When it comes to maintaining and optimizing your outdoor machinery, having a clear understanding of its individual elements is crucial. Each component plays a significant role in the overall functionality and performance of the unit. Recognizing how these pieces fit together can enhance your ability to troubleshoot issues and ensure effective operation.

In this section, we will explore a visual representation of the various elements that contribute to the seamless functioning of your gear. By examining these key parts, you will gain insight into their specific functions and how they interact with one another. This knowledge is essential for anyone looking to maximize efficiency and extend the lifespan of their equipment.

Moreover, understanding these components allows you to make informed decisions when it comes to repairs and upgrades. Whether you’re a seasoned professional or a weekend warrior, having a reference guide can simplify maintenance tasks and enhance your overall experience with your machinery. Let’s delve deeper into the intricate layout that defines the heart of your equipment.

Understanding Polaris Snow Plow Functionality

Efficient clearing of surfaces during winter conditions relies on specialized equipment designed to handle the challenges posed by snow accumulation. These tools incorporate various components that work together to facilitate seamless operation and enhance performance. A solid understanding of their mechanics is essential for users aiming to maintain optimal functionality and longevity.

The primary mechanism involves a robust assembly that allows for the lifting and angling of the clearing unit. This flexibility enables operators to adapt to different environments, whether it’s a driveway or a larger area. By controlling the angle, users can direct the material to the sides, preventing buildup and ensuring thorough removal.

Power sources play a crucial role in the operation of these devices. Hydraulic systems or electric motors are commonly employed to facilitate movement and manipulation, ensuring that the unit can efficiently respond to varying conditions. Regular maintenance of these systems is vital for uninterrupted service, as wear and tear can lead to diminished performance.

Additionally, the attachment points connecting the equipment to the vehicle are designed for stability and ease of use. Understanding the layout of these connections helps in quick assembly and disassembly, allowing for flexibility based on seasonal needs.

Finally, awareness of safety features and operational guidelines is paramount. Familiarizing oneself with these aspects not only enhances efficiency but also minimizes risks during use, ensuring a safe and effective clearing experience.

Essential Components of Snow Plows

The efficiency of any clearing equipment relies on its key elements, each contributing to optimal performance and functionality. Understanding these vital components is crucial for effective operation and maintenance.

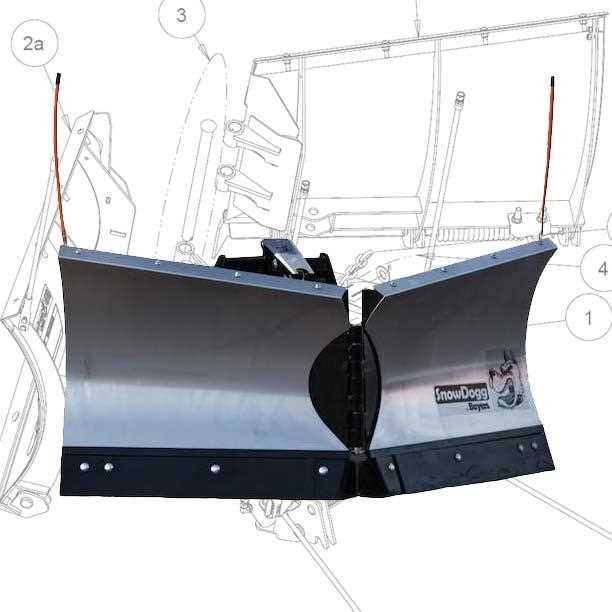

Blade: The foremost element, designed to push away accumulated material, comes in various shapes and sizes to suit different conditions and tasks.

Mounting System: This structure allows secure attachment to the vehicle, ensuring stability during operation and the ability to withstand varying forces.

Hydraulic System: Responsible for controlling the movement of the blade, this system enables operators to adjust angles and heights for efficient clearing.

Control Mechanism: Essential for user interaction, this allows the operator to manage the equipment’s functions easily and intuitively.

Wear Bar: A protective feature that prolongs the life of the blade by reducing wear from contact with surfaces, enhancing durability and performance.

Lighting: Important for visibility during low-light conditions, ensuring safe operation at any time of the day or night.

By familiarizing oneself with these components, users can enhance their understanding and improve the overall effectiveness of their clearing equipment.

How to Read Parts Diagrams

Understanding technical illustrations can significantly enhance your ability to maintain and repair equipment. These visuals serve as a blueprint, providing a detailed overview of components and their interrelations. Familiarizing yourself with how to interpret these representations will streamline the troubleshooting process and improve efficiency in repairs.

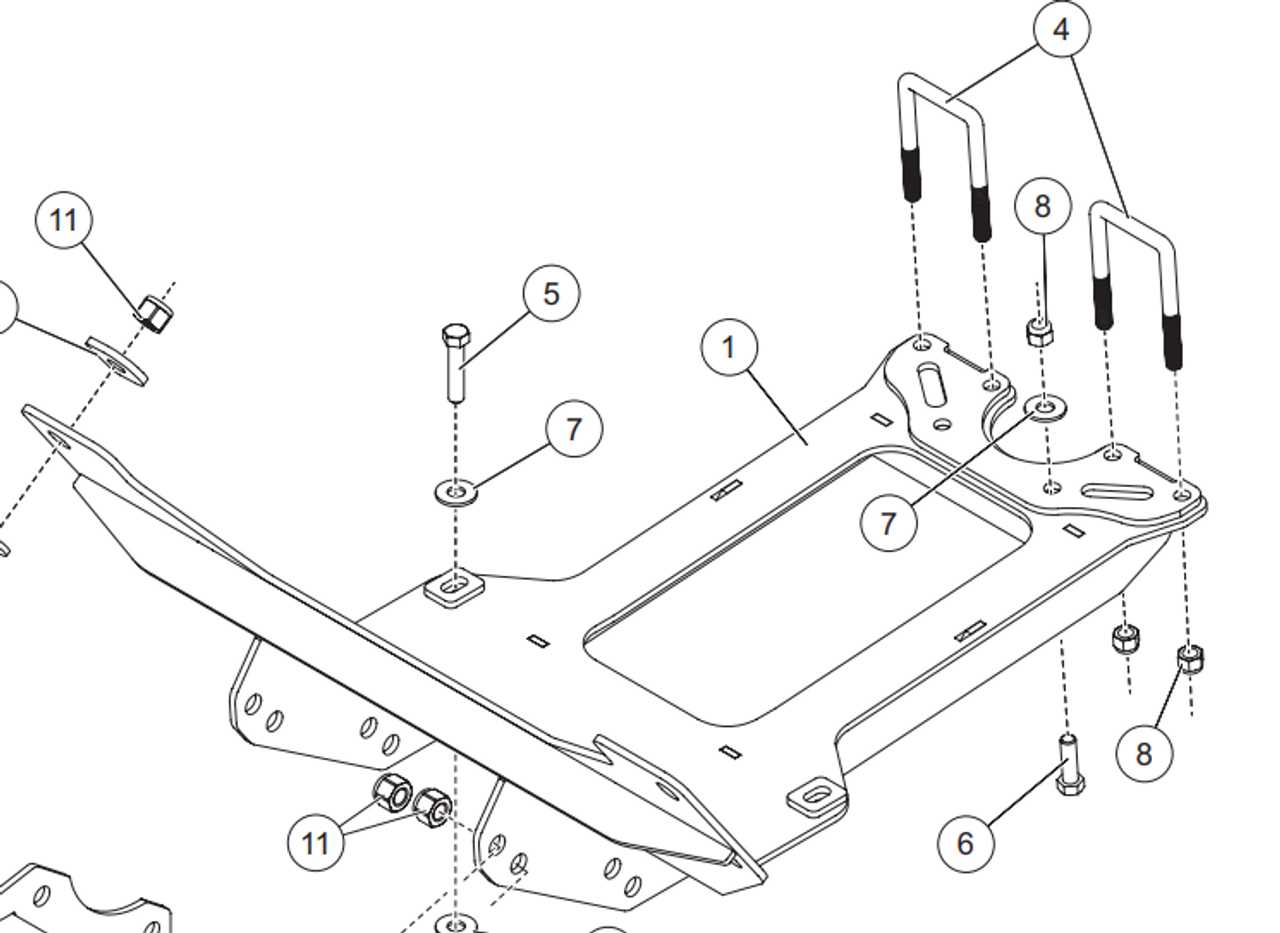

Identifying Components

The first step in decoding these illustrations is recognizing the various elements depicted. Each item is typically labeled with a unique identifier, often corresponding to a catalog or inventory list. Pay attention to symbols and annotations that indicate sizes, quantities, and other essential specifications.

Understanding Connections

Next, focus on how the elements connect with one another. Lines or arrows often represent relationships and assembly instructions. Understanding these connections is crucial for ensuring that parts are fitted correctly, which can prevent operational issues and enhance performance.

Common Issues with Polaris Snow Plows

When operating winter equipment, users may encounter various challenges that can affect performance and reliability. Understanding these issues is crucial for maintenance and ensuring optimal functionality during demanding conditions.

Mechanical Failures

One of the most frequent problems involves mechanical breakdowns, which can stem from wear and tear over time. Components may suffer from fatigue, leading to unexpected malfunctions that hinder effectiveness.

Hydraulic System Troubles

Another common concern is related to the hydraulic system. Leaks, pressure drops, or faulty connections can impede operation, requiring immediate attention to prevent further complications.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended functionality and reliability of your equipment. Regular attention to maintenance can significantly enhance performance and lifespan, making it a worthwhile investment of time and effort.

Routine Inspections

- Check for any signs of wear or damage.

- Inspect fluid levels and ensure they are within the recommended range.

- Examine all moving parts for signs of friction or obstruction.

Regular Cleaning

- Remove debris and buildup to prevent rust and corrosion.

- Clean filters to maintain optimal airflow and efficiency.

- Ensure that all surfaces are free from dirt and grime.

Identifying Parts for Replacement

Understanding the various components of your equipment is essential for effective maintenance and ensuring optimal performance. When seeking replacements, it is crucial to recognize each element’s function and compatibility with your specific model.

Start by examining the user manual, which often contains valuable information about each piece. Additionally, visual inspection can help identify wear and tear on critical elements, guiding you in making informed decisions on what needs to be replaced.

Using a parts reference guide can further assist in pinpointing the correct items, as these resources typically provide detailed illustrations and descriptions. Keeping a checklist of the components you intend to replace can streamline the process and ensure you don’t overlook any necessary elements.

Comparative Analysis of Snow Plow Models

This section aims to explore various models utilized for clearing winter precipitation, highlighting their distinct features, advantages, and disadvantages. By examining these alternatives, users can make informed choices based on performance and suitability for specific tasks.

Key Features to Consider

- Efficiency in clearing

- Durability of materials

- Ease of maintenance

- Compatibility with different vehicles

- Cost-effectiveness

Model Comparison

-

Model A: Known for its robust construction and high efficiency in heavy snowfall conditions.

-

Model B: Offers versatility and is suitable for smaller vehicles, but may struggle in extreme weather.

-

Model C: Prioritizes lightweight design, which enhances fuel efficiency, but compromises on durability.

Aftermarket Parts vs. OEM Parts

The choice between alternative components and those from the original manufacturer can significantly impact performance and reliability. Each option comes with its own set of advantages and drawbacks, influencing not only the cost but also the longevity and effectiveness of the equipment. Understanding these distinctions is crucial for making informed decisions.

Alternative components often provide a cost-effective solution, appealing to those looking to save money without sacrificing quality. They can offer comparable performance and even enhanced features, catering to a diverse range of needs. However, the variability in quality among different manufacturers can be a concern, potentially leading to inconsistent results.

On the other hand, components from the original manufacturer are typically designed to fit seamlessly and meet stringent quality standards. They assure compatibility and reliability, which can be crucial for maintaining optimal functionality. However, this assurance often comes with a higher price tag, making them less accessible for budget-conscious consumers.

Ultimately, the decision between alternative components and those from the original manufacturer depends on individual priorities, including budget, performance requirements, and personal preferences. Careful consideration of these factors will guide users to the right choice for their specific applications.

Tools Needed for Repairing Snow Plows

Maintaining equipment designed for winter conditions requires a specific set of instruments. These tools not only facilitate effective repairs but also ensure the machinery operates efficiently throughout the season.

Essential items include wrenches and sockets for loosening and tightening various components. A quality screwdriver set is crucial for handling screws of different sizes, while pliers can assist in gripping and bending materials as needed. Additionally, having a torque wrench ensures that all connections are secured to the manufacturer’s specifications.

For more extensive repairs, a jack or lift is invaluable for elevating heavy units safely. Safety gear, such as gloves and goggles, is equally important to protect the technician during maintenance tasks. Finally, a well-stocked toolkit will include replacement fasteners and seals to address wear and tear promptly.

Safety Precautions During Repairs

When undertaking maintenance or repairs on machinery, ensuring personal safety and the protection of equipment is paramount. Proper precautions help prevent accidents and injuries, allowing for a more efficient and secure work environment. Understanding potential hazards and taking proactive measures is essential for anyone involved in these tasks.

Protective Gear

Wearing appropriate protective gear is crucial. This includes safety goggles to shield eyes from debris, gloves to protect hands from sharp objects or chemicals, and sturdy footwear to prevent slips and falls. Additionally, using ear protection when working with loud tools can help preserve hearing and maintain focus.

Work Area Safety

Maintaining a clean and organized workspace significantly reduces risks. Ensure that tools are stored properly, and work surfaces are free of clutter. Adequate lighting is also essential to clearly see what you are doing, minimizing the chance of accidents. Furthermore, keeping a first aid kit nearby can provide immediate assistance in case of minor injuries.