In the world of heavy machinery, the efficient operation of hydraulic systems is crucial for optimal performance. These systems are composed of various components that work in harmony to ensure fluid movement and pressure regulation, contributing to the overall functionality of the engine.

Familiarity with the intricate layout of these components enhances troubleshooting and maintenance. Each element plays a distinct role, influencing the system’s responsiveness and reliability.

By exploring the intricate relationships among these components, operators and technicians can delve deeper into the mechanics behind hydraulic efficiency. This knowledge ultimately leads to better decision-making in repairs and upgrades, ensuring machines run at their best.

Understanding Cat C7 HEUI System

The advanced fuel delivery mechanism plays a crucial role in optimizing engine performance and efficiency. This system integrates multiple components to ensure precise control over the injection process, ultimately enhancing power output and reducing emissions. A thorough grasp of its functionality can lead to improved maintenance practices and operational longevity.

Key Components: At the core of this system are several integral elements that work in unison. These parts include electronic controls, hydraulic actuators, and injectors, all designed to respond dynamically to varying operational demands.

Functionality: By analyzing how these components interact, one can appreciate the sophistication behind the fuel delivery. The system employs high-pressure hydraulic fluid to facilitate the injection of fuel, ensuring that each cycle is executed with precision.

Key Components of HEUI Pump

The functionality of hydraulic systems relies on several essential elements that work together to achieve optimal performance. Understanding these components is crucial for efficient operation and maintenance.

Main Elements

At the core, a hydraulic actuator converts fluid energy into mechanical movement. Coupled with this is a control unit that regulates the pressure and flow, ensuring that the system operates within designed parameters.

Supporting Features

Additional features include filters that maintain fluid cleanliness and valves that control the direction and volume of the fluid. Together, these components create a robust framework for reliable operation.

Importance of HEUI in Diesel Engines

The hydraulic electronic unit injection system plays a crucial role in the performance and efficiency of diesel power units. This technology enhances fuel delivery precision, leading to improved combustion processes. By optimizing the timing and amount of fuel injected, it contributes significantly to overall engine functionality.

One of the primary advantages of this system is its ability to adapt to varying operational conditions. This adaptability ensures that engines can maintain optimal performance across a range of environments, whether under heavy loads or during idle periods. As a result, users experience enhanced fuel economy and reduced emissions.

Moreover, the integration of electronic controls allows for real-time adjustments, enhancing response times and reducing lag. This responsiveness is vital for maintaining power and efficiency, particularly in demanding applications. Furthermore, the technology is designed to minimize wear and tear on engine components, thus extending the lifespan of the machinery.

In conclusion, the incorporation of advanced fuel injection technology is essential for modern diesel engines. Its impact on performance, efficiency, and environmental sustainability cannot be overstated, making it a critical aspect of contemporary engine design.

Common Issues with Cat C7 Pumps

Understanding the prevalent challenges faced by hydraulic systems is crucial for ensuring optimal performance and longevity. Several factors can lead to inefficiencies or failures, impacting overall functionality and requiring prompt attention to maintain operational standards.

Performance Fluctuations

One of the most frequent complications involves fluctuations in performance, often attributed to inconsistent fluid flow. This issue can stem from various sources, including clogged filters or deteriorating seals, which ultimately affect the reliability of the system.

Overheating Concerns

Excessive heat generation is another significant concern that can lead to severe damage if left unaddressed. Poor ventilation, low fluid levels, or malfunctioning cooling components can cause overheating, necessitating immediate investigation to prevent catastrophic failures.

Benefits of Regular Maintenance

Consistent upkeep of machinery is crucial for ensuring optimal performance and longevity. By adhering to a regular maintenance schedule, operators can significantly reduce the risk of unexpected failures and enhance overall efficiency.

One primary advantage of routine care is the identification of potential issues before they escalate. This proactive approach allows for timely interventions, minimizing costly repairs and downtime.

Furthermore, regular attention to equipment can lead to improved fuel efficiency, translating to lower operational costs. Keeping components clean and in good condition ensures that systems run smoothly and effectively.

Lastly, proper maintenance practices contribute to safety. Well-maintained machinery poses fewer hazards, protecting both operators and the surrounding environment. Investing time in upkeep ultimately leads to better reliability and performance.

Identifying Pump Malfunctions

Understanding the signs of issues within hydraulic systems is crucial for maintaining optimal performance. By recognizing specific symptoms, operators can take timely action to prevent further damage and ensure efficient operation.

Common indicators of trouble include unusual noises, fluctuating pressures, and unexpected leaks. Each of these signs can reveal underlying problems that require immediate attention. For instance, grinding or whining sounds may suggest wear or misalignment, while erratic pressure levels can indicate blockage or component failure.

Regular monitoring and thorough inspections are essential practices for identifying these malfunctions early. By conducting routine checks and being vigilant about performance changes, users can effectively manage system health and extend the lifespan of their equipment.

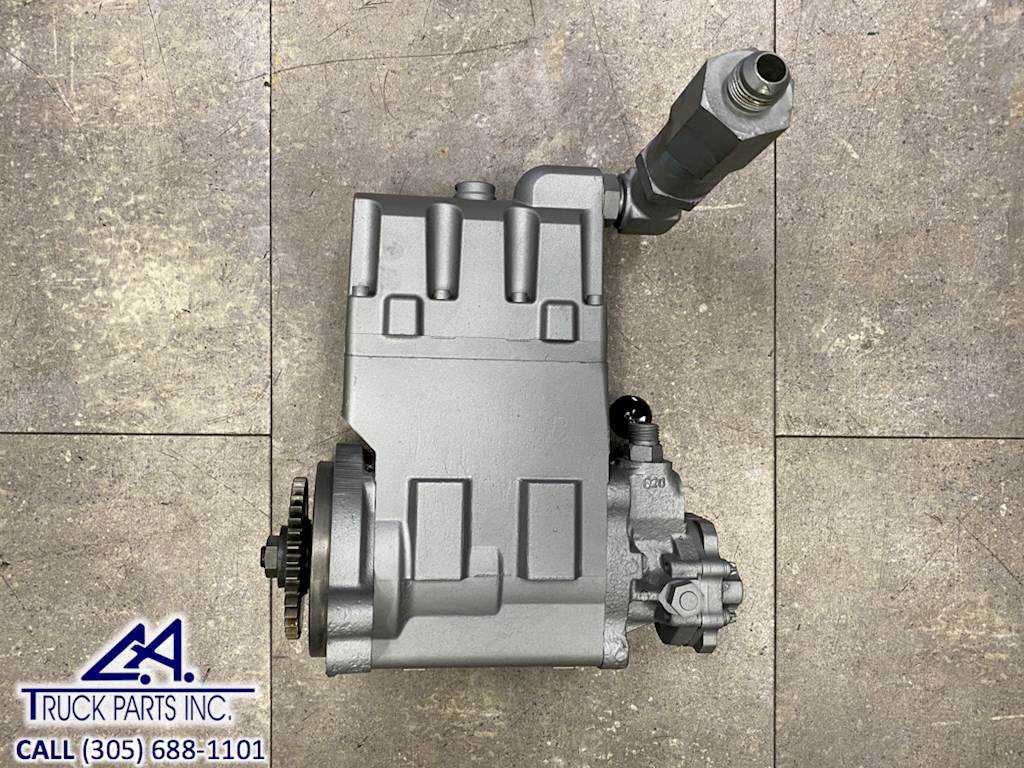

HEUI Pump Replacement Process

Replacing essential components within a hydraulic system is crucial for maintaining optimal performance. This section outlines the steps necessary to execute the replacement efficiently, ensuring the system operates smoothly post-installation.

Preparation Steps

- Gather all necessary tools and equipment.

- Ensure a clean workspace to avoid contamination.

- Review the service manual for specific instructions.

Replacement Procedure

- Disconnect the hydraulic lines to prevent fluid leakage.

- Carefully remove the existing component, noting any special fittings.

- Inspect the surrounding area for wear or damage.

- Install the new component, ensuring all connections are secure.

- Reconnect hydraulic lines and check for leaks.

- Run the system briefly to verify proper operation.

Tools Required for Pump Repairs

Effective maintenance and restoration of fluid transfer systems demand specific instruments that enhance precision and efficiency. Selecting the right tools ensures smooth operation and prolongs the lifespan of the components involved.

Essential Hand Tools

Basic hand tools such as wrenches, pliers, and screwdrivers are crucial for disassembly and reassembly tasks. A torque wrench is particularly important for applying the correct force to fasteners, preventing damage.

Specialized Equipment

For more intricate repairs, diagnostic devices and pressure gauges play a vital role. These tools allow for precise monitoring of performance and identification of underlying issues, enabling technicians to address problems effectively.

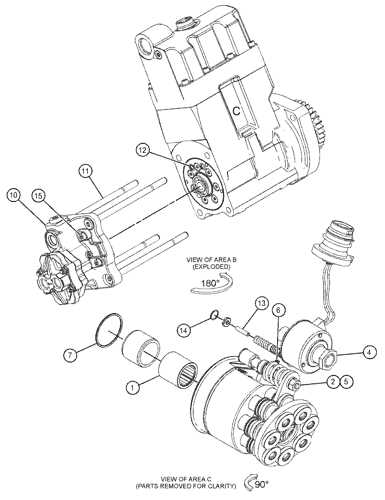

How to Read Pump Diagrams

Understanding schematic representations is essential for effective maintenance and troubleshooting in various machinery. These visual aids provide crucial insights into the arrangement and functionality of components, allowing for a clearer comprehension of the system’s operation. By mastering the elements of these illustrations, you can enhance your technical skills and ensure efficient performance.

First, familiarize yourself with the symbols used in the illustration. Each icon represents a specific element or function within the system. Common symbols include those for valves, sensors, and connections, each conveying important information about how these parts interact. Consulting a key or legend often provided with the schematic can greatly assist in this process.

Next, pay attention to the flow direction indicated by arrows. Understanding the movement of fluids or energy throughout the system is crucial for diagnosing issues. The flow path often reveals how components work together, making it easier to pinpoint potential problems.

Moreover, observe the labeling of each component. Accurate identification helps you to cross-reference with technical manuals or service documents, ensuring that you have the right information for repairs or replacements. Take note of any specifications or ratings that may be indicated, as these details are vital for compatibility and performance.

Lastly, practice interpreting various schematics to build your confidence. Regular exposure to different representations will enhance your ability to quickly understand complex systems. As you gain experience, the process will become more intuitive, enabling you to tackle challenges with greater ease.

Sources for Replacement Parts

Finding quality components for your machinery is crucial for maintaining optimal performance. Numerous suppliers offer a range of alternatives, ensuring you have access to what you need for efficient repairs and maintenance.

Authorized Dealers

Official distributors provide genuine replacements, ensuring compatibility and reliability. It’s advisable to verify the credentials of these vendors to avoid counterfeit products.

Aftermarket Suppliers

Many companies specialize in providing alternative solutions that can be more cost-effective. Researching reviews and product warranties can help you select reputable sources in this category.

Comparing Cat C7 to Other Models

This section explores the differences and similarities between the C7 engine and its counterparts in the industry. By examining various models, we can understand their performance, efficiency, and suitability for different applications.

When comparing the C7 to other engines, several key factors emerge:

- Performance: Assessing horsepower and torque ratings.

- Fuel Efficiency: Evaluating consumption rates under similar workloads.

- Durability: Analyzing longevity and maintenance needs.

- Technology: Reviewing advanced features and innovations.

Each of these aspects can significantly influence the ultimate choice for users depending on their specific requirements.

- Engine Size: Comparison of displacement and overall dimensions.

- Emissions: Understanding compliance with environmental standards.

- Cost: Evaluating initial investment versus long-term savings.

Through this comparison, it becomes evident that selecting the right engine model involves a careful consideration of various characteristics tailored to unique operational demands.

FAQs About Cat C7 HEUI Pumps

This section addresses common inquiries regarding specific hydraulic components used in heavy machinery. Understanding these elements can enhance maintenance and operational efficiency.

| Question | Answer |

|---|---|

| What are the main functions of these hydraulic components? | They control fluid flow and pressure, ensuring optimal engine performance. |

| How can I identify signs of wear or failure? | Look for leaks, unusual noises, or performance drops in the machinery. |

| What maintenance practices should be followed? | Regular inspections, timely fluid changes, and replacing worn components are essential. |

| Where can I find replacement components? | Authorized dealers and specialized online retailers typically offer a wide selection. |

| Is there a warranty on these components? | Most manufacturers provide warranties, so check the specific terms with your supplier. |