When working with outdoor tools, it’s crucial to have a clear understanding of how various elements fit together to ensure smooth operation and efficient maintenance. A well-organized layout provides a clear reference, allowing users to pinpoint specific elements quickly and with accuracy. This clarity can save valuable time when repairs or replacements are needed.

Every piece of equipment is composed of intricate assemblies, and knowing how these pieces interact helps maintain performance and extend the lifespan of the tool. Whether you’re dealing with routine checks or troubleshooting, having a structured reference guide is essential for anyone working with mechanical devices.

In the following sections, we will explore how different components are connected, ensuring that you can easily navigate through the various systems of your equipment. By following this guide, you’ll gain confidence in managing maintenance tasks and optimizing your tool’s functionality.

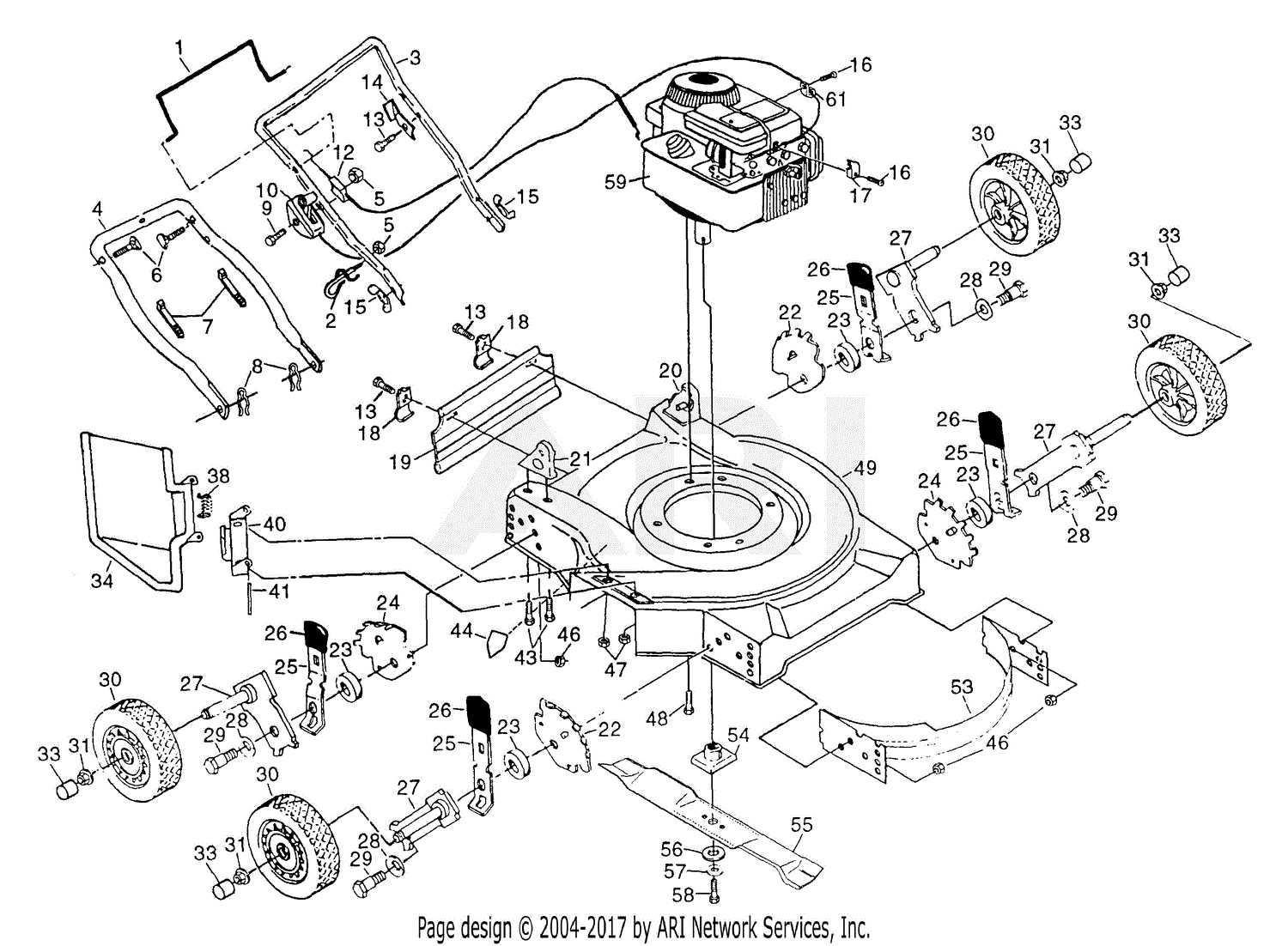

Poulan Parts Breakdown and Identification

Understanding the structure of various components is crucial for efficient maintenance and repair. This section focuses on breaking down individual elements of the equipment, highlighting their specific roles and how they interact with each other. Whether you are dealing with essential mechanisms or smaller fixtures, proper identification ensures smooth operation and simplifies any troubleshooting process.

Key Elements and Their Roles

Each machine is made up of a number of key elements, all designed to work in harmony. Identifying these elements is the first step toward keeping everything functioning as intended. From larger components responsible for power and movement to smaller attachments that provide stability and precision, every detail counts.

Efficient Troubleshooting Tips

Proper identification of equipment elements can also prevent unnecessary repairs. When a malfunction occurs, being familiar with the different components allows for quick pinpointing of the issue. This knowledge not only saves time but also extends the lifespan of the equipment by ensuring that problems are addressed before they escalate.

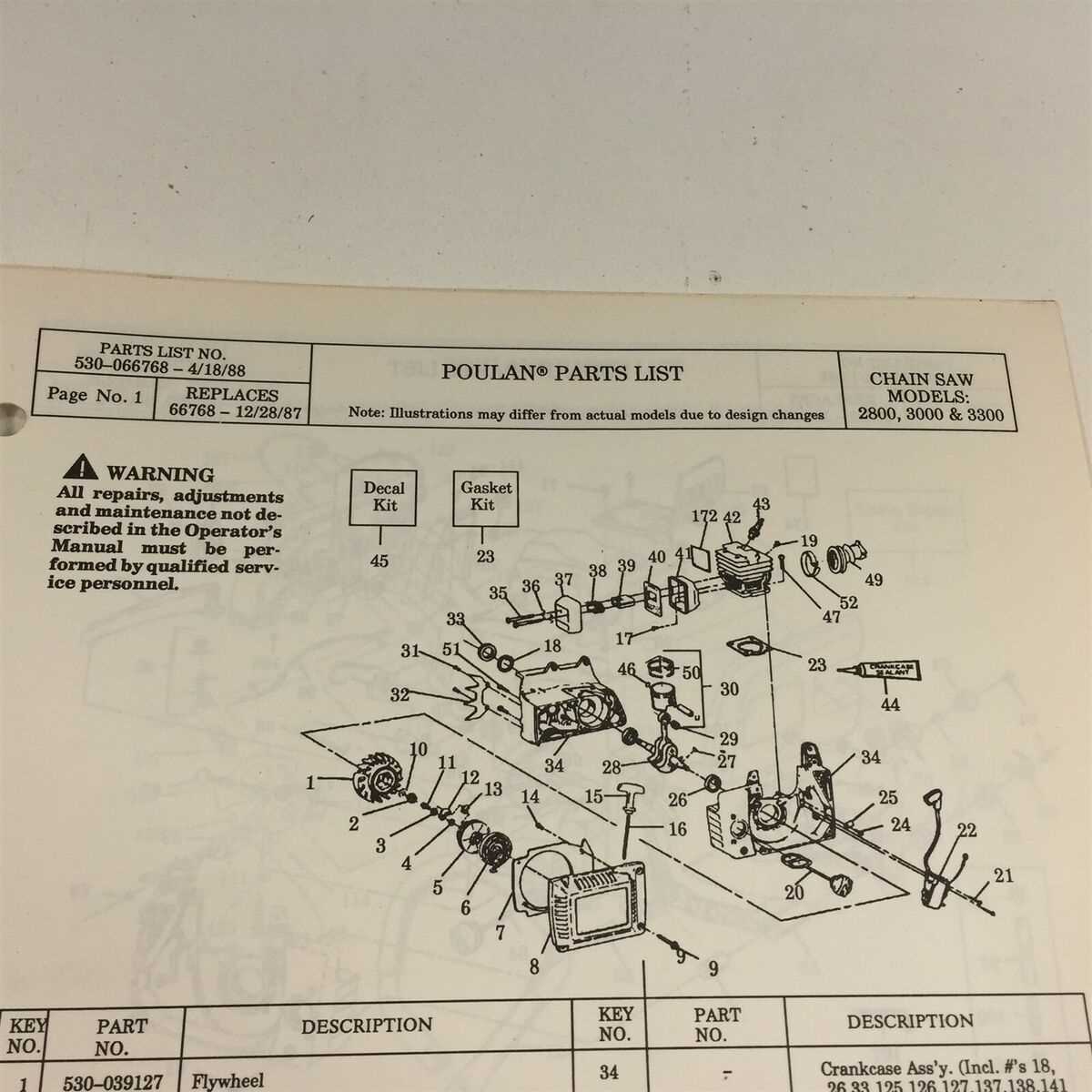

Key Components of Poulan Chainsaws

Understanding the main elements of chainsaws is essential for proper maintenance and optimal performance. Each part plays a crucial role in ensuring the tool operates efficiently and safely.

- Engine: The powerhouse of the tool, responsible for driving the cutting chain and ensuring smooth operation during heavy-duty tasks.

- Guide Bar: A metal bar that supports and guides the cutting chain, determining the length of the cutting area.

- Cutting Chain: The sharp, rotating component that makes contact with the wood or other materials, performing the actual cutting action.

- Fuel and Oil System: This system ensures the chainsaw receives the right amount of fuel for the engine and lubrication for the chain, preventing overheating and damage.

- Safety Features: Includes mechanisms such as chain brakes and anti-vibration handles, designed to protect the user during operation.

Understanding Poulan Engine Mechanics

Engine mechanics play a crucial role in the functionality and efficiency of outdoor power equipment. Understanding how the internal components work together helps in diagnosing issues and maintaining long-term performance. This section delves into the basic principles behind the operation of engines commonly used in garden tools, focusing on key elements that ensure smooth functionality.

Core Components of Small Engines

The internal structure of an engine is made up of several essential parts that work in harmony to produce power. Each component has its specific role in the operation cycle, contributing to the overall performance.

- Combustion Chamber: The area where the air-fuel mixture ignites, driving the piston.

- Piston: A cylindrical part that moves within the cylinder, transferring energy to the crankshaft.

- Crankshaft: Converts the piston’s linear motion into rotational force, which powers the tool.

- Valves: Regulate the flow of fuel and air into the combustion chamber and the release of exhaust gases.

Guide to Chainsaw Blade Assembly

Assembling the chainsaw blade correctly is essential for the tool’s performance and safety. This process involves mounting the blade in the right position and ensuring that all components are securely in place. By following a few simple steps, you can efficiently prepare your chainsaw for use.

Step 1: Begin by making sure that the saw is turned off and placed on a stable surface. It is crucial to have the equipment in a secure position before starting the assembly.

Step 2: Next, position the blade onto the saw. Make sure the teeth are facing the correct direction to ensure efficient cutting. You can adjust the tensioner to achieve the right fit.

Step 3: Once the blade is in place, tighten the bolts to secure the assembly. Ensure everything is firmly locked in place, but avoid over-tightening, as it may damage the saw.

With these steps

Replacing Chainsaw Handles

Handle replacement is a crucial part of chainsaw maintenance, ensuring proper control and safety during operation. Damaged or worn-out grips can significantly affect both comfort and precision, making it essential to address the issue promptly. In this section, we’ll guide you through the steps to effectively replace the handles on your chainsaw.

Steps to Remove the Old Handle

- Start by disconnecting the power source or removing the battery if applicable.

- Use the appropriate tools to detach the screws or bolts securing the handle to the body of the saw.

- Gently lift the handle away, ensuring no internal wiring or components are damaged during the process.

Installing the New Handle

- Align the new handle with the mounting points on the saw.

- Secure it with screws or bolts, ensuring everything is tightened properly.

- Reconnect any necessary wires and test the handle for stability before use.

Exploring the Poulan Ignition System

The ignition mechanism is a critical component in ensuring the proper functioning of small engines. Understanding how this system operates can enhance maintenance practices and improve overall performance.

This system consists of several key elements that work together to initiate combustion. Here are the primary components:

- Spark Plug: Creates the spark necessary to ignite the fuel-air mixture.

- Ignition Coil: Transforms low voltage from the battery into high voltage needed for the spark plug.

- Flywheel: Spins to generate a magnetic field that activates the ignition coil.

- Wiring Harness: Connects all electrical components, ensuring proper signal transmission.

Regular inspection of these elements is crucial for optimal engine performance. If any component shows signs of wear or damage, timely replacement can prevent larger issues and extend the lifespan of the machinery.

In addition, understanding how to troubleshoot ignition problems can save time and costs associated with repairs. Common symptoms to watch for include:

- Engine not starting or sputtering.

- Inefficient fuel consumption.

- Irregular engine operation or stalling.

By familiarizing oneself with the ignition system’s workings and components, users can ensure their equipment operates smoothly and efficiently.

Maintenance Tips for Poulan Chainsaw Parts

Proper upkeep of your cutting tool is essential for optimal performance and longevity. Regular maintenance can prevent wear and tear, ensuring that the device operates efficiently and safely. Following a few simple guidelines can help maintain its components in excellent condition.

| Task | Frequency | Description |

|---|---|---|

| Clean Air Filter | Every 10 hours of use | Remove the air filter and clean it thoroughly to prevent dust buildup that can affect engine performance. |

| Check Bar and Chain Tension | Before each use | Ensure the chain is correctly tensioned to avoid slippage or damage to the guide bar. |

| Inspect Fuel System | Monthly | Check for leaks or cracks in fuel lines and ensure the fuel filter is clean to maintain proper fuel flow. |

| Sharpen Chain | After every 3-5 uses | Sharpen the cutting edges to enhance cutting efficiency and reduce strain on the engine. |

| Lubricate Moving Parts | Every 20 hours of use | Apply appropriate lubricant to moving parts to ensure smooth operation and reduce friction. |

Poulan Fuel System Layout Explained

The fuel system of a small engine plays a crucial role in its performance and efficiency. Understanding the arrangement and components involved can significantly enhance maintenance practices and troubleshooting efforts.

This layout typically consists of several key elements that work together to deliver fuel to the engine. Here’s a brief overview of these components:

- Fuel Tank: The reservoir that stores the fuel until needed.

- Fuel Line: A conduit that transports fuel from the tank to the carburetor.

- Filter: This component removes impurities from the fuel to ensure clean delivery to the engine.

- Carburetor: It mixes the fuel with air to create a combustible mixture that powers the engine.

- Fuel Pump: In some systems, this device helps move fuel from the tank to the carburetor, especially in more complex setups.

Each part has a specific function that contributes to the overall efficiency and reliability of the engine. Regular inspection and maintenance of these components can prevent common issues and prolong the lifespan of the equipment.

Troubleshooting Poulan Air Filter Issues

Maintaining optimal engine performance often involves addressing problems related to the air filtration system. Ensuring that the filter is functioning correctly can prevent a range of operational difficulties, enhancing the overall efficiency of the equipment.

Start by inspecting the filter for any visible signs of dirt or damage. A clogged or worn filter can restrict airflow, leading to poor combustion and reduced power output. If the component appears excessively dirty, consider cleaning or replacing it as necessary.

Symptoms of a Malfunctioning Filter:

- Engine misfiring or stalling: This can indicate insufficient airflow caused by a blocked filter.

- Unusual noises: Uncommon sounds may suggest that the engine is struggling to draw in air.

- Decreased fuel efficiency: If the equipment consumes more fuel than usual, it may be due to inadequate air supply.

Regular maintenance of the filtration system is essential for preventing issues. Schedule routine checks to ensure that the filter is clean and functioning effectively, which will prolong the life of the machinery.

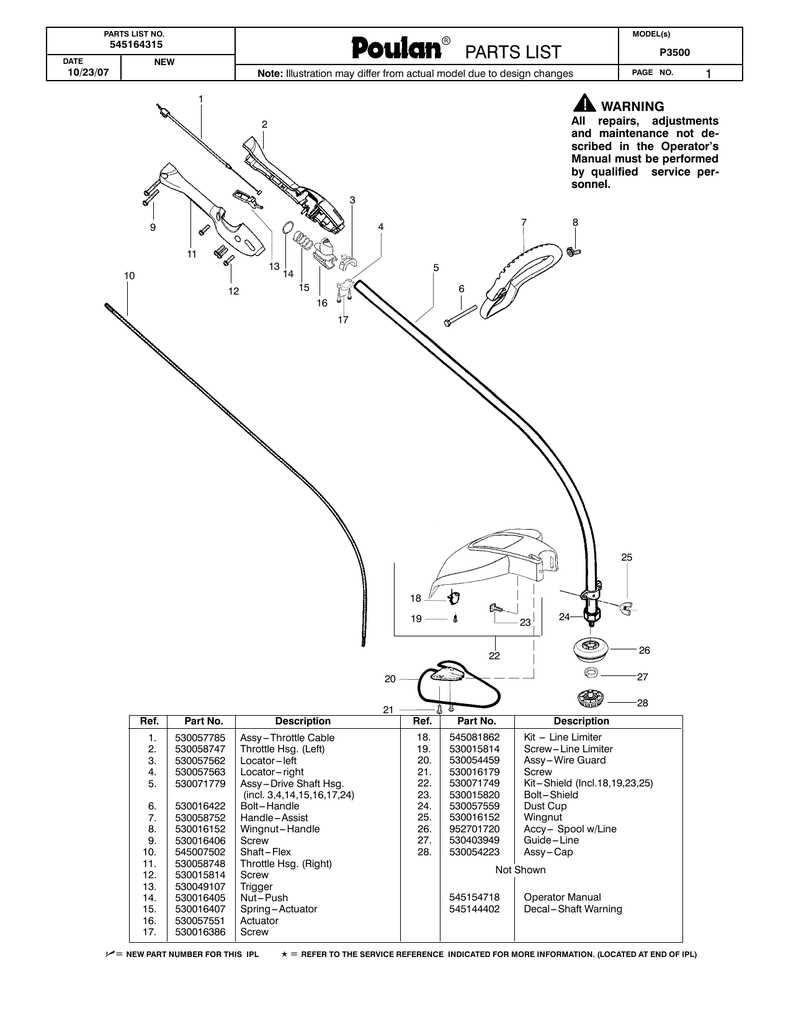

Guide to Poulan Chainsaw Tensioner Parts

This section provides an overview of components essential for maintaining optimal chain tension in a cutting tool. Understanding these elements is crucial for efficient operation and longevity of the equipment.

The tensioning mechanism plays a vital role in ensuring that the cutting chain remains snug against the guide bar. Proper adjustment of this system not only enhances performance but also minimizes the risk of accidents during use. Below are the key components associated with this mechanism:

| Component Name | Description |

|---|---|

| Tensioning Screw | Enables manual adjustment of the chain’s tightness for optimal cutting efficiency. |

| Tensioner Spring | Provides the necessary force to maintain consistent chain pressure against the guide bar. |

| Guide Bar | The surface along which the cutting chain moves, requiring precise tension for effective operation. |

| Chain | The actual cutting element that rotates around the guide bar, necessitating proper tension to prevent derailment. |

| Adjustment Mechanism | A system that allows for quick and easy modifications to the chain’s tension without specialized tools. |

Understanding Poulan Drive System Components

The drive system is a crucial aspect of outdoor equipment, facilitating efficient operation and power transfer. Recognizing its various elements is essential for effective maintenance and optimal performance. Each component plays a specific role, contributing to the overall functionality of the machinery.

The power source initiates the drive process, delivering energy to the system. This energy is then transmitted through a series of interconnected mechanisms, including gears and belts, which ensure that the force is adequately distributed throughout the device.

Another significant element is the drive shaft, which serves as the main conduit for power transmission. It connects the engine to various attachments, allowing the user to operate different tools with ease. Additionally, bearings and supports help to stabilize the drive system, minimizing friction and enhancing longevity.

Lastly, control levers and linkages enable the operator to manage the drive system efficiently, ensuring precise adjustments for varied tasks. Understanding these components helps users maintain their equipment effectively, leading to improved performance and durability.

Repairing Poulan Chainsaw Bar and Chain

Maintaining the cutting mechanism of a chainsaw is essential for optimal performance and safety. The bar and chain are critical components that require regular inspection and occasional repair. Understanding how to address common issues with these parts can enhance the lifespan of your equipment and improve its efficiency.

Common Issues and Troubleshooting

Several problems may arise with the cutting components, including wear, damage, and improper tension. Frequent use can lead to dullness, which hampers cutting ability. If the chain is too loose or too tight, it can affect operation and safety. Regularly check for signs of wear or deformation to ensure effective functionality.

Repair Steps

Begin by removing the chain and inspecting both the bar and the chain for any visible damage. Use a file to sharpen the teeth of the chain if they are dull. Adjust the tension according to the manufacturer’s specifications, ensuring that the chain moves freely without excessive slack. If you notice significant wear on the bar, consider replacing it to maintain optimal cutting performance.

Performing these maintenance steps regularly will not only prolong the life of your equipment but also enhance safety and efficiency during use. Always refer to the specific guidelines for your equipment model for the best results.

Chainsaw Clutch Assembly Overview

The clutch assembly plays a crucial role in the operation of a cutting tool, enabling the efficient transfer of power from the engine to the cutting chain. Understanding its components and functionality can enhance maintenance and troubleshooting efforts.

Key components of the clutch assembly include:

- Clutch Shoes: These are the parts that engage with the drum to connect the engine’s power to the chain.

- Spring: This component ensures that the clutch shoes return to their original position when not engaged, preventing unnecessary wear.

- Clutch Drum: The drum houses the chain and is responsible for driving the chain during operation.

- Retention Ring: This secures the clutch components in place, maintaining their alignment and functionality.

Regular inspection of the clutch assembly is essential for optimal performance. Signs of wear or damage may include:

- Inconsistent chain movement

- Excessive noise during operation

- Difficulty in engaging or disengaging the chain

Proper maintenance and timely replacement of worn components can prolong the life of the tool and improve cutting efficiency.