When maintaining and repairing a home cleaning machine, knowing the internal layout and structure is essential for optimal performance. Having a clear reference for each individual component allows you to identify potential issues, replace worn-out parts, and ensure smooth operation. Understanding how the elements of your vacuum work together will save both time and effort in troubleshooting.

Whether you’re dealing with minor adjustments or significant repairs, visualizing the configuration of the essential components can make the process far more efficient. Knowing where each element fits into the overall design helps in achieving a thorough maintenance routine and prolonging the machine’s lifespan.

In this guide, we’ll explore the key elements of this particular cleaning tool, breaking down the assembly into easy-to-follow sections. This will give you a comprehensive overview, enabling you to approach repairs or replacements with greater confidence and clarity.

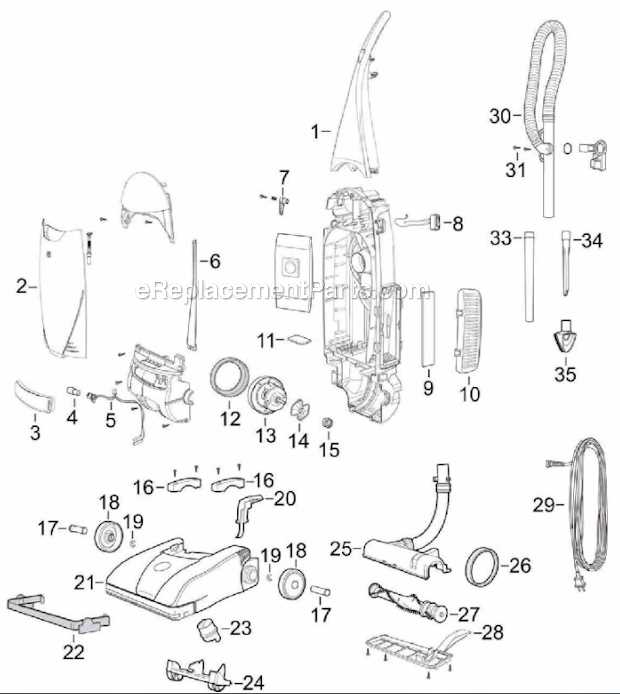

Overview of Bissell Powerforce Helix Turbo Components

The following section will provide an in-depth look at the various elements that make up this efficient cleaning machine. Understanding the key components is essential for maintaining optimal performance and ensuring that the device operates effectively over time. This guide highlights the primary features, designed to enhance both user experience and functionality.

Main Structure and Filtration System

One of the central components of this vacuum is its durable main structure, which houses the filtration system. The multi-layered filtration mechanism captures dust and debris while preventing clogging, which is crucial for maintaining strong suction power. This system also contributes to cleaner air circulation within your home.

Cleaning Tools and Attachments

The machine is equipped with several specialized tools to target different surfaces. These attachments enhance the versatility of the device, allowing users to clean carpets, upholstery, and hard-to-reach areas with ease. Each tool is designed for a specific task, ensuring thorough cleaning results across various surfaces.

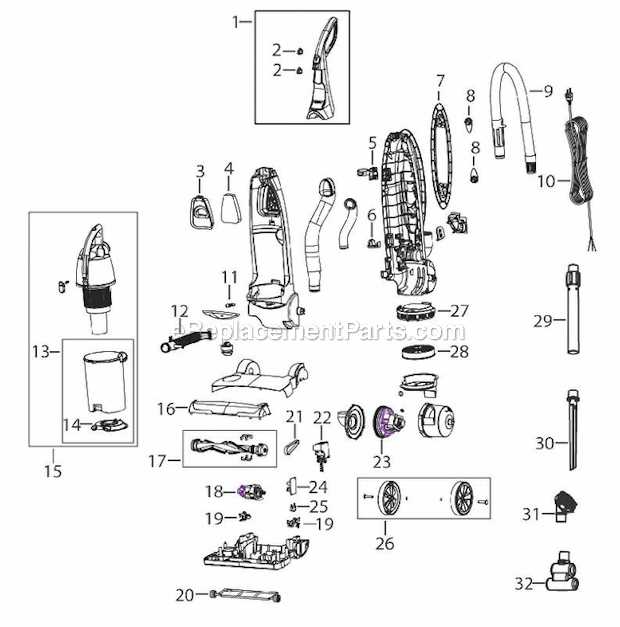

Main Features and Design Elements

The vacuum cleaner boasts an impressive combination of functionality and innovative design elements that enhance overall efficiency. Its engineering focuses on delivering powerful suction, easy maneuverability, and user-friendly maintenance. The structure of the device is thoughtfully designed to ensure optimal performance, while maintaining durability and ease of use.

One of the key features is the multi-level filtration system, which ensures a cleaner environment by effectively trapping dust and allergens. The design incorporates an ergonomic handle for comfortable use and a wide cleaning path for quicker coverage of large areas. Additionally, its versatile attachments allow for efficient cleaning across different surfaces.

Another significant aspect of the design is the easy-to-empty dirt container, which minimizes mess during disposal. The device also includes a height adjustment feature, enabling it to adapt seamlessly to various floor types. These features collectively contribute to a convenient and powerful cleaning experience.

Understanding the Brush Roll Mechanism

The brush roll plays a crucial role in improving cleaning efficiency by agitating carpet fibers and loosening dirt. This component spins rapidly during operation, working in tandem with suction to effectively lift debris from surfaces. Understanding how the brush roll functions is essential for maintaining its performance and ensuring optimal cleaning results.

At the core of the mechanism is a rotating cylinder embedded with bristles. As it turns, the bristles penetrate deep into the fabric of carpets, disturbing dust, hair, and particles that may be lodged. This action allows for a more thorough removal of embedded dirt, which is then captured by the vacuum’s suction system.

Regular maintenance of the brush roll is necessary to prevent clogs caused by tangled hair or debris. Ensuring it rotates freely and remains unobstructed will help maintain the machine’s overall efficiency. Over time, the bristles may also wear down, reducing their ability to reach into carpets effectively, which may signal the need for replacement.

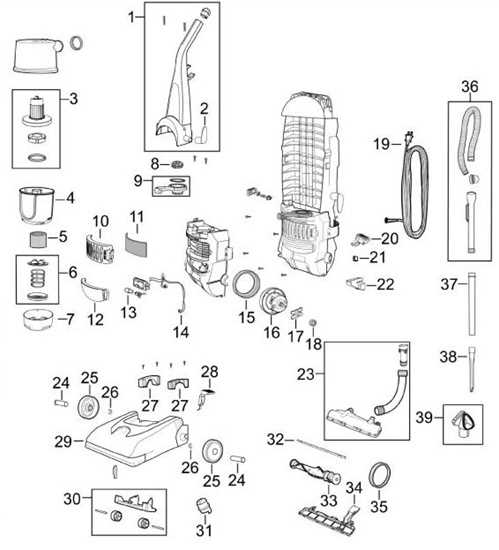

Airflow Path and Filtration System

The airflow path and the filtration system work together to ensure efficient dust and debris removal. By directing the movement of air through carefully designed channels, the device captures dirt and particles, preventing them from being released back into the environment. This section provides an overview of how air circulates through the unit and the role of each filtration component in maintaining optimal performance.

As air enters the vacuum, it travels through a series of passages designed to maximize suction efficiency. The strategic arrangement of these channels ensures that airflow remains consistent, guiding the particles towards the primary filtration stage. Here, larger debris is filtered out, allowing only finer dust to continue through the system.

The next stage involves a finer filtration process, which captures smaller particles like allergens and microscopic dust. This is achieved through the use of advanced filters that trap these particles before the air is expelled back into the room. The combination of multiple filters ensures a cleaner environment, protecting both the device and the user from potential irritants.

Proper maintenance of the airflow path and filters is crucial for maintaining suction power and prolonging the life of the device. Regular cleaning or replacement of filters helps prevent blockages, ensuring that air moves freely through the system without obstruction. This not only enhances cleaning efficiency but also contributes to a healthier living space.

Replacing the Dirt Tank Assembly

The dirt tank assembly plays a crucial role in maintaining your vacuum’s efficiency. Over time, it can wear out or become damaged, requiring replacement. In this section, you’ll learn how to remove the old unit and install a new one to ensure proper suction and filtration.

Steps to Remove the Old Dirt Tank

- Turn off and unplug the vacuum cleaner to prevent any electrical issues.

- Locate the dirt tank release mechanism, typically near the handle or base of the machine.

- Press the release button or lever to detach the tank from the vacuum body.

- Once removed, empty the contents of the tank into a trash bin to avoid mess during the replacement process.

Installing the New Dirt Tank

- Align the new tank with the corresponding slots or connectors on the vacuum.

- Gently push the tank into place until it clicks securely.

- Test the vacuum to ensure the new assembly is correctly installed and functioning properly.

Following these steps will restore optimal performance to your vacuum cleaner and extend its lifespan. Regular maintenance of the dirt tank assembly is essential for continued efficiency.

Motor Unit Structure and Maintenance

The motor assembly is a critical component in vacuum cleaners, playing a vital role in the overall performance and efficiency of the device. Understanding its structure and implementing proper upkeep measures can significantly extend the lifespan of the unit and enhance its functionality.

Components of the Motor Assembly

- Motor Housing: This encasement protects the internal components and helps reduce noise during operation.

- Armature: The rotating part of the motor that interacts with the magnetic field, generating the necessary suction power.

- Commutator: A switching device that reverses the current direction, ensuring consistent motor operation.

- Windings: Copper coils that create a magnetic field when electrical current passes through, enabling motor rotation.

- Fan Blades: Attached to the motor shaft, these blades assist in airflow management and suction capability.

Maintenance Tips for Optimal Performance

- Regularly inspect and clean the motor housing to prevent dust accumulation that can impede airflow.

- Ensure that the fan blades are free from debris to maintain efficient suction and reduce strain on the motor.

- Check the electrical connections for signs of wear or corrosion, as poor connections can lead to decreased performance.

- Lubricate moving parts as recommended by the manufacturer to ensure smooth operation and prevent overheating.

- Consult the user manual for specific maintenance intervals and procedures to follow for your vacuum model.

Hose and Extension Wand Setup

Setting up the vacuum’s hose and extension wand is crucial for maximizing its cleaning capabilities. This section provides a step-by-step guide to ensure you can efficiently connect and use these components, allowing for versatile cleaning in hard-to-reach areas.

Connecting the Hose

To start, locate the hose inlet on the vacuum. Firmly attach one end of the hose to this inlet until you hear a click, indicating a secure connection. Ensure that the hose is free of any kinks or obstructions to facilitate optimal airflow.

Attaching the Extension Wand

Once the hose is in place, you can add the extension wand. Insert the wand into the end of the hose until it fits snugly. This extension allows for better reach, especially when cleaning high or distant surfaces. Make sure the wand is firmly connected to avoid any disconnection during use.

| Component | Instructions |

|---|---|

| Hose | Connect securely to the vacuum’s inlet. Check for kinks. |

| Extension Wand | Insert into the hose until snug. Ensure a tight fit. |

Cleaning and Maintaining the Filters

Regular upkeep of filtration components is crucial for ensuring optimal performance of your cleaning device. By maintaining these elements, you can enhance the efficiency of your appliance, prolong its lifespan, and maintain a healthy living environment. This section will outline essential steps and tips for keeping your filters in top condition.

Importance of Filter Maintenance

Filters play a vital role in trapping dust, allergens, and other particles, contributing to improved air quality. Neglecting their care can lead to clogs, reduced suction power, and increased wear on the device. By committing to a consistent maintenance routine, you can avoid costly repairs and ensure that your cleaner operates at peak efficiency.

Steps for Cleaning Filters

To clean the filtration components effectively, follow these steps:

- Remove the filters: Carefully detach the filters from the unit according to the manufacturer’s instructions.

- Rinse with water: Use lukewarm water to rinse the filters gently. Avoid using detergents or chemicals that may damage the material.

- Dry thoroughly: Allow the filters to air dry completely before reinserting them into the device. This prevents moisture buildup, which can lead to mold growth.

By incorporating these simple practices into your cleaning routine, you can maintain the efficiency of your filtration system and enjoy cleaner air in your home.

Belt Replacement Tips and Guide

Replacing the drive belt in your vacuum cleaner can significantly enhance its performance and prolong its lifespan. This guide provides essential tips to assist you in executing this task efficiently, ensuring your machine operates at optimal levels.

Before proceeding with the replacement, gather the necessary tools and prepare your workspace. A clean, well-lit area is ideal for undertaking this maintenance task.

Follow these steps for a smooth belt replacement process:

| Step | Description |

|---|---|

| 1 | Unplug the vacuum to ensure safety while working on it. |

| 2 | Remove the cover to access the internal components where the belt is located. |

| 3 | Carefully detach the old belt from the motor and brush rolls, noting its orientation. |

| 4 | Install the new belt, making sure it is securely positioned on both the motor and brush rolls. |

| 5 | Replace the cover and ensure all screws are tightened. |

| 6 | Plug the vacuum back in and test its functionality to confirm the replacement was successful. |

Regular maintenance, including timely belt replacements, can help maintain the efficiency and effectiveness of your cleaning equipment. Always consult your user manual for specific instructions related to your device.

Handle and Power Switch Layout

This section provides an overview of the design and arrangement of the handle and power activation mechanism. Understanding this layout is essential for effectively operating and maintaining the equipment, as it plays a crucial role in user interaction and overall functionality.

Ergonomic Design Considerations

The handle is crafted with comfort in mind, ensuring a secure grip for prolonged use. Its shape and texture allow for easy maneuvering, reducing strain on the hands during operation. Additionally, the placement of the power switch is strategically positioned to enable quick access without disrupting the user’s workflow.

Switch Functionality and Accessibility

The activation button is designed for straightforward engagement, providing tactile feedback to confirm that the device is operational. Its location is optimized for effortless access, ensuring users can swiftly turn the unit on or off as needed, enhancing the overall efficiency of the cleaning process.

Common Issues and Parts Replacement

When using vacuum cleaners, users often encounter various challenges that can affect performance and efficiency. Understanding the typical problems that arise and knowing how to replace the necessary components can enhance the longevity of the device and improve cleaning results.

Frequent Problems

One of the most common difficulties involves loss of suction power. This issue may stem from clogged filters or full dust containers. Another prevalent concern is brush roll malfunction, which can lead to inadequate debris pickup. Additionally, electrical faults, such as issues with the power cord or switches, may impede functionality.

Replacement Solutions

To address suction loss, regularly inspect and clean the filters, ensuring they are free from obstructions. For brush roll issues, removing hair or debris and checking for wear can restore performance. If electrical problems are suspected, replacing faulty cords or switches may be necessary. Regular maintenance can prevent many of these problems and ensure a reliable cleaning experience.