| Component |

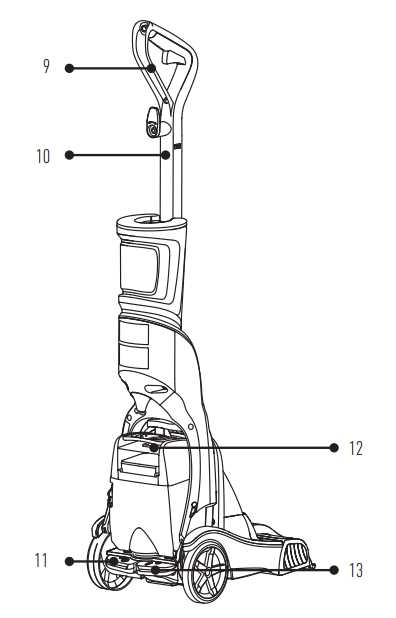

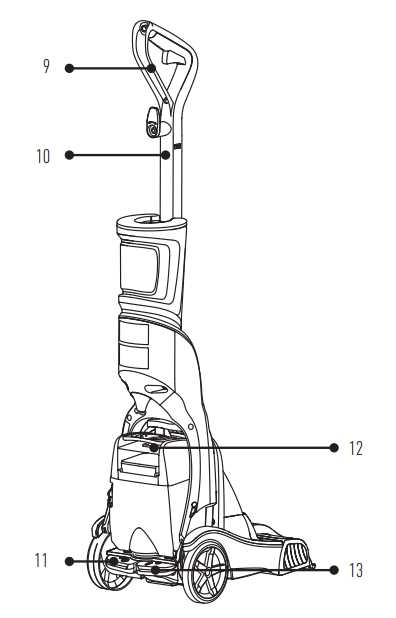

Key Components of the Hoover PowerDash Pet

The cleaning system of this device is made up of several crucial elements that work together to provide efficient carpet and floor maintenance. These components ensure that every area is thoroughly cleaned, targeting tough spots and providing deep cleaning performance.

Motor and Suction Mechanism

The motor is the heart of the machine, delivering the power needed for deep cleaning. Coupled with a strong suction mechanism, it efficiently pulls up dirt and pet hair from carpets and other surfaces. Together, they ensure that even embedded grime is removed, leaving the floor spotless.

Brush Roll Technology

The rotating brush is designed to agitate the carpet fibers, loosening debris for easier extraction. This brush works in tandem with the suction system to enhance the cleaning process, especially in areas that experience heavy foot traffic. It also aids in lifting away stubborn stains and dirt.

How the Cleaning Mechanism Works

The cleaning system operates through a combination of key components that work together to ensure thorough dirt and debris removal. The system is designed to handle various surfaces, efficiently lifting dirt while maintaining a deep cleaning process.

Brush Roll Functionality: The rotating brush is an essential part of the system. It agitates carpet fibers, loosening dirt and pet hair embedded deep within. As the brush rotates, it helps lift particles that are difficult to reach with suction alone.

Suction Power: After the brush has dislodged the dirt, the vacuum’s suction mechanism pulls the loosened debris into the collection unit. The powerful airflow ensures that even fine particles are captured, leaving surfaces clean and refreshed.

Water and Cleaning Solution: The cleaning mechanism also incorporates a water and cleaning solution dispenser. When activated, this mixture is applied to the surface being cleaned, helping

Guide to Replacing Brushes

Maintaining the cleaning performance of your vacuum is crucial for optimal results. One of the most important components that requires periodic attention is the brush system. Over time, these brushes wear down and need to be replaced to ensure the device continues to function effectively. This guide will walk you through the steps of replacing them, helping you restore full efficiency.

Step 1: Accessing the Brush Roll

The first step in replacing the brushes is to safely access the brush roll. Make sure to unplug the vacuum before starting. Turn the device over to expose the bottom side where the brush is located. Typically, you will need to unscrew the plate or cover that holds the brush in place.

Step 2: Installing the New Brush

Once you have removed the old brush, it’s time to install the new one. Align it correctly in its housing, ensuring

Water Tank System Explained

The water tank system plays a critical role in ensuring efficient operation and functionality. It is designed to manage both clean and dirty water during the cleaning process, keeping the system organized and simple to maintain.

This system typically consists of separate compartments to handle different stages of the water cycle. By keeping the clean and used water separate, it enhances the overall cleaning efficiency and prevents contamination.

- Clean water is stored in one compartment for use during cleaning.

- Dirty water is collected in another section to prevent mixing with the clean supply.

- The tank is easy to remove and empty for routine maintenance.

- The design promotes easy handling and quick refilling during extended use.

Understanding how the water tank system works can

Troubleshooting the Suction Function

Ensuring optimal performance from your cleaning device requires attention to various components responsible for effective debris removal. When suction issues arise, identifying the root cause is essential to restore functionality and achieve satisfactory cleaning results.

Common Causes of Reduced Suction

Several factors can lead to diminished suction power. One of the primary reasons is a clogged hose or filter, which can restrict airflow and impede performance. Additionally, if the collection container is full or not properly seated, it may prevent the machine from functioning efficiently. Regular maintenance and inspection of these components can significantly enhance performance.

Steps to Restore Suction

To address suction problems, first inspect the hose for blockages. Detach it from the main unit and check for any obstructions that may hinder airflow. Next, examine the filter; if it appears dirty or damaged, clean or replace it as necessary. Ensure that the collection bin is emptied and correctly positioned. Performing these checks can often resolve suction issues and improve overall cleaning efficiency.

Maintaining the Filter for Longevity

Regular upkeep of the filtration system is essential for enhancing its lifespan and ensuring optimal performance. By following a few simple practices, users can significantly improve the efficiency of their cleaning device and prolong the life of its components. Proper maintenance not only helps in maintaining suction power but also reduces the need for frequent replacements.

Cleaning Frequency

Establishing a routine for cleaning the filter is crucial. It is advisable to inspect the filter after every few uses and clean it as needed. Depending on the frequency of use and the type of debris collected, some filters may require more attention. Ensuring that the filter is free from dirt and blockages will enhance airflow and maintain suction effectiveness.

Replacement Considerations

In addition to regular cleaning, it is vital to be aware of when to replace the filter. Most manufacturers provide guidelines on how long filters should last based on usage. If users notice a decline in performance even after cleaning, it may be time to consider a replacement. Keeping track of the filter’s condition will ensure that the device continues to function efficiently.

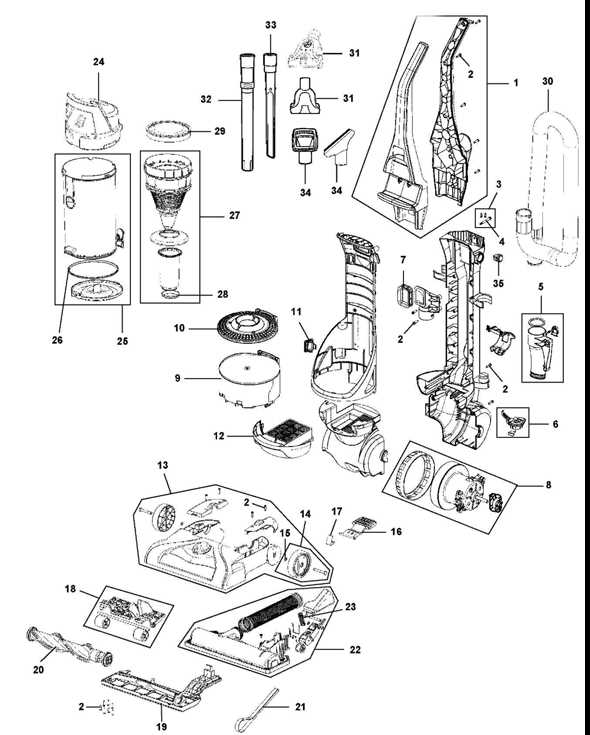

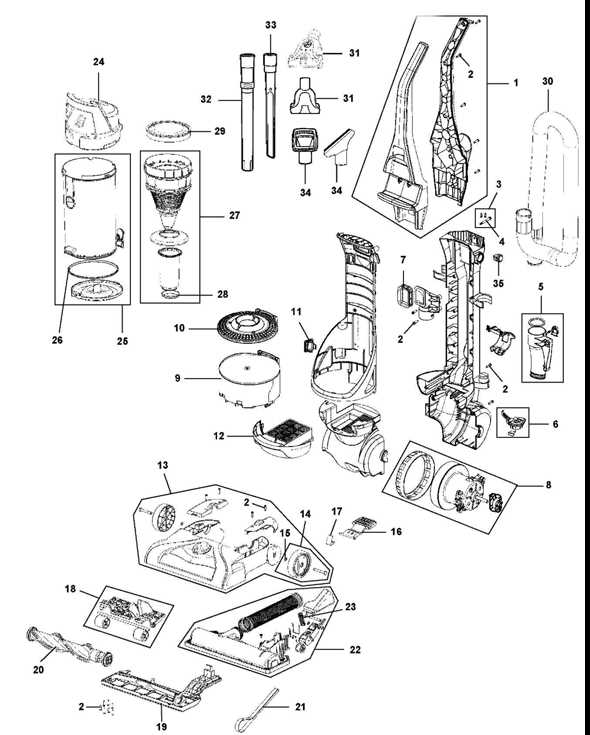

Assembly and Disassembly Process

The process of putting together and taking apart a cleaning device is essential for effective maintenance and repairs. Understanding the steps involved can significantly enhance the user experience, allowing for a smoother operation and prolonged longevity of the equipment.

To successfully assemble or disassemble the unit, follow these guidelines:

- Ensure the device is unplugged and cool before starting.

- Gather necessary tools such as a screwdriver and a soft cloth.

- Follow the steps below to disassemble:

- Start by removing the main housing by unscrewing the designated screws.

- Detach the filter and dust container for thorough cleaning.

- Carefully take out any additional components that may require attention.

For reassembly, adhere to the following:

- Place the cleaned components back in their original positions.

- Secure the housing by tightening the screws firmly.

- Reconnect any accessories that were detached during disassembly.

By following these steps, users can ensure their cleaning device functions optimally and is maintained in excellent condition.

Motor and Electrical Parts Overview

This section delves into the essential components that drive the functionality of cleaning appliances. Understanding these elements is crucial for effective maintenance and troubleshooting. The intricate relationship between the motor and electrical components determines the efficiency and performance of the device.

Key Electrical Components

Electrical components are vital for the operation of any cleaning machine. The wiring harness connects various parts, facilitating the flow of electricity. Additionally, the switch mechanism allows users to control the power supply, ensuring convenience during operation. Capacitors play a significant role in managing the energy stored for the motor’s performance, while fuses safeguard the system by preventing overloads.

Motor Functionality

The motor is the heart of the device, converting electrical energy into mechanical energy to create suction and movement. Its design often includes various features, such as brushes and bearings, which contribute to smooth operation and longevity. Proper care and attention to these components can greatly enhance the overall efficiency of the cleaning appliance.

Understanding the Nozzle and Hose Design

The design of the nozzle and hose in cleaning devices plays a crucial role in enhancing the efficiency of dirt removal and overall performance. These components are engineered to optimize airflow and facilitate the seamless transfer of debris, ensuring a thorough cleaning experience. Understanding their structure and function can help users appreciate how these elements contribute to effective cleaning tasks.

Key Features of the Nozzle

The nozzle is typically designed with specific shapes and sizes to accommodate various surfaces and types of dirt. Its configuration allows for effective suction while minimizing blockages. Additionally, some models feature adjustable settings, enabling users to switch between different cleaning modes. This adaptability enhances performance across diverse cleaning scenarios, from carpets to hard floors.

Importance of Hose Design

The hose serves as a vital link between the cleaning device and the surface being cleaned. Its length and flexibility are critical in reaching tight spaces and corners, ensuring no area is left untouched. Moreover, a well-designed hose minimizes the risk of tangling and kinking, promoting a smooth cleaning experience. The materials used in the hose construction also play a significant role in durability and ease of handling.

How to Properly Care for Attachments

Maintaining cleaning tool accessories is essential for ensuring their longevity and optimal performance. Regular upkeep not only enhances their effectiveness but also prolongs their lifespan, allowing for a more efficient cleaning experience. Understanding the proper techniques for caring for these attachments will help users maximize their investment.

Here are some key practices to consider for effective maintenance:

| Maintenance Task |

Frequency |

Tips |

| Cleaning Brushes |

After every use |

Remove hair and debris; wash with warm soapy water. |

| Inspecting Hoses |

Monthly |

Check for blockages and wear; clean if necessary. |

| Storing Attachments |

After each use |

Keep in a dry place; avoid direct sunlight to prevent warping. |

| Replacing Worn Parts |

As needed |

Monitor for signs of wear and replace promptly. |

By following these practices, users can ensure that their cleaning attachments remain in excellent condition, providing reliable performance whenever needed. Regular maintenance contributes to better cleaning results and a more pleasant experience overall.