In the world of outdoor equipment, familiarity with the various elements that make up a specific model can significantly enhance both maintenance and repair tasks. By delving into the intricate details of these components, users can better appreciate the engineering and functionality of their equipment. This knowledge not only empowers owners to tackle minor issues independently but also aids in efficient troubleshooting.

Every piece of machinery consists of numerous parts, each serving a vital role in its overall operation. Gaining insight into these individual elements can simplify the process of identifying potential problems, ensuring that the tool continues to perform at its best. Moreover, understanding how these components interact can inform users about the importance of regular upkeep and the impact of wear and tear over time.

Equipped with this foundational knowledge, individuals can approach maintenance with confidence, knowing they have the resources to address common challenges. Whether you are a seasoned user or new to outdoor machinery, familiarizing yourself with the essential components will ultimately enhance your experience and prolong the lifespan of your equipment.

Poulan P1500 Parts Overview

This section provides a comprehensive look at the essential components of a well-known outdoor tool. Understanding these elements is crucial for maintenance and effective operation, ensuring users can achieve optimal performance.

Key Components

Among the most important elements are the engine, cutting mechanism, and housing. Each part plays a vital role in the overall functionality, contributing to durability and efficiency.

Maintenance Essentials

Regular upkeep of these crucial elements is necessary to prevent wear and tear. Attention to details, such as lubrication and timely replacements, can significantly enhance longevity and reliability.

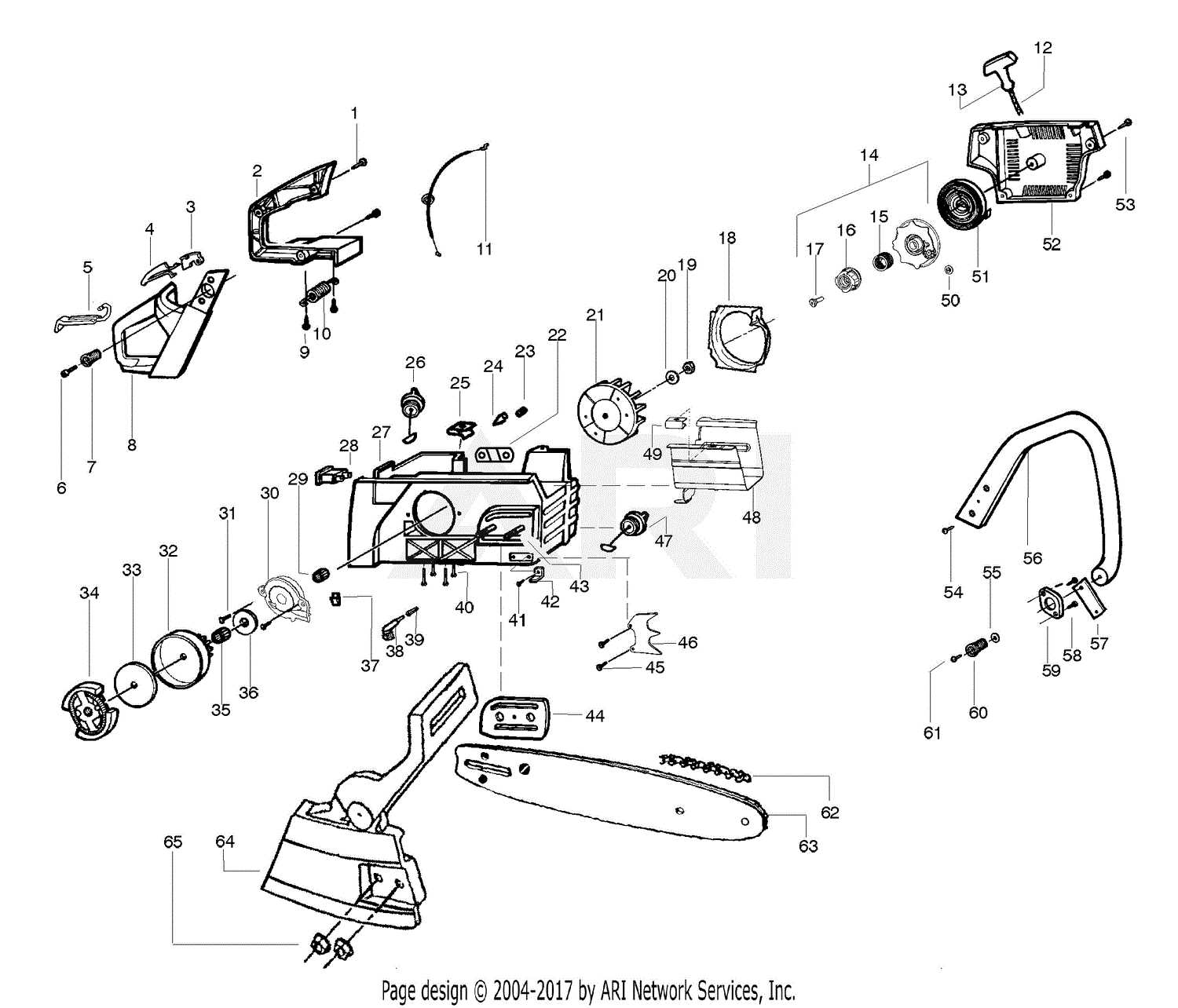

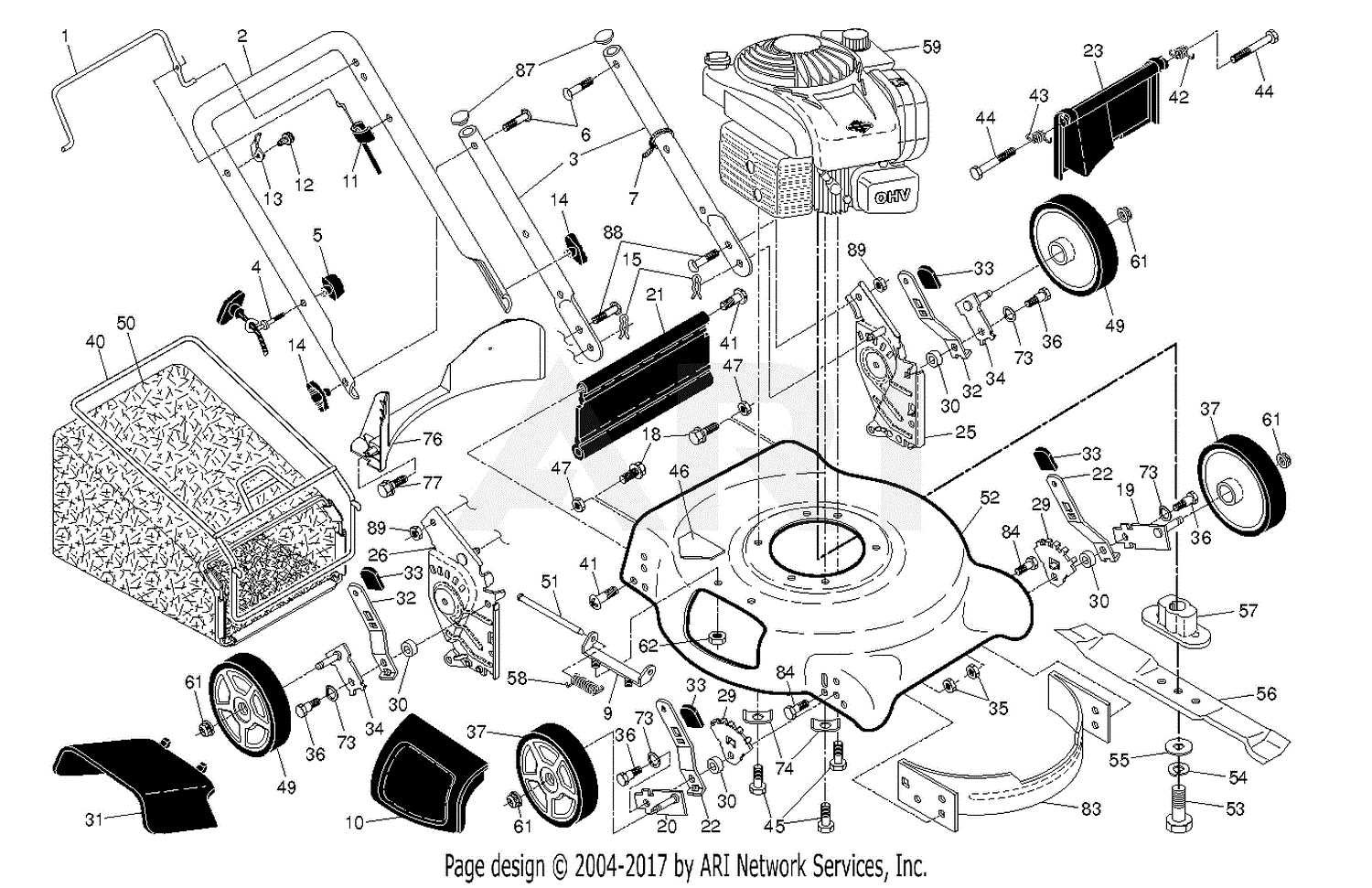

Understanding the Parts Diagram

This section provides insights into the visual representation of components related to a specific machine model. These illustrations are essential for users to identify various elements and understand their functions, ensuring proper maintenance and repairs.

Key Components and Their Functions

Each illustration typically highlights crucial elements, aiding users in recognizing their roles. Here are some common parts you might encounter:

- Engine assembly

- Fuel system

- Electrical components

- Transmission assembly

- Chassis structure

Benefits of Familiarity

Understanding these visuals can lead to several advantages:

- Improved troubleshooting skills.

- Enhanced ability to perform repairs and replacements.

- Better understanding of maintenance needs.

Key Components of the P1500

The functionality of any machinery relies heavily on its essential elements. Understanding these vital components allows for better maintenance and troubleshooting, ensuring optimal performance. Each part plays a significant role in the overall operation, contributing to efficiency and reliability.

One of the primary elements includes the engine, which powers the unit and drives its various functions. This component is crucial for generating the necessary force required for operation. Next, the fuel system is responsible for delivering energy to the engine, ensuring it runs smoothly and efficiently.

Another important aspect is the electrical system, which includes the wiring and ignition components. This system ensures proper starting and operation of the machinery, playing a pivotal role in its functionality. Additionally, the frame provides the structural integrity needed to support all other components, allowing for durability and stability during use.

Finally, the accessories enhance versatility, enabling users to perform a variety of tasks. Understanding these key elements not only aids in recognizing potential issues but also helps in making informed decisions regarding maintenance and upgrades.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the prolonged efficiency and durability of your equipment. By implementing a few simple practices, you can enhance performance and extend the life of your machinery.

Routine Cleaning

Keep the exterior and internal components free from debris. Accumulated dirt can lead to overheating and reduce operational efficiency. Regularly inspect and clean filters and vents to ensure optimal airflow.

Periodic Inspections

Conduct frequent checks on critical components. Look for signs of wear or damage, and replace any parts as needed. Addressing minor issues promptly can prevent major repairs down the line.

Common Issues and Solutions

When working with small engine equipment, various challenges may arise that can hinder performance and efficiency. Understanding these common problems and their remedies can greatly enhance the functionality and longevity of the machinery. Below are some frequent issues encountered, along with practical solutions to address them.

| Issue | Symptoms | Solutions |

|---|---|---|

| Starting Difficulties | Engine won’t start or takes multiple attempts. | Check the fuel level, ensure the choke is in the correct position, and inspect the spark plug for wear or damage. |

| Poor Performance | Reduced power or inefficient operation. | Clean or replace the air filter, adjust the throttle, and ensure fuel quality is adequate. |

| Overheating | Engine temperature rises excessively during operation. | Check for obstructions in the cooling system, ensure proper oil levels, and inspect the fan for functionality. |

| Unusual Noises | Strange sounds coming from the engine. | Examine the components for loose parts, check the oil level, and listen for any irregularities in the motor’s operation. |

How to Order Replacement Parts

When it comes to acquiring components for your equipment, understanding the process can simplify your experience. Knowing where to look and how to navigate the ordering procedure is essential for maintaining the functionality of your tools.

Here’s a step-by-step guide to help you secure the necessary items:

| Step | Description |

|---|---|

| 1 | Identify the specific component needed for replacement. Referencing the user manual can be helpful in determining the correct item. |

| 2 | Visit reputable online retailers or authorized dealers. Ensure the source is reliable to avoid counterfeit products. |

| 3 | Use the model number or reference code to search for the desired item. This will ensure you find the right match for your equipment. |

| 4 | Add the selected component to your cart and proceed to checkout. Double-check the details before finalizing your purchase. |

| 5 | After placing your order, keep an eye on shipping updates to track the delivery of your item. |

Following these steps will facilitate a smooth ordering experience, ensuring that your equipment remains in optimal condition with the correct replacements.

Tools Needed for Repairs

Having the right equipment is crucial for efficient maintenance and repair tasks. A well-prepared toolkit ensures that you can tackle any issues that arise, making the process smoother and more effective. Below are some essential instruments that can aid in various repair activities.

Basic Hand Tools

Start with a set of basic hand tools such as screwdrivers, pliers, and wrenches. These are fundamental for loosening and tightening components, allowing for straightforward adjustments. A good-quality set will serve you well in a range of tasks.

Power Tools

For more intensive repairs, consider investing in power tools. An electric drill or a circular saw can significantly speed up the process and make challenging tasks easier. Additionally, a reliable workbench can provide stability when working on complex components.

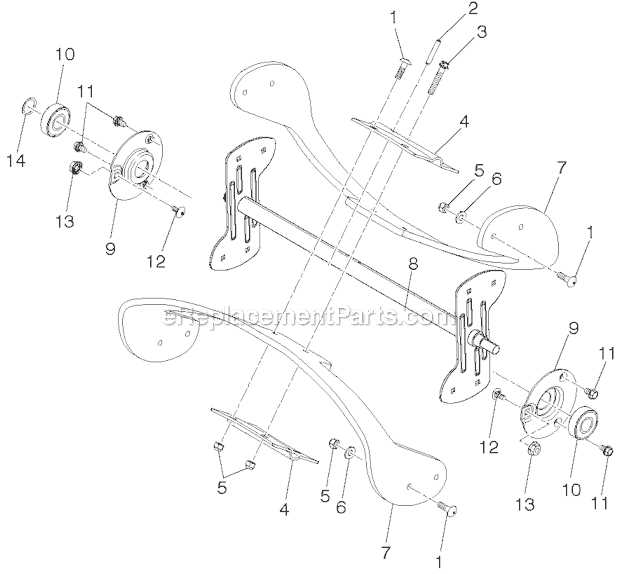

Step-by-Step Assembly Guide

This section provides a detailed approach to assembling the equipment effectively, ensuring that each component fits seamlessly into the overall structure. Following these steps will help you achieve optimal functionality and performance.

Materials Needed

- Required components

- Tools for assembly

- Screws and fasteners

- Safety equipment

Assembly Steps

- Begin by organizing all components on a flat surface for easy access.

- Refer to the assembly instructions to familiarize yourself with each part’s function.

- Start with the main body, attaching any foundational pieces securely.

- Install the additional components as indicated, ensuring all connections are tight.

- Check each joint and fastener to confirm stability.

- Perform a final inspection to verify that everything is assembled correctly.

Following these steps will ensure that the assembly is completed smoothly, leading to a reliable and efficient operation of the device.

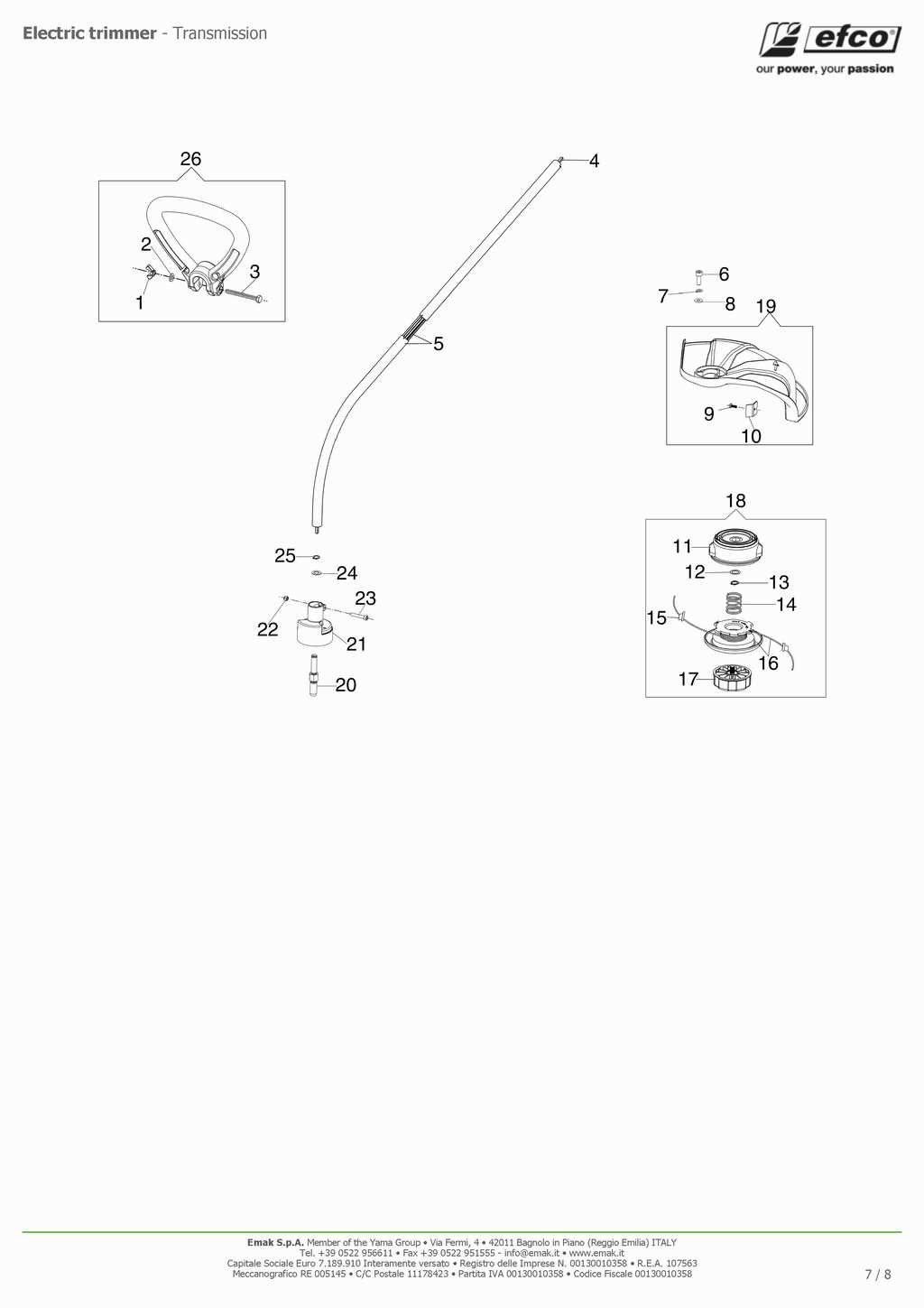

Comparing Parts with Other Models

When examining components from different equipment, it is essential to identify similarities and differences that can affect functionality and performance. Understanding how various models share or diverge in their design can provide valuable insights for maintenance and repairs.

Key Similarities

Many machines feature interchangeable elements, allowing users to easily substitute or upgrade components. For example, engines and motors often utilize common fittings that enhance compatibility across various brands. This can lead to improved accessibility when seeking replacements.

Distinct Variations

However, variations do exist, particularly in specifications and materials used. Certain models may have unique features tailored for specific tasks, influencing durability and efficiency. It is crucial to recognize these differences to ensure optimal performance and prevent potential issues during operation.

Identifying Genuine Parts vs. Aftermarket

When maintaining equipment, distinguishing between original components and alternative options is crucial. Genuine components are designed specifically for the machinery, ensuring optimal performance and longevity. In contrast, aftermarket alternatives may offer cost savings but often lack the same level of quality and compatibility.

Original components typically feature precise manufacturing standards and materials, which contribute to their reliability. They come with warranties that can provide peace of mind in case of defects or issues. Alternative options, while often more affordable, can vary significantly in quality. It’s essential to research the manufacturer’s reputation and read reviews before making a decision.

In summary, choosing the right components can significantly impact the equipment’s functionality. Prioritizing quality and compatibility will ultimately lead to better performance and fewer issues down the line.

Safety Precautions During Repairs

Engaging in maintenance tasks requires a thorough understanding of safety measures to prevent accidents and injuries. Proper preparation and adherence to guidelines ensure that the process remains efficient and hazard-free.

Essential Safety Gear

Always equip yourself with the necessary protective gear. This includes gloves, goggles, and sturdy footwear, which can significantly reduce the risk of injury.

Work Area Organization

A tidy workspace is crucial for safety. Keep tools and components organized to minimize the chance of accidents caused by clutter. Following a systematic approach can enhance focus and efficiency.

| Safety Item | Description |

|---|---|

| Gloves | Protect hands from cuts and abrasions. |

| Goggles | Shield eyes from debris and harmful substances. |

| Footwear | Provide support and protect feet from heavy items. |

Customer Reviews and Feedback

In the realm of outdoor equipment, user experiences provide invaluable insights into product reliability and performance. Customers often share their thoughts, highlighting both the strengths and weaknesses of various models. This section aims to present a collection of reviews that reflect the satisfaction levels and concerns of individuals who have utilized similar machinery.

Overall Satisfaction

Many users express high levels of satisfaction with the performance and durability of their equipment. Features that stand out include ease of use, effectiveness in various tasks, and a robust build quality. One reviewer noted, “This machine has exceeded my expectations, making yard work a breeze.” Such feedback emphasizes the positive impact of reliable tools on everyday tasks.

Common Concerns

While most feedback is positive, some users have raised concerns regarding maintenance and customer service. A few individuals mentioned difficulties in sourcing replacement components, which can hinder long-term usability. Additionally, experiences with support services vary, with some customers expressing frustration over response times. Addressing these issues could enhance the overall experience for future users.