In many fluid handling applications, a detailed overview of the internal elements is essential for both maintenance and performance optimization. Identifying the key elements and their placement can ensure smooth operation and help troubleshoot common issues. This section will explore the fundamental elements found in such systems, offering a comprehensive look at their structure and functionality.

Each element within the system plays a crucial role, working in unison to achieve efficient fluid movement. Understanding how these components interact can significantly enhance the longevity and reliability of the entire system. Here, we will break down these vital components, focusing on their purpose and how they integrate with each

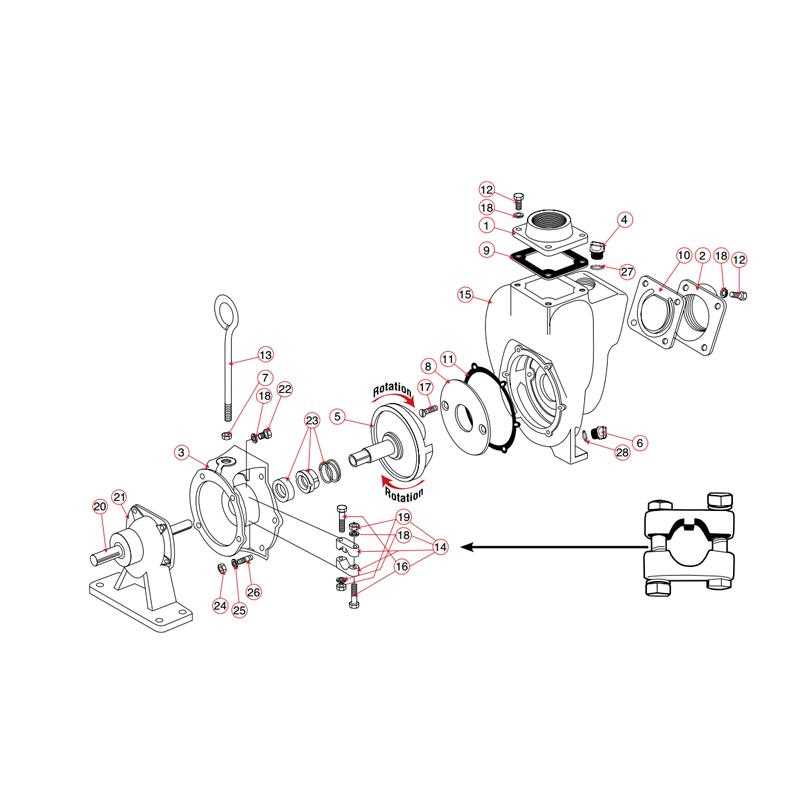

Banjo Pump Parts Diagram Overview

This section provides a comprehensive breakdown of the individual elements that contribute to the overall functionality of the fluid transfer device. Understanding how these components fit and work together ensures optimal performance and easier troubleshooting. By examining each segment in detail, users can gain insights into the structure and maintenance of the system.

Core Components and Their Function

The internal structure consists of various key elements designed to work in harmony. These elements ensure smooth operation by controlling flow and pressure, facilitating efficient movement of liquids through the system. Each part is engineered to withstand wear and tear, ensuring longevity and minimal downtime during operations.

Key Considerations for Maintenance

Regular inspections and upkeep of the main sections are crucial for ensuring the device runs effectively. Identifying any wear in the critical points can help prevent major malfunctions

Understanding the Key Components

The structure of a mechanical system relies on several essential elements, each playing a unique role in ensuring efficient operation. By gaining a deeper knowledge of these elements, it becomes easier to comprehend how the entire mechanism functions smoothly.

- Motor Assembly: This unit drives the motion, providing the necessary force for fluid movement or other actions within the system.

- Seals and Gaskets: These components are responsible for preventing leaks and maintaining a controlled environment within the system.

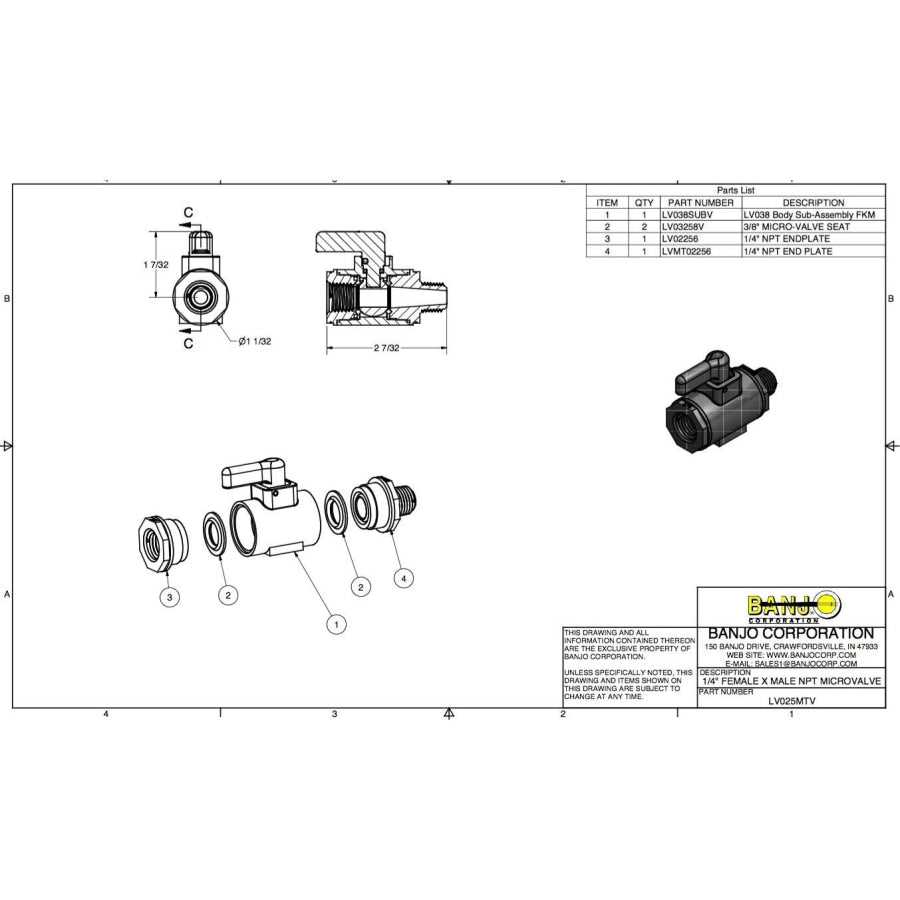

- Flow Control Valves: These elements regulate the flow rate, ensuring that the system operates within desired parameters.

- Housing:

How the Pump Mechanism Works

The internal mechanism of a liquid transfer device operates based on the movement of fluid through various channels. Its design allows the flow to be controlled efficiently while maintaining consistent pressure. Understanding this operation involves knowing the key components that drive the system and how they interact to regulate movement.

Here’s a breakdown of how the system functions:

- First, fluid enters through an inlet, where it’s directed into the primary chamber.

- Inside the chamber, rotating or reciprocating elements force the fluid forward, ensuring continuous flow.

- As the fluid moves, pressure builds, which propels it through an outlet, allowing the liquid to be transferred to the desired location.

The efficiency of this process depends on the precise alignment and synchronization of all moving parts, ensuring

Internal Structure of Banjo Pumps

The internal configuration of these devices is essential for ensuring their efficiency and reliability. By understanding the arrangement of the various elements inside, users can appreciate how each component interacts to produce optimal performance. This section will focus on the key elements that make up the core functionality, emphasizing their roles within the system.

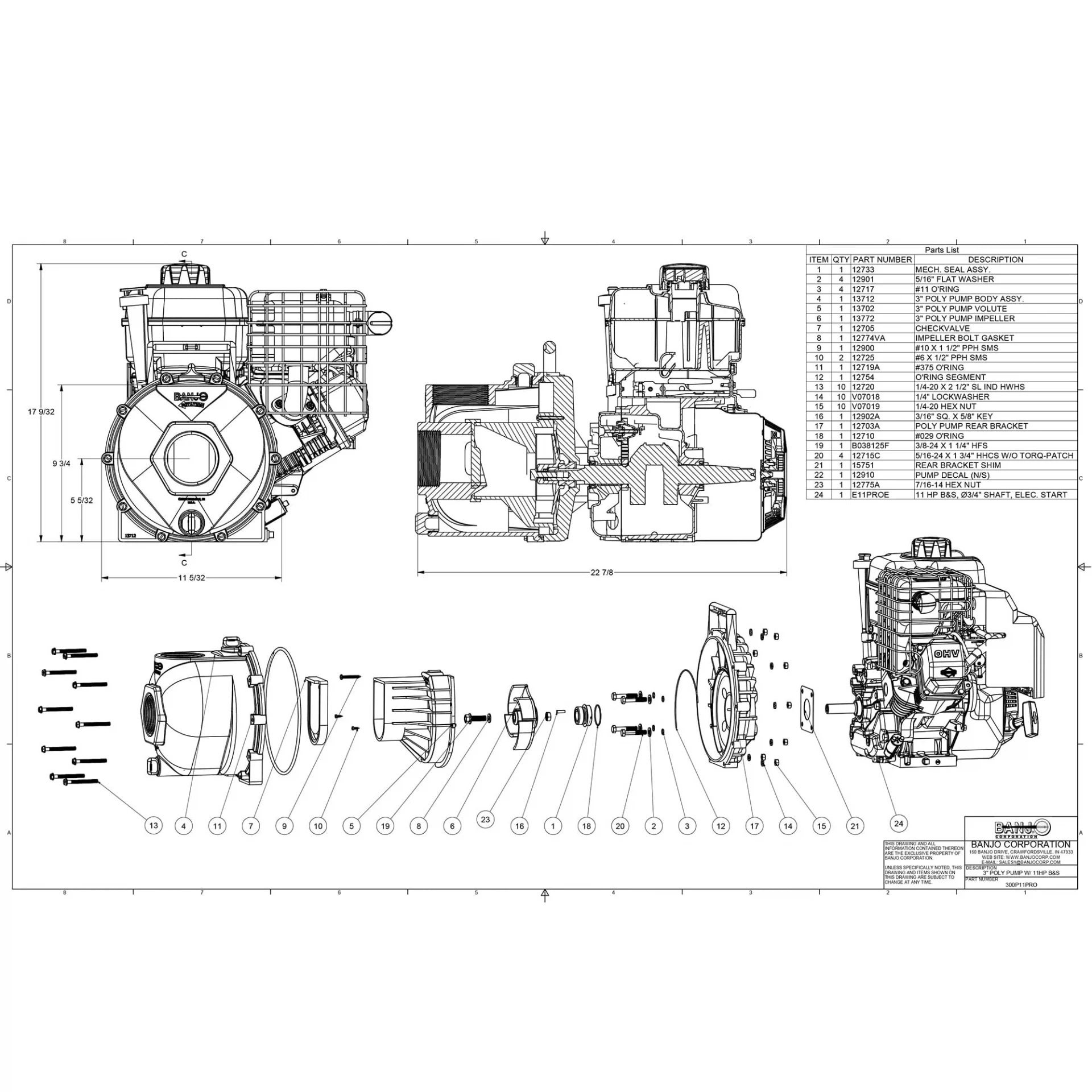

- Casing: The outer shell protects the internal components, preventing damage from external factors. It also provides structural integrity, keeping all internal parts aligned.

- Impeller: This rotating element plays a critical role in moving fluids through the system. Its design ensures that liquid is propelled efficiently from the intake to the discharge outlet.

- Shaft: The rotating shaft transfers energy from the motor to the impeller.

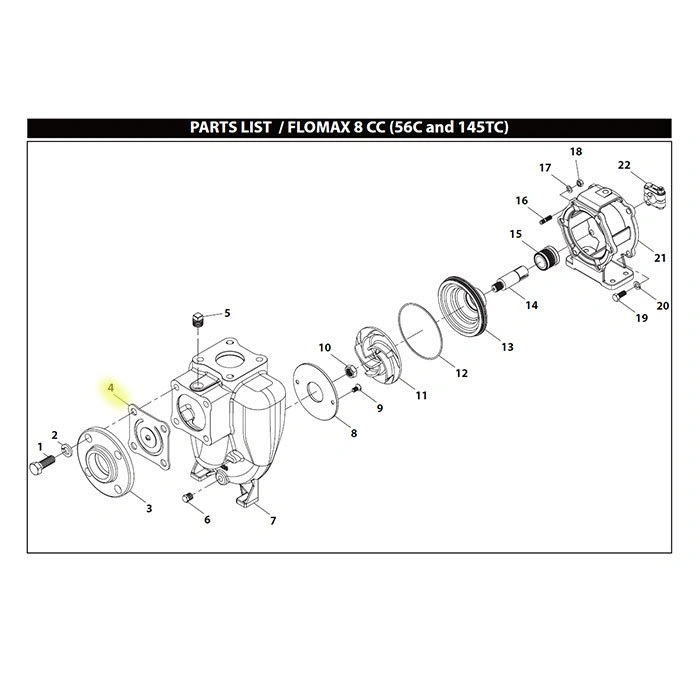

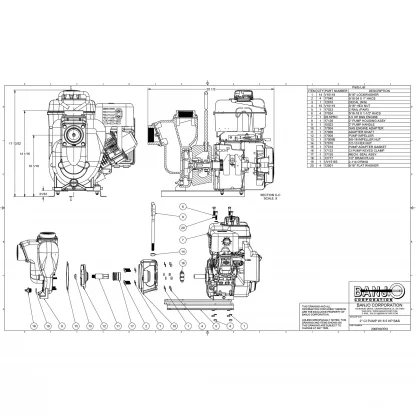

Exploded View of the Pump Assembly

In this section, we’ll delve into the detailed breakdown of the mechanical structure, showcasing how individual components fit together to form the complete unit. This visualization provides a comprehensive look at how each element interacts within the system.

Core Components: The illustration highlights the primary elements, showing their respective positions and how they are assembled into the overall system. Each section is clearly labeled to indicate its role and connection to adjacent components.

Subsections and Fastenings: Further examination of

Identifying the Main Pump Parts

Understanding the key components of a fluid transfer mechanism is essential for effective maintenance and operation. Each element plays a crucial role in ensuring efficient movement and management of liquids. Recognizing these essential elements can greatly enhance functionality and longevity.

The primary unit typically consists of several integral elements, including a housing, which provides structural support and protection for the internal mechanisms. Additionally, the impeller is vital for generating flow, while the seal helps to prevent leaks and maintain pressure. Another important component is the shaft, which connects the motor to the impeller, enabling motion. Lastly, the valve controls the direction and flow rate of the liquid, playing a key role in the overall system efficiency.

By familiarizing yourself with these crucial components, you can better understand their functions and the importance of each in the overall system. This knowledge not only aids in troubleshooting but also facilitates effective repairs and enhancements.

Functionality of the Individual Parts

This section delves into the roles and operations of each component within the system. Understanding how these elements interact and contribute to overall efficiency is essential for effective maintenance and troubleshooting.

Core Components and Their Roles

Each essential element serves a specific function, ensuring the smooth operation of the entire mechanism. For instance, one part is responsible for regulating flow, while another aids in maintaining pressure. These interactions are crucial for achieving optimal performance.

Maintenance and Performance Optimization

Regular inspection of each element is vital for longevity and functionality. Identifying wear and tear can prevent potential malfunctions, leading to enhanced efficiency. Proper care and timely replacement of these components can significantly impact overall effectiveness.

Common Materials Used in Pump Parts

When it comes to the construction of various mechanisms, the choice of materials plays a crucial role in ensuring efficiency and durability. Different components require specific materials to withstand various operational conditions, including pressure, temperature, and chemical exposure.

- Metal Alloys: Often utilized for their strength and resistance to wear, metal alloys are commonly found in critical components. Aluminum and stainless steel are popular choices due to their lightweight nature and corrosion resistance.

- Plastics: Many modern devices incorporate advanced plastics that offer chemical resistance and lightweight properties. Materials such as polyvinyl chloride (PVC) and polyethylene are frequently used for housing and non-structural components.

- Rubber: Flexible materials like rubber are essential for sealing and cushioning. They provide effective barriers against leaks and absorb vibrations, ensuring smooth operation.

- Ceramics: In high-wear applications, ceramics are valued for their hardness and ability to withstand abrasive conditions. These materials are often used in wear-resistant components.

- Composites: Combining different materials, composites can provide tailored properties, such as enhanced strength-to-weight ratios. They are increasingly utilized in applications requiring lightweight yet robust solutions.

The selection of appropriate materials is fundamental in achieving optimal performance and longevity in mechanisms. Understanding the properties and applications of these substances is key to enhancing functionality and reliability.

Maintaining the Pump for Longevity

Proper upkeep is essential to ensure the extended functionality of your equipment. Regular attention to maintenance can significantly reduce the risk of unexpected failures and enhance performance. By adopting a consistent care routine, you can help prolong the lifespan of your device and maintain its efficiency.

Routine Inspections

Conducting frequent checks is vital for identifying potential issues before they escalate. Inspect seals, connections, and components for signs of wear or damage. Ensure that all fittings are secure and free from leaks. Addressing minor problems early can prevent more extensive repairs later on.

Cleaning and Lubrication

Keeping the machinery clean is crucial for optimal operation. Remove any debris or buildup that may obstruct performance. Additionally, applying appropriate lubricants to moving parts minimizes friction and reduces wear. Follow the manufacturer’s guidelines regarding cleaning agents and lubrication intervals for the best results.

Troubleshooting Pump Component Failures

Identifying issues within a fluid transfer system is crucial for maintaining optimal performance. Various elements can lead to malfunctions, affecting efficiency and reliability. By systematically examining each component, potential problems can be detected and addressed effectively.

Common signs of dysfunction may include irregular fluid flow, unusual noises, or visible leaks. It is essential to inspect seals and fittings for any signs of wear or damage, as these can significantly impact the system’s operation. Additionally, ensure that all connections are secure and free from obstructions.

In some cases, mechanical failures may occur within moving parts. If these elements exhibit excessive wear or misalignment, replacing them may be necessary. Regular maintenance and timely inspections can prevent such issues and prolong the lifespan of the entire assembly.

Lastly, consider environmental factors that could influence performance. Extreme temperatures or exposure to harsh chemicals may affect the integrity of various components. Understanding these variables can aid in troubleshooting and enhance the overall efficiency of the system.

Replacement

When it comes to ensuring the longevity and optimal functionality of your device, timely substitution of components is crucial. Over time, certain elements may wear out, leading to decreased performance or even failure. Identifying the right replacements is essential for maintaining the efficiency of your system.

Identifying Components for Replacement

Understanding which elements require replacement involves regular inspection and knowledge of common signs of wear. Here are key indicators to watch for:

- Unusual noises during operation

- Decreased efficiency or output

- Visible signs of damage or wear

Choosing the Right Replacements

Selecting suitable substitutes can significantly affect the overall performance of your machinery. Consider the following when choosing replacements:

- Verify compatibility with your existing setup.

- Research quality and durability of potential options.

- Consult user reviews and expert recommendations.

By ensuring the correct selection and installation of new components, you can extend the life of your equipment and maintain its functionality for years to come.