In any mechanical device, having a clear representation of its various elements is essential for effective maintenance and repair. This section aims to provide insights into the intricate assembly of a specific equipment model, allowing users to identify and comprehend the relationship between different components. By examining these layouts, users can enhance their understanding of how each part contributes to the overall functionality.

Detailed illustrations serve as invaluable tools for both novice and experienced users. They facilitate a deeper appreciation of the inner workings of the machine, promoting informed decision-making when it comes to servicing or replacing specific elements. Whether one is troubleshooting an issue or simply looking to enhance their knowledge, grasping the structural composition is a crucial step.

Moreover, recognizing the significance of each component empowers individuals to approach repairs with confidence. With the right information at hand, users can easily navigate challenges that may arise during the operation or upkeep of their equipment. Ultimately, understanding the layout fosters a sense of mastery over the machinery, transforming potential frustrations into opportunities for growth.

Understanding the essential parts of a chainsaw is crucial for effective operation and maintenance. Each component plays a specific role in ensuring the tool functions efficiently, making it vital for users to familiarize themselves with these elements.

Major Parts

- Engine: The powerhouse of the tool, responsible for driving the chain and providing the necessary power for cutting.

- Guide Bar: This long, flat metal piece holds the cutting chain in place and guides it during operation.

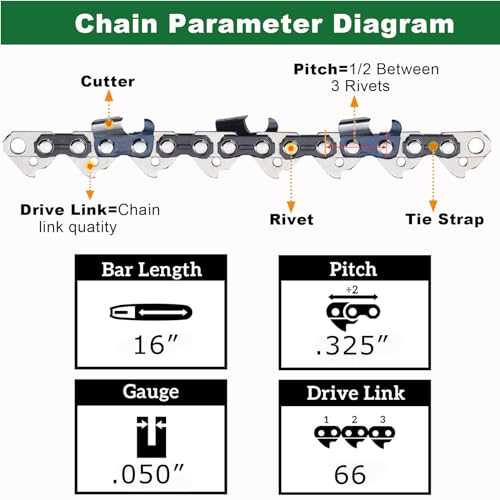

- Cutting Chain: Composed of sharp teeth, this component is responsible for the actual cutting of wood and other materials.

- Handle: Provides a secure grip for the user, ensuring control during operation.

- Safety Features: Includes components like chain brakes and throttle locks, designed to protect the operator during use.

Supporting Elements

- Fuel System: Comprises the fuel tank and lines, supplying the engine with the necessary fuel.

- Lubrication System: Ensures that the cutting chain and guide bar receive proper lubrication, reducing friction and wear.

- Air Filter: Protects the engine from dust and debris, maintaining optimal performance.

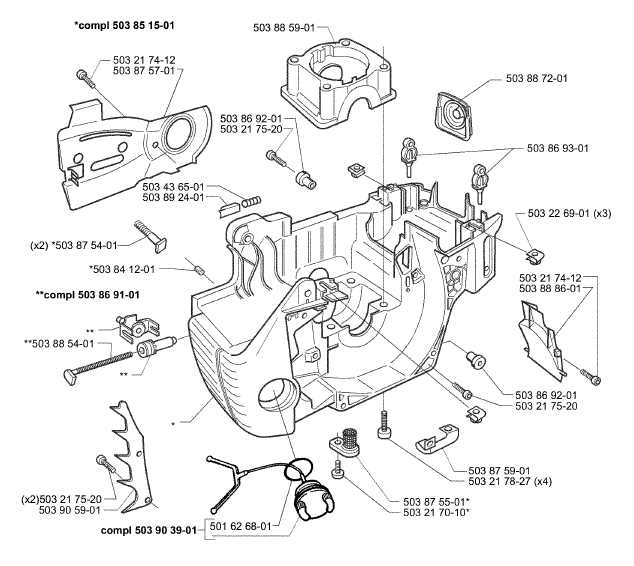

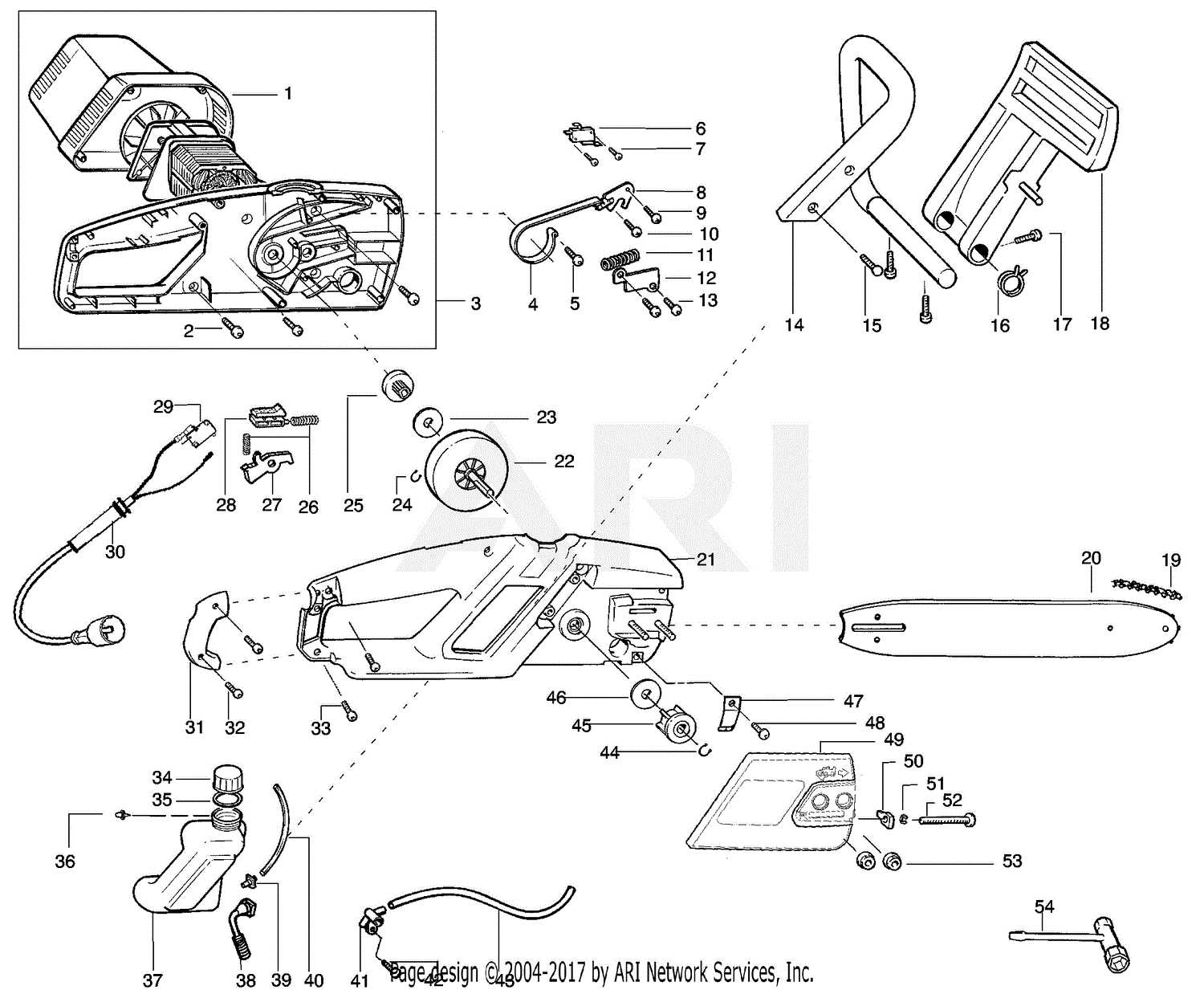

Understanding the Parts Diagram

The components illustration serves as a vital tool for anyone looking to comprehend the various elements that make up a machine. By examining this visual guide, users can gain insight into how each segment functions and interacts with others, enhancing their overall knowledge of the equipment.

Interpreting this visual representation allows for easier identification of each piece, aiding in maintenance and repair tasks. It is crucial to familiarize oneself with the layout and labeling used in the illustration, as this can significantly improve efficiency during troubleshooting and assembly processes.

In addition, having a clear understanding of the components can help users recognize potential issues before they escalate, ensuring optimal performance. Whether for routine checks or more extensive repairs, this reference is indispensable for anyone working with the machinery.

Common Issues with Components

When dealing with various components of outdoor equipment, users may encounter several recurring problems that can affect performance and efficiency. Understanding these issues can help in identifying potential solutions and ensuring proper maintenance.

One frequent challenge is wear and tear, which can lead to reduced functionality. Components may become loose or corroded over time, resulting in decreased effectiveness. Additionally, improper installation or handling can exacerbate these problems, making regular checks essential for optimal performance.

Another common issue arises from compatibility. Using parts that are not designed for specific models can lead to malfunctions and further complications. It’s crucial to ensure that all components are compatible to avoid these issues and prolong the lifespan of the equipment.

Lastly, users should be aware of the importance of regular maintenance. Neglecting routine inspections can lead to undetected issues that may escalate into significant problems, ultimately affecting the overall reliability of the equipment.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficient performance of your equipment. Implementing proper maintenance practices can significantly extend its lifespan, reduce the likelihood of breakdowns, and enhance overall functionality. Here are some key strategies to consider.

Routine Cleaning

Keeping the equipment clean is vital for optimal performance. Remove any debris, dirt, or residue after each use. Pay special attention to air filters and cooling vents to prevent clogging, which can lead to overheating and damage.

Regular Inspections

Conducting periodic inspections allows you to identify wear and tear before it becomes a serious issue. Check for loose or damaged components and replace them promptly. Ensure that all moving parts are lubricated to reduce friction and wear.

Replacement Parts Availability

Access to essential components is crucial for the maintenance and longevity of any outdoor equipment. Ensuring that users can easily obtain high-quality replacements helps in preserving the functionality and performance of their machines. This section will explore the availability of these necessary items and the various sources where they can be acquired.

Where to Find Components

- Local Hardware Stores: Many local retailers stock a variety of replacement components suitable for various models.

- Online Retailers: Numerous e-commerce platforms offer an extensive selection of components, often at competitive prices.

- Manufacturer Websites: Official websites frequently provide listings of compatible items, ensuring authenticity and compatibility.

Factors to Consider

- Compatibility: Always verify that the replacement items match the specifications of the equipment.

- Quality: Opt for high-quality components to ensure optimal performance and durability.

- Cost: Compare prices across different sources to find the best deals without compromising on quality.

Assembly Instructions for Components

Proper assembly of components is crucial for ensuring optimal functionality and performance. This section outlines essential steps and considerations for putting together various elements effectively. Following these guidelines will help you achieve a reliable and efficient assembly process.

Preparation Steps

Before starting the assembly, gather all necessary tools and components. Ensure that your workspace is clean and organized to facilitate a smooth process. Read through the provided instructions carefully to familiarize yourself with each component and its placement.

Assembly Procedure

Begin by aligning the components as indicated in the reference guide. Carefully attach each part, ensuring a snug fit to avoid any operational issues. Use appropriate fasteners and ensure they are tightened securely. Regularly check for alignment and make adjustments as needed during the assembly process.

Note: Always follow safety precautions while handling tools and components. If any part appears damaged or misaligned, address the issue before proceeding to ensure a successful assembly.

Comparing Components with Other Models

This section explores the similarities and differences between various components found in similar equipment. Understanding how these elements compare can help users make informed decisions when selecting replacements or upgrades.

Many models share common characteristics, but subtle variations may affect compatibility and performance. Below are some key aspects to consider when evaluating components:

- Design Features: Examine the design of each component, including dimensions and configurations.

- Material Quality: Consider the materials used in construction, as they can influence durability and longevity.

- Performance Metrics: Compare efficiency ratings and operational capacities to determine suitability.

By comparing these factors, users can identify which components may work best for their specific needs, ensuring optimal functionality and performance across different equipment models.

Safety Features of Poulan Pro 450E

When using outdoor equipment, safety is paramount. This model incorporates various features designed to enhance user protection and minimize risks during operation. Understanding these elements can help users operate their equipment more confidently and effectively.

Protective Mechanisms

The equipment is equipped with several protective mechanisms that help prevent accidents. For instance, the inclusion of a chain brake ensures that the cutting chain stops quickly in the event of kickback. This feature is essential for maintaining control and preventing injuries.

Ergonomic Design

Another critical aspect of safety is the ergonomic design of the handle and overall structure. A well-designed grip reduces fatigue during prolonged use, allowing for better control. Additionally, this model includes anti-vibration technology, which minimizes strain on the user’s hands and arms, promoting a safer operating experience.

How to Troubleshoot Problems

When facing issues with your equipment, a systematic approach to troubleshooting can help identify the root cause and lead to effective solutions. Understanding the common challenges that arise during operation is essential for efficient maintenance and repair.

Begin by examining the device for visible signs of wear or damage. Check connections and components to ensure everything is secure and functioning properly. Often, a loose connection or a worn part can lead to performance issues.

If the problem persists, consider reviewing the operational manual for guidance on specific symptoms and recommended actions. Consulting diagrams or schematics can also provide insights into the internal workings of the device, allowing for more targeted troubleshooting efforts.

In case of persistent difficulties, seeking assistance from a professional or contacting the manufacturer may provide additional support and solutions. Regular maintenance and timely repairs are key to ensuring longevity and reliability in your equipment.

Upgrading Parts for Better Performance

Enhancing components in your machinery can significantly boost its overall efficiency and reliability. By selecting superior replacements, you can optimize performance, extend the lifespan of the equipment, and ensure smoother operation. Upgrading certain elements not only improves functionality but can also lead to a more enjoyable user experience.

When considering upgrades, it’s essential to identify the key components that may benefit from enhancement. Focus on areas such as the engine, fuel system, and cutting mechanisms, as these play a vital role in the effectiveness of the equipment. Investing in high-quality alternatives can make a noticeable difference in performance and maintenance costs.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Engine | High-performance air filters, tuned exhausts | Increased power output, improved fuel efficiency |

| Fuel System | Advanced carburetors, high-flow fuel lines | Smoother operation, better throttle response |

| Cutting Mechanism | Enhanced blades, upgraded chain | Improved cutting speed, reduced wear |