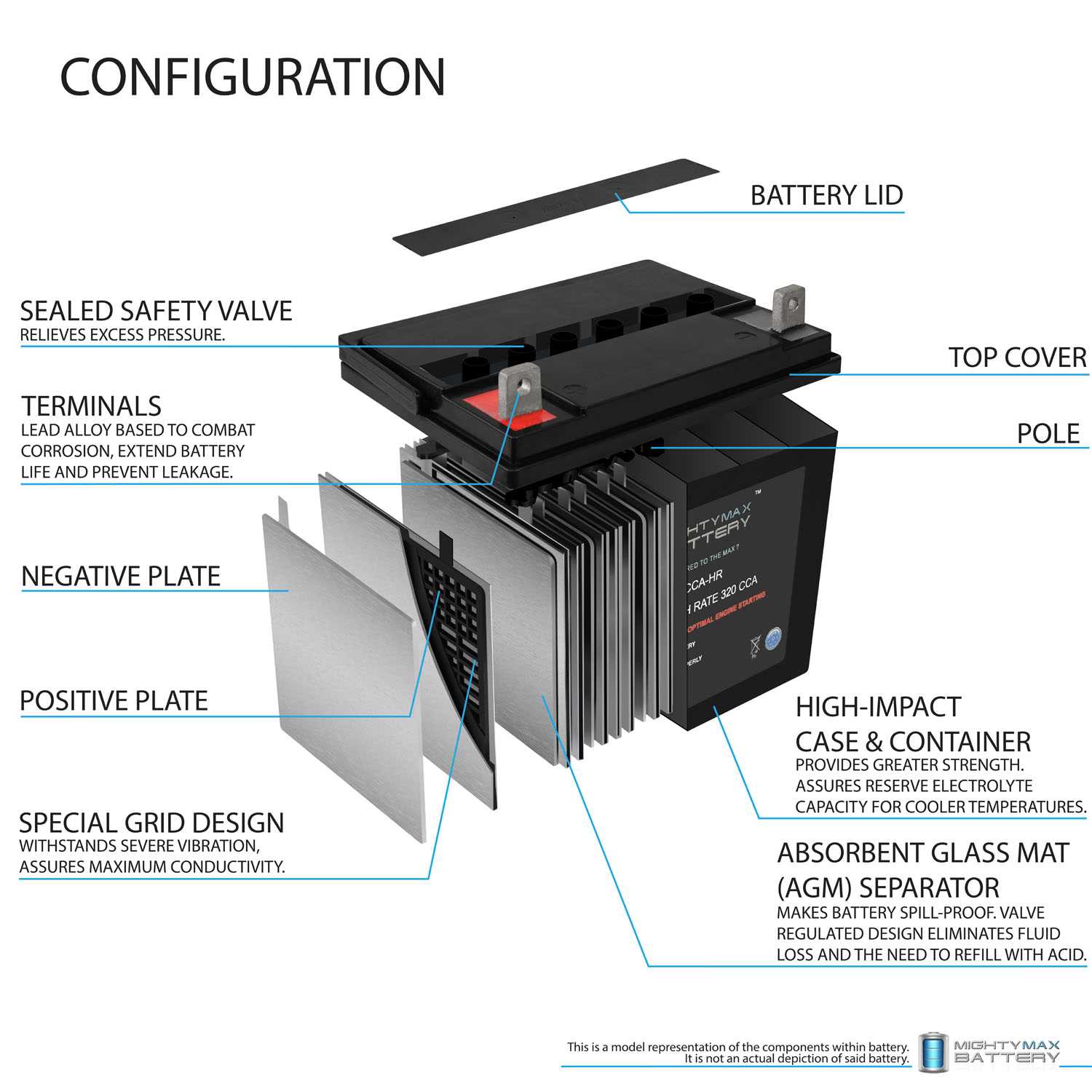

Identifying Components for Replacement

Before initiating the replacement process, accurately identifying the components that require attention is crucial. Review the operational manual or maintenance resources to understand the typical wear patterns and failure signs. Regular inspections can prevent unexpected downtime and ensure that necessary replacements are performed proactively.

Replacement Process Overview

When you have identified the components to be replaced, gather the required tools and ensure you have the appropriate replacements on hand. Follow the outlined steps meticulously to avoid damaging surrounding areas. Always consult the technical documentation for specific instructions related to the replacement of individual components.

In addition, it is advisable to maintain a log of replacements made. This practice can assist in tracking the longevity of each component and provide valuable data for future maintenance activities.

Upgrading and Enhancing Performance

Improving the functionality and efficiency of your machinery can significantly impact its overall performance. By focusing on specific modifications and enhancements, you can optimize the system for better productivity and reliability.

One effective approach to boost performance involves upgrading key components. Consider integrating advanced elements that offer greater durability and efficiency. Additionally, implementing software updates can refine the operating system, leading to smoother functionality and improved user experience.

Regular maintenance is essential for sustaining optimal performance. Routine checks and timely replacements of worn-out components can prevent potential issues and extend the lifespan of the equipment. Furthermore, investing in high-quality materials ensures that the system operates at its best, minimizing downtime and enhancing reliability.

Finally, seeking expert advice when planning upgrades can provide valuable insights into the most effective enhancements. Collaboration with professionals can lead to tailored solutions that address specific needs, ultimately driving better results.