Efficient water movement is crucial in various settings, from residential needs to agricultural applications. Every system that ensures the proper distribution of liquids relies on multiple interconnected elements. A comprehensive look at these elements helps in understanding how they contribute to the overall functionality of the system.

Each part plays a specific role in maintaining smooth operations. Whether you’re troubleshooting issues or simply maintaining optimal performance, recognizing the importance of individual components can make all the difference. Familiarity with the internal workings can extend the life of the system and improve its efficiency.

In this section, we will break down the key elements involved and how they interact within a fluid transfer mechanism. By examining the structure and purpose of each component, you’ll gain valuable insights into how to maintain and troubleshoot your system effectively.

Understanding the Anatomy of a Davey Pump

Grasping the structure of a water-moving device is essential for ensuring efficient operation and proper maintenance. Each component plays a specific role, contributing to the overall functionality. By exploring how these elements work together, one can better address issues and ensure long-lasting performance.

Main Components and Their Roles

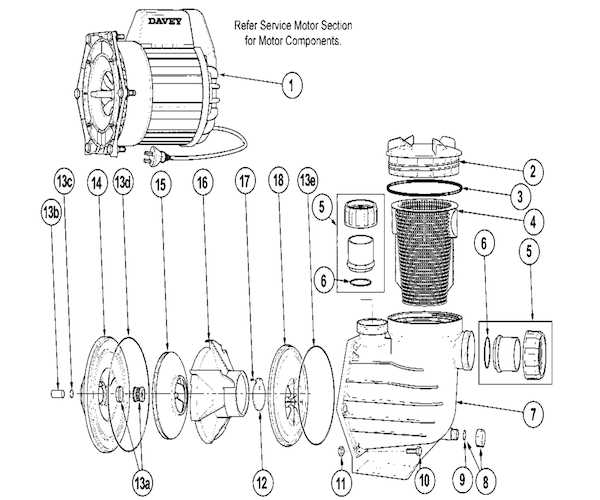

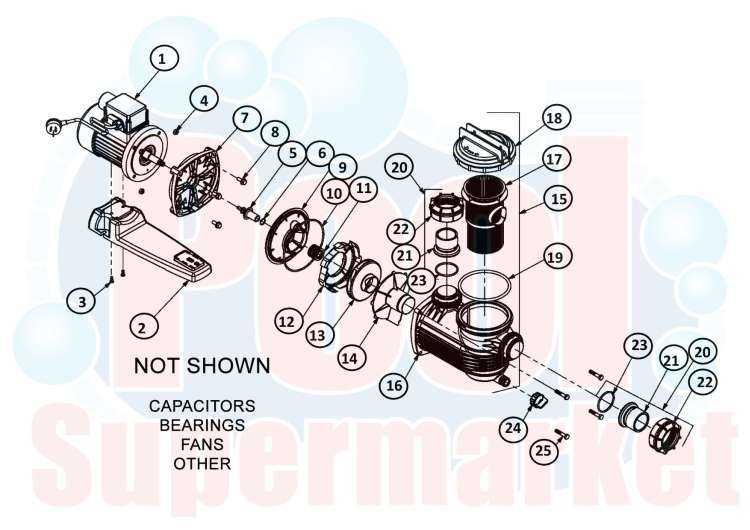

The central unit is driven by a motor, which powers the movement of fluids through various mechanisms. At the heart lies an impeller, responsible for generating flow and pressure. The system relies on a casing, which not only houses internal parts but also ensures the containment of the liquid. Furthermore, seals prevent leakage and safeguard internal mechanisms from external contamination.

Additional Features for Enhanced Efficiency

To ensure optimal performance, certain enhancements are incorporated. Filters are installed to prevent debris from entering, and pressure regulators maintain consistent flow. Over time,

Key Components in a Davey Pump System

Understanding the structure of a water management system involves familiarizing yourself with its essential elements. Each part plays a critical role in ensuring efficient fluid movement, pressure regulation, and overall system durability. By recognizing the importance of each component, one can better maintain and optimize performance for various applications.

Motor Assembly is the driving force behind the movement of liquids. It converts electrical energy into mechanical power, ensuring consistent and reliable operation. Proper maintenance of this part can significantly prolong the system’s life.

Impeller acts as the heart of the mechanism, spinning to create the necessary flow and pressure. Its design determines the volume of fluid that can be moved and the efficiency of

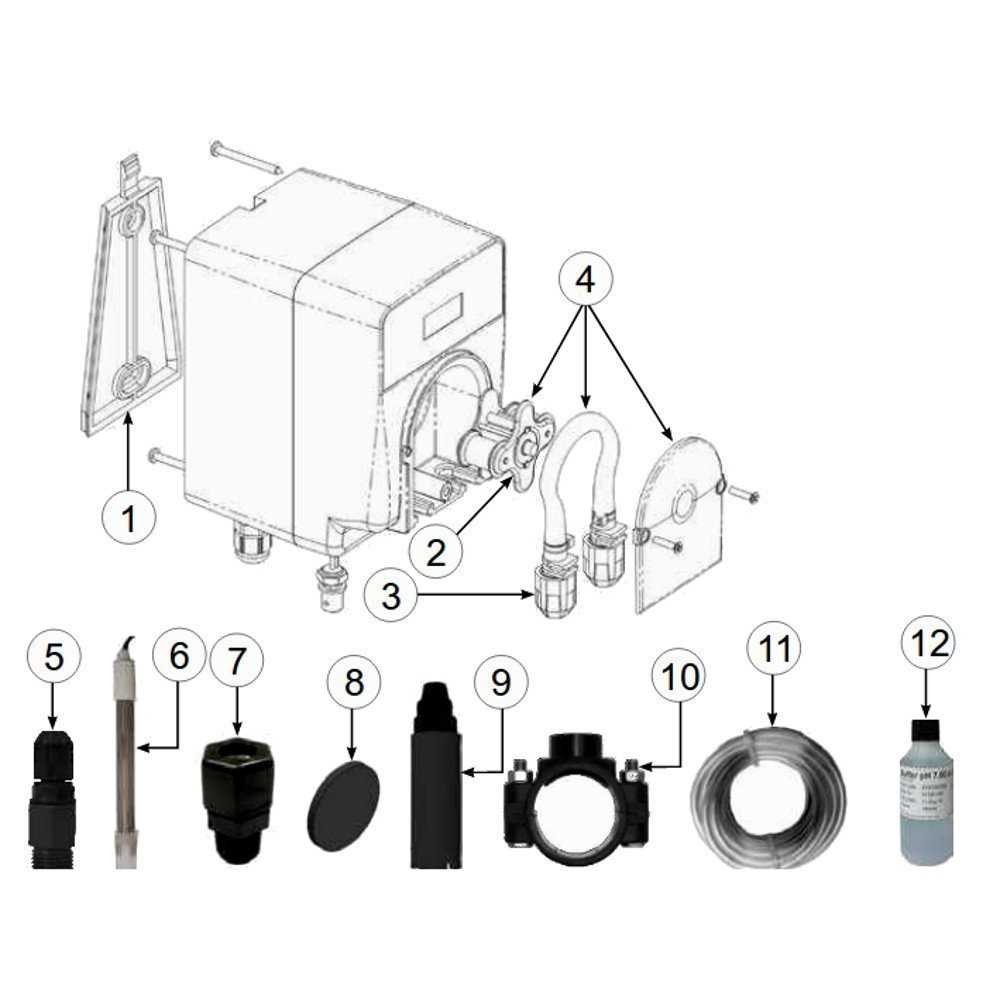

Common Replacement Parts for Davey Pumps

In any water management system, certain components are more likely to require replacement over time due to wear and tear. Identifying and understanding these frequently serviced elements can significantly improve the longevity and efficiency of your equipment.

Seals are often subject to degradation. Regular exposure to pressure and fluid can cause them to weaken, resulting in leaks or reduced performance.

Impellers are critical for maintaining proper flow. Over time, they may become clogged or damaged by debris, leading to reduced efficiency or system failures.

Bearings support rotational movement, ensuring smooth operation. With continued use, they may wear out, leading to increased noise and mechanical stress.

The diaphragm plays a crucial role in regulating pressure. A damaged one can lead to significant pressure loss, impacting the overall functionality of the system.

Replacing these key elements at regular intervals helps prevent breakdown

How to Identify Pump Component Failures

When dealing with mechanical systems, recognizing issues early is key to preventing more significant breakdowns. Various signs, such as unusual noises, reduced efficiency, or sudden changes in operation, can indicate that specific elements within the system are beginning to wear out or malfunction. Identifying these symptoms promptly allows for quick intervention, ensuring that the overall machinery continues to function smoothly.

Common indicators of failing components may include increased vibrations, unexpected temperature fluctuations, or irregular fluid flow. Each of these signs points to potential wear or damage in a specific area, necessitating a more detailed inspection to pinpoint the exact cause of the problem. Understanding how to assess these symptoms is crucial for maintaining optimal performance and avoiding costly repairs.

To effectively diagnose the issue, it’s essential to examine key areas such as seals, bearings, and impellers. Wear and tear in these areas can manifest through various mechanical irregularities, and addressing them promptly can prevent more extensive damage. By focusing on these components during regular maintenance checks, you can significantly reduce the likelihood of unexpected failures.

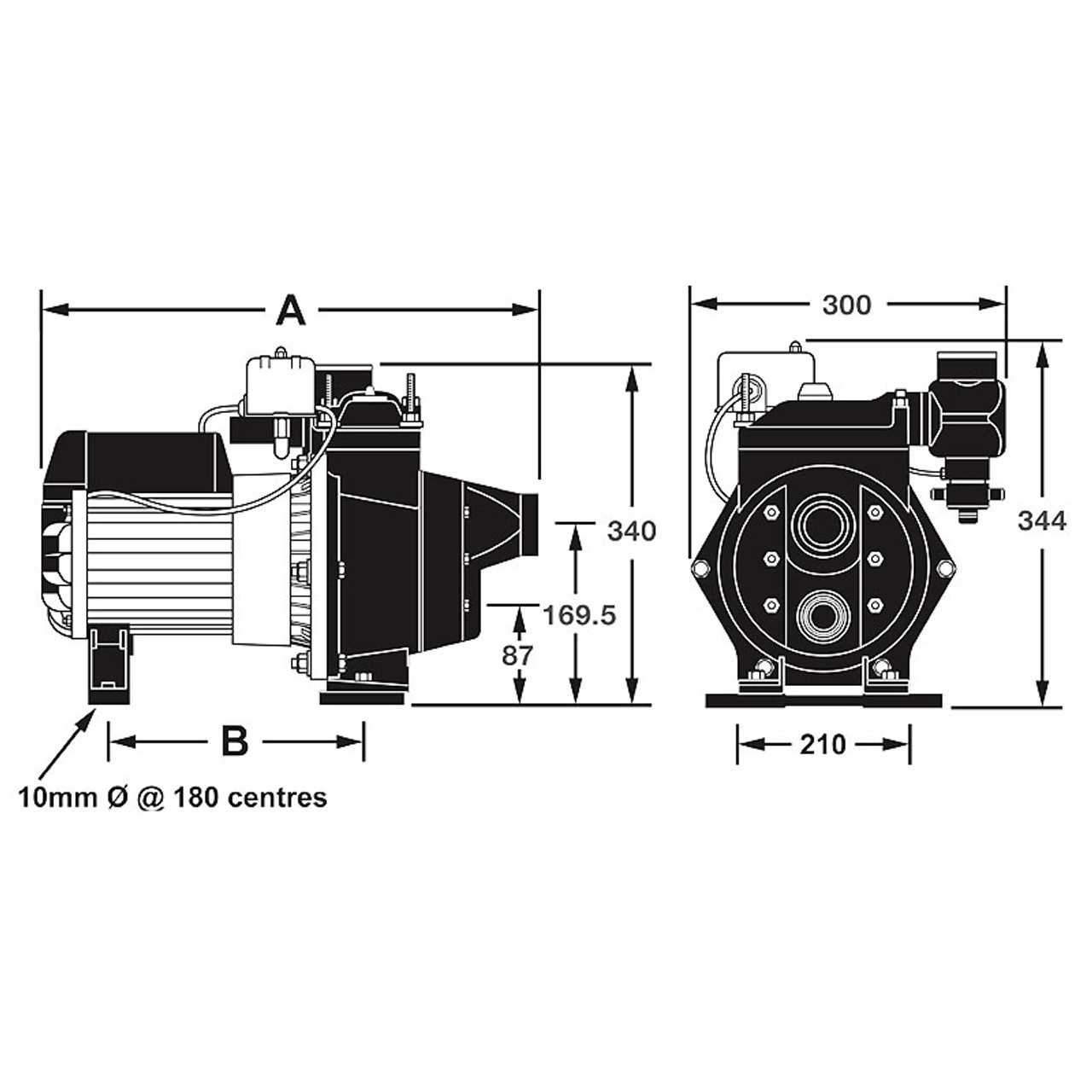

Detailed Breakdown of Davey Pump Components

Understanding the internal structure of a liquid transfer system is essential for efficient operation and maintenance. This section provides an in-depth look at the key mechanisms that ensure the reliable flow and management of fluids. Each component plays a crucial role in overall functionality, and having insight into their interactions can help identify potential issues or optimize performance.

Main Elements of the Assembly

The core of the system revolves around several essential units, each designed to handle specific tasks. The impeller is responsible for generating the necessary movement, creating pressure that drives the liquid forward. Connected to this is the volute casing, which directs the flow in a controlled manner, ensuring minimal loss of pressure.

Auxiliary and Supportive Features

Surrounding these primary units are additional supportive features. The mechanical seal prevents unwanted leakage, maintaining the integrity of the system. Meanwhile, the diffuser aids in further

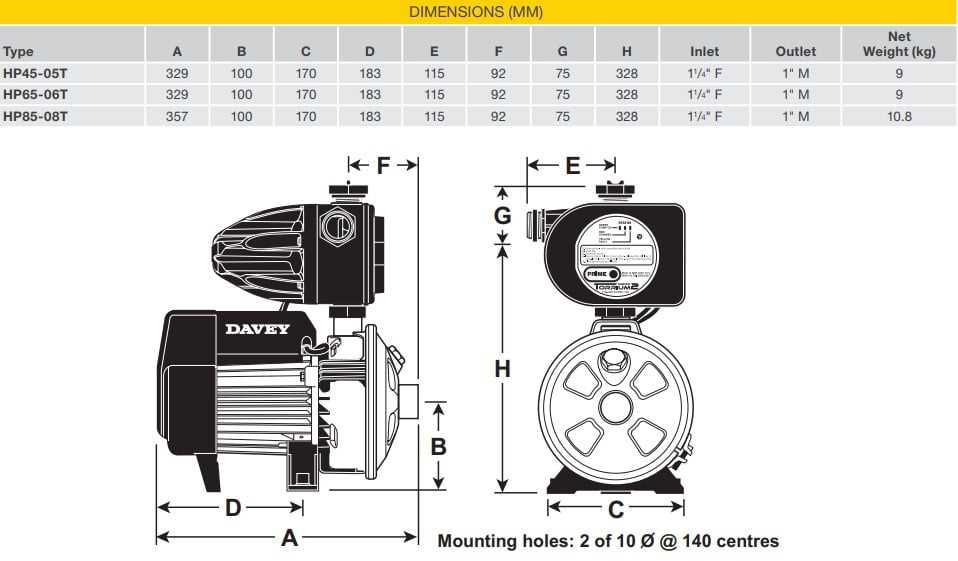

Guide to Selecting Davey Pump Parts

Choosing the right components for your water circulation system is essential for optimal performance and longevity. Understanding the various elements available in the market and their specific functionalities can greatly influence the efficiency of your setup. This guide aims to provide insights into the selection process, ensuring that you make informed decisions tailored to your needs.

Assess Your Requirements: Begin by evaluating the specific needs of your water management system. Consider factors such as flow rate, pressure requirements, and the type of fluid being handled. This assessment will serve as a foundation for selecting the most suitable components.

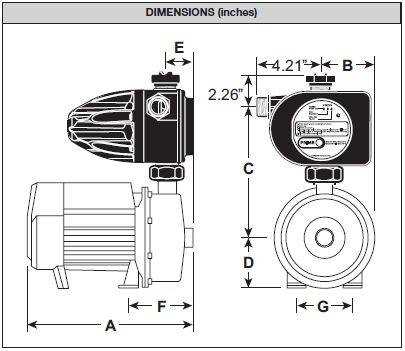

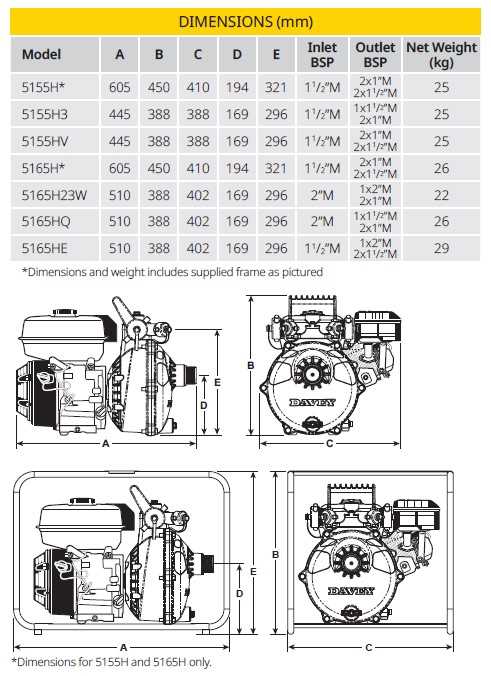

Compatibility: It is crucial to ensure that the components you choose are compatible with your existing system. Check specifications and dimensions to avoid any potential issues during installation. Consulting product manuals can also provide valuable insights into compatibility.

Quality and Reliability: Opt for high-quality components from reputable manufacturers. Reliable parts contribute to the overall durability of the system and minimize the risk of unexpected failures. Look for components that come with warranties or guarantees to further ensure their reliability.

Maintenance and Support: Consider the ease of maintenance when selecting components. Some elements may require regular upkeep or specific tools for servicing. Additionally, assess the availability of customer support and resources for troubleshooting and repairs.

Cost-Effectiveness: While it may be tempting to choose the least expensive options, focus on long-term value instead. Higher initial costs for superior components can result in savings over time due to reduced maintenance and increased efficiency. Analyze the cost against the expected lifespan and performance of each item.

By following these guidelines, you can confidently select the appropriate components for your water circulation needs, ensuring a robust and efficient system for years to come.

Maintaining Efficiency in Davey Pump Systems

Ensuring optimal performance in hydraulic systems requires regular attention and strategic management. By focusing on various aspects of functionality, operators can significantly enhance the longevity and effectiveness of these essential devices. This section delves into the best practices that contribute to maintaining high operational standards in such systems.

Regular Inspection and Maintenance

Conducting routine assessments is crucial for identifying potential issues before they escalate. Regular checks on the system’s components allow for early detection of wear and tear, preventing unexpected breakdowns. Moreover, maintaining cleanliness and ensuring that the mechanisms are free from debris contribute to smooth operation and minimize energy consumption.

Monitoring Performance Metrics

Keeping track of operational data is essential for evaluating efficiency. Key metrics such as flow rate, pressure, and energy usage should be monitored consistently. Implementing automated systems to log this information can provide valuable insights, enabling timely adjustments to improve overall performance. Understanding these metrics can aid in identifying patterns and optimizing the system’s functionality.

Incorporating these practices into the routine management of hydraulic systems not only boosts performance but also extends their lifespan, ensuring reliable service for years to come.

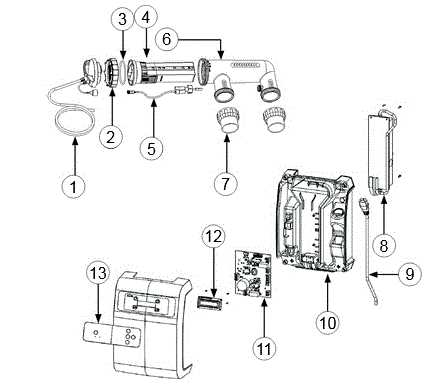

Step-by-Step Davey Pump Repair Instructions

In this section, we will guide you through the essential steps to troubleshoot and restore your equipment effectively. Understanding the components and how they work together is crucial for a successful maintenance process. With the right approach, you can enhance the lifespan and functionality of your machinery.

Preparation for the Repair

Before starting the maintenance procedure, ensure you have the necessary tools and safety equipment. It’s advisable to work in a well-lit area and have a clean workspace to organize your components effectively. Gather the following tools:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening fasteners |

| Screwdriver Set | For removing screws |

| Pliers | For gripping and bending wires |

| Multimeter | For testing electrical connections |

Step-by-Step Procedure

Follow these detailed instructions to carry out the repair:

- Disconnect the power supply to ensure safety during the process.

- Remove the outer casing by unscrewing the screws located at the base and sides.

- Inspect the interior components for any visible damage or wear.

- Carefully detach any malfunctioning parts, noting their placement for reassembly.

- Replace damaged components with new or refurbished ones, ensuring proper alignment.

- Reassemble the casing, securing all screws tightly.

- Reconnect the power supply and conduct a functional test to verify successful repairs.

Compatibility of Davey Pump Parts with Other Models

Understanding the interchangeability of components across different models is essential for optimizing performance and maintenance. This section explores the potential for various elements from one manufacturer’s units to work with others, providing insights into the benefits and considerations of such compatibility.

Many components are designed with standardized measurements and specifications, allowing for a certain degree of universal applicability. However, it is crucial to consider the unique attributes of each model, as subtle differences can impact functionality. Identifying compatible elements can enhance efficiency and reduce costs associated with repairs or replacements.

When evaluating compatibility, examining both the physical dimensions and functional capabilities of the components is important. Users are encouraged to consult technical manuals or compatibility charts to ensure optimal performance. Furthermore, leveraging the knowledge of experienced professionals can provide valuable guidance in selecting suitable components.

In summary, while opportunities for interchangeability exist, careful consideration and research are necessary to ensure that components work harmoniously together, ultimately leading to improved reliability and performance.

Signs Your Davey Pump Needs New Parts

Recognizing the indicators that your water-moving system requires new components is essential for maintaining optimal performance. Early detection of these signs can prevent further damage and ensure efficient operation.

Unusual Noises

Strange sounds coming from your machinery can signal an underlying issue. If you hear grinding, rattling, or excessive vibrations, it may indicate worn-out components that need replacement. Ignoring these noises could lead to more significant problems down the line.

Reduced Efficiency

A noticeable drop in efficiency can be a clear sign that something is amiss. If the flow rate has decreased or the system struggles to maintain pressure, it might be time to inspect the internal mechanisms for any damaged or failing elements.

Upgrading Your Davey Pump for Better Performance

Enhancing the efficiency of your hydraulic system can significantly improve its overall functionality. Various modifications can be made to achieve optimal performance and reliability, ensuring longevity and effectiveness in your operations. This guide will outline essential upgrades to consider for your system.

Benefits of Upgrades

- Improved efficiency and energy savings

- Enhanced durability and lifespan

- Better flow rates and pressure management

- Reduced maintenance costs

Key Areas for Improvement

- Seals and Gaskets: Replacing worn seals can prevent leaks and maintain pressure.

- Impeller: Upgrading to a more efficient impeller design can enhance fluid movement and reduce energy consumption.

- Motor: Consider a more powerful motor for increased performance, especially for larger systems.

- Control Systems: Implementing advanced control technologies can improve responsiveness and efficiency.

- Piping and Fittings: Assess and replace any restrictive piping to optimize flow and reduce friction losses.

By focusing on these areas, you can effectively enhance the performance of your hydraulic system and ensure it operates at peak efficiency.

Davey Pump Assembly: Key Considerations

When assembling a fluid transfer mechanism, several crucial factors must be taken into account to ensure optimal functionality and longevity. Understanding the components involved and their interrelations is essential for effective installation and maintenance. This section will explore vital elements that should be considered during the assembly process.

Component Quality

Choosing high-quality materials is paramount for the durability and performance of the system. Consider the following:

- Material compatibility with the intended application.

- Resistance to corrosion and wear.

- Certifications and standards compliance.

Installation Techniques

Proper assembly techniques significantly impact the performance of the equipment. Adhere to these practices:

- Follow the manufacturer’s guidelines meticulously.

- Ensure all components fit snugly without excessive force.

- Utilize appropriate tools to prevent damage during assembly.

Where to Find Genuine Davey Pump Parts

Locating authentic components for your equipment is essential for ensuring optimal performance and longevity. Whether you’re in need of replacements or upgrades, it’s crucial to source from reliable suppliers to maintain the integrity of your machinery.

Official Distributors: One of the best ways to secure original components is through authorized distributors. These entities are recognized by the manufacturer and can provide assurance regarding the quality and authenticity of the items they sell.

Online Marketplaces: Numerous online platforms specialize in industrial supplies. When using these websites, ensure you check seller ratings and reviews to avoid counterfeit options. Look for listings that specifically mention being genuine and certified.

Manufacturer’s Website: Many manufacturers offer direct sales through their official websites. This option often provides the most reliable access to original components. Additionally, the site may have resources such as installation guides and support.

Local Suppliers: Don’t overlook local supply stores that specialize in industrial equipment. They may carry genuine items or be able to order them for you, providing personalized service and immediate assistance.

Trade Shows and Expos: Attending industry-specific events can connect you with manufacturers and suppliers. These gatherings often showcase the latest innovations and provide opportunities to purchase authentic components directly from the source.

Taking the time to find genuine replacements can save you from future complications and ensure your machinery operates smoothly for years to come.