In the realm of fluid movement technologies, a thorough grasp of the individual elements is essential for optimal functionality. Each component plays a critical role in ensuring that the entire mechanism operates smoothly and efficiently. Recognizing how these various parts interconnect can lead to improved performance and longevity.

Visual representations of these intricate systems serve as invaluable tools for both novice and experienced users. They highlight the arrangement and relationship between each segment, allowing for better comprehension and troubleshooting. This guide aims to delve into these illustrations, offering insights that are crucial for maintenance and repair.

Ultimately, understanding these intricate details not only enhances operational efficiency but also empowers users to make informed decisions regarding repairs and upgrades. By familiarizing oneself with the configuration of these components, one can ensure reliable and effective performance over time.

Understanding Jabsco Pumps

This section delves into the intricacies of fluid transfer devices commonly utilized in marine and industrial applications. These essential mechanisms play a crucial role in maintaining efficient operation, ensuring reliable movement of liquids through various systems. By comprehending their functionality and construction, users can enhance performance and troubleshoot issues effectively.

Key Components

The effectiveness of these devices is determined by several critical elements. Each component contributes to the overall efficiency and reliability of the system. Knowledge of these elements allows users to identify potential areas for maintenance or improvement, ensuring optimal performance under varying conditions.

Common Applications

Key Components of Jabsco Pumps

Understanding the essential elements of these mechanical devices is crucial for their effective operation and maintenance. Each component plays a significant role in ensuring optimal performance and reliability in various applications.

| Component | Description |

|---|---|

| Impeller | This rotating part is responsible for moving the fluid by converting rotational energy into hydraulic energy. |

| Housing | The outer shell that contains the internal components and provides structural integrity. |

| Seal | Essential for preventing leaks, this element ensures that the fluid remains contained within the system. |

| Motor | The driving force behind the mechanism, converting electrical energy into mechanical motion. |

| Inlet/Outlet Ports | These openings facilitate the entry and exit of fluids, allowing for efficient flow management. |

Each of these key elements works in concert to deliver the desired outcomes, highlighting the importance of regular inspections and maintenance to ensure longevity and efficiency.

Common Applications for Jabsco Pumps

These versatile devices are widely utilized across various industries, serving crucial roles in fluid management and transfer. Their efficiency and reliability make them ideal for diverse settings, from recreational boating to industrial processes.

Marine Use

In the marine sector, these devices are essential for bilge evacuation, freshwater delivery, and wastewater management. Their robust design ensures consistent performance even in challenging aquatic environments.

Industrial and Agricultural Applications

In industrial and agricultural settings, these units facilitate fluid circulation, irrigation, and chemical transfer. Their adaptability to different media and conditions enhances operational efficiency, making them invaluable tools for many professionals.

Importance of Maintenance in Pumps

Regular upkeep is crucial for ensuring optimal performance and longevity of fluid-moving equipment. Neglecting maintenance can lead to inefficiencies, breakdowns, and increased costs over time. Proactive measures help in identifying potential issues before they escalate.

Benefits of Regular Upkeep

- Enhances efficiency and reliability.

- Reduces the risk of unexpected failures.

- Extends the lifespan of the equipment.

- Improves safety for operators.

Key Maintenance Practices

- Regular inspections to detect wear and tear.

- Cleaning components to prevent blockages.

- Lubricating moving parts for smooth operation.

- Replacing worn or damaged elements promptly.

How to Identify Jabsco Parts

Recognizing components in marine systems can enhance maintenance and efficiency. Accurate identification is crucial for seamless repairs and replacements, ensuring optimal functionality. This guide provides insights into the key aspects to consider when pinpointing individual elements.

Key Features to Examine

- Model Numbers: Look for the unique identifier often stamped on the casing.

- Material Composition: Determine whether parts are plastic, metal, or rubber.

- Size and Dimensions: Measure the length, width, and diameter for accurate fitting.

Helpful Resources

- Manufacturer manuals often contain detailed specifications.

- Online forums can provide insights from experienced users.

- Consulting with local suppliers can offer hands-on assistance.

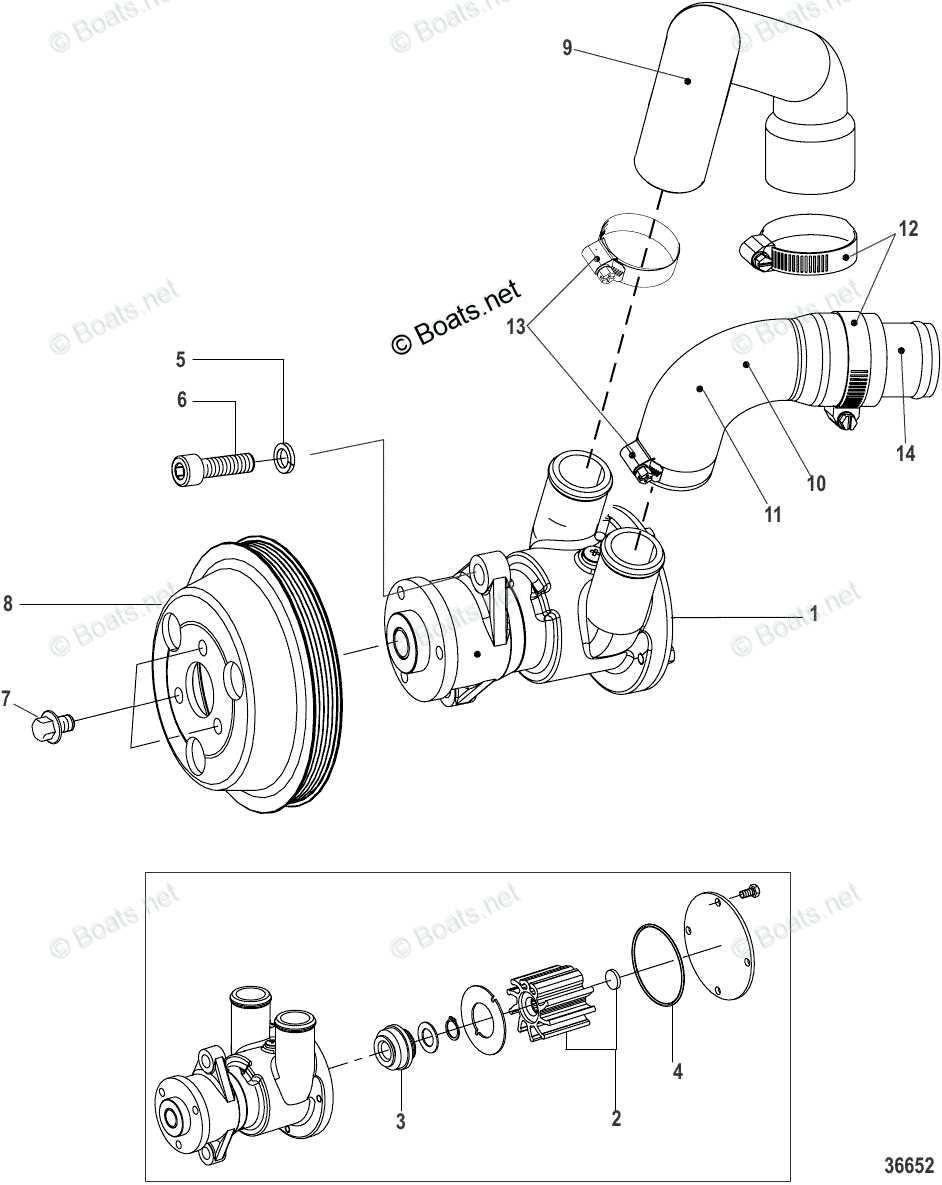

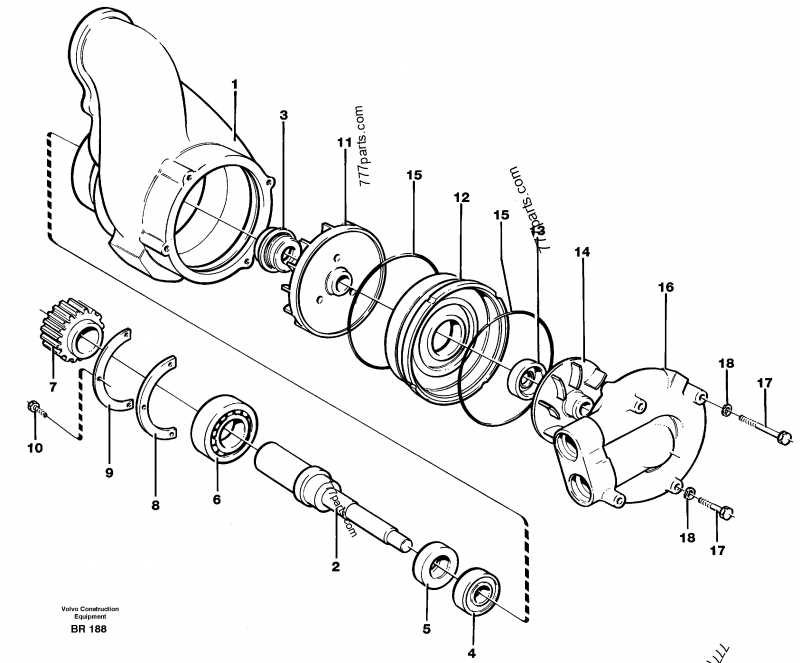

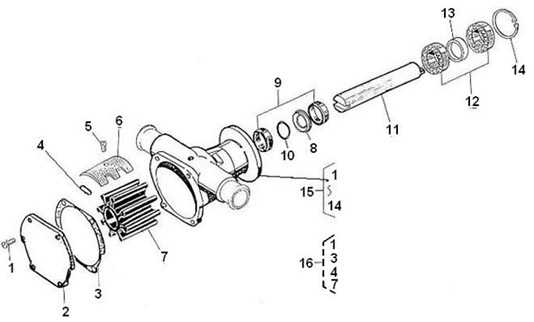

Reading a Parts Diagram Effectively

Understanding an illustration of components can greatly enhance your ability to identify and locate essential elements within a system. By grasping the layout and the relationships among various pieces, you can streamline maintenance and troubleshooting processes.

Key Elements to Focus On

- Labels: Pay attention to annotations and identifiers that specify each component’s function.

- Connections: Observe how different elements are linked, as this can help in understanding the flow and interaction between them.

- Scale: Check the size indicators to comprehend the relative dimensions of the components involved.

Steps for Effective Interpretation

- Begin by examining the overall layout to get a sense of the arrangement.

- Identify key components using the labels provided.

- Trace connections between elements to understand their relationships.

- Make notes on critical parts that may require replacement or servicing.

Troubleshooting Jabsco Pump Issues

Identifying and resolving common problems can significantly improve the efficiency and lifespan of your equipment. By understanding typical symptoms and their underlying causes, you can take effective measures to restore functionality.

- Low Flow Rate:

- Check for blockages in the intake or discharge.

- Inspect seals for wear or damage.

- Examine the drive mechanism for faults.

- Unusual Noises:

- Listen for grinding sounds indicating potential mechanical issues.

- Ensure that all components are securely attached.

- Verify that the motor operates smoothly.

- Overheating:

- Check for adequate ventilation around the unit.

- Ensure fluid levels are appropriate.

- Look for signs of electrical overload.

By systematically addressing these issues, you can enhance performance and prevent future complications.

Replacement Parts: What You Need

When it comes to maintaining your equipment, understanding the essential components required for replacements is crucial. Having the right items on hand ensures optimal performance and longevity of your machinery. This section will guide you through the necessary elements to consider for efficient upkeep.

Before purchasing, it’s important to identify the specific components you might need. Various factors can influence your choice, including the model of your device, the application it serves, and the environment in which it operates. Below is a table summarizing key components and their typical functions:

| Component | Description |

|---|---|

| Seal | Prevents leaks and maintains pressure. |

| Impeller | Drives the fluid through the system. |

| Housing | Encloses and protects internal mechanisms. |

| Motor | Provides the necessary power for operation. |

| Strainer | Filters debris to ensure smooth operation. |

By ensuring you have these components readily available, you can effectively address any issues that arise and keep your system running smoothly. Regular maintenance and timely replacements are key to preventing costly repairs and downtime.

DIY Repairs for Jabsco Pumps

Understanding how to perform repairs on your marine device can save both time and money. With a bit of knowledge and the right tools, many issues can be addressed without the need for professional assistance. This section provides guidance on common problems and their solutions, empowering you to tackle maintenance tasks with confidence.

Common Issues and Solutions

-

Leakage:

If you notice any leaks, check the seals and gaskets first. Over time, these components can wear out. Replacing them is often a straightforward task.

-

Reduced Flow:

Low output can indicate clogs in the intake or discharge. Inspect these areas for obstructions and clean them as necessary.

-

Noise:

Unusual sounds may signal issues with the motor or impeller. Ensure that all parts are secured and free from debris.

Tools You Will Need

- Wrenches

- Screwdrivers

- Sealant or replacement gaskets

- Cleaning supplies (brushes, cloths)

- Safety gear (gloves, goggles)

Regular maintenance checks can prolong the lifespan of your device and enhance its efficiency. By taking a proactive approach, you can ensure smooth operation and prevent costly repairs in the future.

Choosing the Right Pump Model

When selecting the appropriate model for fluid transfer, several factors come into play to ensure optimal performance and efficiency. Understanding the specific requirements of your application is crucial to making an informed decision that will lead to effective operation and longevity.

Consider the following criteria when evaluating options:

| Factor | Considerations |

|---|---|

| Flow Rate | Determine the required volume per unit of time for your system. |

| Fluid Characteristics | Assess viscosity, temperature, and chemical composition. |

| Application Environment | Evaluate exposure to elements and physical space constraints. |

| Power Source | Identify the available energy type and necessary voltage. |

| Maintenance Needs | Consider the ease of servicing and the availability of replacement components. |

By carefully analyzing these elements, you can delve deeper into your choices and ultimately select the most suitable model for your specific needs.

Upgrading Your Jabsco Pump System

Enhancing your fluid circulation system can lead to improved efficiency and longevity. By selecting quality components and modernizing certain elements, you can significantly boost performance and reliability.

Key Considerations

- Assess current functionality and performance.

- Identify specific components that may need replacement.

- Research newer technologies and compatible upgrades.

Benefits of Modernization

- Increased efficiency and reduced energy consumption.

- Improved durability and lower maintenance costs.

- Enhanced overall performance and reliability.

Where to Find Jabsco Resources

Accessing reliable materials and information can significantly enhance your understanding of marine equipment. Various sources provide valuable insights, technical specifications, and support for enthusiasts and professionals alike. Below are some recommended avenues for gathering essential knowledge.

Official Websites

- Manufacturer’s Site: Visit the official website to find comprehensive manuals, FAQs, and product details.

- Distributors: Authorized distributors often host a wealth of resources, including installation guides and troubleshooting tips.

Online Communities and Forums

- Marine Enthusiast Forums: Engage with fellow users who share experiences and solutions.

- Social Media Groups: Join platforms dedicated to marine equipment where members share insights and advice.

By utilizing these resources, you can deepen your expertise and ensure optimal performance of your marine devices.