In this section, we delve into the vital elements that constitute a well-functioning outdoor power equipment model. Understanding the various components is crucial for effective maintenance and troubleshooting. Each part plays a significant role in ensuring optimal performance and longevity of the machinery.

By examining the intricate layout of these components, users can gain insights into the assembly and functionality of their equipment. This knowledge empowers individuals to undertake repairs and replacements with confidence, ultimately enhancing the overall user experience. A clear understanding of these vital aspects contributes to better care and efficient operation.

This section will provide a comprehensive introduction to the featured equipment, focusing on its essential components and functionality. Understanding the various elements of this tool is crucial for effective maintenance and operation.

Key aspects to consider include:

- Functionality: Insights into how the machine operates and the role of each component.

- Maintenance: Importance of regular upkeep to ensure longevity and performance.

- Components: Overview of the main parts and their significance in the overall functionality.

By familiarizing oneself with these elements, users can enhance their understanding and maximize the efficiency of the equipment.

Essential Components Explained

Understanding the fundamental elements of a chainsaw is crucial for effective maintenance and operation. Each component plays a specific role, contributing to the overall functionality and performance of the tool. Familiarizing yourself with these parts not only aids in troubleshooting but also enhances the longevity of the equipment.

Key Elements of the Equipment

Every chainsaw consists of several vital elements that work in harmony. These components include the engine, bar, chain, and various controls. Each part serves a unique function that ensures the device operates smoothly and efficiently.

Table of Main Components

| Component | Function |

|---|---|

| Engine | Powers the chainsaw, providing the necessary energy for cutting. |

| Guide Bar | Acts as a track for the chain, determining the length of the cut. |

| Chain | Equipped with sharp teeth that perform the actual cutting of wood. |

| Throttle Trigger | Regulates the engine speed and chain movement. |

| Chain Brake | Enhances safety by stopping the chain in case of kickback. |

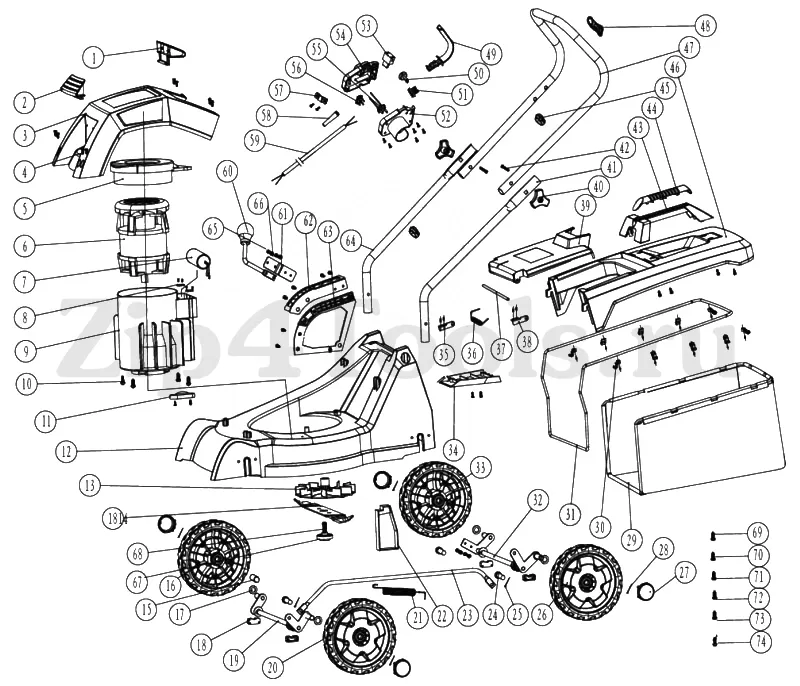

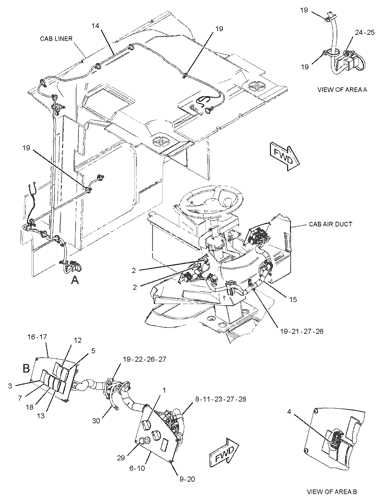

Understanding the Parts Diagram

Grasping the layout of components is essential for effective maintenance and repair of machinery. This visual representation provides insights into the various elements that make up the equipment, highlighting their interconnections and functions. By familiarizing oneself with this overview, users can enhance their comprehension of how each segment contributes to the overall operation.

The illustration serves as a valuable guide, enabling users to identify individual elements quickly. This knowledge is crucial when it comes to troubleshooting issues or performing replacements. Each component is typically numbered or labeled, making it easier to reference specific parts during discussions or when ordering replacements.

Additionally, understanding this schematic can aid in recognizing common wear points and potential failure areas, allowing for proactive maintenance. Regularly consulting this reference not only streamlines repairs but also extends the lifespan of the equipment by ensuring that all parts are functioning correctly and efficiently.

Maintenance Tips for Longevity

Ensuring the durability and reliability of your equipment requires regular care and attention. Implementing a consistent maintenance routine can significantly extend its lifespan, enhance performance, and reduce the likelihood of unexpected failures. By following a few simple practices, you can keep your machine in top condition for years to come.

Regular Cleaning

Keeping your device clean is essential for optimal functionality. After each use, remove any debris, dirt, or residues that may accumulate. Pay special attention to the air filters and cooling vents, as obstructions can lead to overheating and diminished efficiency. Using a soft brush or compressed air can effectively remove stubborn particles without damaging delicate components.

Routine Inspections

Conducting periodic checks on various components can help identify wear and tear before they escalate into major issues. Inspecting items such as the chain, bar, and spark plug should be part of your regular maintenance checklist. Replace any worn parts promptly to avoid compromising the overall performance of your equipment. Additionally, consult the user manual for specific recommendations related to your model.

Identifying Common Issues

Understanding typical problems that may arise during the operation of a chainsaw can significantly enhance its performance and longevity. By recognizing these common challenges, users can take proactive measures to address them and maintain optimal functionality.

Some frequent complications include:

- Engine failure or difficulty starting

- Irregular or uneven cutting

- Excessive vibration during use

- Fuel leakage or poor fuel efficiency

- Chain slippage or improper tension

To effectively troubleshoot these issues, it is essential to conduct regular inspections and maintenance, ensuring that all components are functioning correctly. Here are steps to help identify and resolve these challenges:

- Check the fuel and oil levels, ensuring they are appropriate for operation.

- Inspect the chain for wear and proper tension.

- Examine the air filter for clogs or dirt accumulation.

- Review the spark plug condition, replacing it if necessary.

- Monitor the exhaust for unusual emissions or sounds.

By being attentive to these factors, users can mitigate issues and enhance their chainsaw’s performance.

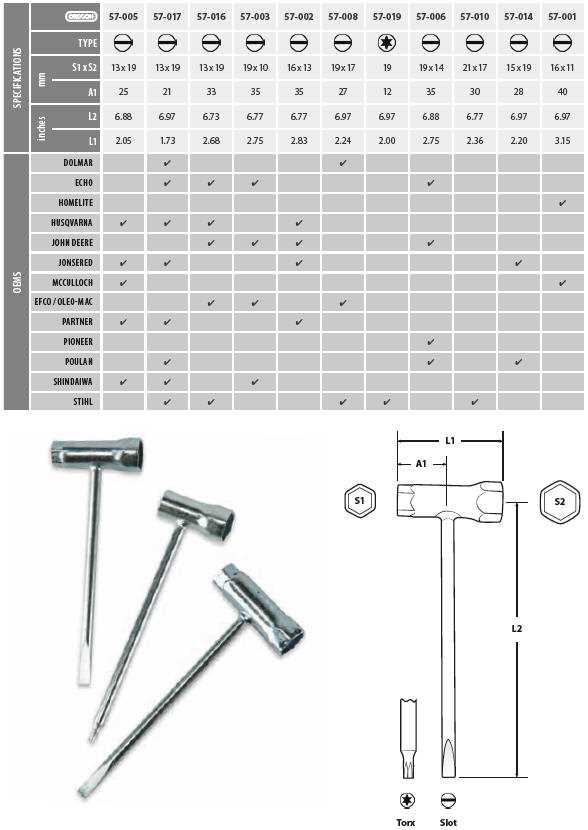

Tools Required for Repairs

To successfully carry out maintenance and repairs on outdoor power equipment, having the right tools is essential. These tools not only ensure efficiency but also enhance safety during the repair process. This section outlines the key instruments that are typically necessary for effective service and restoration tasks.

| Tool Name | Description |

|---|---|

| Wrench Set | Essential for loosening and tightening bolts and nuts during disassembly and assembly. |

| Screwdriver Set | Used for various screws; both flathead and Phillips types are recommended. |

| Socket Set | Helpful for accessing hard-to-reach fasteners and providing greater torque. |

| Pliers | Useful for gripping, twisting, and cutting wires or other materials. |

| Measuring Tools | Includes calipers and tape measures to ensure proper dimensions and alignments. |

| Safety Gear | Includes gloves, goggles, and ear protection to ensure personal safety during repairs. |

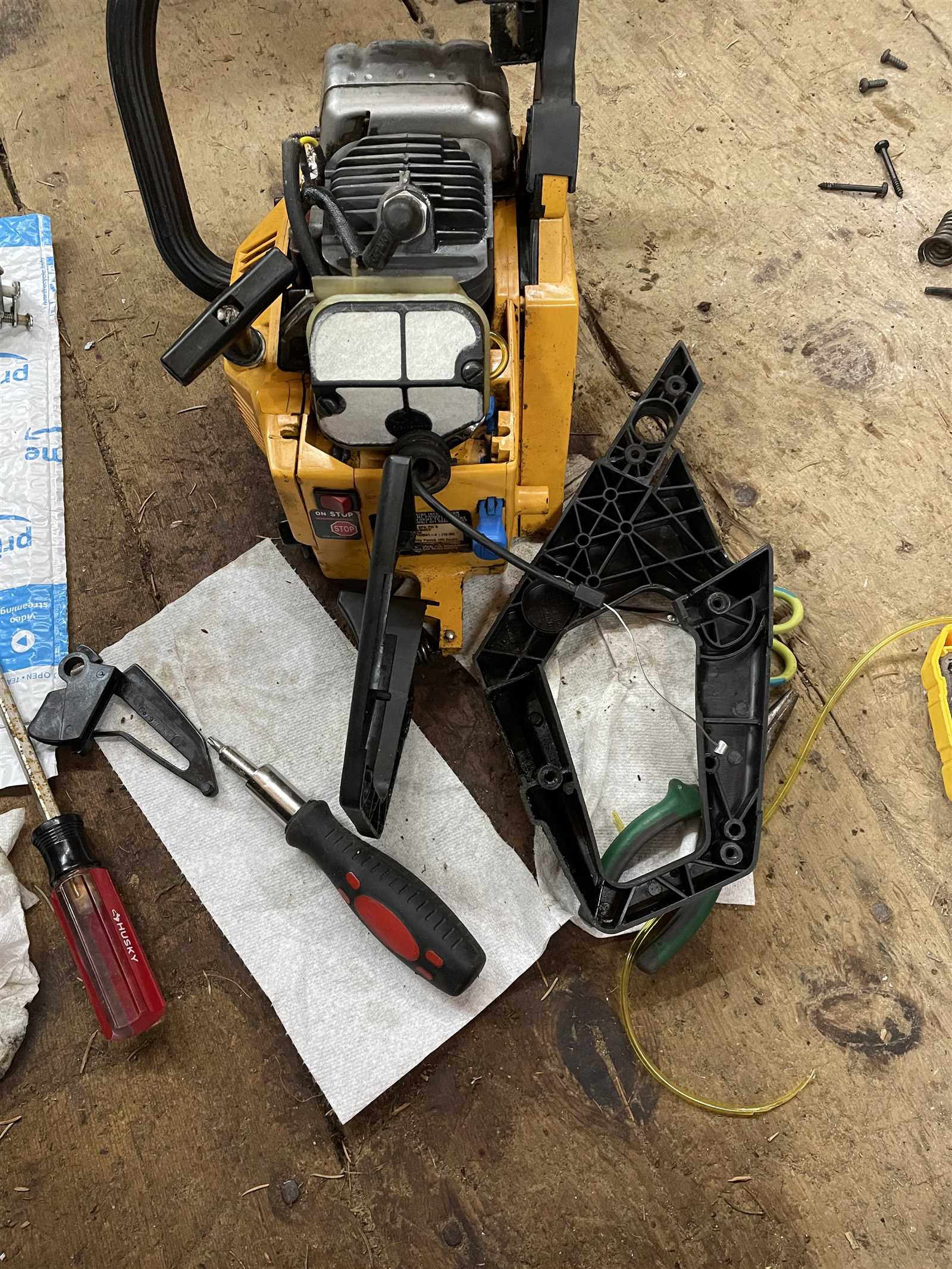

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to the disassembly process of your equipment. Following a systematic method ensures that each component is carefully removed and organized, facilitating easier reassembly and maintenance. This guide is designed to help you navigate the disassembly with confidence, minimizing the risk of damage and ensuring that no parts are lost.

Preparation Before Disassembly

Before starting the disassembly, it is crucial to prepare your workspace. Ensure that you have a clean, well-lit area with all necessary tools at hand. Gather items such as screwdrivers, wrenches, and containers for small parts. Additionally, reviewing the assembly instructions beforehand can provide valuable insights into how the components fit together.

Step-by-Step Removal Process

Begin the disassembly by removing any external coverings or guards. Next, systematically loosen and take out the screws or bolts securing each part. It’s advisable to keep the fasteners organized to avoid confusion during reassembly. As you work, gently pull apart the components to prevent any undue stress on the connections. If a part resists removal, check for any hidden screws or clips that may still be securing it.

Following these steps will ensure that you can efficiently disassemble the equipment while safeguarding its components for future use.

Reassembly Best Practices

Successfully putting together components requires careful attention to detail and methodical approaches. Proper reassembly ensures the longevity and optimal performance of the device, preventing issues that may arise from incorrect assembly. Adhering to best practices can significantly enhance the overall efficiency of the machine.

Preparation and Organization

Before starting the reassembly process, gather all necessary tools and components in a well-lit workspace. Organizing parts by type and size can simplify the process and reduce the likelihood of errors. Using labeled containers can further assist in keeping track of smaller items.

Step-by-Step Assembly

Following a systematic approach during reassembly is essential. Refer to assembly guidelines whenever possible, as they provide valuable insights into the correct order and method of putting parts together. Ensure that all components fit securely and that no parts are left out, as this could lead to operational failures or safety hazards.

Where to Find Replacement Parts

Locating suitable components for your equipment can greatly enhance its performance and longevity. There are several reliable avenues to explore when seeking out the necessary items for maintenance or repair. Understanding where to source these essentials can streamline the process and ensure you have the correct items for your needs.

Online Retailers: Numerous websites specialize in outdoor equipment and accessories, offering a wide selection of components. Major retailers often provide detailed catalogs, enabling you to search for specific items by type or model. This option allows for convenient comparisons of prices and availability.

Local Hardware Stores: Many community hardware shops carry a range of components suitable for various machinery. Visiting these stores can provide immediate access to what you need, and staff members can often offer valuable advice on compatibility and installation.

Authorized Service Centers: If you prefer professional assistance, authorized service centers can be an excellent resource. They typically have access to genuine items and can assist with installation, ensuring your equipment operates at peak efficiency.

Online Marketplaces: Platforms like auction sites or classified ads can also be helpful. These venues might feature new or gently used components at competitive prices, making them a cost-effective option.

By exploring these different channels, you can confidently find the components necessary to maintain and repair your equipment, ensuring optimal functionality for years to come.

Compatibility with Other Models

This section explores the interchangeability of components across various chainsaw models, highlighting the potential for users to utilize similar parts in different machines. Understanding compatibility can enhance maintenance efficiency and reduce costs for operators who may own multiple units.

Many chainsaws share design elements and functionalities, allowing certain components to be swapped between models. Factors such as the type of engine, bar length, and drive mechanisms often influence whether a part will fit another machine. By examining these characteristics, users can determine if they can use existing components from one model in another, thereby simplifying repairs and part replacements.

It is crucial to consult product manuals or manufacturer specifications when assessing compatibility. Doing so ensures that the correct parts are selected, promoting optimal performance and safety during operation. Users should also consider the age and model variations, as newer versions may have updated designs that affect interchangeability.

Safety Precautions to Follow

Ensuring safety during the operation of power equipment is crucial for preventing accidents and injuries. By adhering to specific guidelines, users can significantly reduce risks while using their tools. This section emphasizes the essential practices that should be observed to maintain a safe working environment.

Use Personal Protective Equipment

Wearing appropriate personal protective gear is vital when operating machinery. Essential items include safety goggles to protect the eyes from debris, gloves to enhance grip and shield hands, and sturdy footwear to ensure stability. Hearing protection is also recommended, as prolonged exposure to loud noises can lead to hearing damage.

Maintain Equipment Regularly

Regular maintenance of tools and machinery is necessary to ensure they function correctly and safely. Inspecting for wear and tear, keeping blades sharp, and checking fuel levels can prevent malfunction during use. Always refer to the manufacturer’s guidelines for maintenance schedules and procedures to ensure optimal performance and safety.

Resources for Further Assistance

When seeking support and information related to your equipment, various resources can provide valuable insights and guidance. Utilizing these tools can enhance your understanding and help you resolve any issues you may encounter.

- Online Forums: Engage with communities of users who share their experiences and solutions.

- Manufacturer’s Website: Explore the official site for manuals, FAQs, and troubleshooting guides.

- Retailer Support: Contact the store where the device was purchased for additional assistance and parts information.

- YouTube Tutorials: Access visual guides that demonstrate repairs and maintenance techniques.

- Local Repair Shops: Consult professionals who can provide expert help and advice on specific issues.

These resources can significantly aid in maintaining your device’s performance and longevity, ensuring you have the necessary information at your fingertips.

Customer Reviews and Feedback

This section highlights the opinions and experiences shared by users regarding the product’s performance and overall quality. Feedback from customers serves as a valuable resource for potential buyers, offering insights into usability, reliability, and any challenges encountered during usage.

Positive Experiences

- Many users appreciate the ease of operation, highlighting its user-friendly design.

- Customers have noted the efficiency and power of the device, making it suitable for various tasks.

- Several reviews mention the durability of the construction, ensuring long-term usage without significant wear.

Areas for Improvement

- Some users have pointed out the need for clearer assembly instructions to enhance initial setup.

- A few customers experienced minor issues with maintenance, suggesting more accessible guides.

- Feedback indicates a desire for additional accessories to complement the device’s functionality.