The intricate world of fluid management systems is crucial for various applications, from agricultural to industrial processes. Mastery of these systems requires a solid grasp of their fundamental elements, which directly influence efficiency and performance.

Within this realm, visual representations of system configurations play a vital role in both troubleshooting and maintenance. These illustrations serve as guides, enabling operators to quickly identify and comprehend the individual components that contribute to the overall functionality.

In this article, we will delve into the critical aspects of a specific model, focusing on the layout and interaction of its vital components. By understanding these relationships, users can ensure optimal operation and longevity of their systems.

Understanding Hypro D30 Pump Functionality

The operation of a liquid transfer device involves several key components working in harmony to ensure efficient performance. Each element plays a crucial role in the overall mechanism, contributing to the fluid’s movement and pressure regulation. Understanding how these components interact can enhance the user’s ability to troubleshoot and optimize performance.

Central to this system is the mechanism that creates suction, allowing liquids to flow seamlessly from one area to another. This action is often powered by a motor, which drives the internal components. In turn, these parts must be durable and reliable to withstand varying operational conditions, making material quality essential for longevity.

Moreover, the flow rate can be adjusted by manipulating certain features within the setup, enabling users to tailor the performance to specific needs. Regular maintenance ensures that all parts function correctly, preventing wear and tear that could hinder operation. Knowledge of the entire system equips users to make informed decisions regarding repairs and upgrades, enhancing the device’s overall effectiveness.

Key Components of Hypro D30 Pumps

The efficient operation of fluid transfer mechanisms relies on a variety of essential elements. Understanding these critical components can enhance performance, reliability, and maintenance, ensuring optimal functionality in various applications. This section highlights the key parts that contribute to the effective working of these devices.

1. Housing Assembly

The outer structure serves as the protective shell, maintaining the integrity of the internal mechanisms. Its robust design ensures durability and resistance to environmental factors, playing a crucial role in overall performance.

2. Impeller System

This dynamic component is responsible for moving fluid through the mechanism. Its design affects the flow rate and pressure, making it vital for achieving the desired operational efficiency. Regular inspection and maintenance of the impeller are necessary to prevent wear and ensure sustained functionality.

Understanding these components is essential for anyone looking to maintain or enhance the efficiency of their fluid handling systems. Proper care and attention to each part can lead to improved performance and longevity.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the extended life of any machinery. By adhering to a systematic maintenance schedule, users can significantly reduce the likelihood of unexpected failures and costly repairs. This proactive approach not only enhances performance but also promotes safety and efficiency in operation.

Timely inspections and servicing allow for the early detection of wear and tear, preventing minor issues from escalating into major complications. Additionally, maintaining optimal conditions helps to preserve the integrity of the components, ultimately leading to improved reliability and effectiveness in various applications.

Investing in consistent care is crucial, as it fosters a culture of responsibility and awareness among operators. When individuals understand the significance of routine maintenance, they are more likely to take the necessary steps to ensure that equipment remains in peak condition. This not only safeguards investments but also contributes to sustainable practices within the industry.

Common Issues with D30 Pump Parts

In the realm of fluid management systems, certain challenges frequently arise that can hinder optimal performance. Understanding these typical complications is crucial for maintaining efficiency and longevity of the equipment. Addressing these concerns promptly can prevent larger, more costly repairs down the line.

Wear and Tear

Over time, components can experience degradation due to constant use and exposure to various substances. Regular inspection and timely replacement of worn-out elements are essential to ensure smooth operation.

Seal Failures

Seals are vital for preventing leaks, yet they are often prone to damage from pressure fluctuations or chemical exposure. Identifying signs of seal failure early can help maintain system integrity and performance.

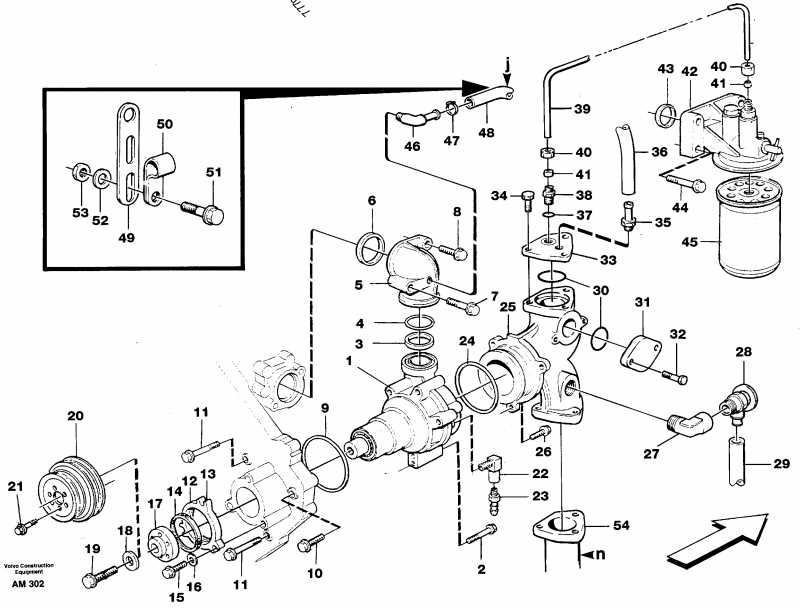

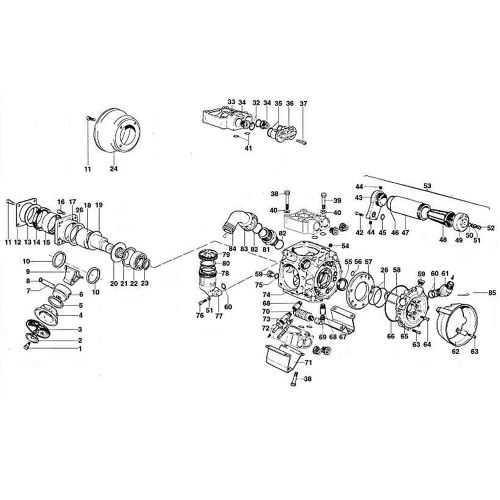

How to Read a Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repairs. Such illustrations provide a detailed view of each element, their arrangement, and relationships. Familiarity with this type of graphic can enhance your ability to identify, source, and replace parts as needed.

To effectively interpret these visuals, follow these key steps:

| Step | Description |

|---|---|

| 1 | Examine the Legend: The legend often indicates symbols and numbering used throughout the illustration, helping you understand what each component represents. |

| 2 | Identify Components: Locate the various parts shown in the image, paying attention to their shapes and sizes, as these can provide clues to their functions. |

| 3 | Follow Connections: Observe how different elements are linked. This can highlight how they interact and assist in troubleshooting potential issues. |

| 4 | Refer to Manuals: Consult any accompanying documentation for additional context, including installation instructions and specifications that may not be visually represented. |

| 5 | Practice Regularly: The more you engage with these types of visuals, the more intuitive reading them will become, improving your overall comprehension. |

By mastering these techniques, you’ll be better equipped to navigate the complexities of any mechanical system and ensure its efficient operation.

Step-by-Step Assembly Guide for D30

This section provides a comprehensive guide for the assembly of the specified equipment. Following these instructions will ensure a smooth and efficient process, resulting in optimal performance.

- Gather all necessary components and tools required for assembly.

- Begin by laying out all elements in an organized manner to facilitate easy access.

- Start with the base unit, ensuring it is placed on a stable surface.

- Secure the primary housing by aligning it with the designated brackets.

- Fasten the screws using a suitable wrench, ensuring a snug fit without over-tightening.

- Attach the secondary components according to the provided instructions, ensuring proper orientation.

- Incorporate any seals or gaskets to prevent leaks, checking for alignment as you proceed.

- Connect the hoses and fittings, ensuring each connection is tight and secure.

- Once all components are assembled, perform a thorough inspection for any loose parts or potential issues.

- Finally, conduct a test run to verify that everything operates smoothly.

By adhering to these steps, you will ensure a successful assembly and long-lasting functionality of the device.

Upgrading Components for Better Performance

Enhancing the efficiency of mechanical systems often hinges on the quality of their individual elements. By focusing on superior materials and innovative designs, users can significantly boost functionality and longevity. This process not only involves replacing outdated components but also integrating advanced technology to achieve optimal results.

One of the ultimate strategies is to evaluate the compatibility of upgraded components with existing systems. Understanding the unique requirements of each system ensures that enhancements lead to improved performance without compromising reliability. Investing in high-performance elements can yield dividends in productivity and reduce maintenance costs over time.

Moreover, regular assessments and updates are crucial in maintaining peak efficiency. As technology advances, the availability of enhanced options increases, allowing for continuous improvement. Ultimately, a proactive approach to component upgrades can transform overall system performance and user satisfaction.

Comparing D30 with Other Pump Models

When evaluating various models in the fluid transfer industry, it is essential to understand the unique features and performance capabilities that set each unit apart. By comparing one model to others, users can identify strengths and weaknesses that may influence their operational efficiency and suitability for specific applications.

Performance Metrics: Different designs often exhibit varying levels of efficiency, flow rates, and pressure outputs. Analyzing these metrics helps users determine which model can meet their specific requirements. For instance, while one may excel in high-volume transfer, another might offer better precision at lower flow rates.

Durability and Maintenance: The materials and construction methods used in each model can significantly impact longevity and maintenance needs. Some systems may require frequent upkeep, while others are designed for extended periods of operation with minimal intervention. Understanding these factors can lead to better long-term investment decisions.

Compatibility: Another crucial aspect is the compatibility with existing systems and attachments. Some models may integrate seamlessly with certain configurations, while others may need additional components, affecting overall efficiency and cost-effectiveness.

Ultimately, a thorough comparison not only aids in selecting the most suitable option but also enhances overall operational performance by aligning equipment capabilities with specific tasks.

Identifying Replacement Parts Easily

Understanding how to locate and identify components for your equipment is essential for efficient maintenance and repairs. By familiarizing yourself with various elements and their functions, you can streamline the replacement process.

- Consult your equipment manual for specific references.

- Use online resources to find visual aids that illustrate each component.

- Join forums or communities where users share insights and experiences.

Once you have gathered information, follow these steps to ensure accuracy:

- List all the components that require attention.

- Cross-reference your findings with manufacturer specifications.

- Order the correct items from reputable suppliers.

This systematic approach will not only save time but also ensure that you are utilizing the ultimate components for your machinery’s optimal performance.

Best Practices for Pump Care

Maintaining optimal functionality and longevity of fluid-moving equipment requires a systematic approach to care. Adhering to established guidelines can prevent malfunctions and ensure efficient performance over time.

Regular Inspection

- Check for leaks and unusual noises during operation.

- Inspect seals and fittings for wear and tear.

- Ensure that connections are tight and secure.

Routine Maintenance

- Clean filters and strainers regularly to avoid clogs.

- Lubricate moving components as per manufacturer recommendations.

- Replace worn parts promptly to avoid cascading failures.