The intricate systems designed for fluid movement rely on a variety of essential elements that work in harmony. These components, each serving a unique function, contribute to the overall efficiency and effectiveness of the machinery.

By examining the arrangement and interaction of these key pieces, one can gain insight into how these systems operate. A comprehensive exploration allows enthusiasts and professionals alike to delve into the mechanics behind their functionality, paving the way for improved performance and maintenance practices.

Ultimately, having a clear understanding of each element’s role is crucial for anyone involved in the operation or servicing of these mechanisms. This knowledge empowers users to make informed decisions regarding repairs and upgrades, ensuring longevity and reliability.

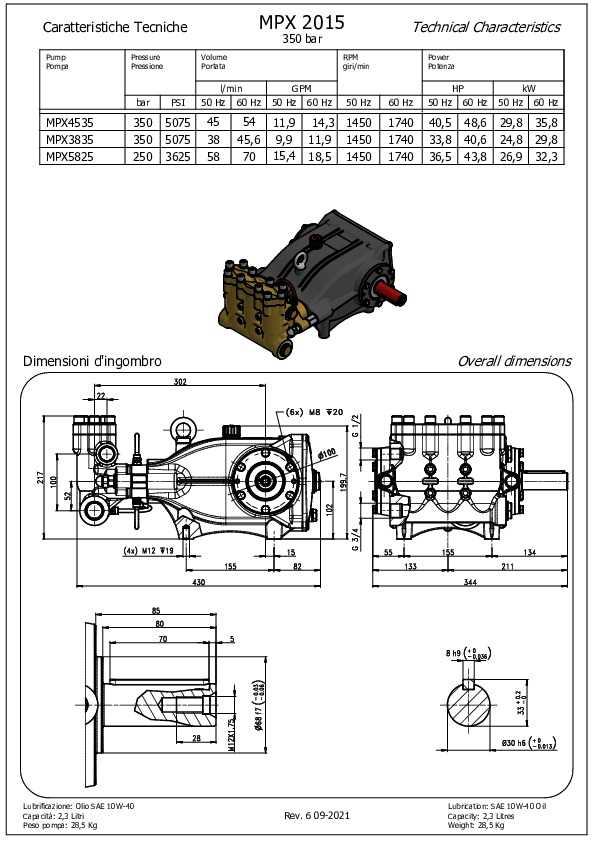

Understanding Himore Pump Components

Grasping the intricacies of mechanical systems involves delving into their fundamental elements. Each component plays a crucial role in ensuring optimal functionality and performance. By familiarizing oneself with these key elements, one can appreciate how they interact to facilitate the overall operation.

Key Elements and Their Functions

The main components within such systems typically include the housing, impeller, and motor. The housing serves as a protective casing, providing structural integrity and safeguarding internal mechanisms. The impeller is responsible for fluid movement, generating the necessary pressure to propel the liquid. Meanwhile, the motor provides the energy required for operation, driving the entire assembly with precision and efficiency.

Importance of Proper Maintenance

Regular upkeep of these components is vital for longevity and performance. Ensuring that each element is functioning correctly not only enhances efficiency but also prevents potential failures. Understanding the role of each part fosters a proactive approach to maintenance, ultimately leading to improved reliability and reduced operational costs.

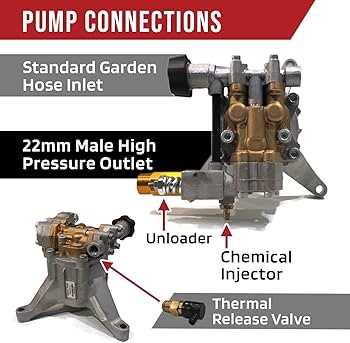

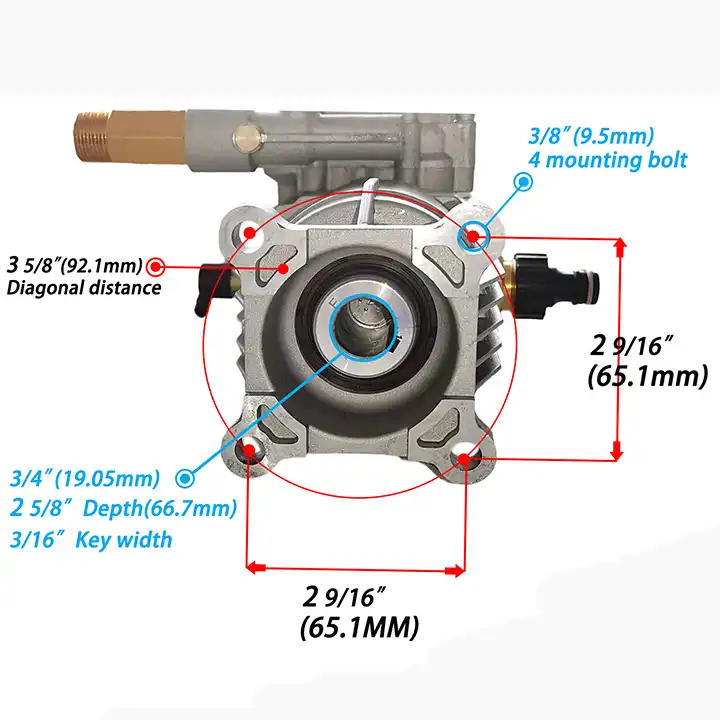

How to Read Pump Diagrams

Understanding technical illustrations can be crucial for effective maintenance and operation. These visual representations convey essential information about components, their relationships, and the overall functionality of the system. By mastering the ability to interpret these images, users can enhance their troubleshooting skills and optimize performance.

Identifying Key Components

Start by familiarizing yourself with the symbols and labels used in these visuals. Each icon typically represents a specific element, such as inlets, outlets, or control mechanisms. Recognizing these symbols will enable you to quickly grasp the layout and flow of the system.

Understanding Flow Direction

Next, pay attention to arrows or lines indicating movement. These often illustrate the direction of fluid travel, which is critical for assessing functionality. By comprehending flow patterns, you can better identify potential issues or areas for improvement.

Key Parts of Himore Pumps

This section highlights the essential components that contribute to the effective functioning of fluid transfer systems. Understanding these crucial elements can enhance the overall performance and maintenance of the equipment, ensuring optimal operation in various applications.

Core Components

The heart of the system often includes a robust housing that provides structural integrity. Inside, you’ll find an impeller that is responsible for moving the fluid, along with seals that prevent leaks and maintain pressure. Each component plays a vital role in ensuring seamless operation.

Supporting Elements

Additions like bearings support rotational parts, while drive mechanisms ensure the necessary energy is supplied for operation. Each of these supporting elements must be carefully designed and maintained to achieve maximum efficiency and longevity of the entire assembly.

Common Issues with Pump Parts

When dealing with mechanical devices, understanding the frequent challenges that arise can greatly enhance their longevity and efficiency. Various components may face wear and tear, leading to reduced performance and potential failures.

Leakage is one of the most prevalent concerns, often resulting from worn seals or faulty connections. This can lead to not only a loss of efficiency but also environmental hazards.

Blockages can occur due to debris accumulation, impacting the fluid flow and causing the system to work harder than necessary. Regular maintenance can help mitigate this issue.

Noise often indicates underlying problems, such as misalignment or lack of lubrication. Addressing these sounds promptly can prevent more severe damage.

Overheating can be a sign of excessive friction or inadequate cooling mechanisms. Monitoring temperatures is essential to ensure optimal operation.

By understanding these common difficulties, users can take proactive steps to maintain their equipment and enhance its overall performance.

Maintenance Tips for Pump Longevity

Ensuring the extended life of your machinery requires diligent care and attention. By implementing effective maintenance practices, you can prevent unexpected breakdowns and optimize performance over time.

Regular Inspections

- Conduct visual checks for any signs of wear or damage.

- Examine seals and gaskets for leaks.

- Listen for unusual noises that may indicate a problem.

Scheduled Servicing

- Follow a routine maintenance schedule to clean and lubricate components.

- Replace worn or outdated elements promptly.

- Ensure alignment and balance are properly maintained to reduce strain.

Choosing Quality Replacement Parts

When it comes to maintaining equipment, selecting high-quality components is crucial for optimal performance and longevity. Investing in reliable alternatives not only enhances efficiency but also reduces the risk of failures. Understanding how to identify superior options can save time and resources in the long run.

Key Factors to Consider

- Material Quality: Look for components made from durable materials that can withstand wear and tear.

- Compatibility: Ensure that the alternatives are specifically designed to fit your equipment to avoid issues during installation.

- Brand Reputation: Research manufacturers known for their reliability and customer satisfaction.

- Warranty and Support: Opt for options that come with warranties, ensuring you have assistance if problems arise.

Benefits of High-Quality Alternatives

- Increased Efficiency: Well-made components function better and enhance overall productivity.

- Cost-Effectiveness: While initial costs may be higher, long-term savings from reduced maintenance and replacements are significant.

- Peace of Mind: Knowing you have reliable alternatives allows for smoother operations without frequent interruptions.

Impact of Wear on Performance

Wear and tear significantly affect the efficiency and longevity of mechanical systems. As components undergo stress and friction during operation, their performance can deteriorate, leading to a range of issues that compromise functionality.

The consequences of wear can manifest in several ways:

- Reduced Efficiency: As surfaces degrade, energy loss increases, leading to decreased operational efficiency.

- Increased Vibration: Worn components can create imbalances, resulting in heightened vibration levels that may further damage machinery.

- Heat Generation: Friction from wear produces excess heat, which can cause overheating and additional wear on adjacent parts.

- Compromised Seals: Degradation can lead to leaks, reducing the system’s ability to maintain necessary pressures or fluid levels.

Regular monitoring and maintenance can mitigate the effects of wear, ensuring optimal performance over time. Strategies include:

- Routine Inspections: Regular checks can identify early signs of wear and facilitate timely interventions.

- Proper Lubrication: Ensuring adequate lubrication minimizes friction and slows down the wear process.

- Material Selection: Utilizing durable materials can enhance resistance to wear, prolonging the life of components.

By understanding the impact of wear and implementing preventative measures, the reliability and efficiency of mechanical systems can be significantly improved.

Assembly Instructions for Himore Pumps

This section provides a comprehensive guide for the correct assembly of the equipment, ensuring optimal performance and longevity. Following these instructions will help you achieve the best results while minimizing the risk of errors during the setup process.

Required Tools and Materials

Before beginning the assembly, gather all necessary tools and components. Ensure that you have the following items ready:

| Item | Quantity |

|---|---|

| Screwdriver | 1 |

| Wrench | 1 |

| Sealant | 1 tube |

| Fasteners | As needed |

Step-by-Step Assembly Process

Begin the assembly by carefully following these steps: Start with the base, ensuring it is securely placed. Next, attach the main housing, followed by the installation of the internal components. Ensure that all seals are applied properly to prevent leaks. Finally, tighten all connections and perform a thorough inspection before operation.

Diagnosing Pump Malfunctions

Identifying issues in fluid-moving machinery is crucial for maintaining efficiency and preventing costly downtimes. Understanding common symptoms and their potential causes allows for timely interventions and effective repairs.

Common Symptoms of Malfunction

- Unusual noises during operation

- Decreased flow rate or pressure

- Vibration or instability

- Overheating

- Leaking fluids

Potential Causes

- Blockages: Debris or sediment can obstruct flow pathways.

- Worn Components: Age-related wear can affect seals and impellers.

- Misalignment: Improper installation may lead to mechanical strain.

- Insufficient Lubrication: Lack of lubrication can cause excessive friction.

- Electrical Issues: Faulty wiring can disrupt motor function.

Regular maintenance and monitoring can help prevent these issues from escalating, ensuring reliable performance over time.

Innovations in Pump Design

Recent advancements in fluid transfer technology have revolutionized the efficiency and performance of various systems. These innovations focus on enhancing energy consumption, improving material durability, and optimizing overall functionality. The integration of cutting-edge engineering practices plays a crucial role in meeting the demands of diverse industries.

One notable trend is the application of smart technology, which allows for real-time monitoring and predictive maintenance. This capability not only increases reliability but also minimizes downtime, ensuring seamless operations. Additionally, the development of advanced materials contributes to weight reduction and resistance to wear, significantly extending the lifespan of equipment.

Furthermore, innovative designs that promote better flow dynamics enhance operational efficiency. Engineers are increasingly exploring new geometries and configurations that reduce turbulence and energy loss. These approaches not only support sustainability efforts by lowering power requirements but also align with global initiatives aimed at reducing environmental impact.

Resources for Further Learning

This section aims to provide valuable materials and references for those seeking to deepen their understanding of mechanical components and their assembly. Engaging with diverse resources can enhance knowledge and facilitate skill development in this specialized field.

Books and Guides

- Mechanical Engineering Principles – A comprehensive overview of fundamental concepts.

- Component Assembly Techniques – Detailed methodologies for effective assembly practices.

- Fluid Dynamics Fundamentals – Insights into the behavior of fluids in motion, crucial for understanding functionality.

Online Courses and Tutorials

- Coursera: Engineering Mechanics – Explore the basics of mechanics through engaging video lectures.

- edX: Introduction to Fluid Mechanics – A foundational course covering essential principles.

- YouTube: Assembly Tutorials – Visual demonstrations of assembly processes and techniques.

Utilizing these resources can significantly enhance your expertise and confidence in working with mechanical systems.