In the realm of high-pressure mechanisms, a comprehensive understanding of the individual elements is crucial for optimal functionality and maintenance. Each component plays a specific role in ensuring the system operates efficiently, contributing to the overall performance and longevity of the equipment. This section delves into the intricacies of these vital elements, providing clarity on their interconnections and significance.

The exploration of these components not only aids in troubleshooting and repairs but also enhances the user’s ability to maximize the effectiveness of their machinery. By familiarizing oneself with the layout and function of each part, operators can better anticipate potential issues and address them proactively. Knowledge of the configuration empowers users to make informed decisions regarding maintenance and upgrades.

Furthermore, understanding how these pieces interact with one another helps in grasping the overall mechanics at play. Recognizing the relationship between the various sections can lead to improved performance, as well as a deeper appreciation of the engineering that underlies modern pressure systems. This insight fosters a more effective approach to both routine care and emergency responses, ensuring that equipment remains in peak condition.

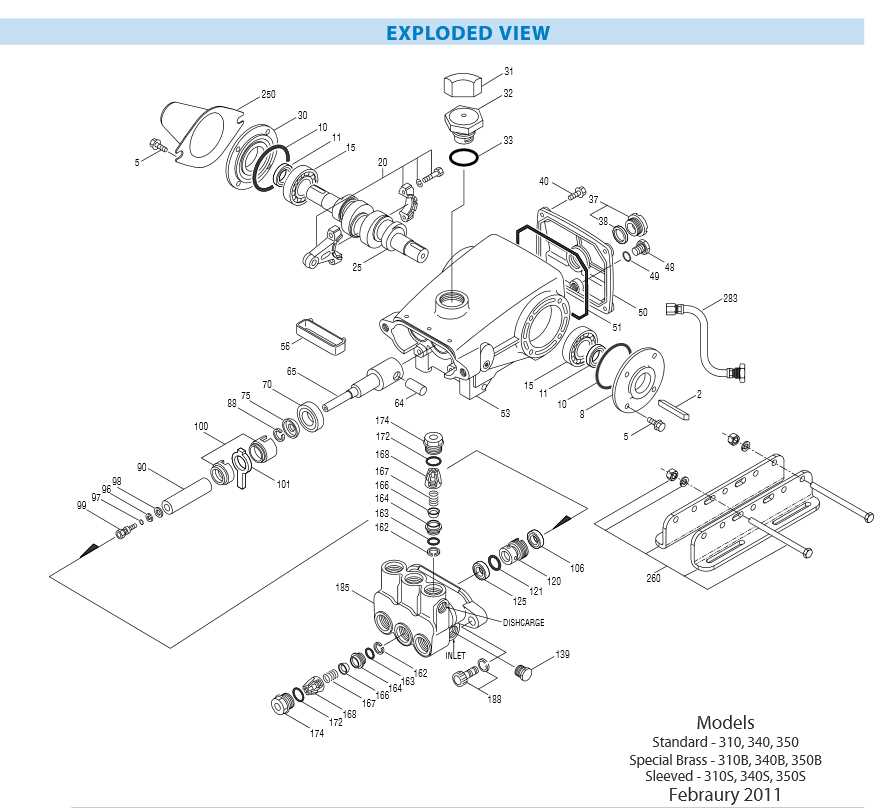

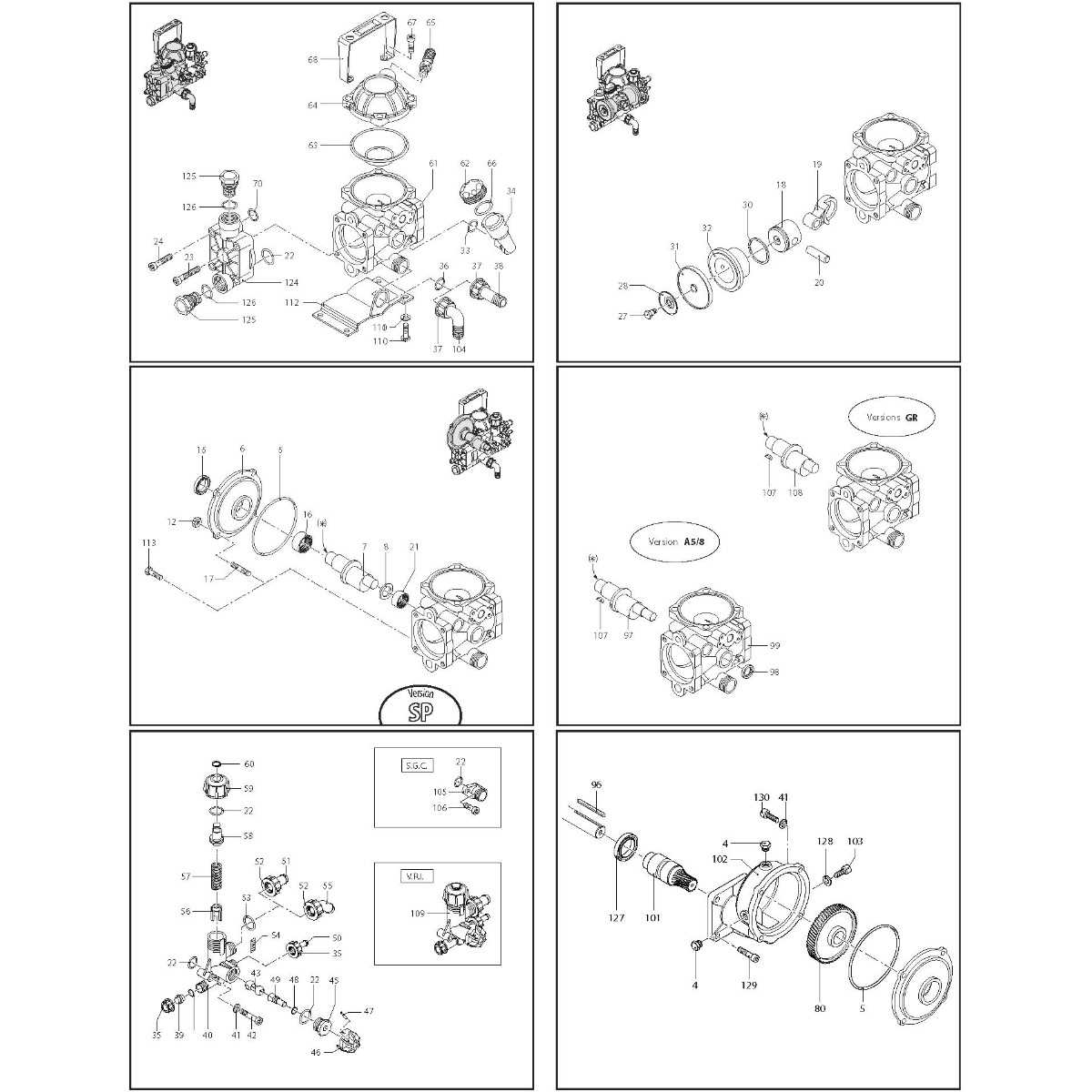

Annovi Reverberi Pump Parts Overview

This section provides a comprehensive look at the various components that make up high-pressure equipment designed for efficiency and durability. Understanding these elements is crucial for maintenance and optimal performance.

Key Components

- Motor: The driving force behind the system, converting electrical energy into mechanical power.

- Pistons: Essential for creating the pressure necessary for effective operation.

- Valves: Regulate the flow and ensure proper distribution of fluids.

- Seals: Prevent leaks and maintain system integrity.

- Crankshaft: Transforms rotational motion into the linear motion needed for pumping.

Maintenance Considerations

- Regular Inspection: Check for wear and tear on critical components.

- Lubrication: Ensure all moving parts are adequately lubricated to prevent friction.

- Replacement Schedule: Keep track of parts that need to be replaced periodically to avoid breakdowns.

- Cleaning: Maintain cleanliness to enhance performance and longevity.

By familiarizing yourself with these essential elements and their upkeep, you can significantly improve the efficiency and lifespan of your high-pressure equipment.

Understanding Pump Functionality

Grasping the workings of fluid-moving devices is crucial for effective maintenance and optimal performance. These mechanisms rely on various components that interact seamlessly to facilitate fluid transfer, ensuring efficiency in a wide range of applications.

Key elements influencing their operation include:

- Input Mechanism: Initiates the flow of liquid.

- Compressor: Increases the pressure to move fluids through the system.

- Discharge Outlet: Directs the fluid to its destination.

- Seals and Gaskets: Prevent leaks and maintain pressure.

Understanding these components allows users to troubleshoot issues and enhance the longevity of the device.

Common Components of AR Pumps

Understanding the essential elements of high-pressure machinery is crucial for effective maintenance and operation. Each component plays a significant role in ensuring optimal functionality and performance. Here, we will explore the typical features that make up these machines, highlighting their importance and interconnectivity.

| Component | Description |

|---|---|

| Housing | The outer shell that provides protection and structural integrity to the internal components. |

| Pistons | Movable parts that create pressure by compressing the fluid within the cylinder. |

| Valves | Devices that control the flow of fluid in and out, ensuring proper operation during cycles. |

| Seals | Gaskets or O-rings that prevent leaks and maintain pressure within the system. |

| Crankshaft | A rotating component that converts linear motion into rotational energy, driving the pistons. |

Familiarity with these integral components enables users to troubleshoot issues effectively and perform routine maintenance, ultimately extending the lifespan of the machinery.

Importance of Regular Maintenance

Consistent upkeep is crucial for the longevity and efficiency of any mechanical system. By adhering to a routine maintenance schedule, users can prevent unexpected breakdowns and costly repairs, ensuring smooth operation over time.

Benefits of Routine Upkeep

- Enhances Performance: Regular check-ups keep systems functioning optimally.

- Extends Lifespan: Timely interventions prevent wear and tear, prolonging equipment life.

- Reduces Costs: Proactive care can significantly lower repair expenses.

- Improves Safety: Well-maintained systems pose fewer risks to operators.

Key Maintenance Practices

- Regular Inspections: Schedule routine assessments to identify potential issues.

- Cleaning Components: Remove debris and buildup to maintain efficiency.

- Replacing Worn Parts: Swap out any deteriorating elements before they cause problems.

- Monitoring Performance: Keep an eye on functionality and make adjustments as needed.

How to Identify Wear and Tear

Recognizing signs of deterioration is essential for maintaining optimal performance in any mechanical system. Over time, components may experience fatigue, leading to reduced efficiency and potential failures. By understanding the key indicators of wear, operators can proactively address issues and extend the lifespan of their equipment.

First, inspect the surface of each component for visible damage, such as cracks, abrasions, or discoloration. These imperfections often signal excessive friction or improper alignment. Additionally, pay attention to any unusual noises during operation, as sounds like grinding or rattling may indicate internal damage.

Another important factor to consider is performance inconsistency. If the machinery operates below expected standards or exhibits erratic behavior, it may be a sign that certain elements are wearing out. Regularly monitoring operational metrics can help in identifying such discrepancies early.

Lastly, check for leaks or fluid degradation. Leaking substances or changes in viscosity can compromise the functionality of the entire system. Maintaining a routine inspection schedule will allow for timely intervention, ultimately preserving the integrity of your equipment.

Step-by-Step Repair Guide

This section provides a detailed procedure for fixing common issues in hydraulic devices. By following these structured steps, users can effectively troubleshoot and restore functionality to their equipment.

| Step | Description |

|---|---|

| 1 | Identify the problem by observing any irregular behavior or performance issues. |

| 2 | Gather necessary tools and replacement components to ensure a smooth repair process. |

| 3 | Carefully disassemble the unit, taking note of the arrangement and condition of each element. |

| 4 | Inspect all components for wear, damage, or blockages that may require attention. |

| 5 | Replace any faulty parts with new or refurbished items, ensuring compatibility. |

| 6 | Reassemble the device, confirming that all components are securely fitted and in proper order. |

| 7 | Conduct tests to verify that the repair was successful and the equipment operates correctly. |

Finding Replacement Parts Easily

Locating suitable components for machinery can be a straightforward process when you know where to look. By leveraging reliable resources and understanding your equipment, you can ensure smooth operation and longevity.

Utilizing Online Resources

Many websites offer extensive catalogs and schematics that can help you identify the right components. Manufacturer websites often provide detailed information, while third-party retailers may have user-friendly interfaces for easier navigation.

Consulting Experts

Don’t hesitate to reach out to professionals who specialize in this field. Knowledgeable technicians can offer valuable insights and guidance, helping you pinpoint the ultimate solutions for your needs.

Tips for Enhancing Pump Longevity

To ensure a prolonged lifespan of your equipment, it is essential to adopt proactive measures that address maintenance and operational efficiency. By focusing on care and understanding, users can significantly reduce wear and tear, ultimately leading to better performance over time.

Regular Maintenance

Consistent upkeep is vital. Regularly check seals, lubricate moving components, and clean filters to prevent debris buildup. Following the manufacturer’s guidelines can provide a structured approach to maintenance.

Optimal Operating Conditions

Utilizing the equipment within specified parameters enhances durability. Avoid extreme temperatures and ensure the fluid used is compatible. Monitoring operational settings helps prevent unnecessary stress on the system.

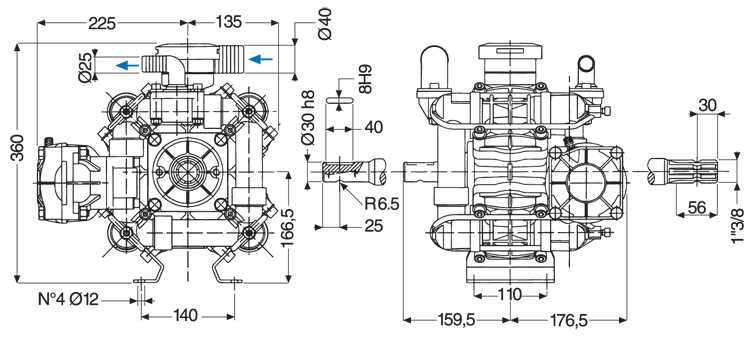

Comparing Different AR Models

In the realm of high-performance fluid transfer devices, various models stand out due to their unique features and specifications. Each version caters to specific needs and applications, making it essential to analyze their characteristics to determine the best fit for diverse tasks.

Performance Metrics play a crucial role in distinguishing between models. Some variants are designed for enhanced pressure output, while others focus on flow rate efficiency. Evaluating these aspects can help users select a model that aligns with their operational requirements.

Durability is another key factor to consider. Certain designs incorporate advanced materials and engineering techniques, providing greater longevity and reliability. Understanding the construction and components used can guide potential buyers in making informed decisions.

Additionally, maintenance and serviceability differ among models. Some options are engineered for easy upkeep, featuring accessible components that simplify routine checks and repairs. Others may require more specialized knowledge, which can impact operational downtime and overall efficiency.

Finally, cost-effectiveness is vital in comparing these devices. While some models may have a higher upfront investment, their operational efficiency and longevity could yield significant savings over time. Weighing initial costs against long-term benefits is essential for any prospective user.

Common Issues and Troubleshooting

Understanding typical challenges that arise with hydraulic equipment is essential for maintaining optimal performance. This section explores frequent problems users encounter and offers practical solutions to enhance functionality and extend lifespan.

Low Pressure: If the unit fails to deliver adequate pressure, check for blockages in hoses and filters. Ensure that all connections are secure and that there are no leaks in the system.

Noisy Operation: Unusual sounds during operation may indicate wear or lack of lubrication. Inspect moving components for damage and apply appropriate lubricants as needed.

Inconsistent Performance: Fluctuations in output can stem from air in the system or a malfunctioning valve. Bleed the system to remove trapped air and examine the valve for proper function.

Overheating: If overheating occurs, verify that the cooling system is functioning properly. Ensure adequate airflow and inspect for any obstructions that could impede cooling.

Excessive Vibration: This may signal misalignment or imbalance in components. Regularly check alignment and balance to mitigate these issues and ensure smooth operation.

Resources for Further Learning

To deepen your understanding of hydraulic systems and their components, a variety of valuable resources are available. Engaging with these materials can enhance your knowledge and proficiency in maintaining and troubleshooting these mechanisms.

- Books:

- Hydraulics and Pneumatics: A Technician’s and Engineer’s Guide – A comprehensive text covering fundamentals and advanced concepts.

- Fluid Power Engineering – This book provides an in-depth exploration of fluid dynamics and its applications.

- Online Courses:

- Websites:

- Hydraulics & Pneumatics – A resource for articles, case studies, and industry news.

- Fluid Power World – Provides insights and trends related to fluid power technology.

- Forums and Communities:

- Engineering Toolbox – A platform for discussing various engineering challenges and solutions.

- Reddit Engineering – A community where enthusiasts share experiences and advice.

Exploring these resources will facilitate a comprehensive understanding of the subject, enabling both novice and experienced individuals to expand their expertise.