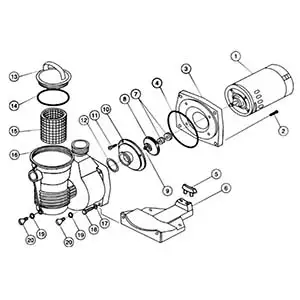

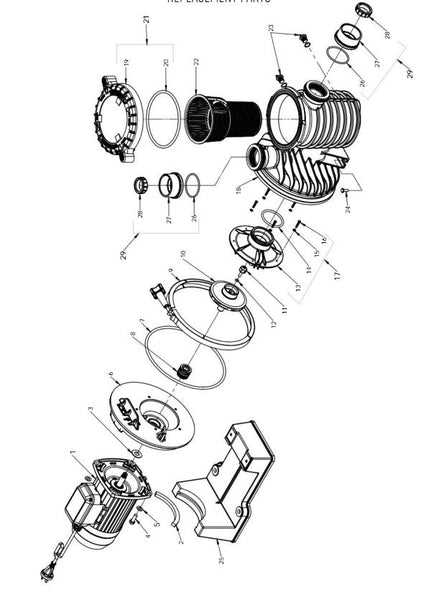

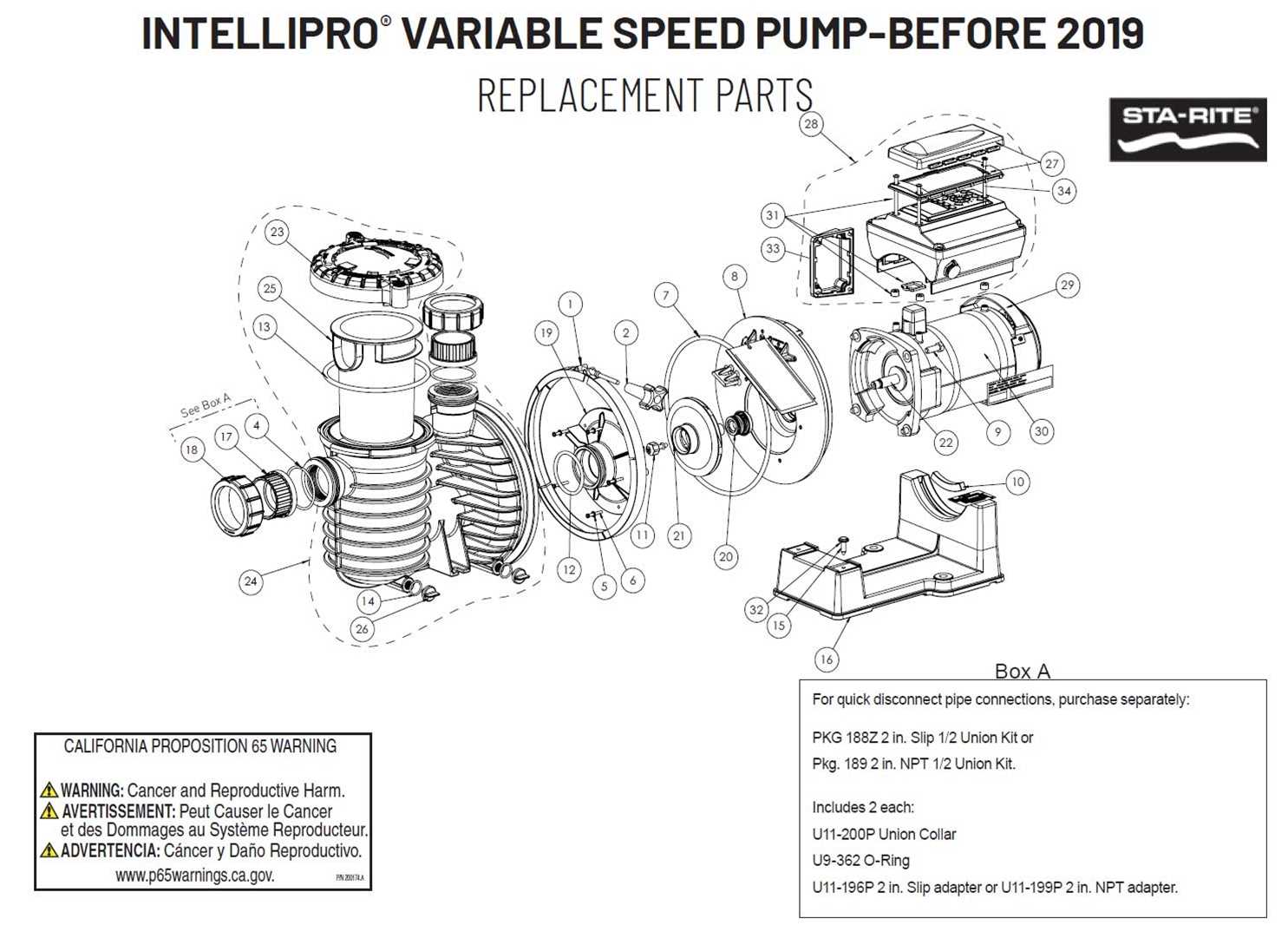

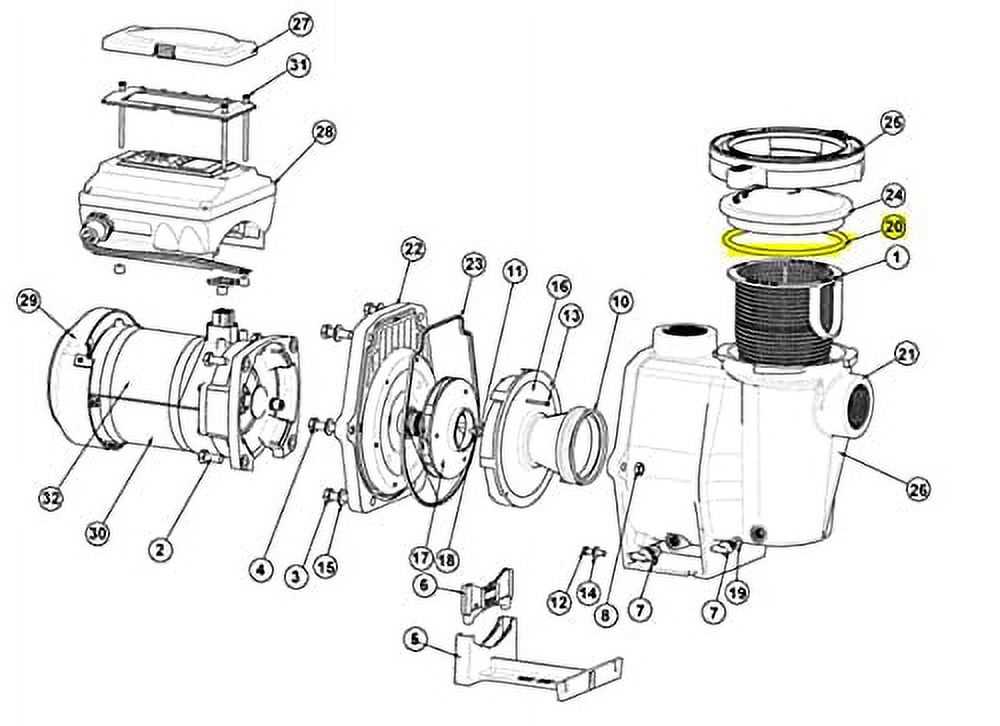

When maintaining or repairing mechanical devices, it’s crucial to have a detailed understanding of their structure. The internal mechanisms of water distribution devices are often complex, with numerous small elements working in unison to ensure efficient performance. Identifying the connections and roles of these components is essential for ensuring their longevity and optimal function.

A comprehensive breakdown of the internal structure provides insight into how each element contributes to the system’s overall efficiency. Knowing how these various elements fit together allows for easier troubleshooting and maintenance. Whether you’re addressing a minor issue or conducting a full inspection, this knowledge ensures that every action taken is accurate and effective.

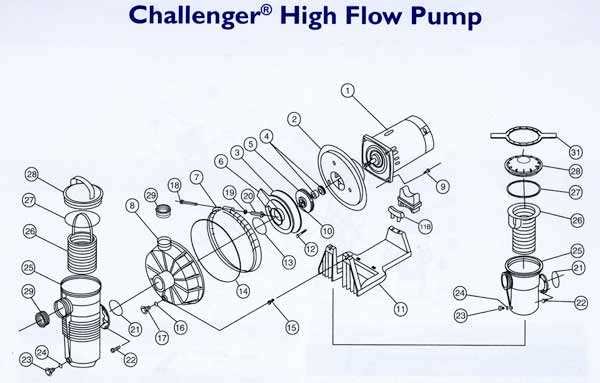

Challenger Pump Components Overview

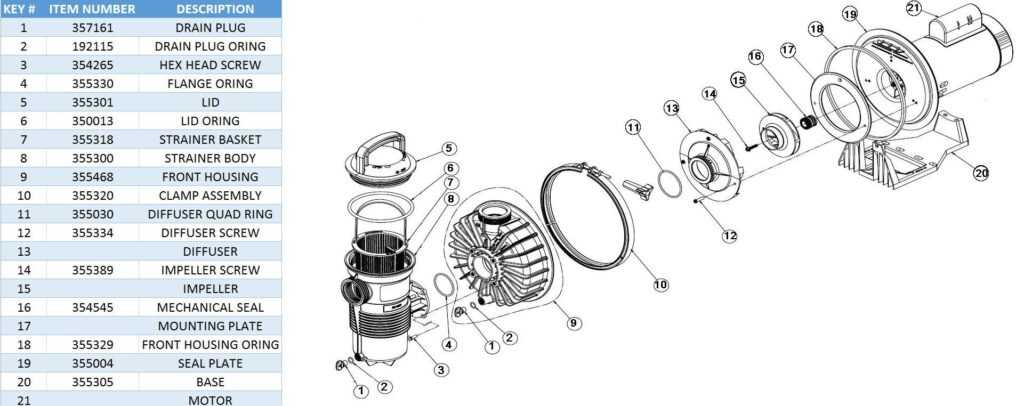

In any system responsible for moving liquids, several critical elements work together to ensure smooth operation and efficiency. Each element plays a specific role, contributing to the overall performance and durability of the equipment. Understanding these components helps in maintaining the system and identifying potential issues early.

Main Structural Elements

The key structural components include the housing and impeller, which are crucial for handling the flow of liquids. The housing acts as a protective shell, while the impeller directs the fluid through the system. The interaction between these elements determines the operational effectiveness of the entire unit.

Support and Control Elements

Other essential parts include seals, bearings, and a motor. Seals prevent leakage, ensuring that fluids remain within the system. Bearings reduce friction and wear on moving parts, while the motor provides the power necessary for operation. Together, these elements ensure the system runs smoothly and with minimal disruption.

| Component | Function | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Placement Guidelines |

|---|---|

| O-Rings | Ensure the O-ring is clean and free of debris before installation. Lubricate lightly with compatible fluid. |

| Gaskets | Align the gasket evenly on both sides. Use appropriate fasteners to secure it without over-tightening. |

By following these guidelines, the effectiveness of the sealing elements can be maximized, contributing to a reliable assembly and prolonged lifespan of the equipment.

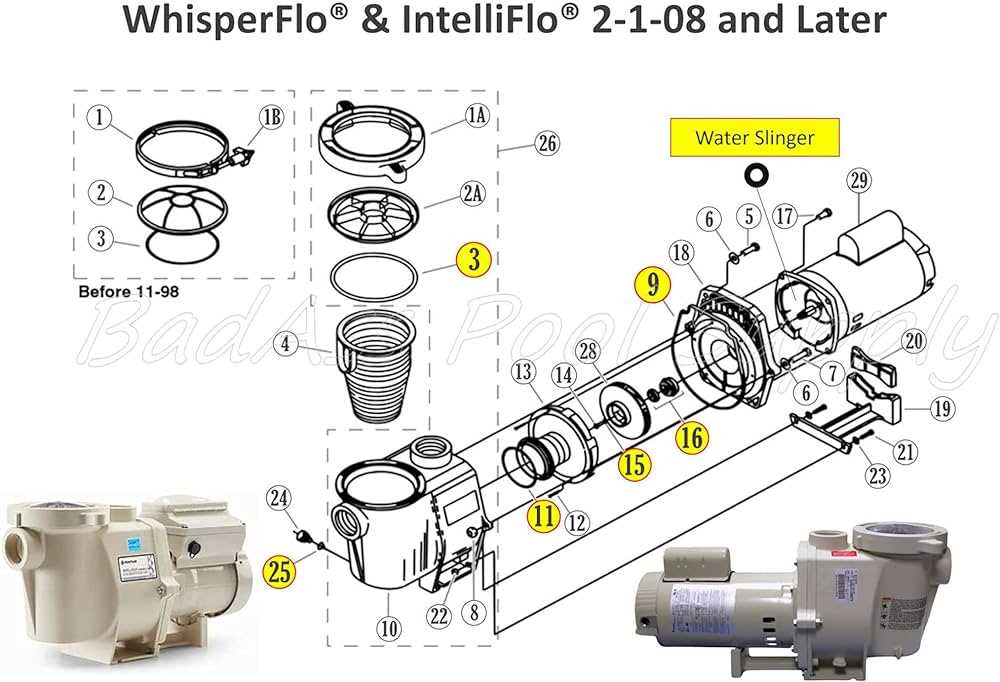

Discharge Port Assembly Explained

The discharge port assembly plays a crucial role in the efficient transfer of fluid within various systems. This component is essential for directing the flow of the medium to the desired outlet while ensuring minimal pressure loss. Understanding its structure and function is vital for anyone involved in the maintenance and operation of these systems.

Typically, the assembly comprises several key elements, each contributing to its overall effectiveness. The arrangement ensures that the fluid exits smoothly and prevents backflow, which can lead to operational inefficiencies. Below is a detailed overview of the primary components found in a typical discharge port assembly:

| Component | Description |

|---|---|

| Housing | Encases the internal parts and directs the flow of fluid. |

| Flange | Connects the assembly to other components, ensuring a secure fit. |

| O-Ring | Seals the assembly to prevent leaks during operation. |

| Outlet Pipe | Guides the fluid to the discharge point, minimizing turbulence. |

| Check Valve | Prevents backflow, maintaining pressure and efficiency. |

Suction Port and its Role

The suction port serves a crucial function in the overall efficiency and effectiveness of fluid movement systems. It is the entry point through which liquid is drawn into the assembly, facilitating the transfer process from one location to another. Understanding its significance helps in grasping how various components work together to achieve optimal performance.

This entryway is designed to create a vacuum that enables fluid flow, ensuring that the system operates smoothly and effectively. Its placement and design can greatly influence the volume and speed of liquid intake, which are essential for maintaining operational balance. Proper maintenance and monitoring of the suction inlet are vital for preventing issues that may arise from blockages or leaks.

Additionally, the geometry of the suction port can affect the system’s overall pressure dynamics, contributing to the efficiency of the entire mechanism. A well-engineered entry point reduces turbulence and enhances the flow rate, making it essential for achieving the desired operational outcomes.

Motor Connection and Mounting

The connection and installation of the motor play a crucial role in ensuring the optimal performance of the equipment. Proper alignment and secure mounting not only enhance efficiency but also extend the lifespan of the motor. Understanding the various components involved and following the correct procedures is essential for achieving reliable operation.

Connection Requirements

When establishing a connection, consider the following aspects:

- Electrical Compatibility: Ensure that the motor voltage and frequency match the power supply specifications.

- Wiring Standards: Follow the appropriate wiring codes to maintain safety and functionality.

- Grounding: Properly ground the motor to prevent electrical faults and enhance safety.

Mounting Guidelines

For effective installation, adhere to these mounting guidelines:

- Surface Preparation: Ensure the mounting surface is clean, level, and capable of supporting the motor’s weight.

- Alignment: Align the motor with the driven equipment to minimize wear and vibration.

- Securing: Use the appropriate fasteners and torque specifications to secure the motor firmly in place.

Following these connection and installation practices will help in achieving a robust setup that promotes longevity and performance.

Shaft and Bearings Configuration

The configuration of the shaft and its associated components is crucial for ensuring optimal performance and longevity in rotational machinery. Understanding the arrangement and function of these elements can significantly impact efficiency and reliability.

At the core of this setup is the shaft, which serves as the central axis around which various components operate. The interaction between the shaft and bearings is essential for minimizing friction and supporting the loads imposed during operation.

Key considerations for the configuration include:

- Material Selection: The choice of materials for the shaft and bearings affects durability and performance. Common materials include steel, bronze, and composite materials.

- Alignment: Proper alignment of the shaft within its bearings is vital to prevent uneven wear and reduce vibration.

- Lubrication: Adequate lubrication is necessary to ensure smooth operation and to extend the lifespan of both the shaft and bearings.

- Load Capacity: The bearings must be appropriately selected to handle the expected loads without failure.

In summary, careful consideration of the shaft and bearing arrangement can lead to enhanced performance and reliability of rotational systems, making it a critical aspect of machinery design and maintenance.

Troubleshooting Common Pump Part Failures

Understanding the typical issues that can arise within a fluid transfer system is essential for maintaining optimal performance. By identifying and addressing these challenges, operators can enhance reliability and reduce downtime.

Common symptoms indicating a malfunction may include:

- Unusual noises during operation

- Reduced flow rate or pressure

- Visible leaks around connections

- Overheating of components

- Frequent tripping of protective devices

To effectively address these issues, follow these troubleshooting steps:

- Check for Obstructions: Inspect all intake and discharge pathways for blockages that may hinder fluid movement.

- Examine Seals and Gaskets: Look for signs of wear or damage that could lead to leaks and reduced efficiency.

- Inspect Electrical Connections: Ensure that all wiring and connections are secure and free from corrosion.

- Test Mechanical Components: Evaluate bearings, shafts, and other moving parts for signs of wear and tear.

- Monitor Operating Conditions: Ensure that the system is not being subjected to conditions beyond its design specifications.

By systematically addressing these factors, users can resolve many common issues and prolong the lifespan of their equipment.