In the realm of air rifles, comprehending the arrangement and function of various elements is essential for effective usage and maintenance. A clear visualization of these components can enhance the user’s ability to troubleshoot and optimize performance. This section delves into the intricate layout of the essential pieces that make up the airgun, offering insights into their roles and interactions.

The internal structure plays a pivotal role in the functionality of the firearm. Each segment is designed with precision to ensure reliability and efficiency. By familiarizing oneself with this layout, enthusiasts can gain a deeper appreciation for the craftsmanship involved in airgun design. Whether for hobbyists or competitive shooters, understanding these elements can lead to improved handling and care of the weapon.

Additionally, knowing the arrangement aids in identifying potential issues that may arise during operation. Recognizing how each part fits into the larger mechanism empowers users to conduct basic repairs and maintenance. This knowledge not only prolongs the lifespan of the airgun but also enhances the overall shooting experience, making it more enjoyable and rewarding.

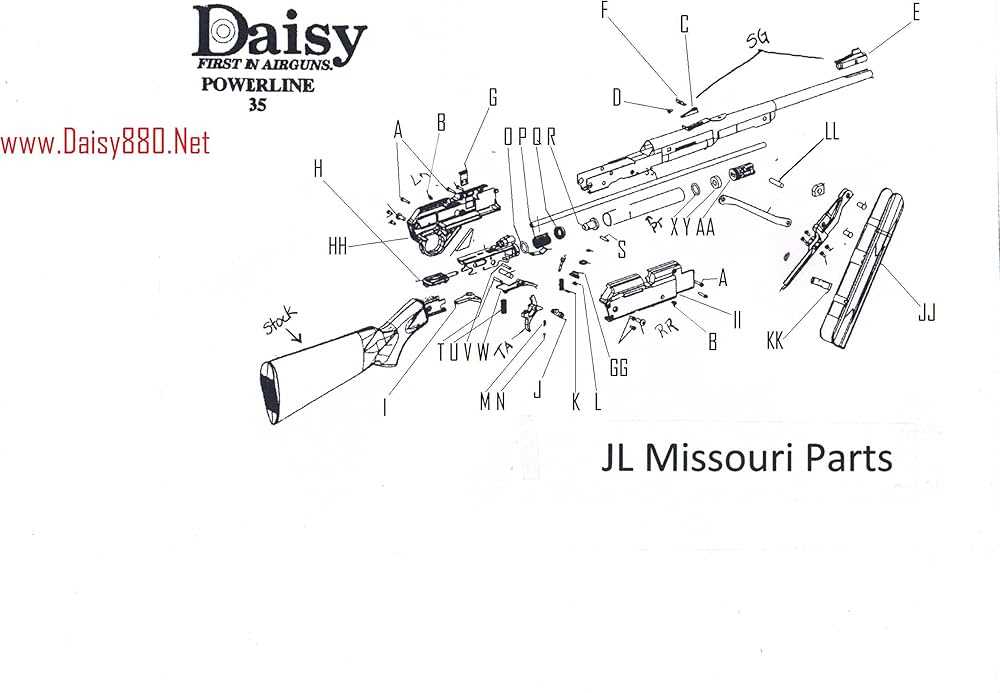

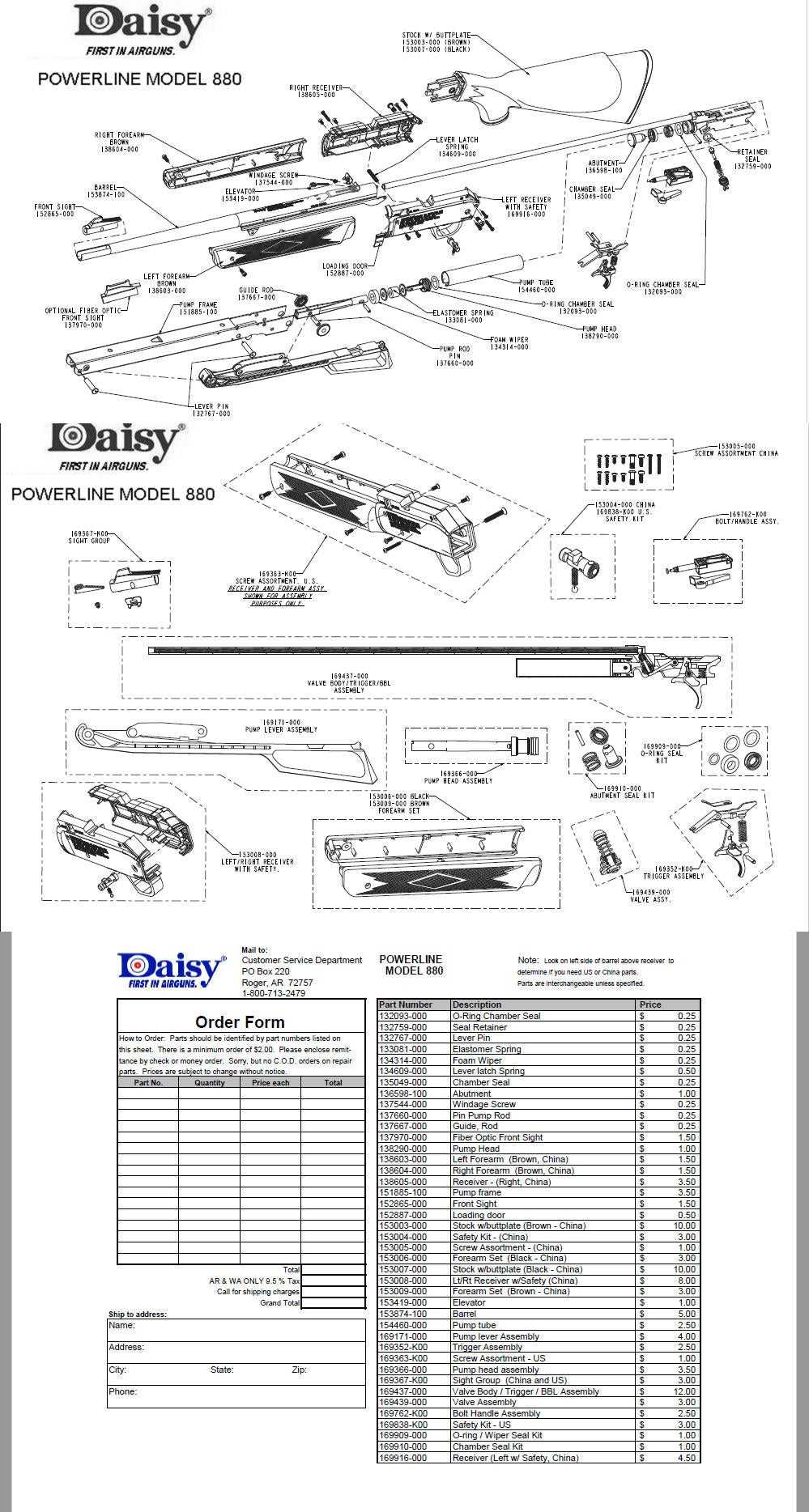

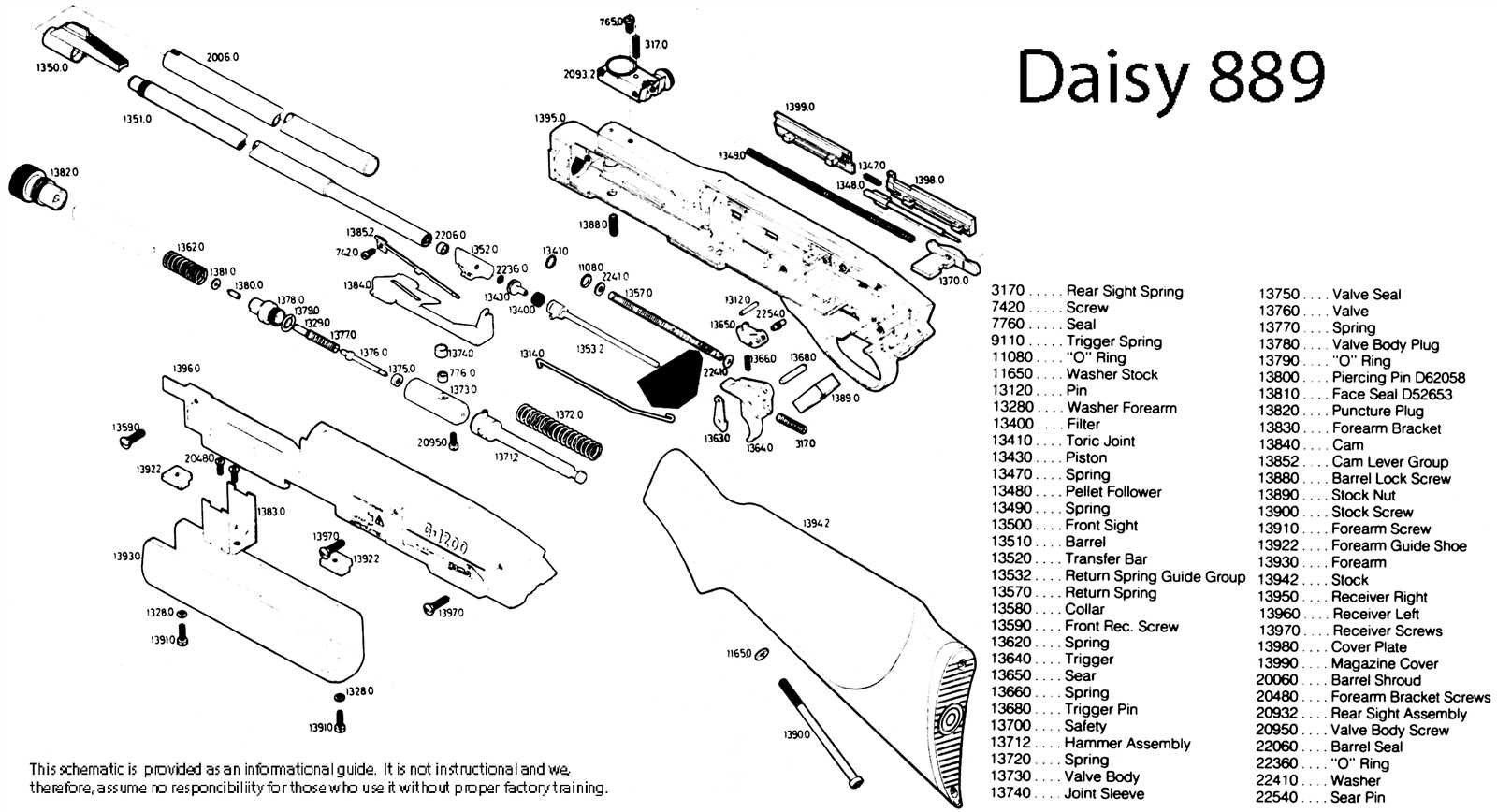

Components Overview of the Airgun Model

This section provides a comprehensive examination of the essential elements that constitute a specific airgun model, highlighting the intricate assembly and interrelationships between various components. Understanding these elements is crucial for effective maintenance and repair.

The following list outlines the primary components typically found in this model:

- Trigger Mechanism

- Barrel Assembly

- Spring System

- Receiver Housing

- Loading Chamber

- Sights

- Stock

- Safety Catch

Each component plays a vital role in the overall functionality of the airgun, and familiarity with their design will assist users in understanding how to operate and troubleshoot the device effectively.

For further insights, detailed schematics and assembly instructions are often available in user manuals or online resources, which can serve as valuable references for both novice and experienced users alike.

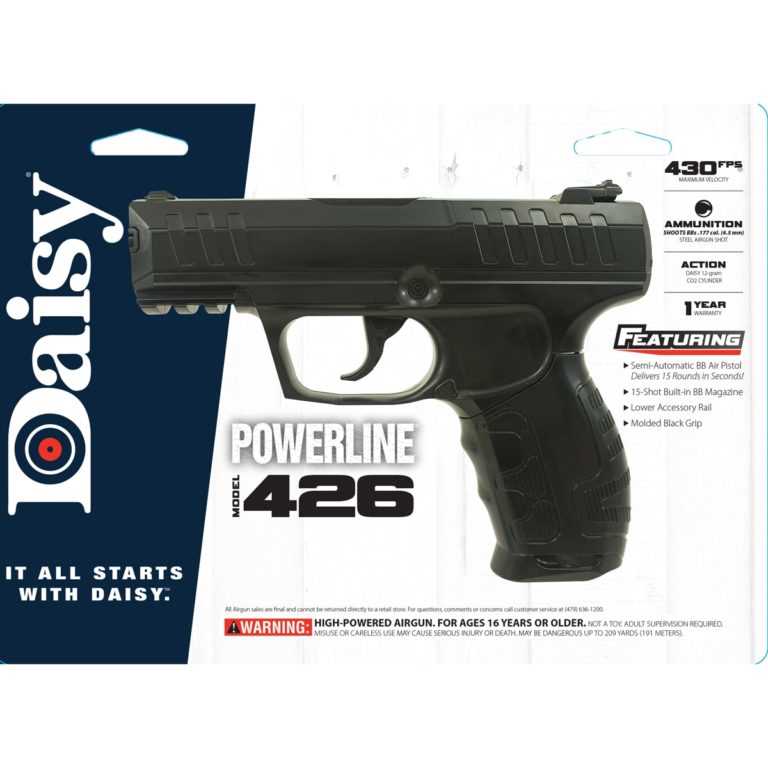

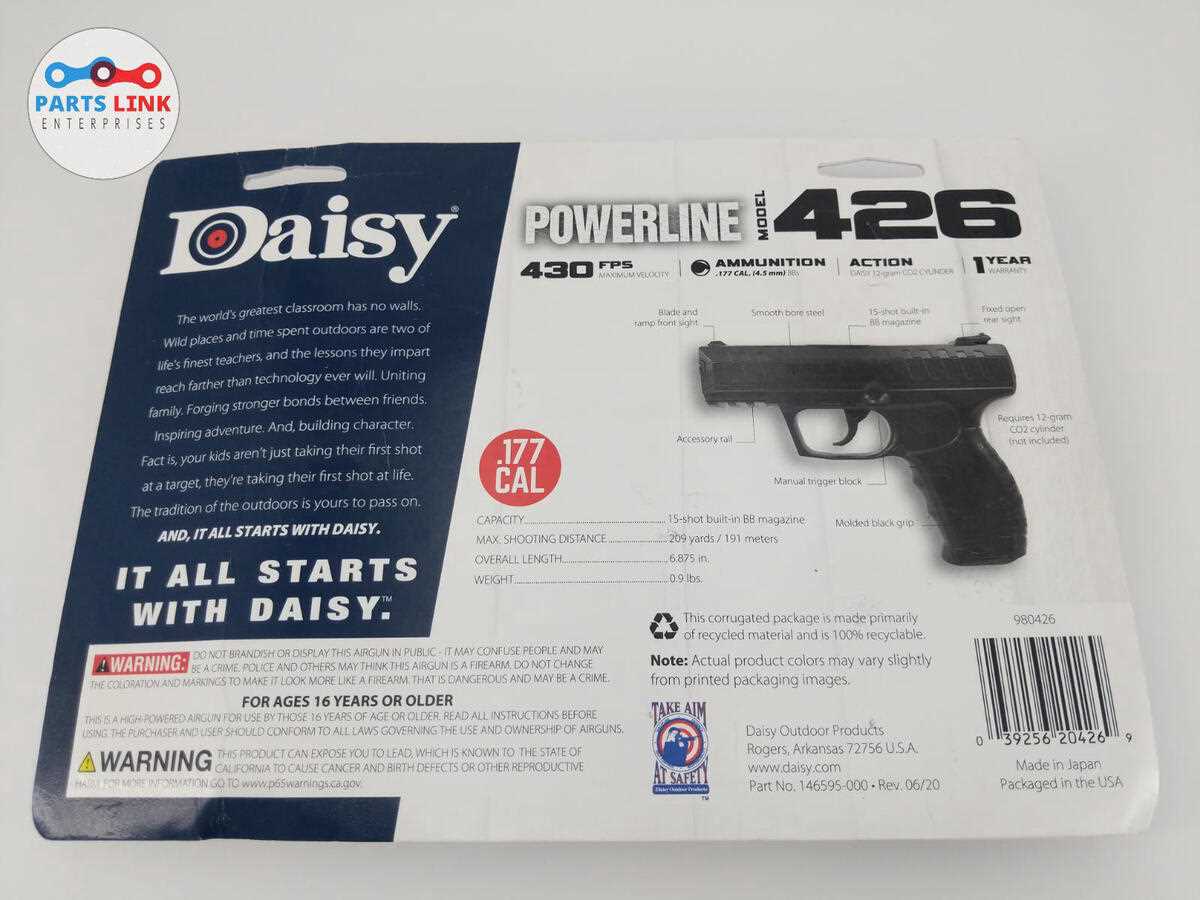

Understanding the Powerline 426 Mechanism

The intricate workings of this air-powered device reveal a fascinating blend of engineering and design. By examining its core components, users can gain insights into how it operates efficiently. Understanding the mechanism enhances the appreciation of its functionality and performance in various applications.

Core Components

At the heart of this device lies a series of essential elements that work in unison to facilitate its operation. Each part plays a significant role, contributing to the overall effectiveness and reliability of the system.

| Component | Function |

|---|---|

| Trigger | Initiates the firing sequence by releasing air pressure. |

| Cylinder | Holds the air and propels the projectile when triggered. |

| Valve | Regulates the airflow to maintain optimal pressure. |

| Barrel | Guides the projectile toward the target with precision. |

Operational Mechanism

The interaction between these components ensures smooth functionality. When the trigger is engaged, it opens the valve, allowing pressurized air from the cylinder to push the projectile through the barrel. This seamless process exemplifies the principles of pneumatics, showcasing the balance of power and control within the system.

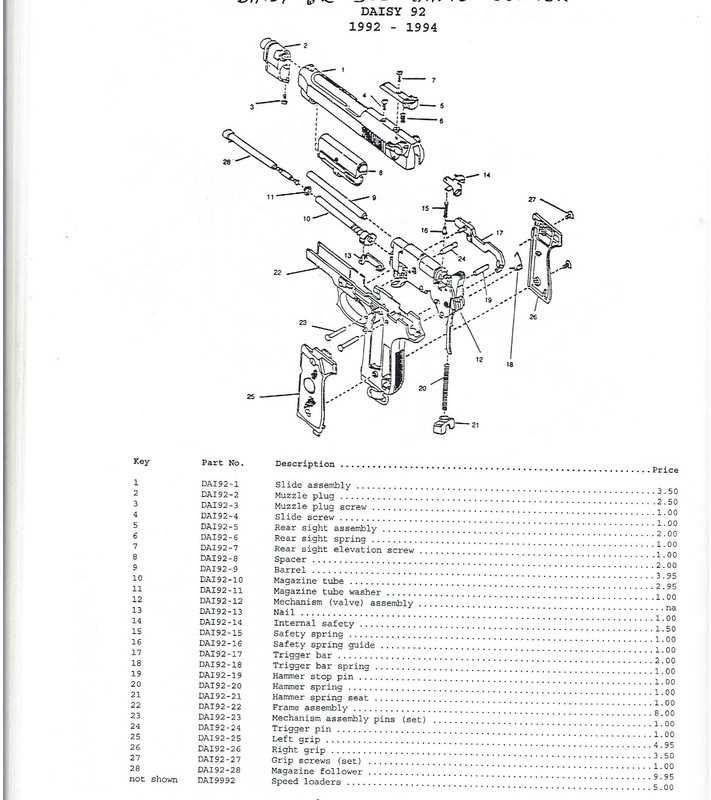

Key Components of Daisy Powerline

This section outlines the essential elements that constitute a popular airgun model. Understanding these components is crucial for users aiming to enhance their shooting experience and maintain their equipment effectively.

Essential Elements

The primary components of this air weapon include the barrel, trigger mechanism, and stock. Each part plays a vital role in the overall functionality and performance of the device, ensuring accurate shots and user comfort.

Component Specifications

| Component | Description | Functionality |

|---|---|---|

| Barrel | Long cylindrical part where the projectile travels. | Ensures precision and speed of the shot. |

| Trigger Mechanism | System that activates the release of the projectile. | Controls the timing and pressure needed to fire. |

| Stock | The part held against the shoulder when aiming. | Provides stability and comfort during use. |

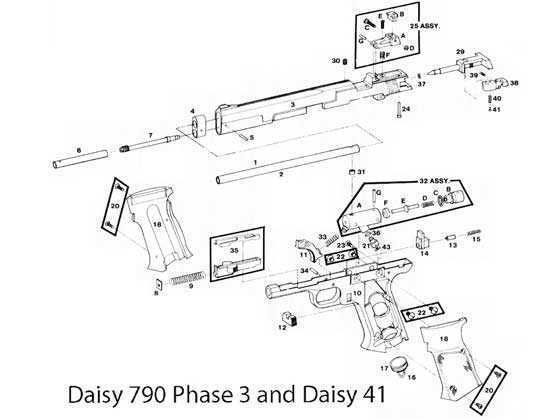

Assembly Instructions for Powerline 426

To successfully assemble your air-powered device, it is essential to follow a systematic approach. Each component plays a vital role in ensuring optimal performance, so attention to detail during the assembly process is crucial. Below are detailed steps to guide you through the assembly.

Required Components

- Trigger mechanism

- Barrel

- Receiver

- Stock

- Sealing elements

- Fasteners

Assembly Steps

- Start by connecting the receiver to the stock, ensuring the alignment is precise.

- Secure the connection using the provided fasteners. Tighten them firmly, but avoid overtightening to prevent damage.

- Attach the barrel to the front of the receiver. Make sure it fits snugly and is correctly oriented.

- Install the trigger mechanism by sliding it into the designated slot in the receiver. Ensure it moves freely.

- Insert the sealing elements in their respective positions to prevent air leakage.

- Conduct a final inspection of all connections and components to confirm that everything is secure and properly aligned.

Following these instructions will help ensure your assembly is successful and that your device functions as intended. Always consult the manufacturer’s guidelines for any specific requirements or additional details related to the assembly process.

Common Issues and Solutions

When working with air-powered mechanisms, users may encounter various challenges that can hinder performance. Identifying these common issues and applying effective solutions is essential for maintaining optimal functionality and ensuring a satisfying experience. Below are some frequently encountered problems along with practical resolutions.

Frequent Challenges

- Air Leaks: Inadequate sealing can lead to loss of pressure, affecting power.

- Misalignment: Components that are not properly aligned may result in reduced accuracy and efficiency.

- Jamming: Obstructions in the mechanism can cause it to jam, preventing operation.

- Inconsistent Performance: Variability in shooting speed or power may indicate underlying issues.

Effective Resolutions

- Addressing Air Leaks: Regularly inspect seals and connections. Replace damaged parts to ensure a tight fit.

- Realigning Components: Adjust and secure all parts to ensure they are correctly positioned for smooth operation.

- Clearing Jams: Carefully disassemble the mechanism, remove any debris, and reassemble it to restore functionality.

- Troubleshooting Performance: Check for obstructions, and ensure proper maintenance practices are followed, including regular cleaning and lubrication.

Replacement Parts Availability

Access to essential components is crucial for maintaining the functionality and longevity of your equipment. Whether you’re a casual user or a dedicated enthusiast, having a reliable source for these items ensures that your device remains in optimal working condition. Various vendors offer a wide range of replacements that cater to different needs and specifications.

Where to Find Components

Numerous retailers, both online and in physical stores, specialize in supplying necessary elements for maintenance. Websites dedicated to outdoor gear, sporting goods, or specialty tool shops typically carry an inventory of parts suitable for a variety of models. Additionally, manufacturers often provide direct options for acquiring the necessary components, ensuring compatibility and quality.

Considerations for Purchasing

When looking for replacements, it is essential to verify that the items meet the required specifications for your equipment. Check compatibility, read customer reviews, and consider purchasing from reputable suppliers to avoid issues. Quality assurance is key to ensuring that the parts perform as intended and extend the life of your device.

Tools Needed for Maintenance

Regular upkeep of your equipment is essential to ensure its optimal performance and longevity. Having the right tools at your disposal can significantly simplify the maintenance process. Below is a list of essential instruments that will assist you in effectively servicing your device.

1. Screwdriver Set: A variety of screwdrivers is crucial for loosening and tightening screws, allowing for easy access to internal components.

2. Cleaning Brushes: These are important for removing debris and dirt from sensitive areas, ensuring that the mechanism operates smoothly.

3. Lubricants: Proper lubrication is necessary to minimize friction and wear on moving parts. Be sure to use suitable products to avoid damaging components.

4. Pliers: A good pair of pliers can help grip and manipulate small parts, making adjustments easier during maintenance.

5. Safety Goggles: Protecting your eyes while performing maintenance tasks is vital. Always wear goggles to safeguard against dust and debris.

Equipping yourself with these tools will help facilitate a thorough maintenance routine, contributing to the efficiency and reliability of your device.

Exploring the Safety Features

Understanding the safety mechanisms incorporated into air-powered shooting devices is essential for ensuring a secure and responsible usage experience. These features are designed to minimize the risk of accidents and promote safe handling practices. By examining these elements, users can gain valuable insights into the operational safety of their equipment.

Integrated Safety Mechanisms

One of the fundamental aspects of safe operation is the inclusion of various integrated safety mechanisms. These may encompass features such as automatic safety catches that prevent accidental discharge and trigger locks that require intentional action to activate the shooting mechanism. Such innovations not only enhance user confidence but also help in preventing unintended incidents.

Proper Handling and Maintenance

In addition to built-in safety features, the importance of proper handling and routine maintenance cannot be overstated. Users should familiarize themselves with the operational guidelines and adhere to recommended maintenance practices. Regular inspections and timely servicing ensure that all safety features function correctly, thereby extending the lifespan of the device while prioritizing user safety.

Importance of Regular Inspections

Conducting frequent evaluations of equipment and mechanisms is crucial for ensuring their optimal performance and longevity. Regular assessments help identify potential issues before they escalate, allowing for timely interventions. These inspections are integral to maintaining functionality and safety, thereby enhancing overall user experience.

Benefits of Consistent Evaluations

Implementing routine inspections offers numerous advantages:

- Early Problem Detection: Spotting minor faults early prevents them from developing into major malfunctions.

- Improved Safety: Regular checks ensure that all components operate safely, reducing the risk of accidents.

- Increased Lifespan: Proper maintenance through evaluations extends the operational life of the equipment.

- Cost Efficiency: Identifying issues early can save significant repair costs in the long run.

Best Practices for Inspections

To maximize the benefits of evaluations, consider the following practices:

- Schedule inspections at regular intervals based on usage frequency.

- Document findings and actions taken during each evaluation.

- Involve qualified personnel in the inspection process to ensure thoroughness.

- Keep a checklist of critical components to assess during inspections.

By adhering to these practices, users can significantly enhance the reliability and performance of their equipment.

Identifying Compatible Accessories

When considering enhancements for your airgun, understanding which supplementary items are suitable can significantly improve your shooting experience. It is essential to identify components that not only fit correctly but also enhance performance and safety. By doing so, users can ensure optimal functionality and reliability while engaging in their shooting activities.

Evaluating Compatibility

To determine compatibility, begin by researching specifications and features of your device. Look for information regarding the type of accessories designed for your model, including scopes, grips, and mounts. Cross-reference with manufacturer guidelines and user reviews to gain insight into which accessories work best and offer a seamless integration.

Popular Accessories to Consider

Commonly sought-after enhancements include optical sights, tactical lights, and upgraded grips. Each of these can provide distinct advantages, such as improved accuracy or enhanced control. Ensure that any accessory you consider is compatible with your specific model to avoid installation issues or performance setbacks.

Cleaning and Care Guidelines

Maintaining the functionality and appearance of your equipment is essential for its longevity and optimal performance. Regular cleaning and proper care not only enhance the user experience but also prevent potential malfunctions. Here are some recommended practices to ensure your device remains in excellent condition.

Routine Cleaning Procedures

- Always ensure the device is turned off and unloaded before cleaning.

- Use a soft, lint-free cloth to wipe down the exterior surfaces, removing any dust or residue.

- For stubborn spots, slightly dampen the cloth with water or a mild detergent, avoiding harsh chemicals.

- Pay attention to the barrel and sight; these components should be free of obstructions and grime.

Storage Recommendations

- Store the device in a dry, cool place away from direct sunlight and humidity.

- Consider using a protective case or sleeve to prevent scratches and other damage.

- Before long-term storage, ensure the device is clean and free from moisture.

- Regularly check the condition of any seals and O-rings to maintain performance.

Following these guidelines will help maintain your equipment’s functionality, ensuring it remains reliable for your future activities.

Technical Specifications Overview

This section provides a comprehensive examination of the technical details related to the specified model. Understanding these specifications is essential for users seeking to grasp the capabilities and features that define its performance and usability.

Key Features

- Caliber: The size of the projectile used, which significantly affects the power and accuracy.

- Muzzle Velocity: The speed at which the projectile exits the barrel, impacting range and impact force.

- Action Type: The mechanism through which the weapon is operated, influencing both user experience and functionality.

- Feed System: Describes how the projectiles are loaded and fired, affecting ease of use and maintenance.

Performance Metrics

- Effective Range: The distance at which the device can accurately hit a target.

- Energy Output: Measured in foot-pounds, indicating the force delivered to the target.

- Weight: The overall weight of the device, affecting portability and ease of handling.

- Length: The total length of the apparatus, which may impact maneuverability.

In summary, grasping these technical specifications is crucial for any user looking to utilize the model effectively, ensuring an informed choice for various applications.